3D printing metal powder, 3D printing method and method for preparing 3D printing metal powder

A metal powder, 3D printing technology, applied in the field of 3D printing metal powder, 3D printing and preparing 3D printing metal powder, can solve the problems of low fatigue performance, high temperature creep performance, mechanical performance reduction, etc., to achieve good surface quality and manufacturing accuracy , reducing micro-cracks and component deformation, avoiding the effect of different evaporation losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

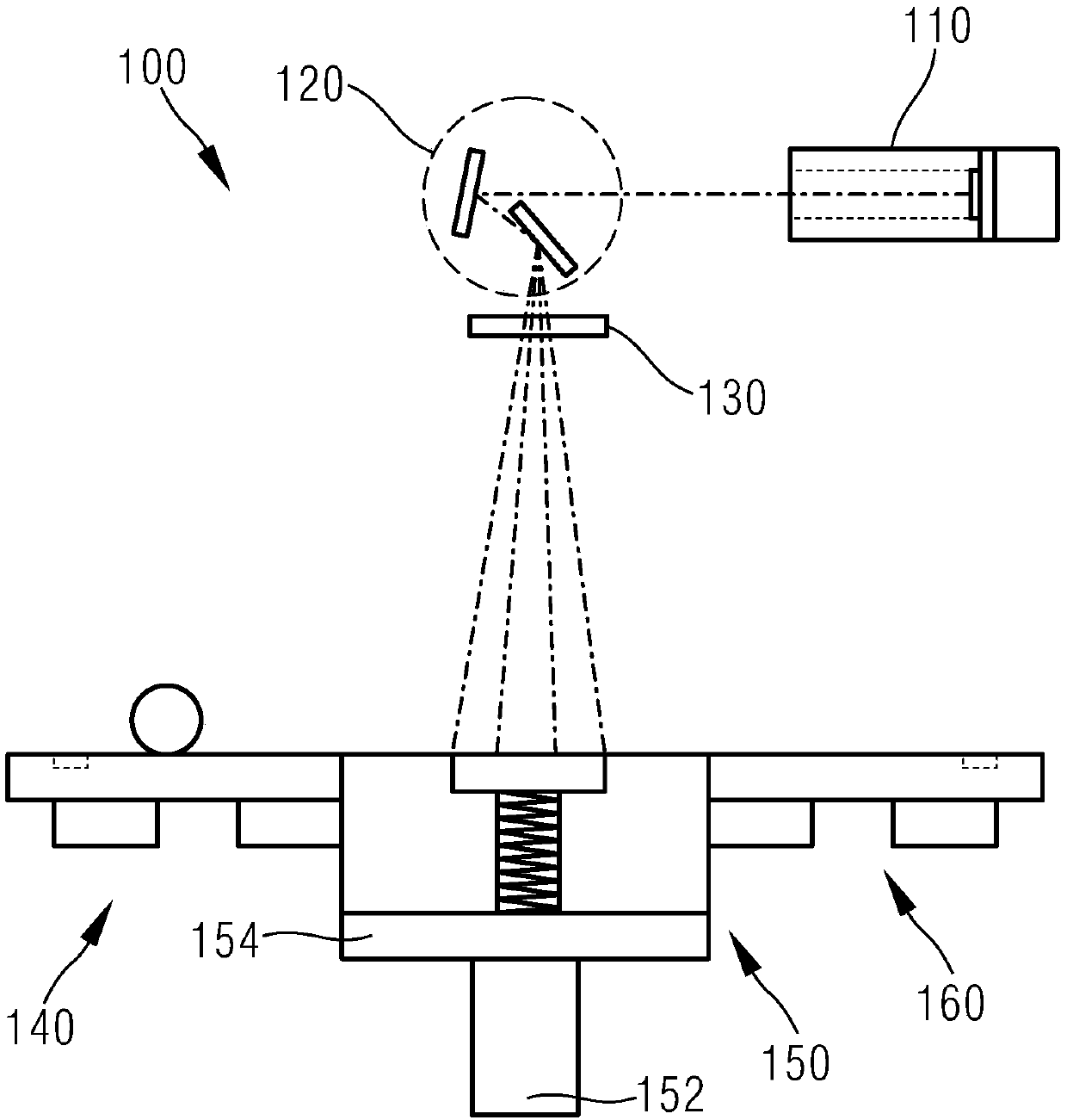

[0017] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

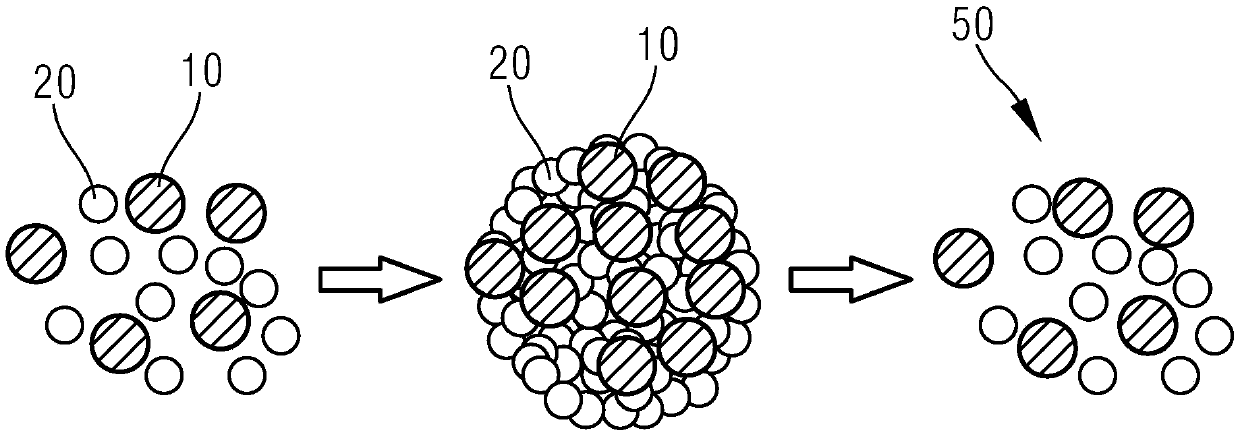

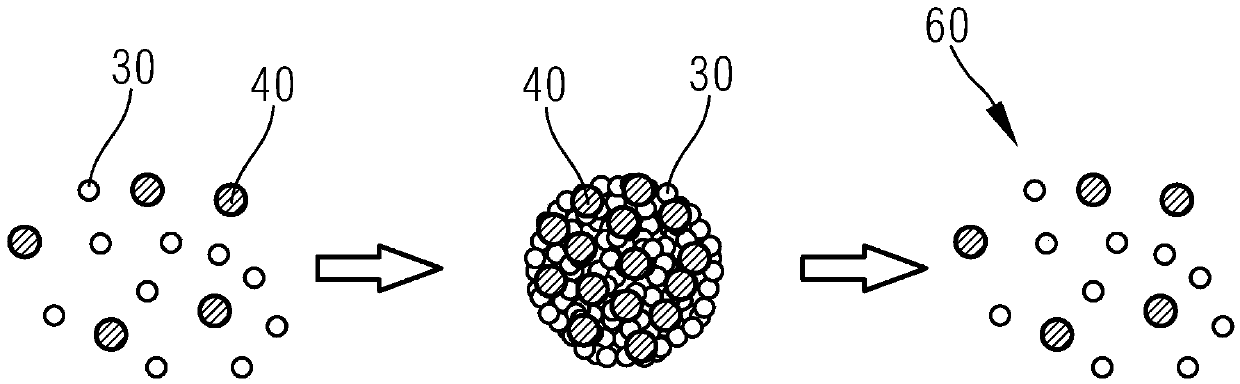

[0018] The invention provides 3D printing metal powder, 3D printing and a method for preparing 3D printing metal powder. Metal powders produced according to the invention are metal composite powders to which reinforcing particles have been added. The reinforcing particles can improve the strength of the metal composite powder bonded by countless small particles, fix the small particles, and hinder the generation of cracks in the metal composite powder. The metal composite powder provided by the present invention can also have two metals in the form of a metal alloy. In addition, the metal composite powder provided by the present invention is a large-sized powder formed by bonding small particles. Its advantage is that the large particles are easy to spread and evenly distributed without cracks. The small particles in the powder can be quickly melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com