Method for preventing phosphosilicate glass or boron phosphosilicate glass film from absorbing water

A technology of phosphosilicate glass and silicate glass, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing process cost, reducing product yield, controlling wafer waste, etc., and achieving savings Process cost, increased yield, simple and easy-to-operate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] Figure 4 It is the current BPSG / PSG process flow chart in the background technology of the present invention;

[0031] Figure 5 It is a process flow diagram of the method for preventing phosphosilicate glass or borophosphosilicate glass film from absorbing water in the present invention;

[0032] Figure 6-8 It is a structural flow diagram of the method for preventing phosphosilicate glass or borophosphosilicate glass film from absorbing water in the present invention.

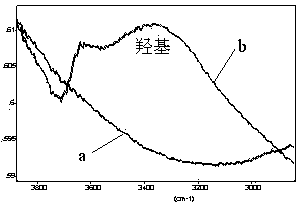

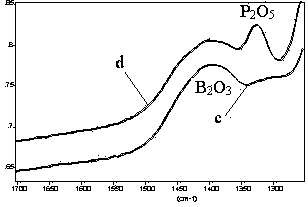

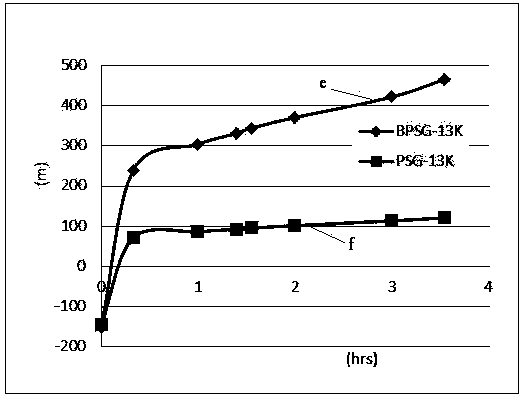

[0033] Such as Figure 4-8 As shown, first, deposit phosphosilicate glass or borophosphosilicate glass (BPSG / PSG) film 2 on a silicon substrate (Sisub) 1; then, at a temperature of 300-500°C, use plasma Enhanced Chemical Vapor Deposition (Plasma Enhanced Chemical Vapor Deposition, referred to as PECVD) process, depositing an amorphous carbon (amorphous carbon) film 3 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com