Solid raw material storing and mixing technology

A raw material and process technology, applied in the field of solid raw material storage and mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

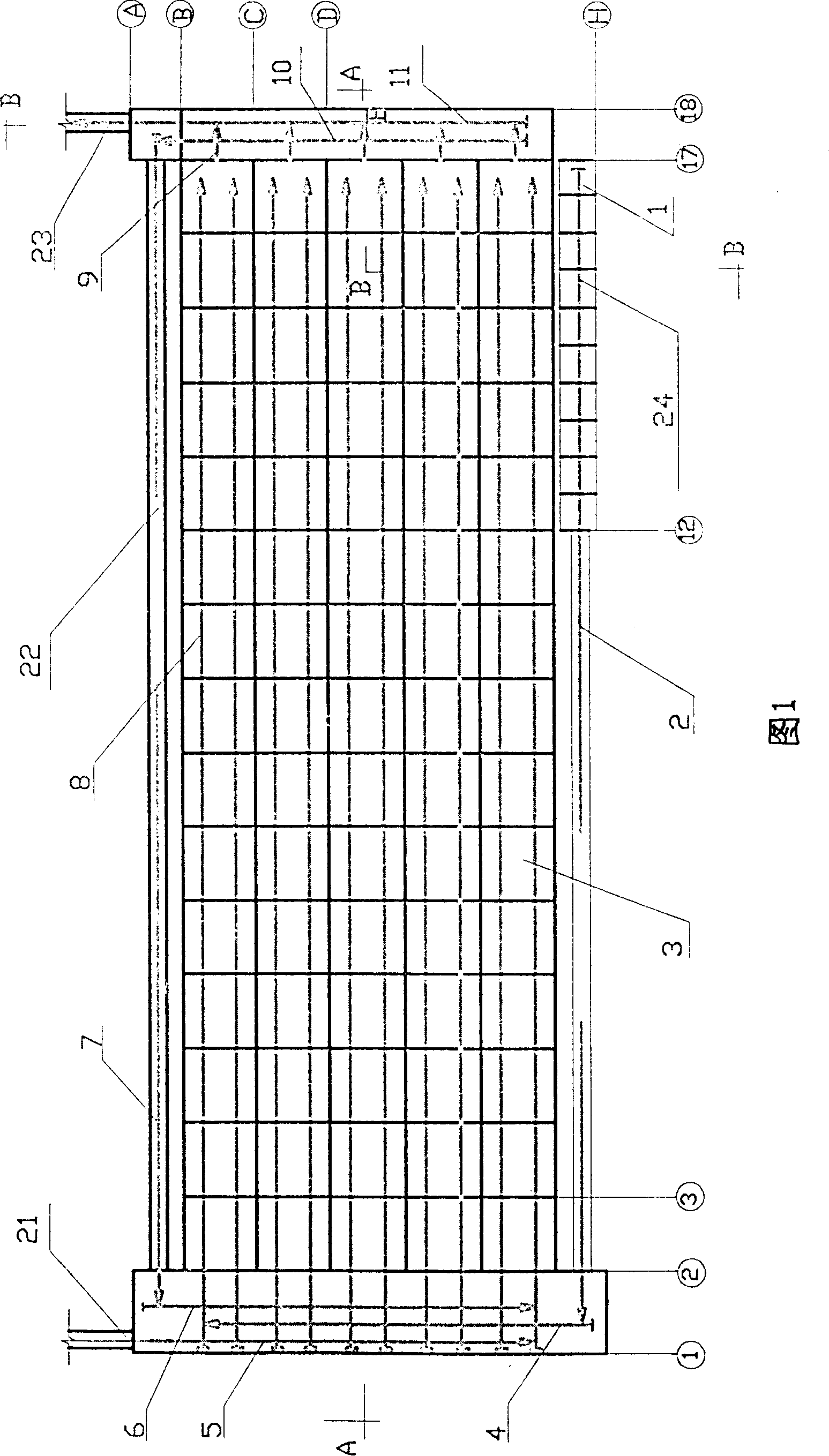

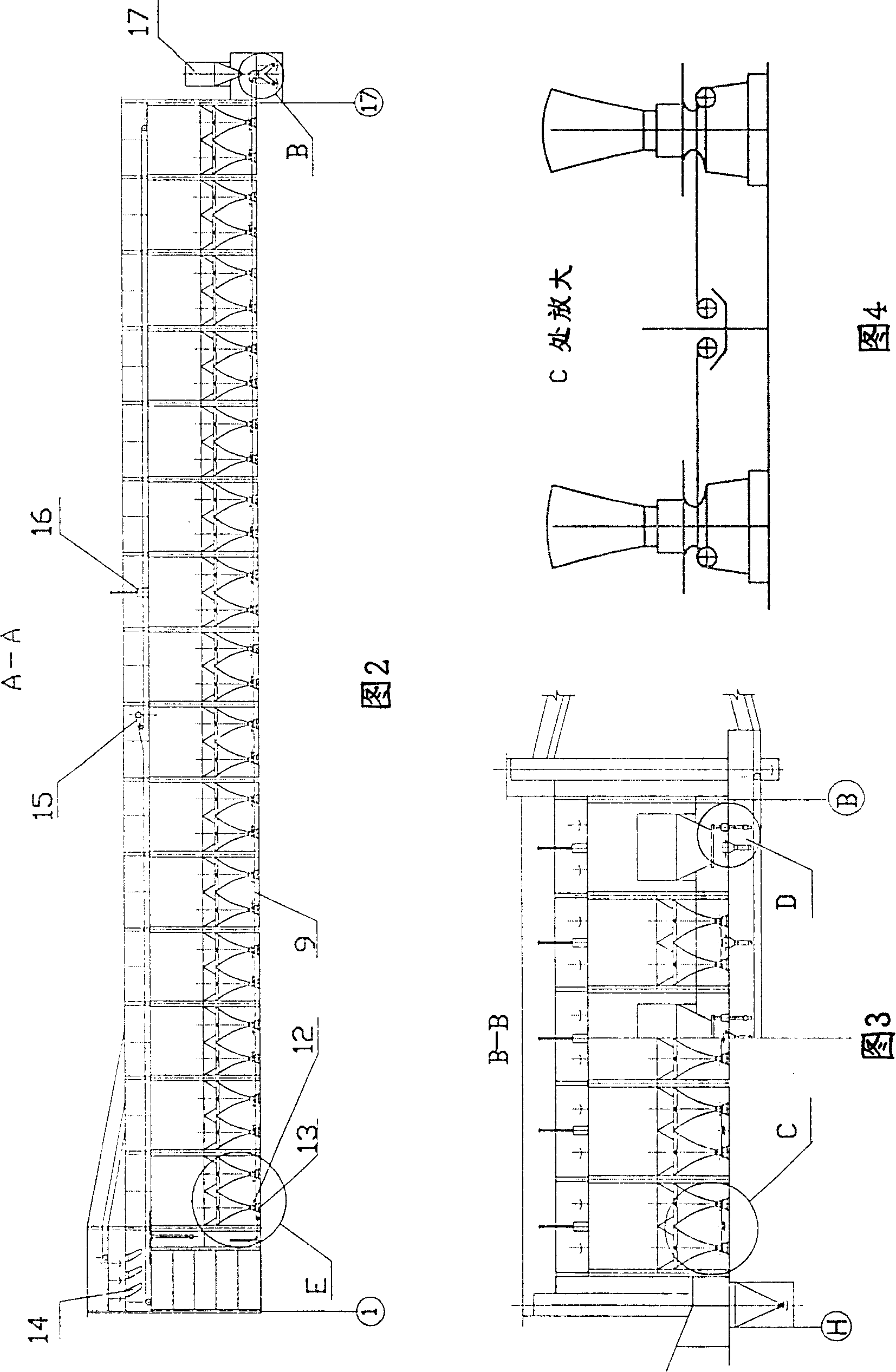

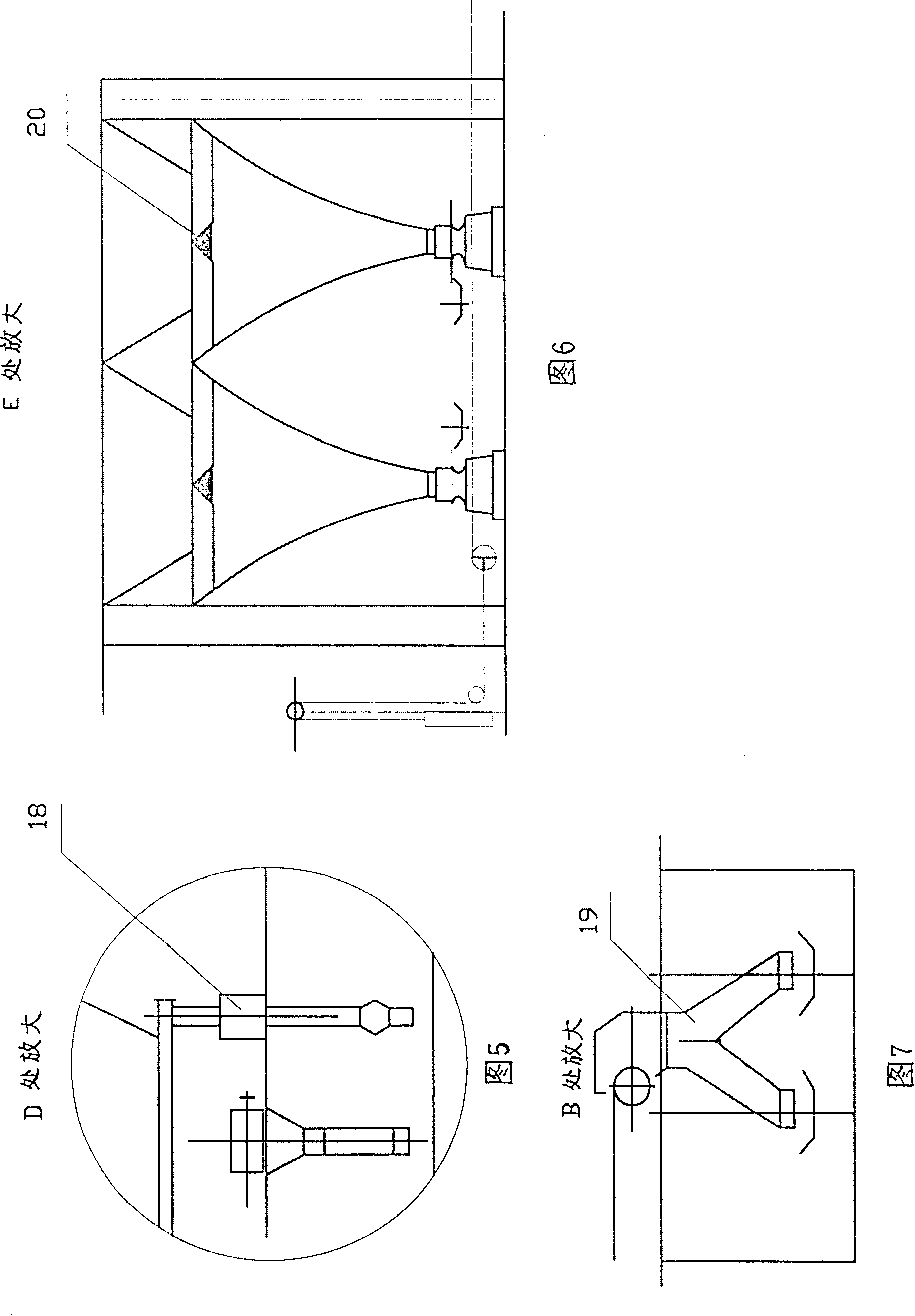

[0029] 1. Setting of project production scale

[0030] The project scale consists of four capacities: input, storage, ingredient mixing and output, among which the storage capacity is the basic capacity, and the setting value is determined by the following elements.

[0031] (1) The calculation result of the enterprise's material balance; (2) The three confirmation results of raw material varieties and supply (market); (3) The foreseeable total production capacity of the final product of the enterprise; (4) The foreseeable changes in the raw material market and transportation mode . (5) Total input capacity ≥ total output capacity upstream of the process; (6) Output capacity = input capacity downstream of the process; (7) Mixing capacity of ingredients > output capacity, the excess should be calculated and calculated through equipment capacity balance based on storage capacity and quality indicators The process layout is determined.

[0032] 2. Setting of quality index and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com