Fuel filter assembly

A fuel filter and assembly technology, applied in the direction of machines/engines, liquid fuel feeders, engine components, etc., can solve the complex structure of valve seat and base, mold opening cost, high product cost, and insufficient water discharge Thoroughness and other issues to achieve the effect of improving water separation efficiency, avoiding damage and fracture, and ensuring smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

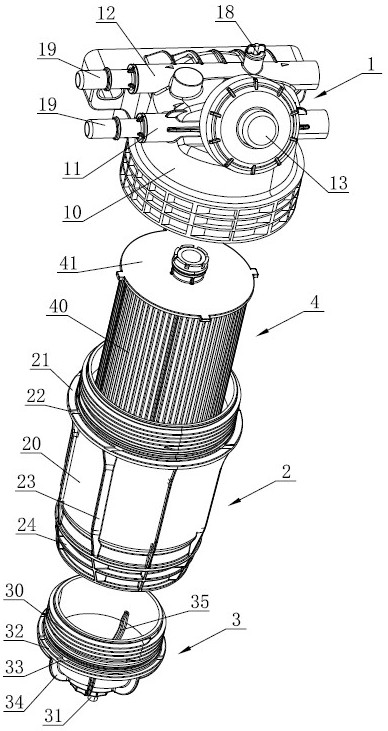

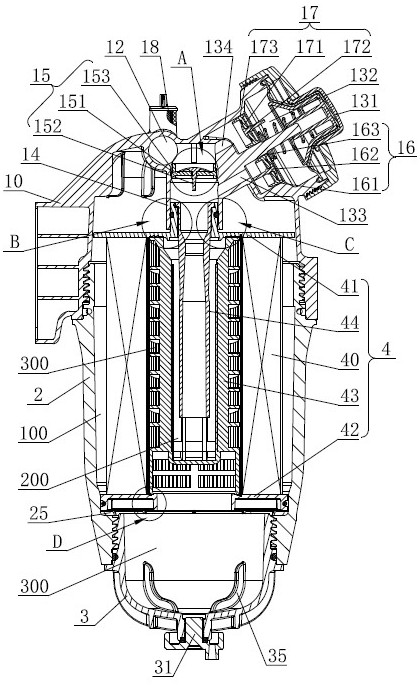

[0047] Such as figure 1 , figure 2 As shown, the fuel filter assembly of the present invention includes a base assembly 1, a casing 2, a water collection cup assembly 3 and a filter element assembly 4, and the base assembly 1 and the water collection cup assembly 3 are respectively fixed on the The upper and lower ends of the housing 2, the filter element assembly 4 is inserted into the inner cavity formed by the base assembly 1 and the housing 2, the outer cavity of the filter element assembly 4 is the dirty oil chamber 100, and the inner center of the filter element assembly 4 is The oil cleaning chamber 200 and the inner cavity of the water collecting cup assembly 3 are the water collecting chamber 300 .

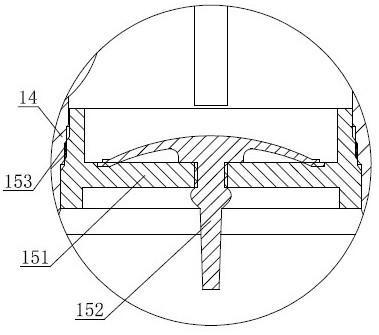

[0048] Such as figure 1 , figure 2 , Figure 7 , Figure 8 As shown, the base body 10 of the base assembly 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com