Moulding milling cutter

A technology for forming milling cutters and cutter bodies, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious, a lot of manual work, etc., and achieve the effects of convenient use, shortened processing time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

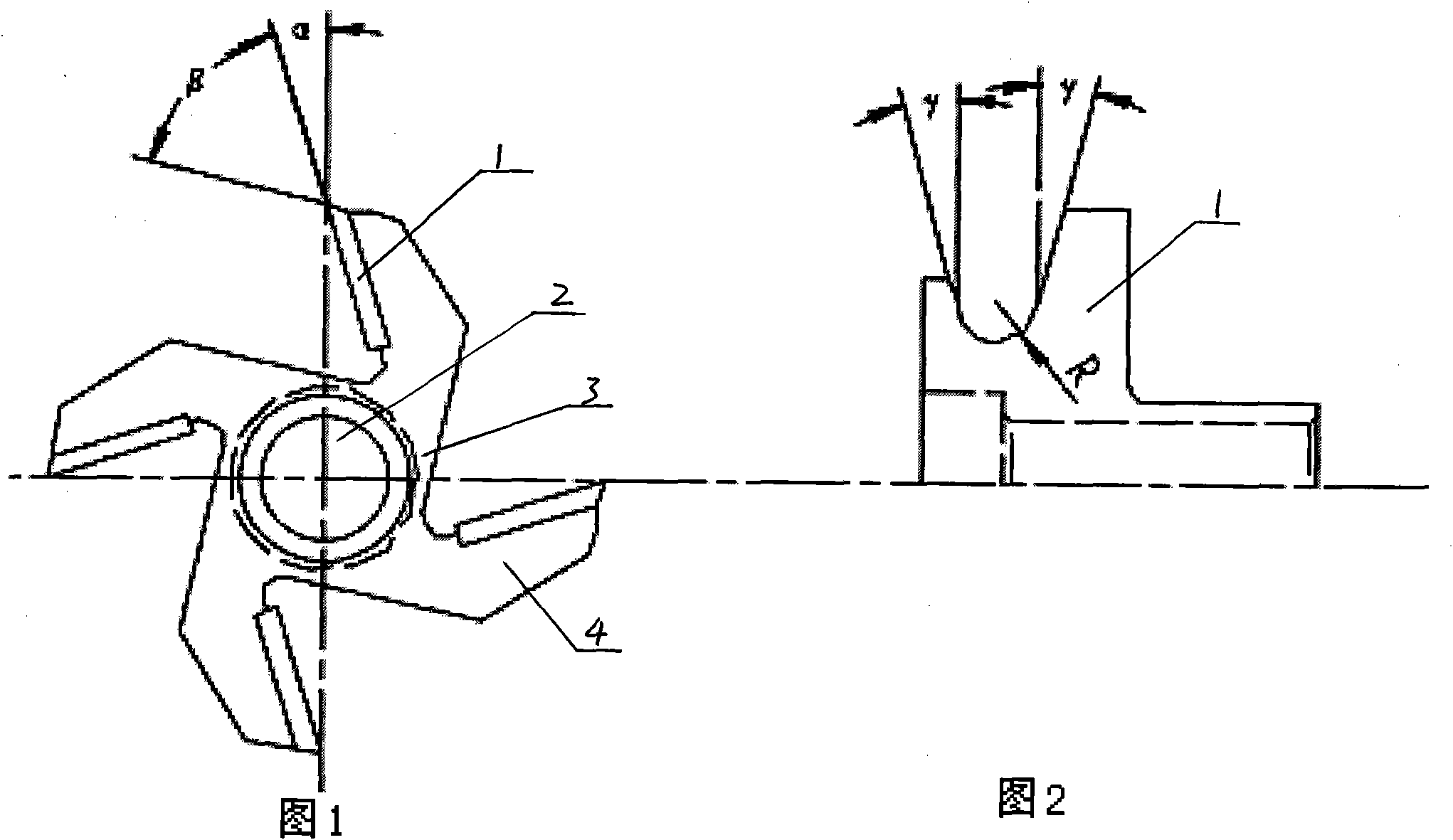

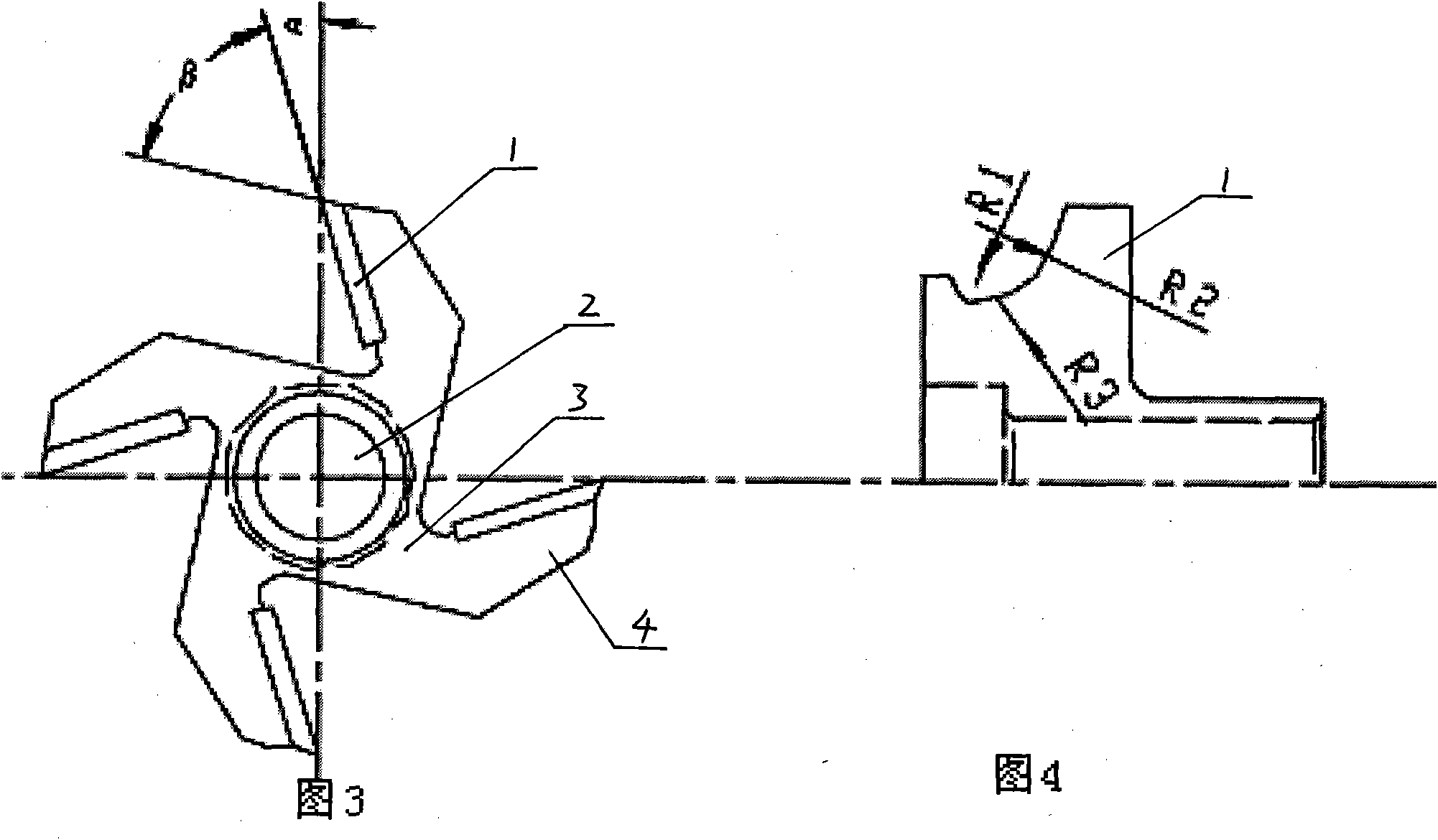

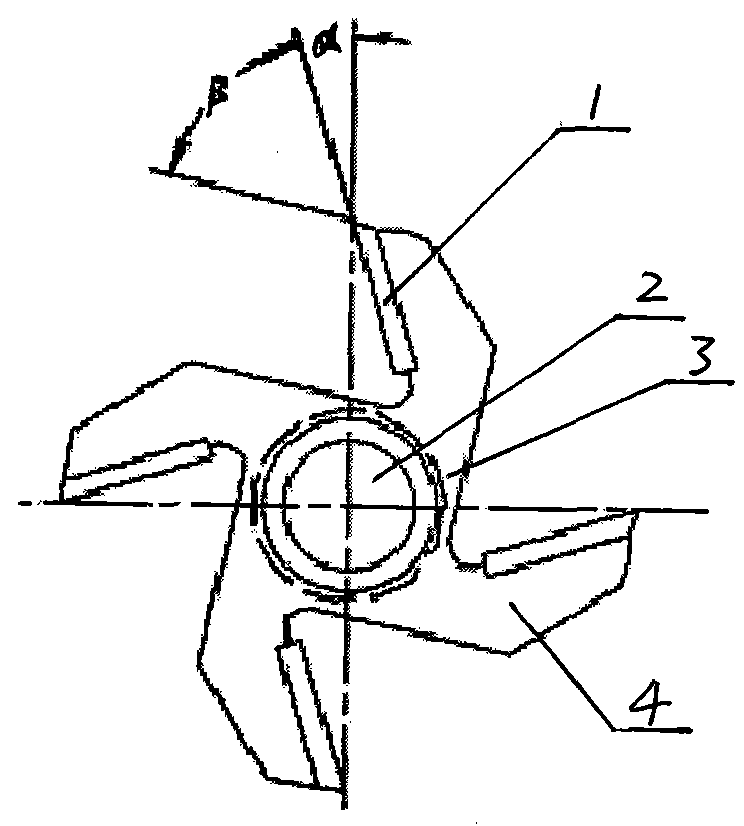

[0012] Such as figure 1 and figure 2 The illustrated embodiment 1 includes a cutter body 3 and a cutting tool 1 . The cutter body 3 is in the shape of a circular platform, and four slopes 4 are evenly distributed on the outer edge of one end end surface, and the ends of the slopes 4 have recesses, and the cutting knife 1 is welded on the recesses of the four slopes 4 respectively. Cutting knife 1 cutting edge is the circular arc that the radius that matches with cutting workpiece cutting circular arc is R. The two ends of the cutting knife 1 blade form an angle γ with the tangent of the two ends of the arc respectively, and γ is any angle less than or equal to 15°, which is convenient for entering and exiting the knife and processing workpieces with a little deformation on the edge. The front end face of the cutting blade 1 and the radial axis of the end face of the cutter body 3 form an angle α, where α is any angle between 5° and 8°. An angle β is formed between the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com