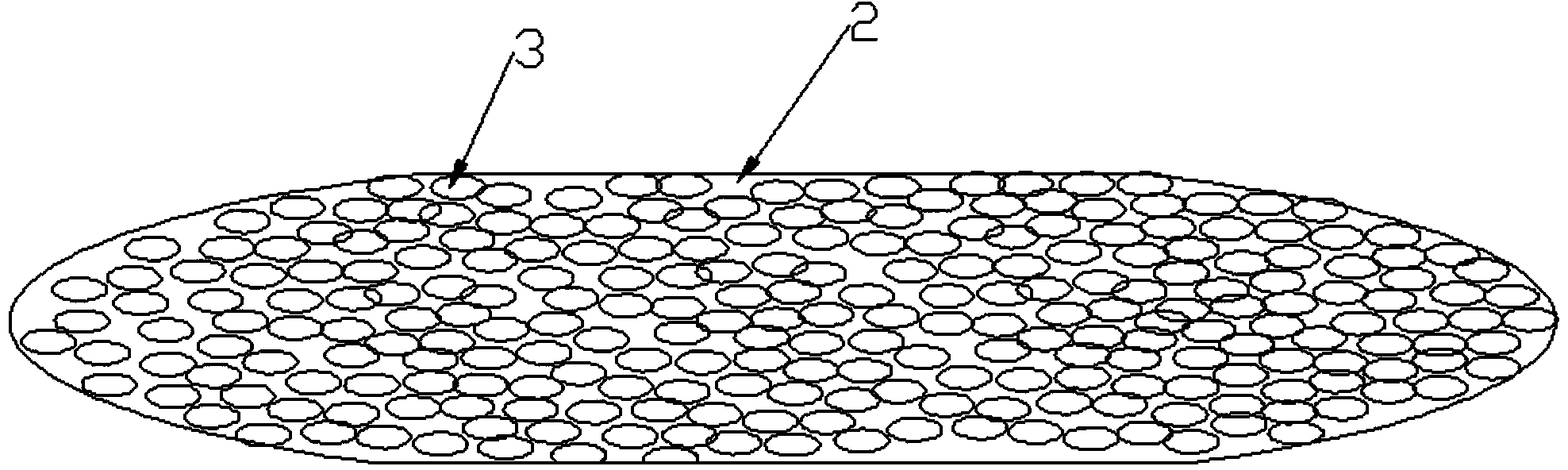

Dacron fine denier multi-hole flat fiber and method for producing same

A flat fiber and production method technology, which is applied in fiber processing, textiles and papermaking, and clustering of newly extruded filaments. It can solve the problems of uneven quality of the inner and outer layers of the laminated filaments, low package density, and inconsistent hardness. Beautiful appearance, high packing density and good internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

