Grinding ball production method

A production method and grinding ball technology, which can be applied to furnace types, other manufacturing equipment/tools, furnaces, etc., can solve the problems of high production cost, affecting the production quality of grinding balls, and unfavorable large-scale promotion, and achieve the effect of low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

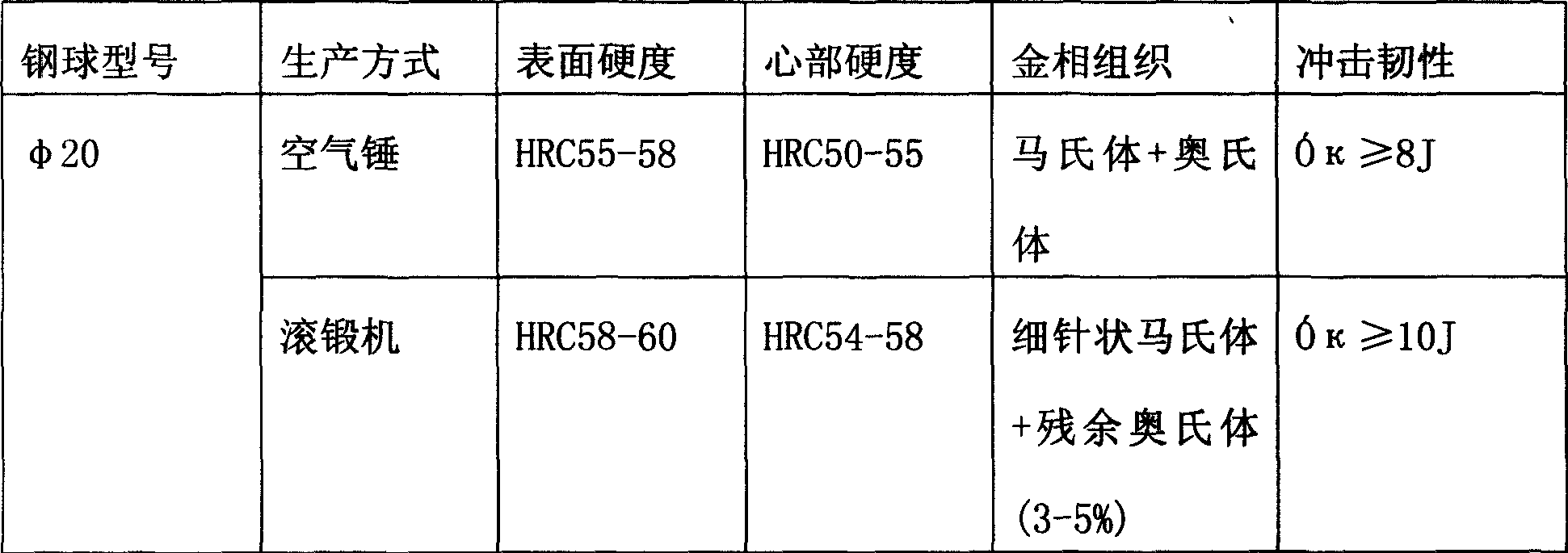

[0022] Taking the production of φ20 steel balls as an example,

[0023] Blanking: The theoretical mass of φ20 steel ball is 0.0338kg. According to the calculation of 3% fire consumption, the blanking quality of φ20 steel ball is 0.0338kg, so φ14 round steel is used, and the blanking length is 28mm; square steel is used for blanking also may.

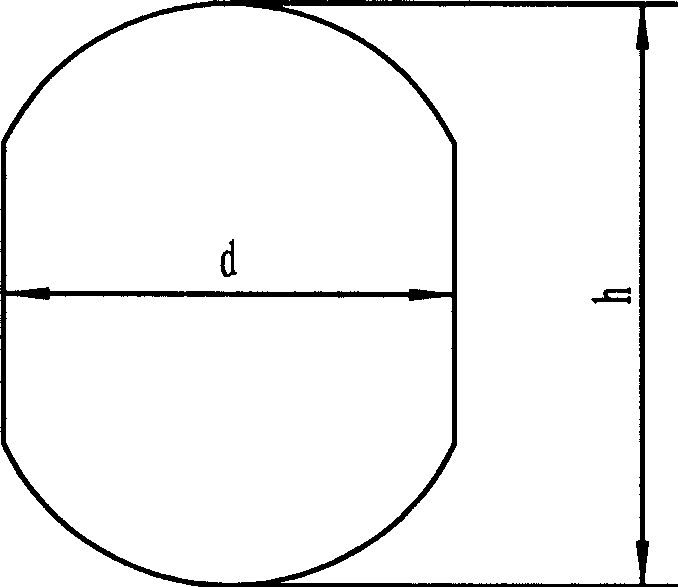

[0024] Heating forging: Put the raw material into the heating furnace and heat it to 1100-1150°C, start forging with an air hammer (controlled by the limit die), and forge it into an oval shape (such as figure 2 Shown), at this time the temperature is controlled at about 950 ~ 1120 ℃.

