Rotary cylindrical garbage storage bin leachate guide device

A diversion device, rotary technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of increasing the difficulty and cost of concrete structure processing, high work intensity, high investment cost, etc., to achieve the benefit of storage Effects of wall concrete structure treatment, reduction in the number and area of openings, and reduction in labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

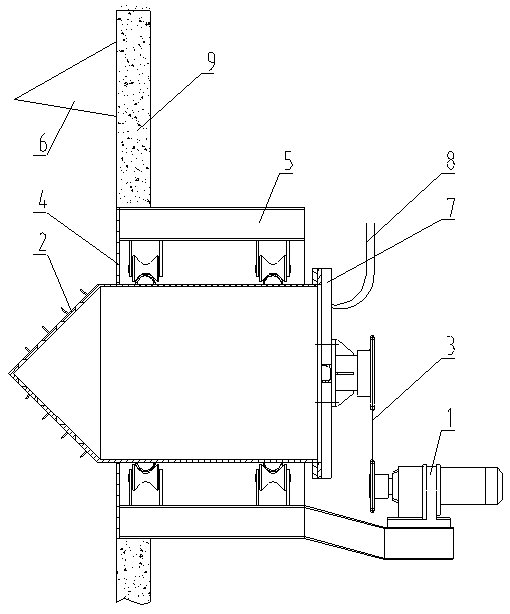

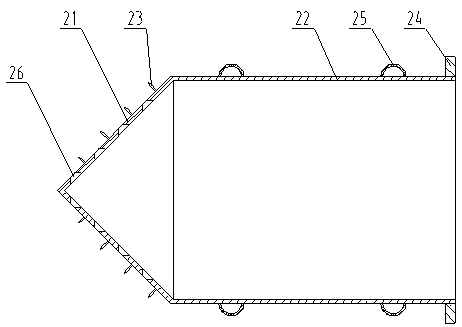

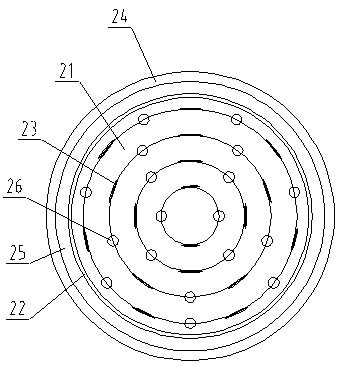

[0031] Please see attached figure 1 , a rotary cylindrical garbage storage bin leachate diversion device, including a rotating transmission assembly, a rotary diversion tube assembly 2, a sealing baffle 4 and a base 5; There are reserved holes, the inner end of the base 5 is matched and embedded in the reserved hole, and the outer end of the base 5 is fixed in the maintenance channel outside the garbage bin; please refer to the attached figure 2 And attached image 3 , the rotary guide tube assembly 2 includes a garbage intrusion disc 21, a rotary guide tube 22, a blade 23 and a leachate hole 26, the rotary guide tube 22 runs through the base 5 coaxially, and the garbage intrusion disc 21 is in a conical structure And coaxially connected to the inner end of the rotary guide tube 22, the garbage intrusion disc 21 is located in the garbage sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com