Step-by-step sectional type tunnel curtain grouting construction pipe set, device and construction method

A curtain grouting and construction method technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of unsatisfactory effects, low strength of grouting stones, and small amount of grout injection, so as to improve the effective utilization rate, The grouting effect is good and the effect of increasing the injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

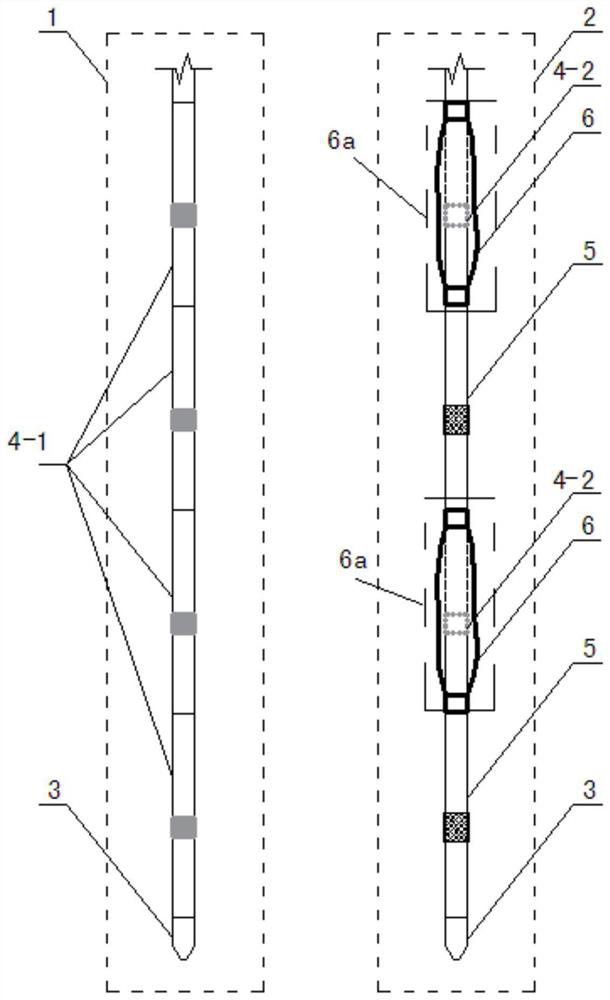

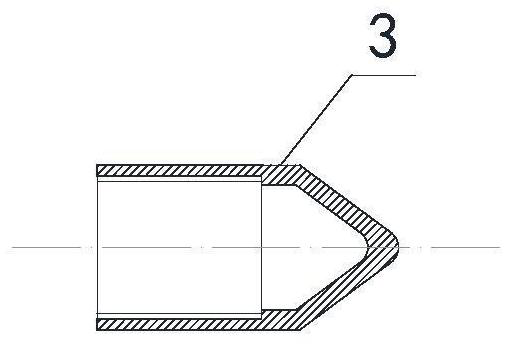

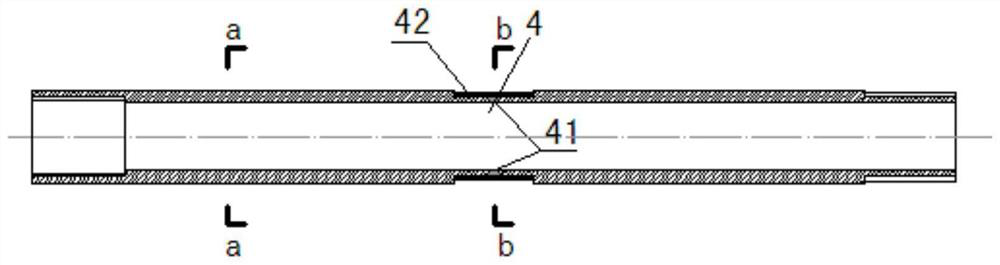

[0065] The invention discloses a step-by-step segmented tunnel curtain grouting construction pipe group, such as figure 1 The shown includes multiple sets of construction kits, each construction kit includes two grouting pipes 1 and a vacuum pipe 2 for inserting into grouting holes with different depths; the lengths of the two grouting pipes 1 are not equal. Wherein: each grouting pipe 1 is composed of a plurality of first grouting pipe sections 4-1 connected in sequence.

[0066] Such as image 3 and 5 As shown, the vacuum tube 2 is composed of a plurality of connected vacuum tube sections 5 and a plurality of isolation tube sections 6a connected at intervals, and the vacuum tube section 5 is connected at the front end, and the middle part of each vacuum tube section 5 is connected with the grouting hole; The isolation pipe section 6a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com