Method for making run-flat tire and assembly drum device for same

A runflat and manufacturing method technology, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of carcass ply pasting position dislocation, uneven length, tire uniformity deterioration, etc. Achieve the effect of improving the paste accuracy, improving the uniformity, and improving the paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

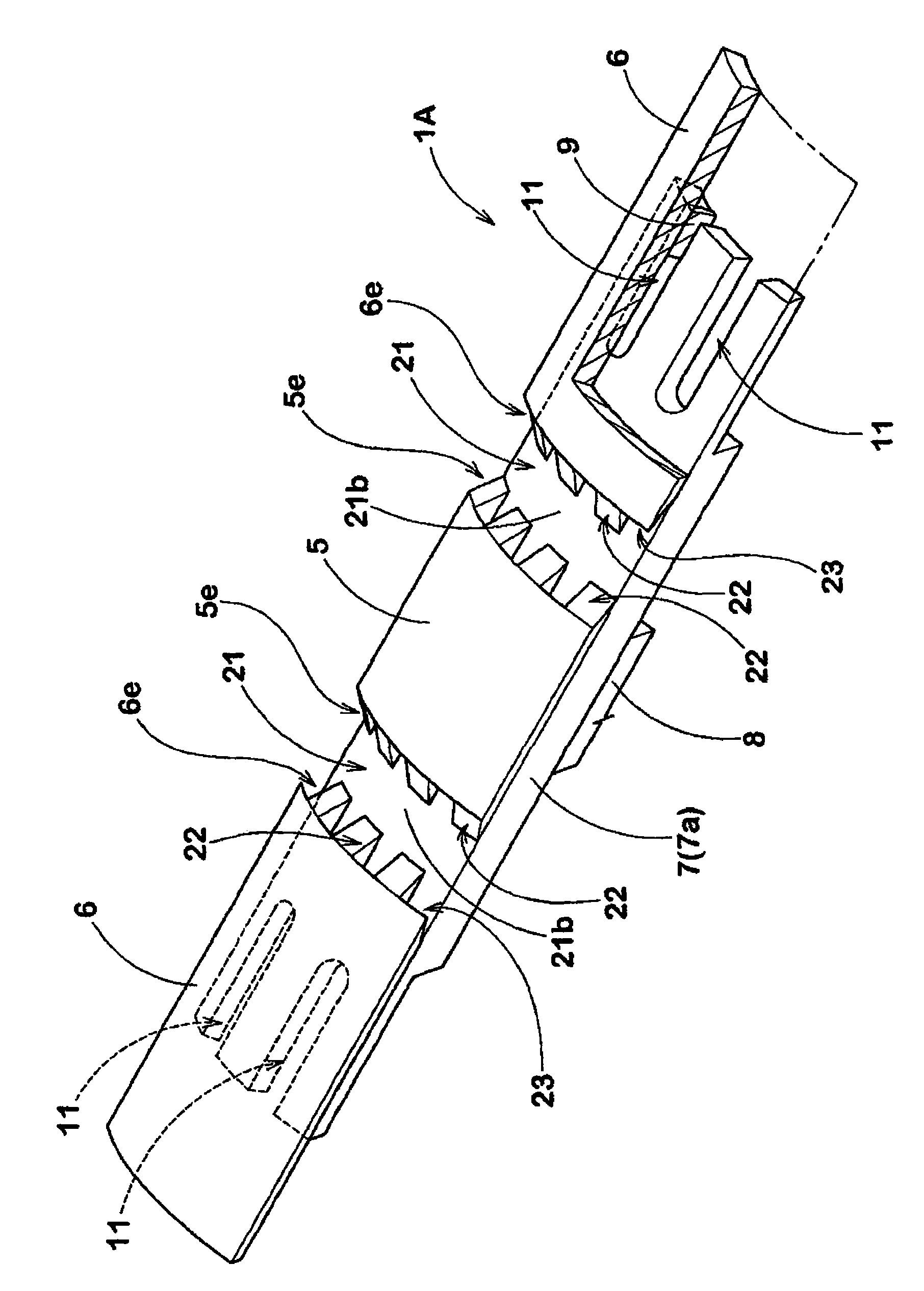

[0077] With the method of the present invention ( Image 6 and Figure 7 process) and previous methods ( Figure 11 ) respectively trial-manufacture green tire substrates for run-flat tires, and then use the same process to finalize the green tires to shape various run-flat tires (size 265 / 50R20). In addition, for comparison, a molding method (comparative example) in which a pair of circumferential grooves were initially formed on the outer peripheral surface of the drum main body, and inner liner rubber, sidewall reinforcing rubber, and Carcass ply is used to form the method of green tire matrix. Also, they were tested for uniformity.

[0078] For uniformity, the radial force variation (RFV) and the lateral force variation (LFV) were measured for 30 run-flat tires using a uniformity testing machine, and the average value and standard deviation were obtained. Here, RFV and LFV are measured in accordance with JASO C607 (Test method for uniformity of automobile tires).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com