Modular construction camshaft adjuster with a chain or belt wheel

A camshaft adjuster, modular technology for belts/chains/gears, components with teeth, machines/engines, etc., to solve problems such as deformation, damage to camshaft drives, damage to motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

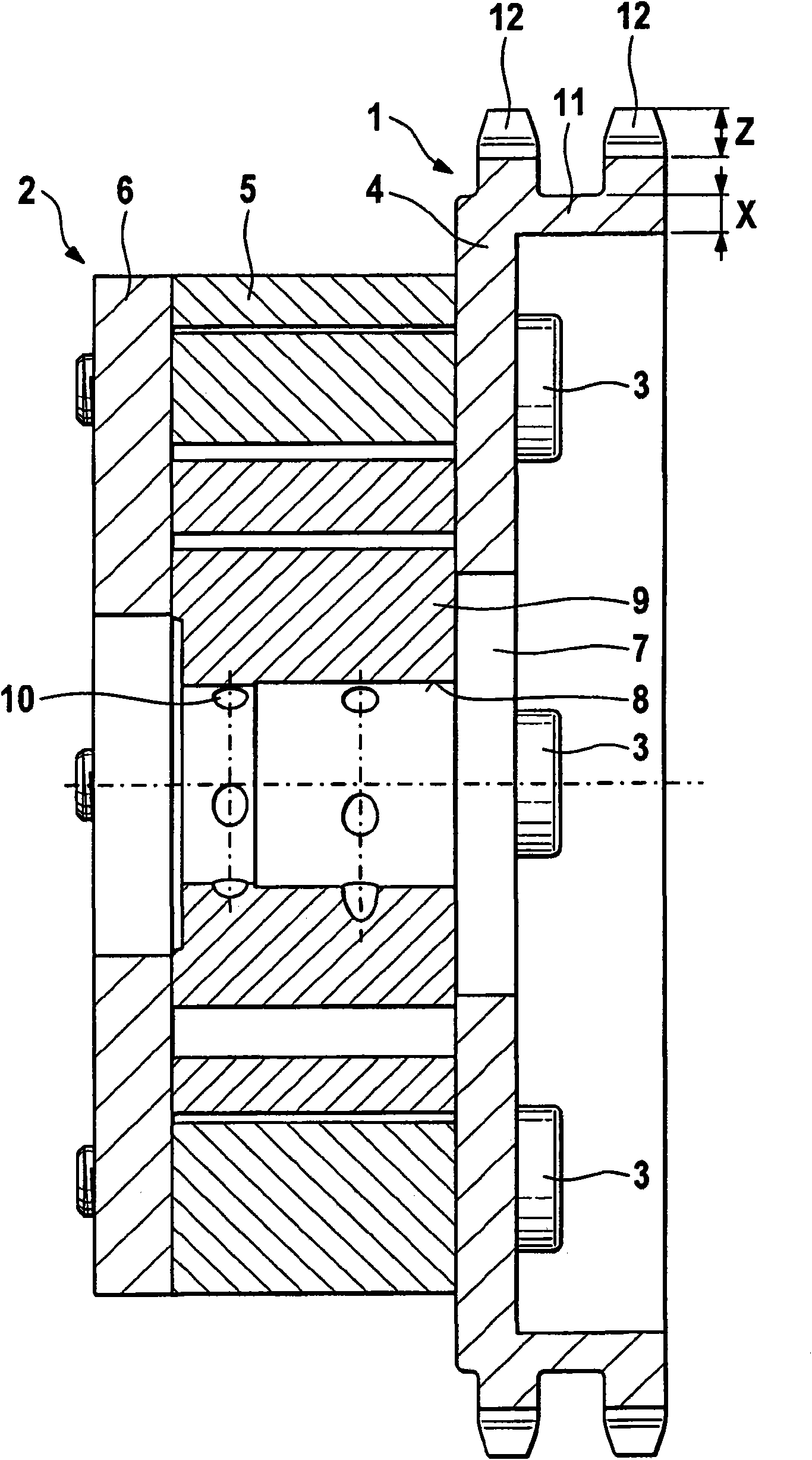

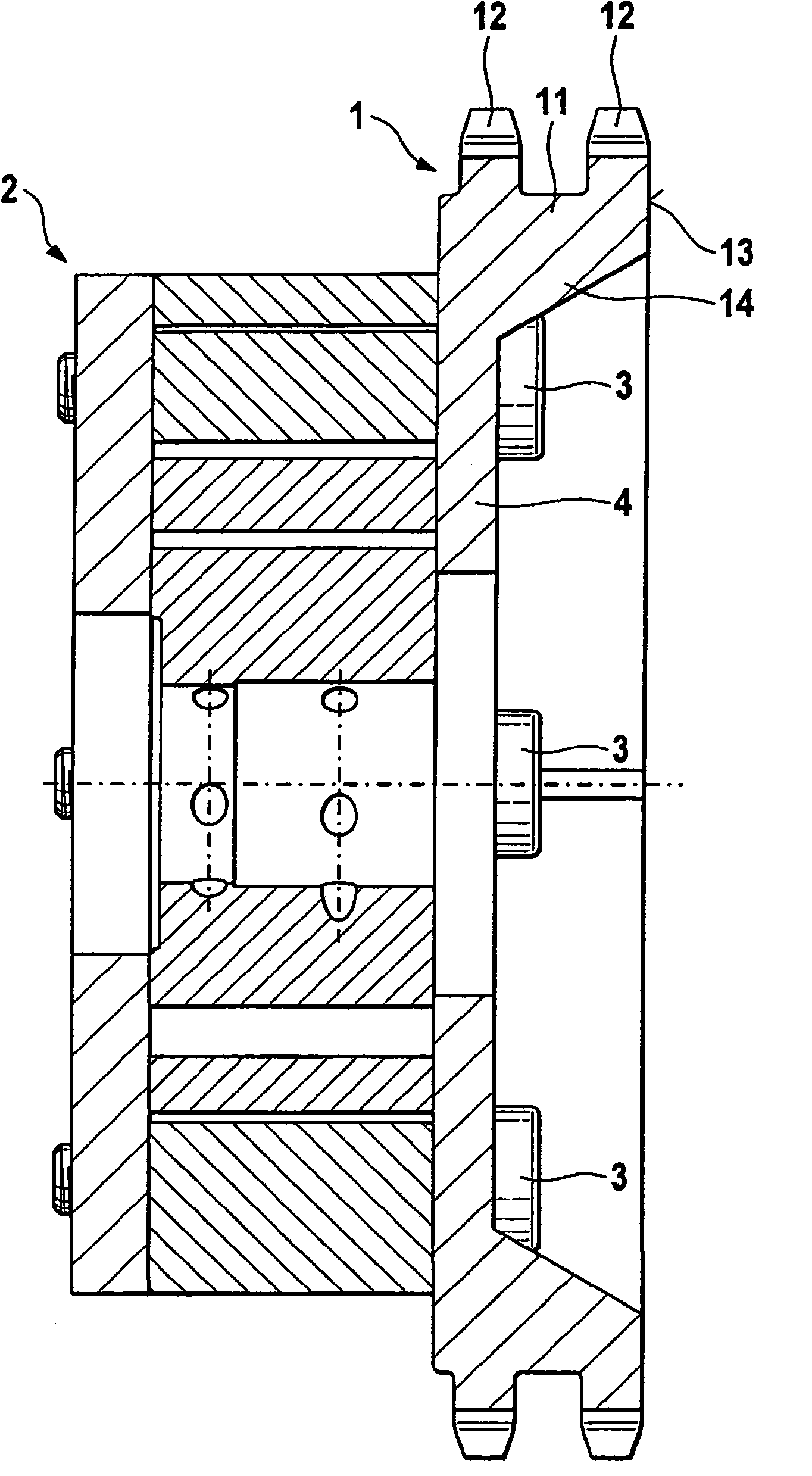

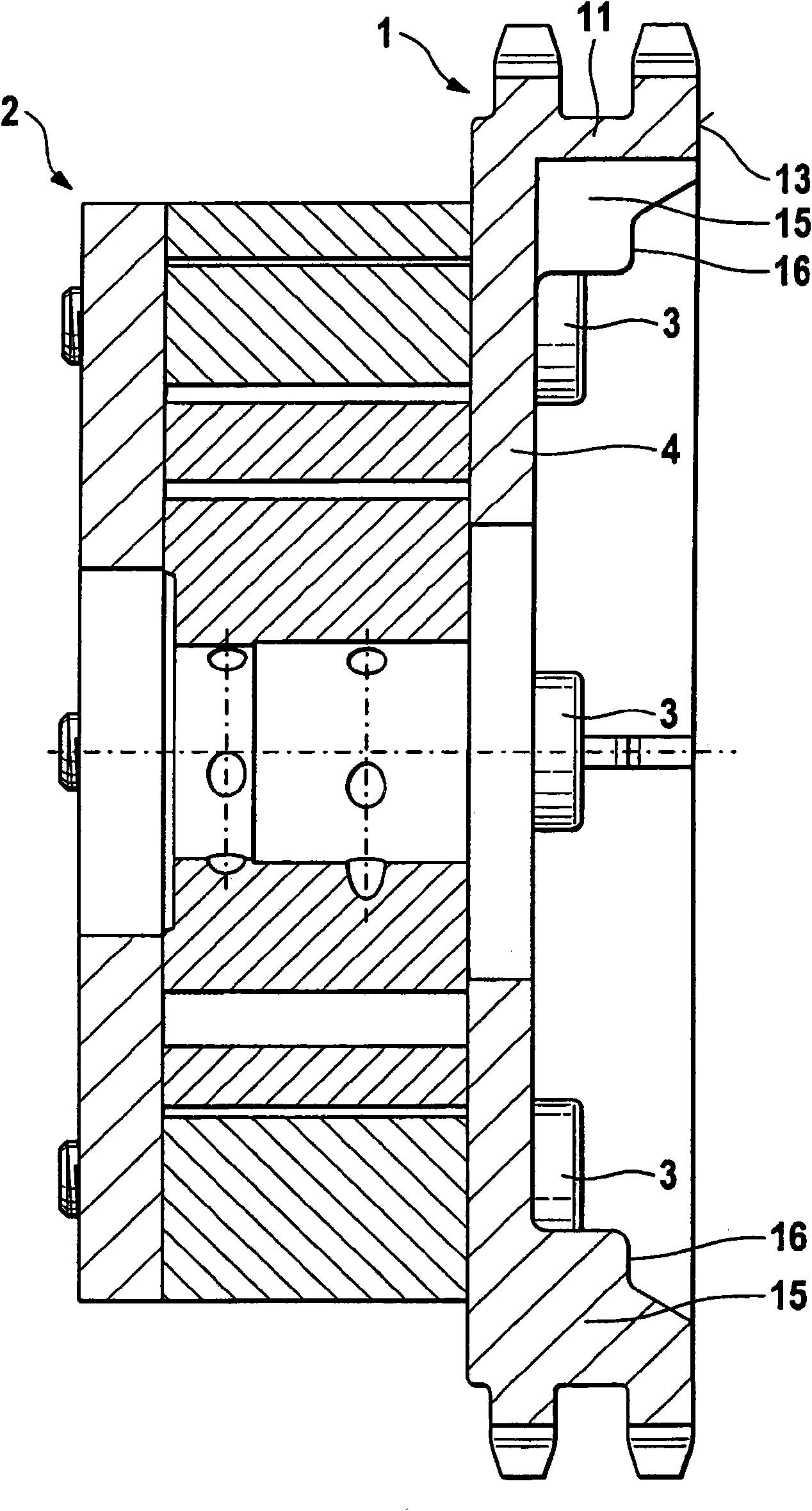

[0017] figure 1 Shown: A pot sprocket 1 made of lightweight material such as aluminum is passed coaxially through the annular gurney 4 of the pot sprocket 1 , the stator 5 and the end of the camshaft adjuster 2 by means of radially uniformly distributed bolts 3 The cover 6 is attached to the modular steel camshaft adjuster 2 of the internal combustion engine (not shown). The central circular opening 7 in the ring gurney 4 is used to accommodate a camshaft (not shown) on which the chain wheel 1 is rotatably mounted via the camshaft adjuster 2 . The bearing structure 8 of the camshaft has lubricant holes 10 in the rotor 9 of the camshaft adjuster 2 .

[0018] On the outer circumference of the annular gurney 4 , essentially axially—away from the camshaft adjuster 2—the outer, substantially cylindrical wheel wall 11 of the pot sprocket 1 protrudes. In the protruding region of the wheel wall 11 of wall thickness X are arranged radially outwardly directed two wheel rims 12 each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com