A kind of superplastic forming, diffusion connection mold and preparation method of thin-walled large inclination angle parts

A technology of diffusion joining and superplastic forming, applied in the field of titanium alloy processing, can solve the problems of difficult to control precision, mismatch between mold surface and product, poor surface quality of parts, etc. The effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

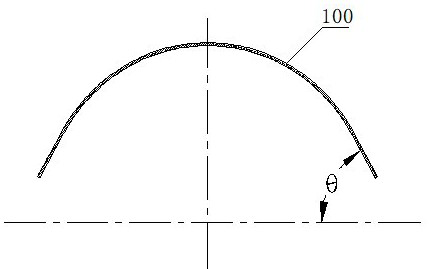

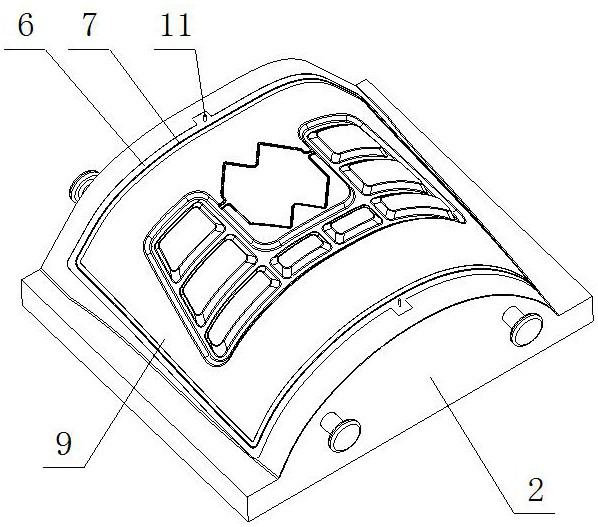

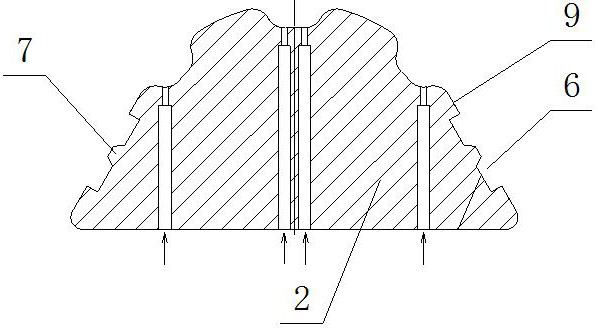

[0053] like Figure 1-7 As shown, this embodiment provides a mold for superplastic forming and diffusion joining of thin-walled and large-curvature parts, the mold includes an upper mold 1 and a lower mold 2, and the mold between the upper mold 1 and the lower mold 2 The surface is adapted to the shape of the inner and outer surfaces of the part 100; a matching groove 6 is arranged circumferentially in the area of the sealing profile 9 of the lower mold 2, and a first sealing rib 7 is arranged in the matching groove 6, and the first sealing The ribs 7 are circumferentially arranged in the matching groove 6;

[0054] It also includes an auxiliary sealing plate 5, the auxiliary sealing plate 5 is a hollow structure, the auxiliary sealing plate 5 is arranged to cover the matching groove 6, and the thickness of the auxiliary sealing plate 5 is adapted to the depth h of the matching groove 6 ;

[0055] The auxiliary sealing plate 5 is oppositely provided with a positioning piec...

Embodiment 2

[0066] The present invention provides a mold for superplastic forming and diffusion joining of thin-walled and large-curvature parts. The thickness t of t is 1 / 0.31=3.23; the depth h of the matching groove 6 is 3.53. Combined with formula ③, the maximum value of h is 3, so the value of t is 2.7.

Embodiment 3

[0068] A method for preparing thin-walled and large-curvature parts based on the superplastic forming and diffusion-connected molds of Example 1, specifically comprising the following steps:

[0069] Step 1: Pre-forming the sheet material and the auxiliary sealing plate 5, so that the profile of the pre-formed sheet diffusion area is consistent with the profile of the part to be prepared, and the sheet material is compatible with the profile of the auxiliary sealing plate 5; the sheet material Including the upper sheet 3 and the lower sheet 4; the upper sheet 3 is used to fit with the upper die 1 of the mold, and the lower sheet 4 is used to fit with the lower die 2 of the mold;

[0070] Step 2: Drill out the positioning holes 121 on the sheet material and the auxiliary sealing plate 5 respectively according to the spraying template, and place them on the bonding surface between the upper sheet material 3 and the lower sheet material 4 according to the designed position Apply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com