[0025] Ellipse graphics, where d≈h≈19.5-20.5.

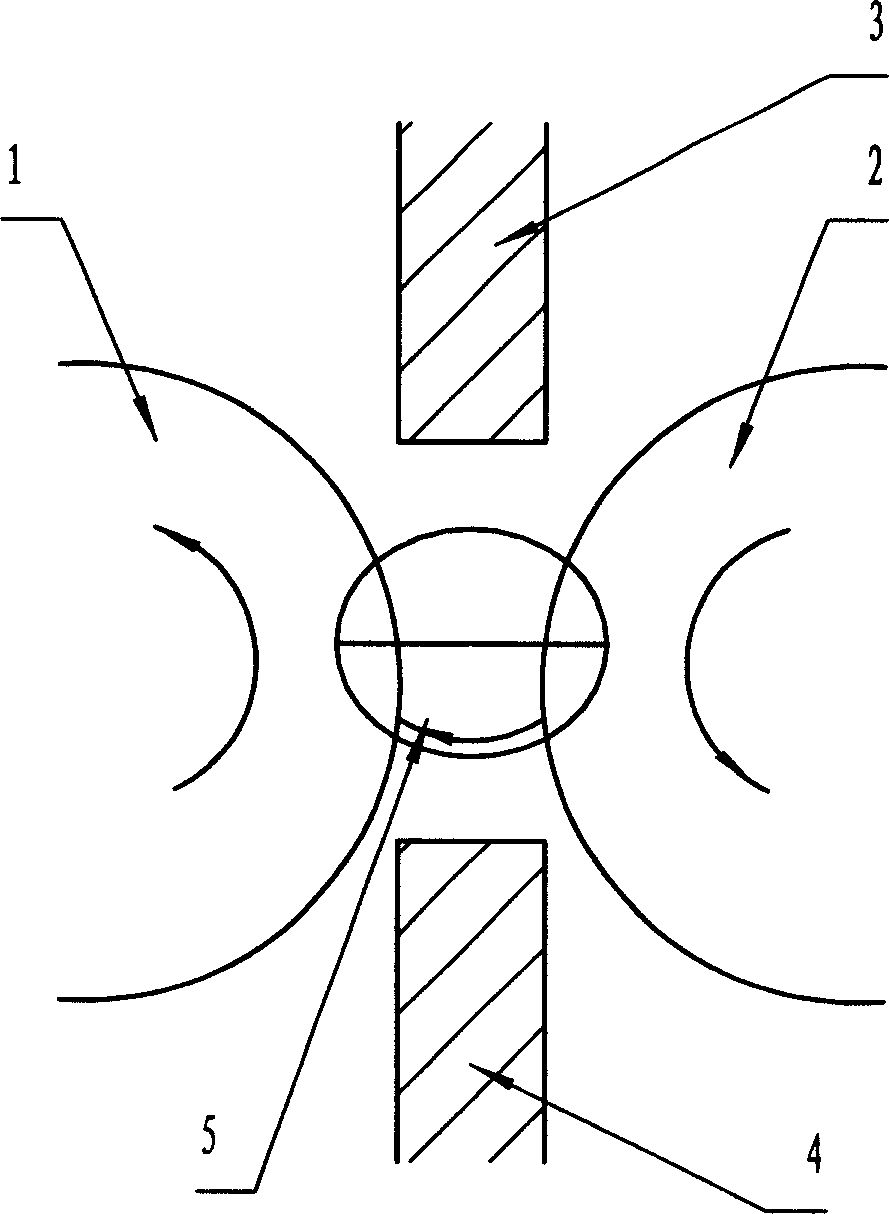

[0026] Roll forging machine roll forging: such as figure 1 The left roll 1 and the right roll 2 are arranged in parallel on the roll forging machine, and the upper and lower baffles 3 and 4 are respectively arranged between the left roll 1 and the right roll 2; the workpiece 5 is located between the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com