Patents

Literature

107results about How to "Paste accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

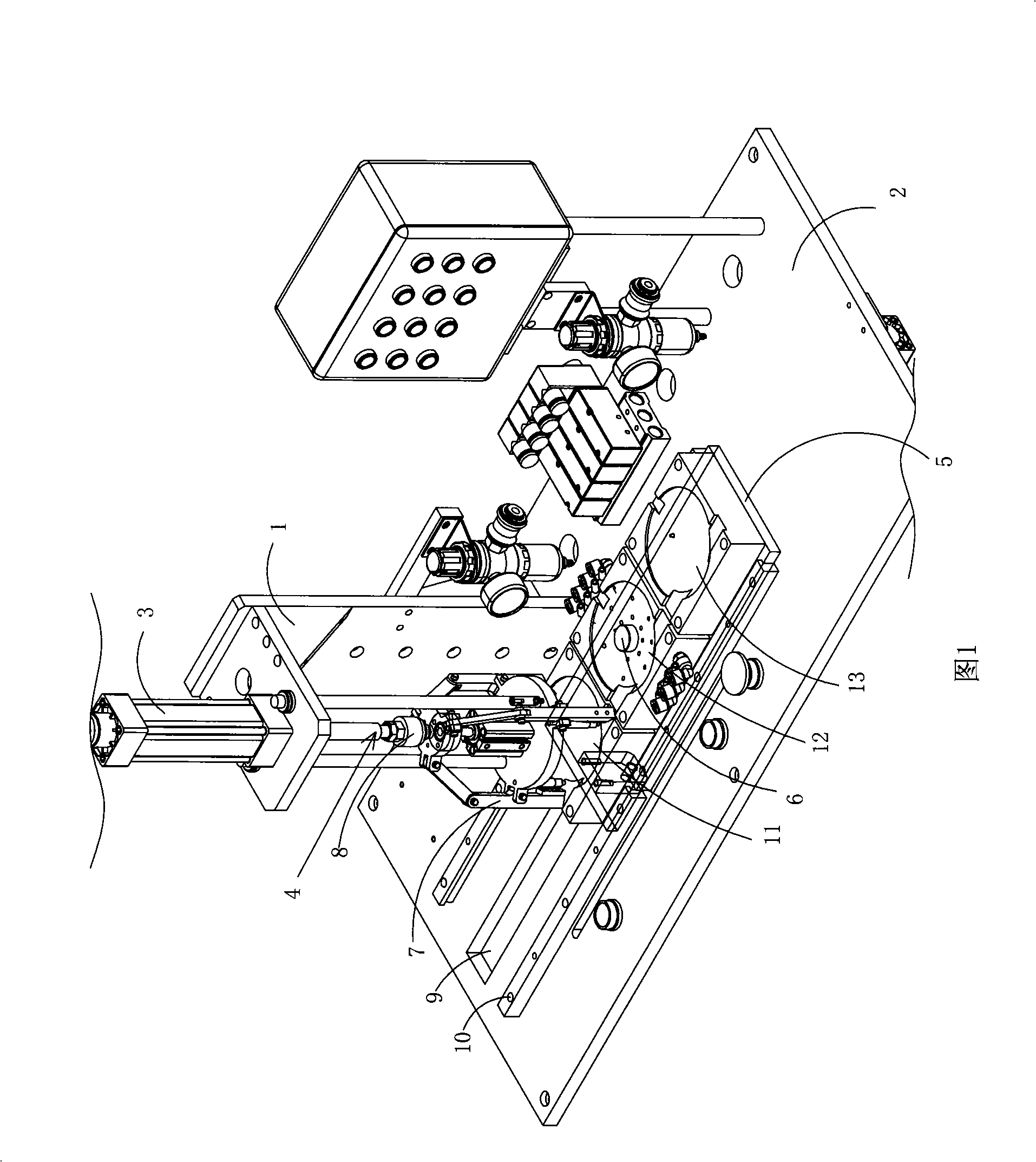

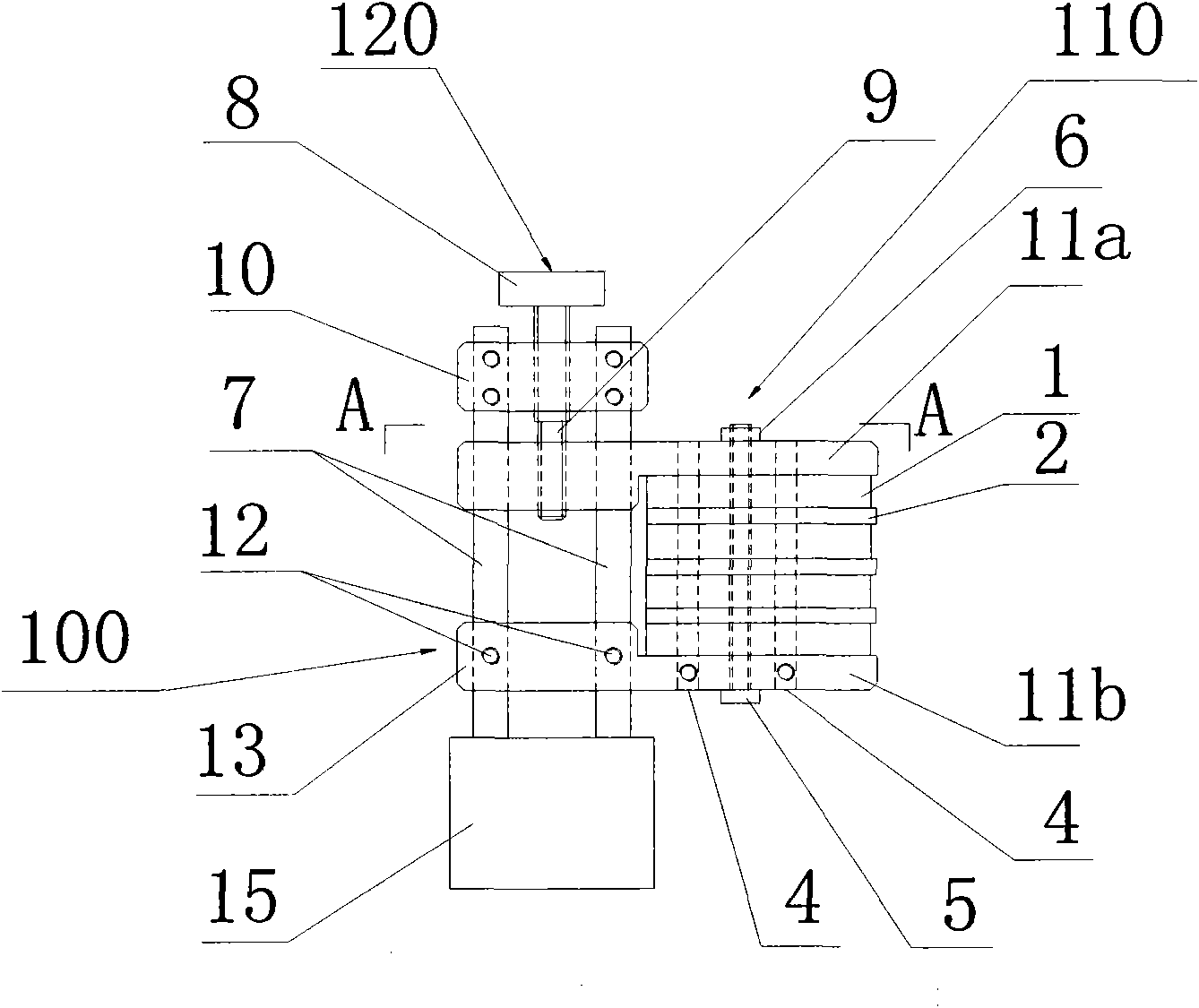

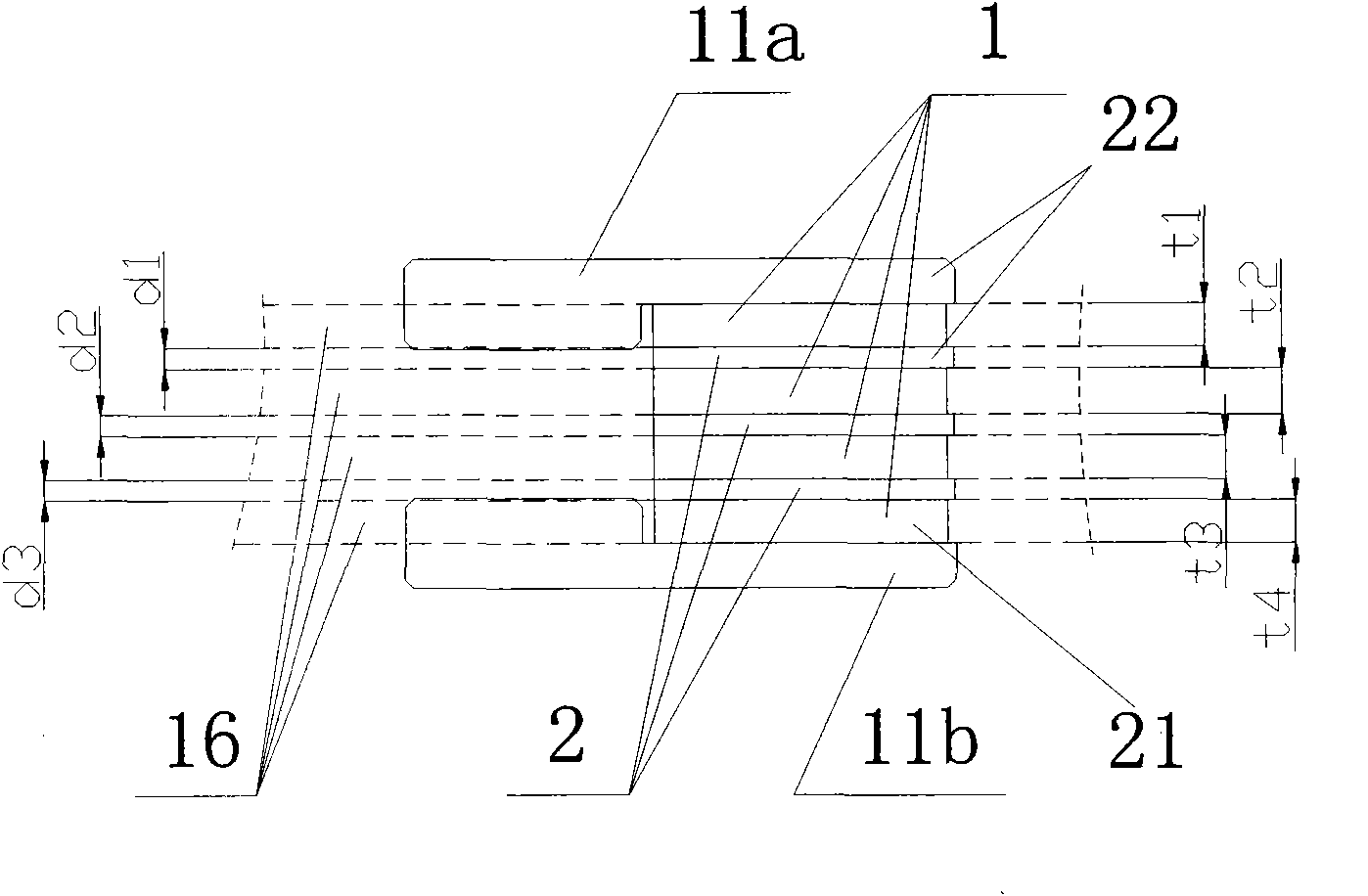

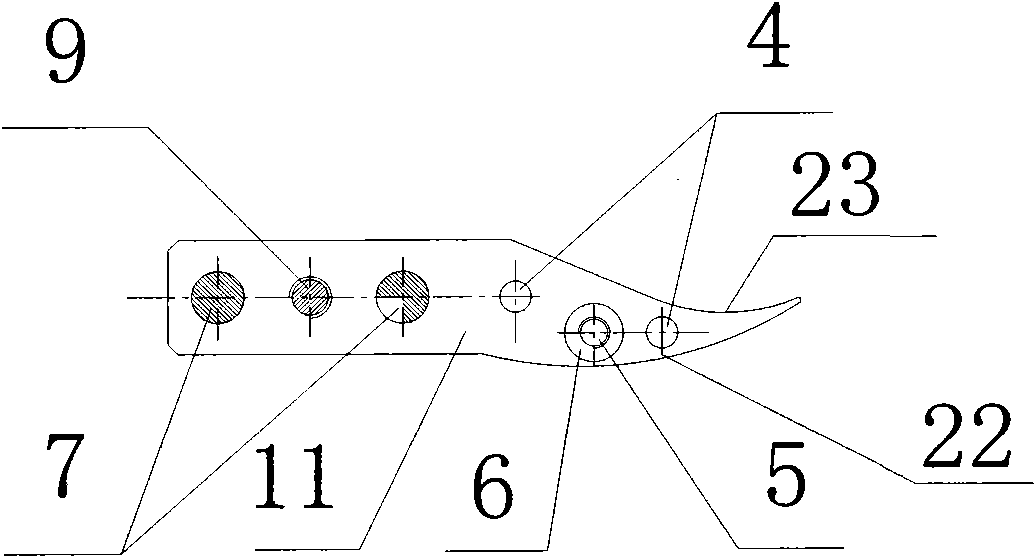

Vehicle nameplate gluing machine

The present invention discloses a vehicle nameplate pasting machine, and comprises a frame and a base. The frame is fixedly provided with a material pressing and lifting cylinder; the piston of the material pressing and lifting cylinder is fixedly connected with a clamping device which can clamp a handle cover; the clamping device is positioned on and can vertically slide on the frame; the base is fixedly provided with a material base; the material base is arranged below the clamping device, positioned on the base, and can horizontally slide on the base; and the material base is provided with a first position which is used for holding the handle cover, a second position which is used for holding double-sided glue, and a third position which is used for holding the nameplate; a vacuum suction mouth is arranged below the third position. Thus the nameplate can be correctly pasted only by arranging the handle cover, the double-sided glue and the panel according to the marks; and the operation is easy.

