Method for efficiently absorbing water and solidifying under films through controllable vacuum negative pressure well

A controllable, negative pressure well technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problem that a single set of vacuum pumping equipment has a small influence range, does not consider the fluid mechanics characteristics of the pipeline, and has a large vacuum pressure transmission loss. and other problems, to achieve the effect of easy to master the construction process, significant economic effect, and high drainage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

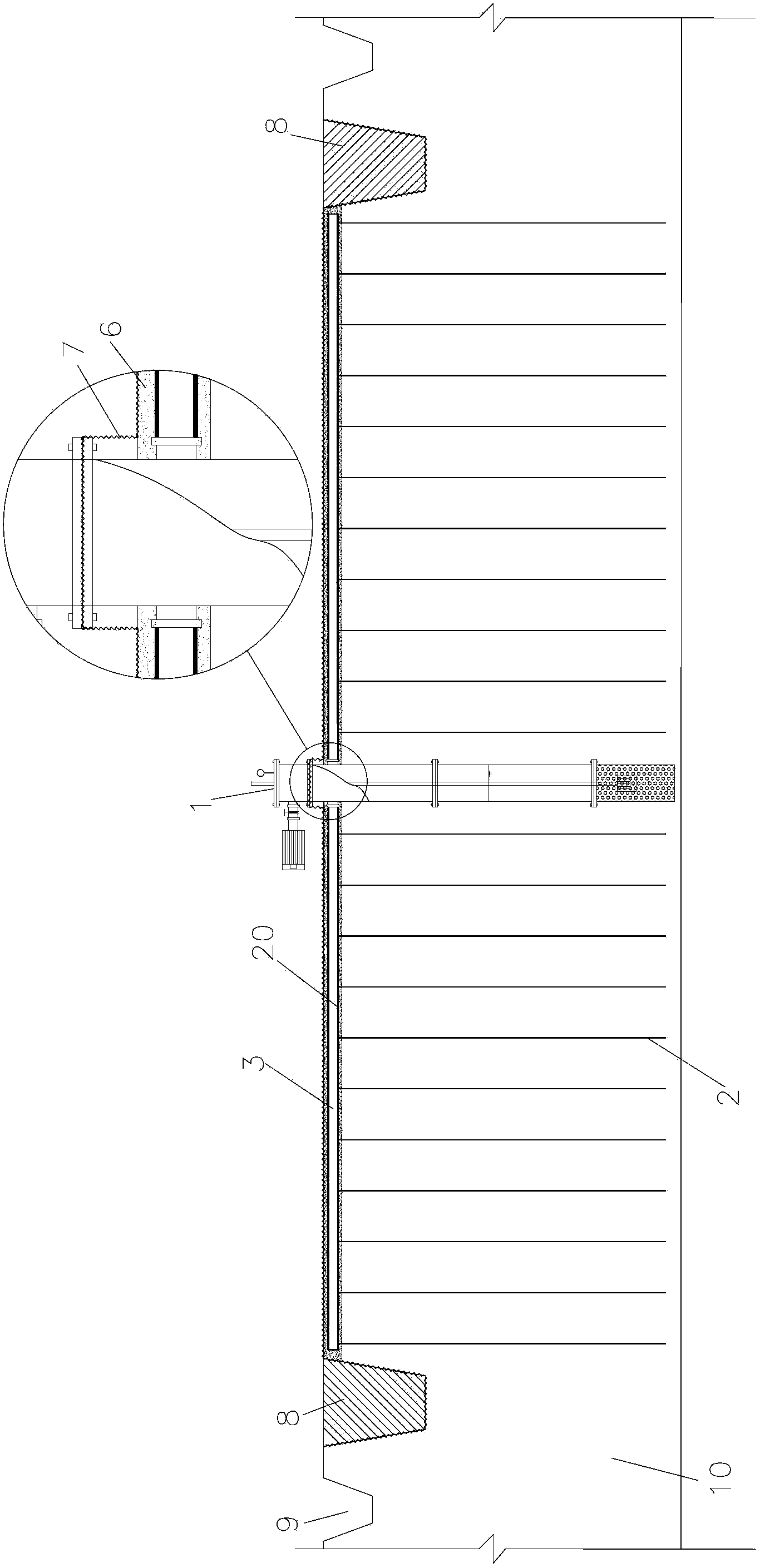

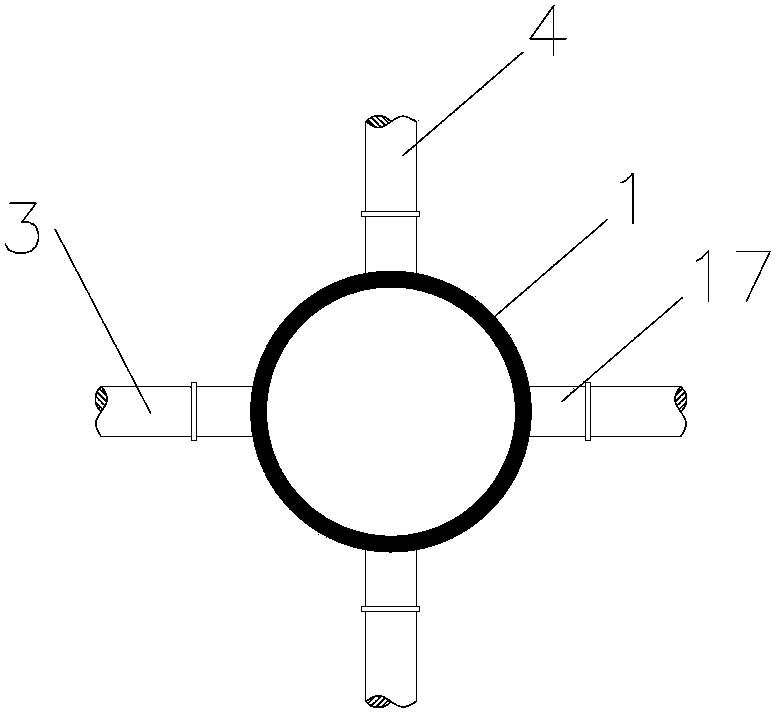

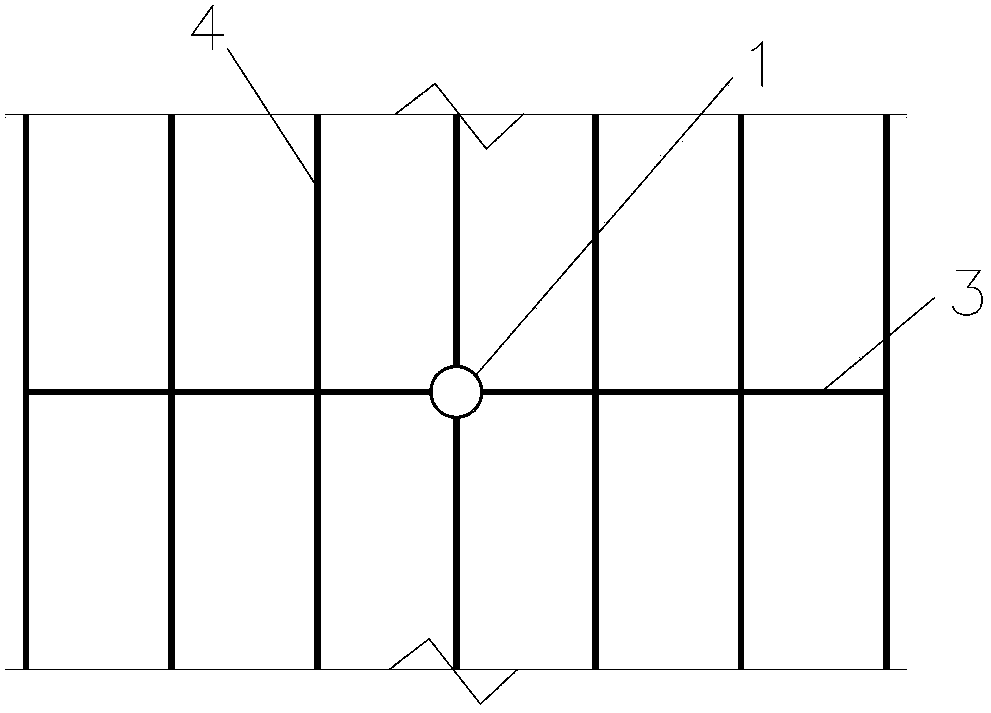

[0055] In this embodiment, a negative pressure sealing well is arranged in the center of the site for the deep treatment of general soft soil, such as Figure 1 to Figure 3 shown.

[0056] The implementation process is as follows:

[0057] Before implementing the above-mentioned reinforcement method, the surface of the site should be cleared and the defense line should be measured.

[0058] Then start to implement the above reinforcement method, and the points that need specific attention are as follows:

[0059] In the first step, hydraulic or vibratory machinery is used to drill the drainage board, and the drainage board is arranged in a square or plum blossom shape.

[0060] In the second step, the horizontal pipeline is laid in the sand cushion layer 20 with a thickness of 30-50 cm.

[0061] In the fourth step, the water inlet of the sealed well is sealed and communicated with the main pipe and the branch pipe respectively.

[0062] In the fifth step, the non-woven geo...

Embodiment 2

[0065] In this embodiment, a negative pressure sealing well is arranged on one side of the site for the deep treatment of general soft soil, such as Figure 4 , Figure 7 , Figure 8 shown.

[0066] The implementation process is basically the same as in Example 1, the difference is:

[0067] In the fourth step, the water inlet of the sealed well is sealed and connected with the main pipe.

Embodiment 3

[0069] In this embodiment, a negative pressure sealing well is arranged on one side of the site for the deep treatment of general soft soil, such as Figure 5 , Figure 7 , Figure 8 shown.

[0070] The implementation process is basically the same as in Example 1, the difference is:

[0071] In the third step, the horizontal pipeline is laid on a layer of braided cloth 5 .

[0072] In the fourth step, the water inlet of the sealed well is sealed and connected with the main pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com