Method for producing absorptivity products

A manufacturing method and absorbent technology, which is applied in the manufacturing field of hourglass-shaped absorbent articles, can solve the problems that the waistline cannot be closely attached to the skin, the baby's skin is damaged, and the customer satisfaction is reduced, so as to save hot melt adhesive, Effects of cost reduction and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

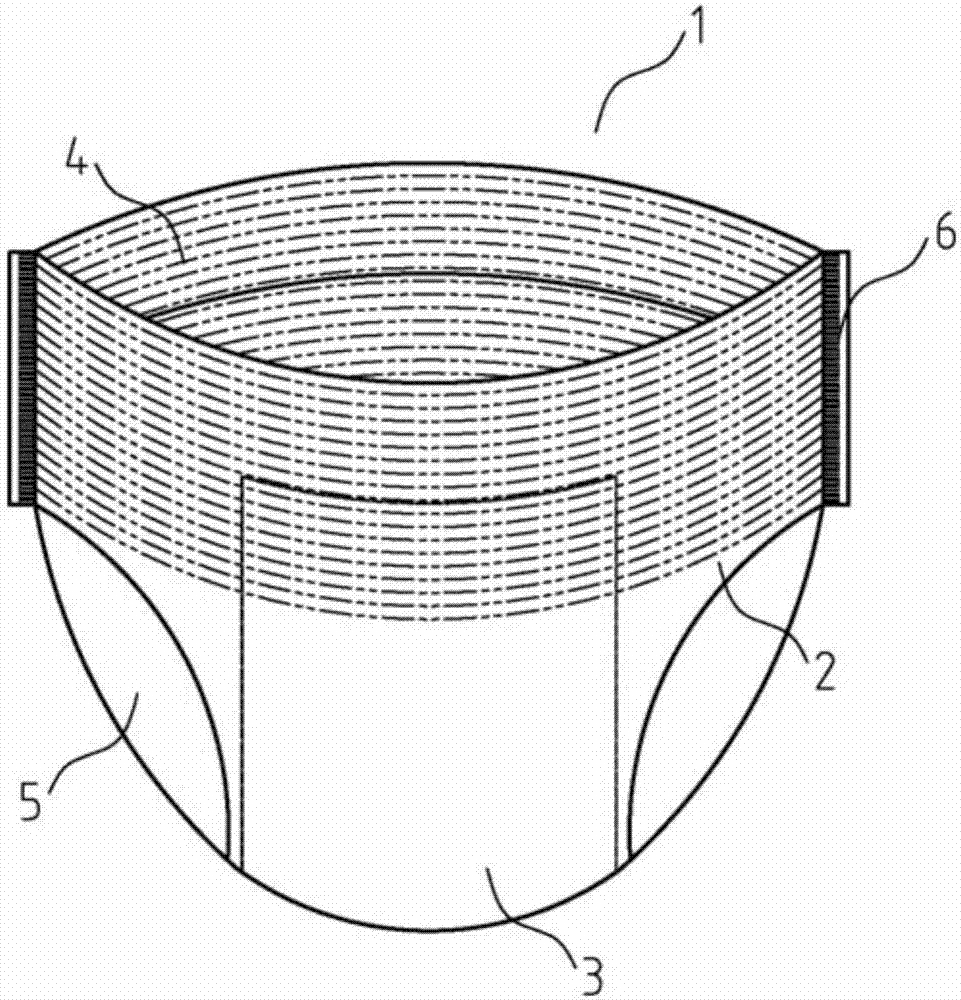

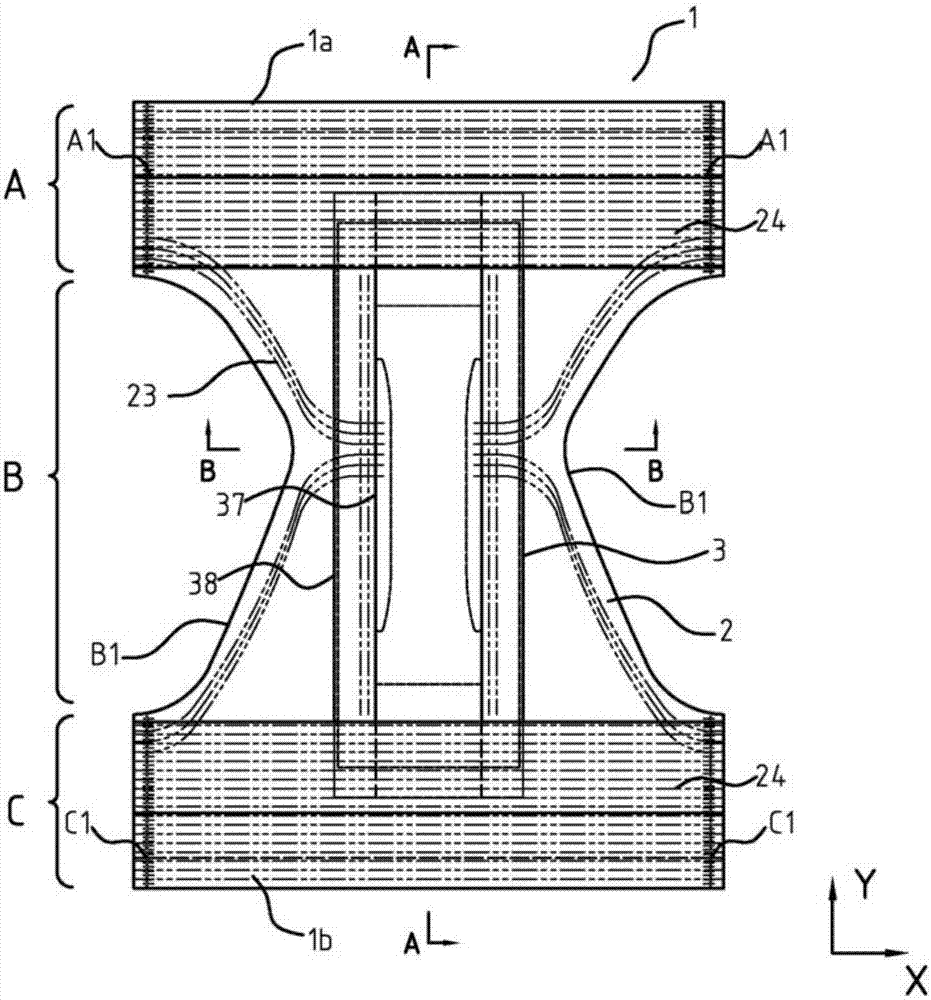

[0057] Such as Figures 1 to 5 As shown, an hourglass-shaped absorbent article 1 includes an outer covering structure 2 and an inner absorbent structure 3 .

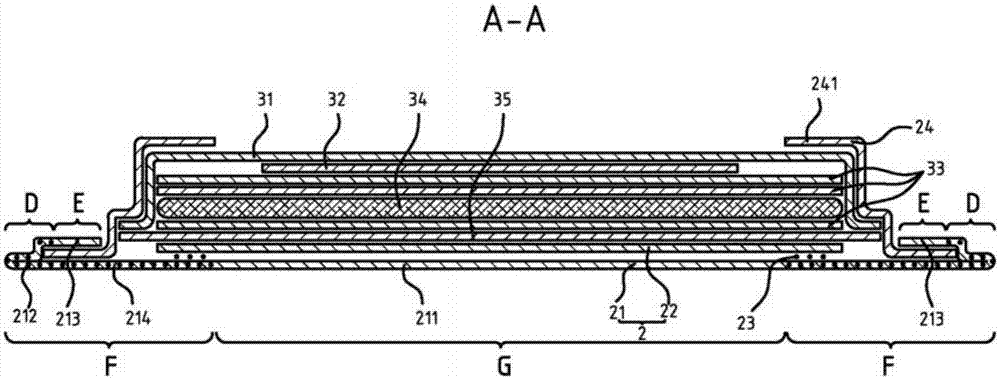

[0058] The inner absorbent structure 3 includes a front sheet 31 , a back sheet 35 , an absorbent material 34 , a conductive layer 32 , a wrapping layer 33 and an anti-leakage side wrap 36 .

[0059] Wherein, the front sheet 31 is a liquid-permeable non-woven fabric material, and is arranged on the side close to the wearer's skin; the back sheet 35 can be selected from a liquid-impermeable film material, and is arranged on the side away from the wearer's skin; the absorbent material 34 and the covering The layers 33 together form an absorbent core, and the absorbent material 34 is covered by the covering layer 33 and is arranged between the front sheet 31 and the back sheet 35, and has a certain width in the horizontal direction X and extends along the longitudinal direction Y; the conductive layer 32 It is arranged bet...

Embodiment 2

[0091] Such as Figures 7 to 9 As shown, an hourglass-shaped absorbent article 1 includes an outer covering structure 2 and an inner absorbent structure 3 . Wherein, one end of the waist covering sheet 24 joined with the outer layer sheet 21 is fixed on the side of the outer layer sheet 21 where the folded segment 213 is away from the extension segment 214 . All the other are with embodiment 1.

Embodiment 3

[0093] Such as Figures 10 to 12 As shown, an hourglass-shaped absorbent article 1 includes an outer covering structure 2 and an inner absorbent structure 3 . Different from Embodiments 1 to 2, the number of first elastic components on the outer layer sheet 21 of this embodiment is slightly less than the number of first elastic components on the outer layer sheet 21 in Embodiments 1 to 2.

[0094] The outer layer sheet 21 is folded along the folding line FL which coincides with the edge of the first elastic member weaving region H on the side close to the third non-elastic region J. The wrapping section 213 extends to the crotch region B along the front waist region A and the rear waist region C, thereby forming a barrier structure 211a that prevents bodily fluids from leaking from the front abdomen and the back back. Since the outer sheet 21 itself is liquid-tight Therefore, the barrier structure 211a can completely replace the waist covering sheet 24. It can be seen that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com