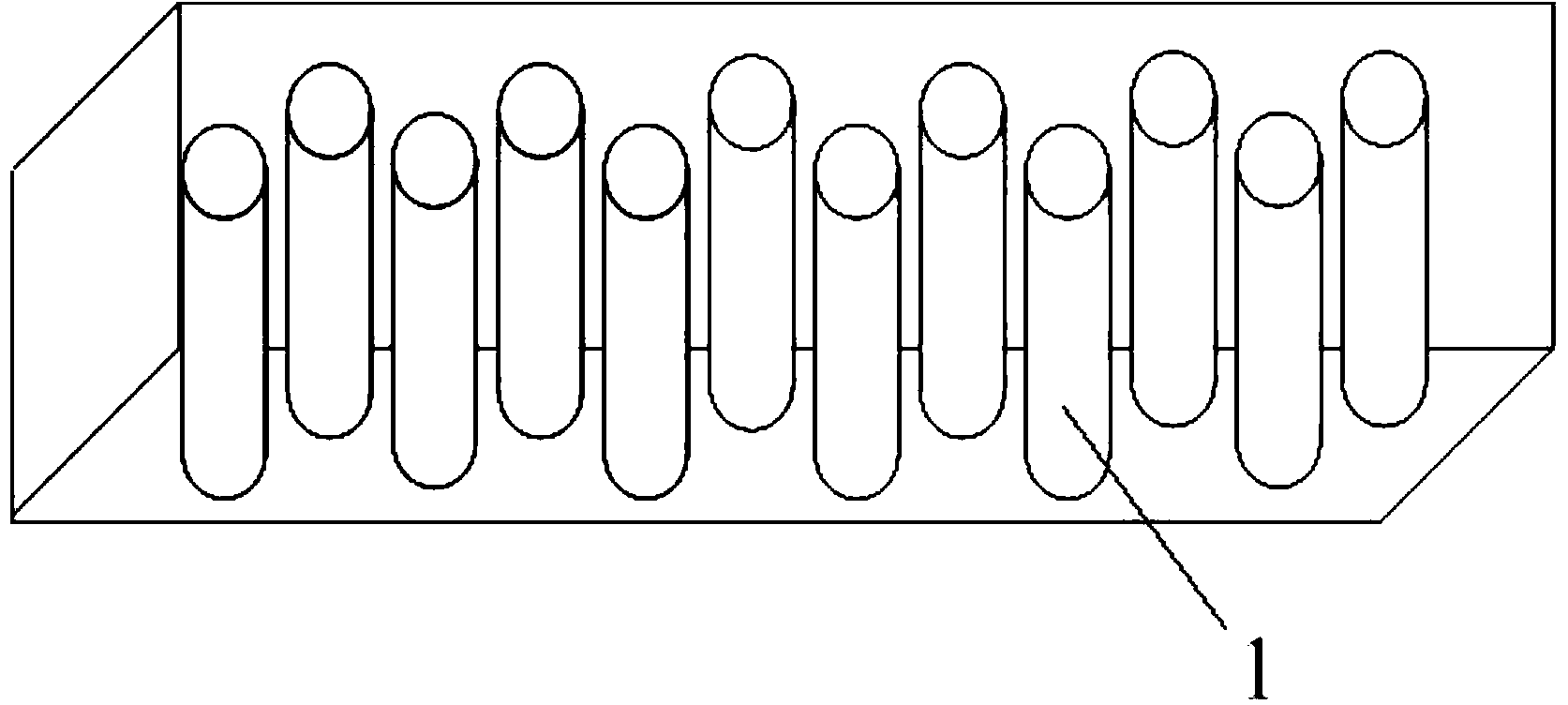

Embodiment 1

[0032] Weigh the polyester melt and put it into the polymerization kettle for melting; import the polyester melt after step 1 into a melt distribution valve provided with a four-way valve, and transport the melt to the cooler under the action of the booster pump, After cooling, the melt is transferred to a static mixer, and finally introduced into a melt distribution valve equipped with a five-way valve; the melt after step 2 is introduced into the spinning box, and the temperature of the heat medium in the spinning box is set to 292°C; The metering pump melt is extruded to the spinning assembly, and the misplaced cooling ring is used to blow the air. The air pressure of the control ring air conditioner is 1000Pa, the air pressure of the cooling air duct is 40Pa, the air temperature is 21°C, and the air humidity is 90%. Cluster forming; The distance from the spinneret is 60cm to carry out the oiling operation on the cluster; the cluster after step 5 is passed through the spinni...

Embodiment 2

[0034]Weigh the polyester melt and put it into the polymerization kettle for melting; import the polyester melt after step 1 into a melt distribution valve provided with a four-way valve, and transport the melt to the cooler under the action of the booster pump, After cooling, the melt is transferred to a static mixer, and finally introduced into a melt distribution valve equipped with a five-way valve; the melt after step 2 is introduced into the spinning box, and the temperature of the heat medium in the spinning box is set to 294°C; The metering pump melt is extruded to the spinning assembly, and the misplaced cooling ring is used to blow the air. The air pressure of the control ring air conditioner is 1050Pa, the air pressure of the cooling air duct is 45Pa, the air temperature is 23°C, and the air humidity is 90%. Cluster forming; The distance from the spinneret is 60cm to carry out the oiling operation on the cluster; the cluster after step 5 passes through the spinning t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com