Steel structure plane reinforcing structure

A technology for strengthening structures and steel structures, which is applied in building construction, building maintenance, construction, etc., can solve problems such as not being able to better deal with actual conditions, difficulty in achieving required strength, and potential safety hazards, and achieve a sense of user experience Good, good reinforcement effect, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

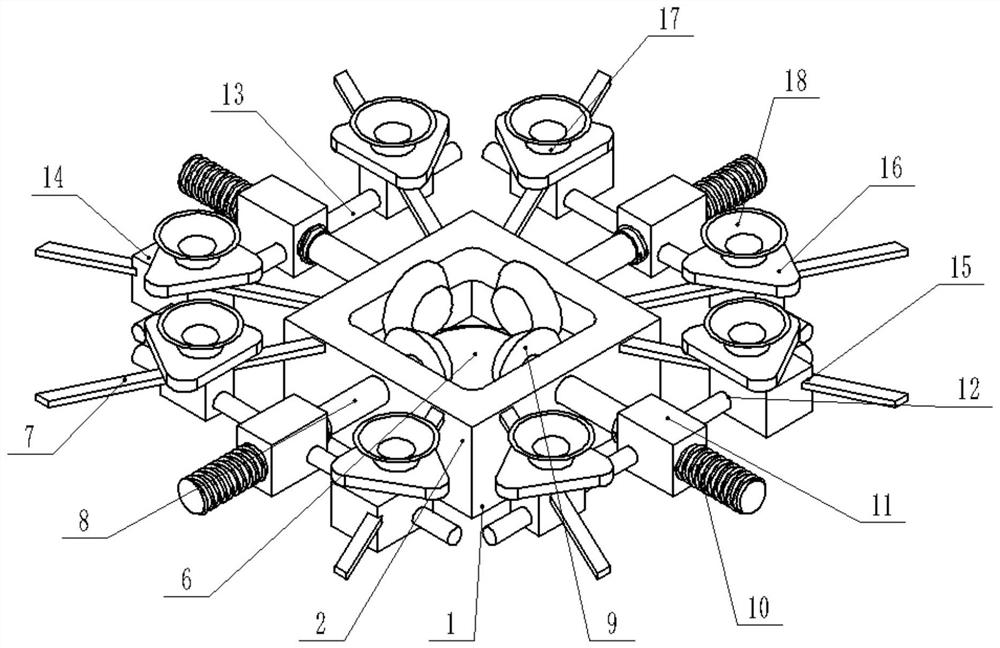

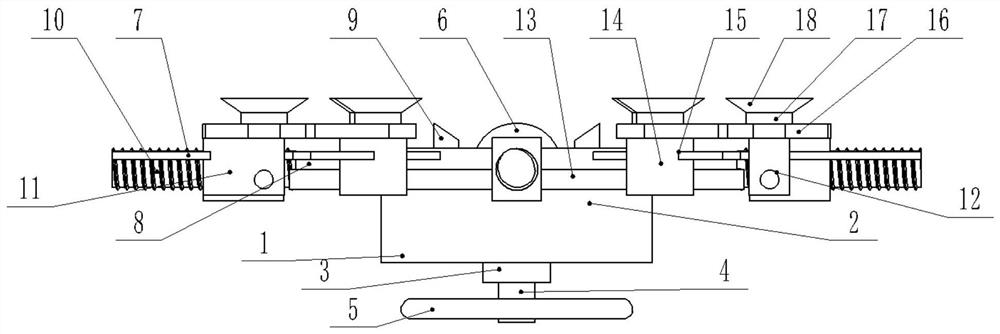

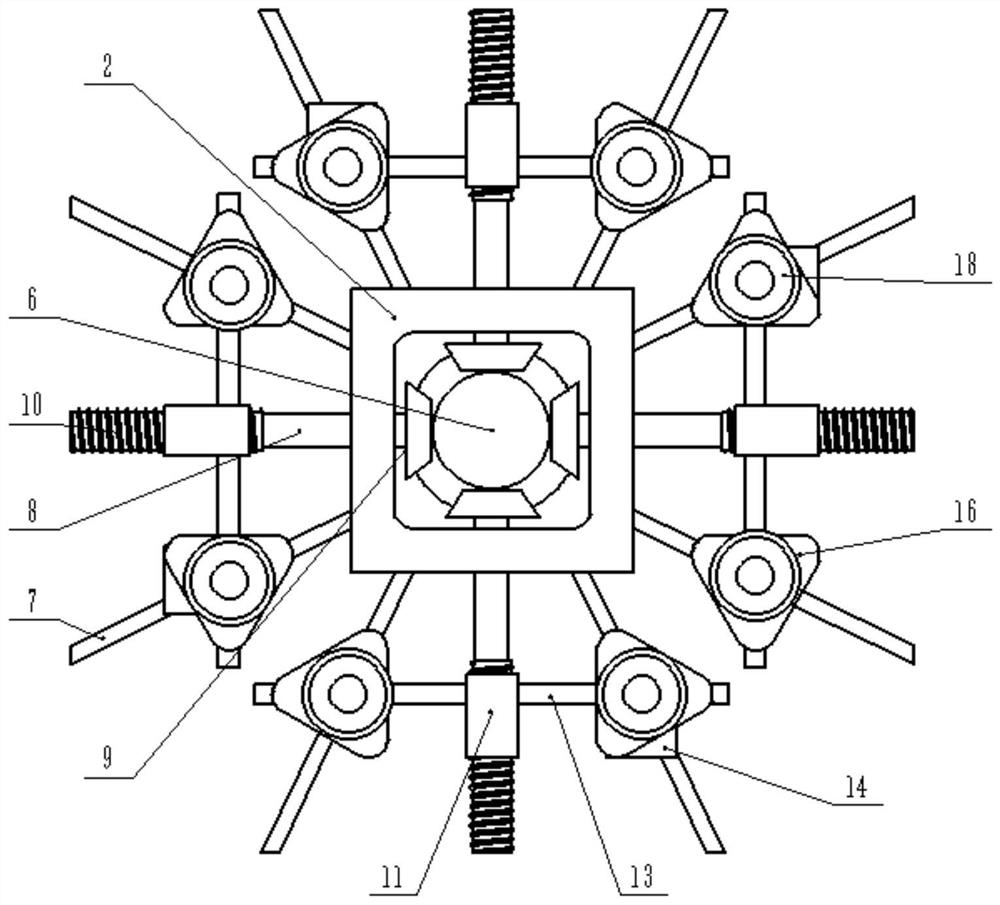

[0021] Example 1: Please refer to Figure 1-4 , a steel structure plane reinforcement structure, comprising a chassis 1, a box body 2 is fixedly connected above the chassis 1, a shaft sleeve 3 is fixedly connected below the middle part of the chassis 1, and the shaft sleeve 3 is rotatably connected with a rotating shaft 4, The bottom end of the rotating shaft 4 is fixedly connected with a control dial 5;

[0022] Turn the control dial 5 during use, and then make the rotating shaft 4 fixedly connected with the control dial 5 rotate, and then drive the driving bevel gear 6 fixedly connected with the rotating shaft 4 to rotate, and then make the driven bevel gear meshed with the driving bevel gear 6 9 rotates, and then drives the rotating rod 8 that is fixedly connected with the driven bevel gear 9 to rotate, and then drives the screw rod 10 that is fixedly connected with the rotating rod 8 to rotate, and then makes the moving block 11 that is threadedly connected with the screw ...

Embodiment 2

[0032] Embodiment 2: The difference between this embodiment and the previous embodiment is: please refer to Figure 1-4 , a steel structure plane reinforcement structure, comprising a chassis 1, a box body 2 is fixedly connected above the chassis 1, a shaft sleeve 3 is fixedly connected below the middle part of the chassis 1, and the shaft sleeve 3 is rotatably connected with a rotating shaft 4, The bottom end of the rotating shaft 4 is fixedly connected with a control dial 5;

[0033] Turn the control dial 5 during use, and then make the rotating shaft 4 fixedly connected with the control dial 5 rotate, and then drive the driving bevel gear 6 fixedly connected with the rotating shaft 4 to rotate, and then make the driven bevel gear meshed with the driving bevel gear 6 9 rotates, and then drives the rotating rod 8 that is fixedly connected with the driven bevel gear 9 to rotate, and then drives the screw rod 10 that is fixedly connected with the rotating rod 8 to rotate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com