Method for adjusting out-of-roundness of rotor bracket for motor

A technology of rotor bracket and adjustment method, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of waste material cost and production cycle, large deformation of rotor bracket, uneven air gap, etc., and reduce material waste. and production cycle, the effect of reducing the possibility of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

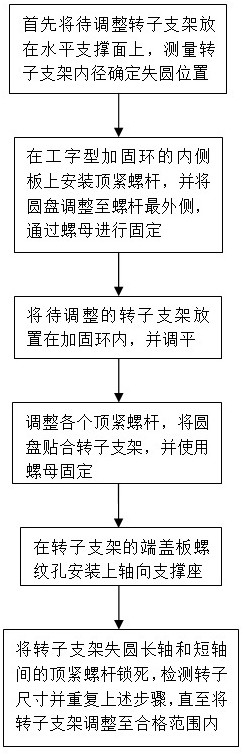

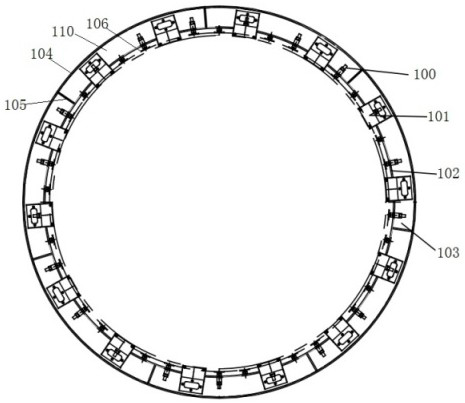

[0025] Example: See Figure 1-4 , A modification method for a rotor bracket (106) of a motor, the method comprising the steps of:

[0026] 1) The rotor bracket (106) to be adjusted is placed on the horizontal support surface, and the position of the long axis and the short axis are determined by measuring the rotor bracket (106) inner diameter.

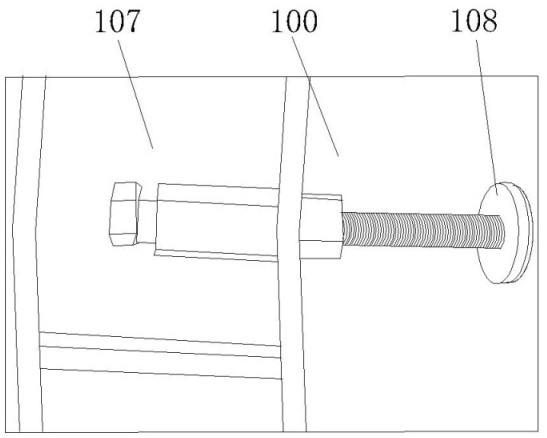

[0027] 2) Place the oscillate reinforcement ring on the horizontal plane, in the inner side plate (102) of the oscillate reinforced ring, the top screw (100) of the disc (108), and the circle The disk (108) is adjusted to the outermost side of the screw, and is fixed by the nut (107) outside the inner plate (102);

[0028] 3) Place the rotor bracket (106) to be adjusted in the ingredients of the ingredient reinforcement ring and leveling the leveling screw;

[0029] 4) Adjusting the top screw (100) in each direction, the disk (108) is bonded to the surface of the rotor bracket (106), and is fixed with an inner plate (102) outer nut (107); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com