A kind of seepage cofferdam design back-sealing concrete construction structure and its method

A technology for back-sealing concrete and cofferdams, which is applied in infrastructure engineering, buildings, protection devices, etc., can solve the problems of inconvenient removal of the cofferdam body, and achieve the effect of not easy deformation and uniform reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

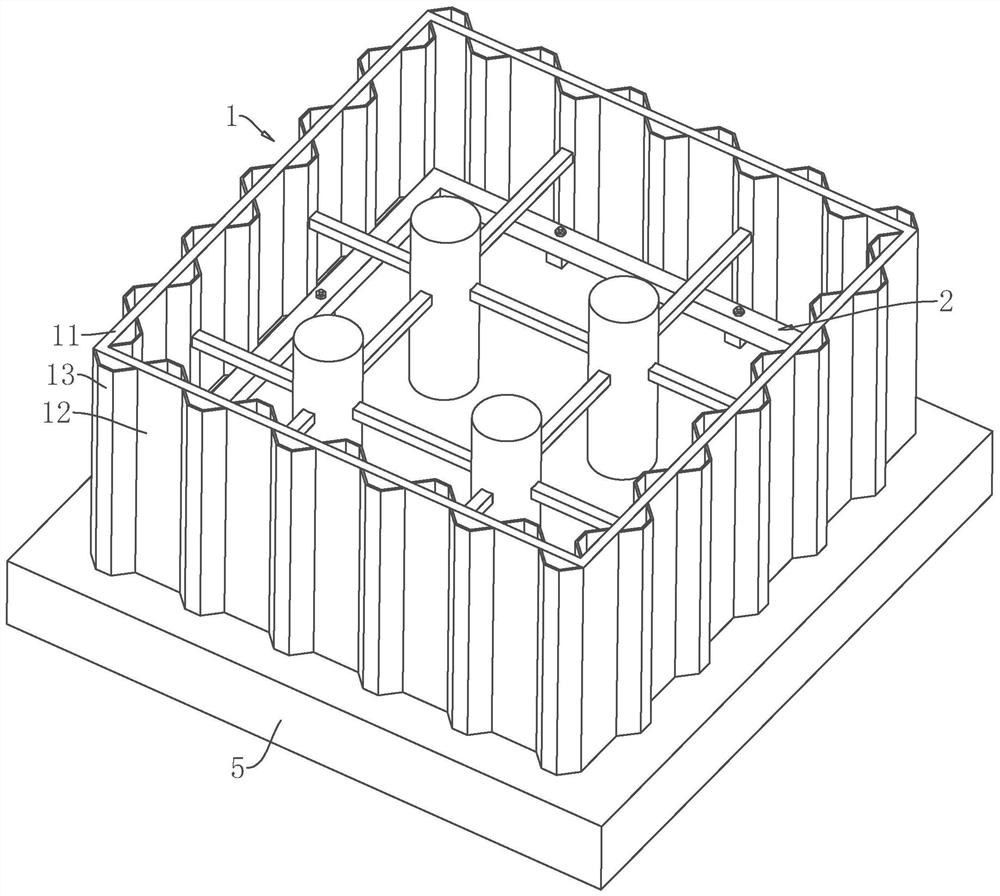

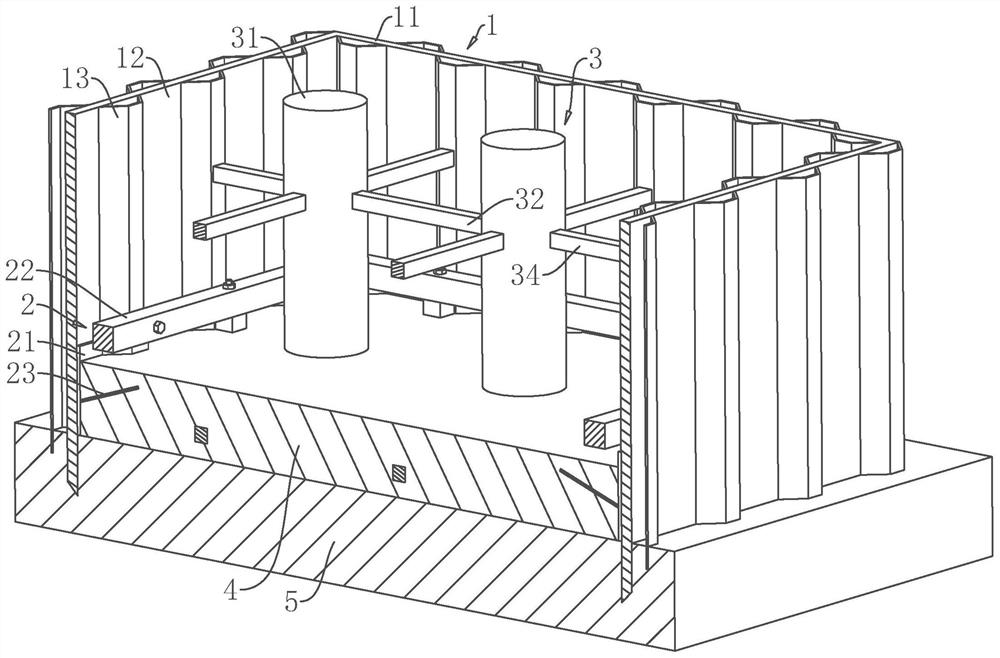

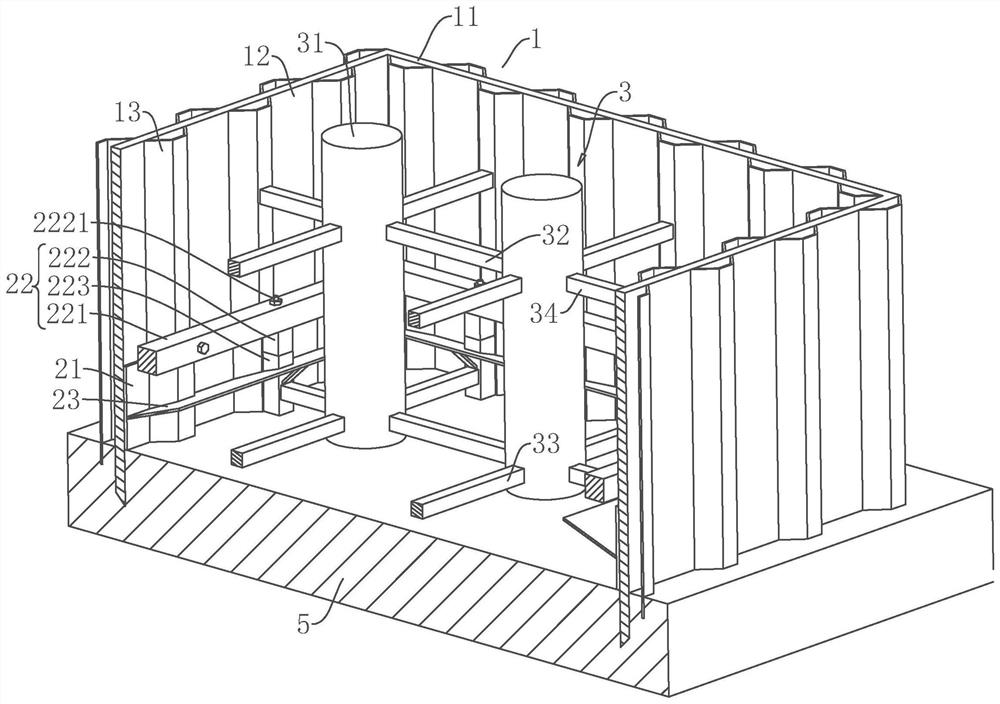

[0038] Attached to the following Figure 1-3 This application will be described in further detail.

[0039] The embodiment of the present application discloses a concrete construction structure of a seepage cofferdam designed to seal the bottom. refer to figure 1 and figure 2, the seepage cofferdam design bottom-sealing concrete construction structure includes a cofferdam body 1, the cofferdam body 1 is a vertically arranged cubic steel casing 11, and the inner side of the cubic steel casing 11 is provided with an anti-seepage mechanism 2 and a positioning mechanism 3.

[0040] refer to figure 1 , the cubic steel casing 11 includes four casing plates 12, and the casing plates 12 are connected end to end in sequence. Protrusions 13 are mounted on the casing board 12 . The protruding part 13 is a long steel plate, the two long sides of the steel plate are bent towards the same side of the steel plate, and the bending angle is an acute angle, and the two long sides of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com