Flux-cored alloyed ductile cast iron homogeneous gas-welding wire and electric welding rod

A nodular cast iron and alloying technology, which is applied in the field of flux-cored ductile iron homogeneous welding rod and flux-cored ductile iron homogeneous gas welding wire, can solve the problem of white spots and cracks in the welding repair area and hot welding preheating The method is complex, unable to meet the color consistency, performance matching and comprehensive performance requirements, etc., to achieve the effect of enhancing the crack resistance of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

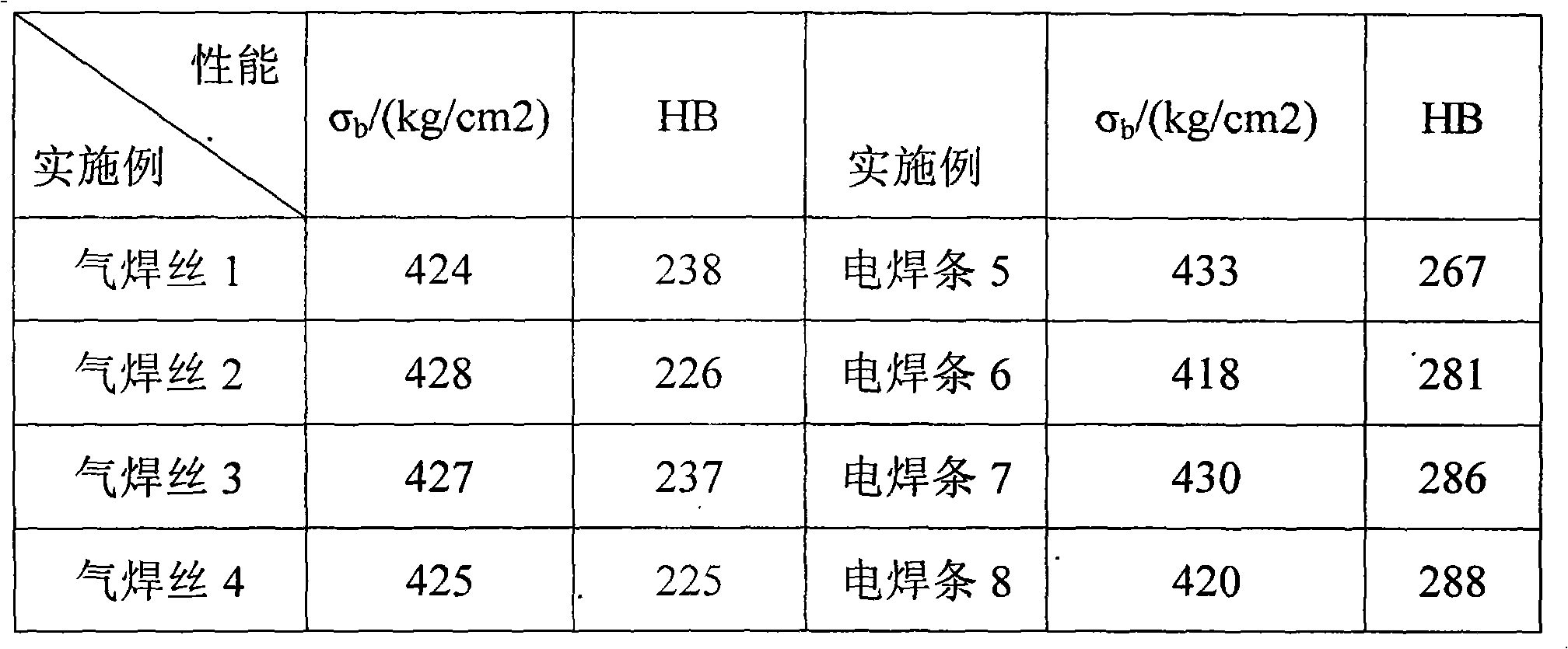

Examples

Embodiment 1

[0017] Embodiment 1: implement according to the following steps:

[0018] First, weigh the following component powders by weight percentage: G 20%, 75Si-Fe 50%, Ni 7%, Ti 4%, Mg 4%, Bi 2.5%, Zr 2.5%, Ba 4.5%, Ce 1.5% , RE-Y 4.0%, the total weight percentage is 100%; mix the various powders that have been weighed, and then use the cold-rolled steel strip H08A on the YHZ-1 flux-cored wire forming machine to prepare it by the steel strip method Raw wire with a diameter of Φ6mm; then the raw wire is drawn through a Φ5.5mm die and a Φ5.0mm second die to prepare a Φ5mm flux cored gas welding wire or flux cored core.

Embodiment 2

[0019] Example 2: According to the steps of Example 1, the following parameters are selected for control: G 12%, 75Si-Fe60%, Ni 8%, Ti 3.6%, Mg 3.8%, Bi 0.8%, Zr 1%, Ba 2.0%, Ce 2.8%, RE-Y 6%, the total weight percentage is 100%. A Φ5mm flux cored gas welding wire or flux cored welding core is prepared.

Embodiment 3

[0020] Example 3: According to the steps of Example 1, the following parameters are selected for control: G 18%, 75Si-Fe55%, Ni 5%, Ti 2%, Mg 6%, Bi 2%, Zr 2%, Ba 3%, Ce 2%, RE-Y 5.0%, the total weight percentage is 100%. A Φ5mm flux cored gas welding wire or flux cored welding core is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com