Owner:伟速达(中国)汽车安全系统有限公司

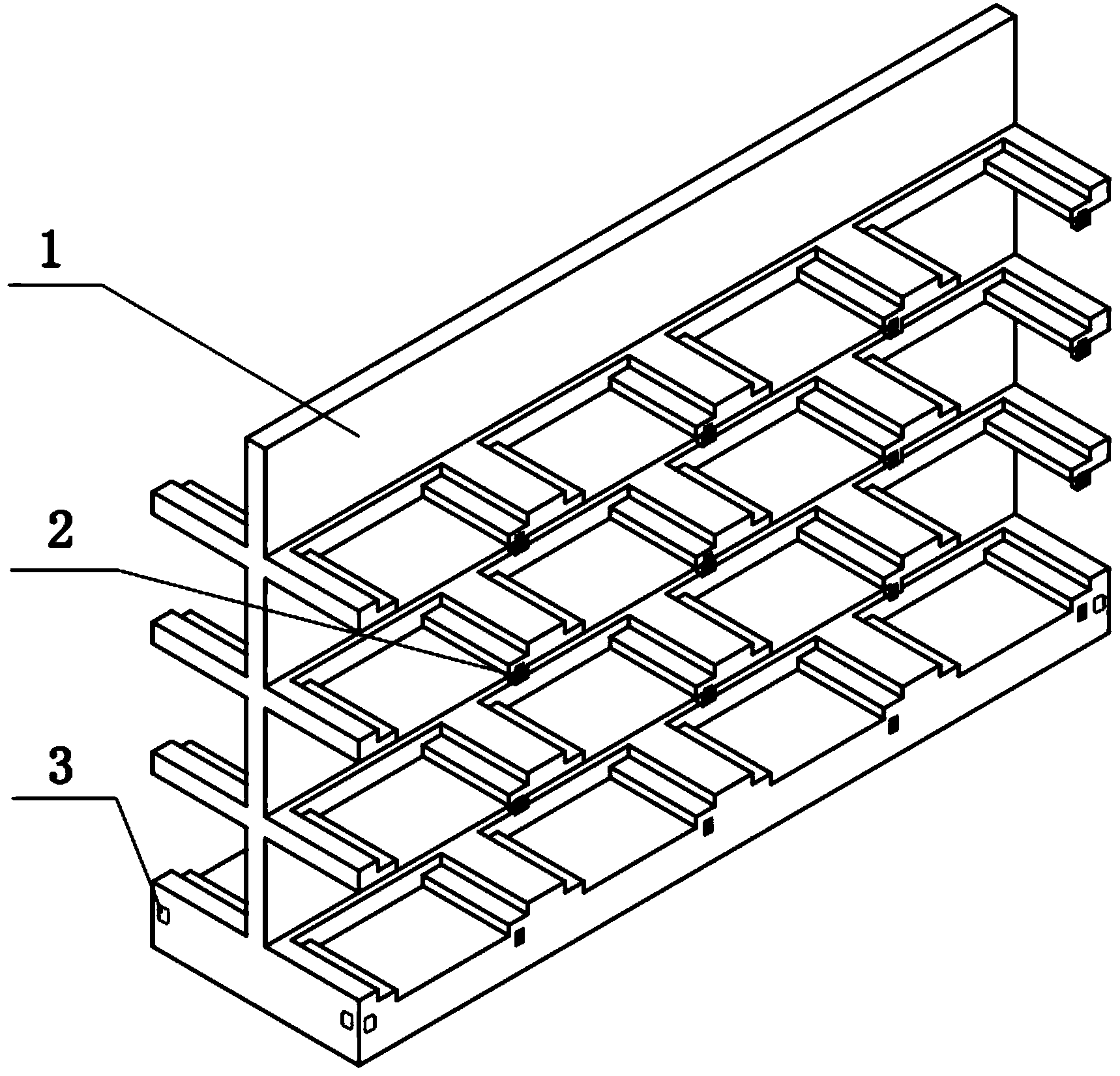

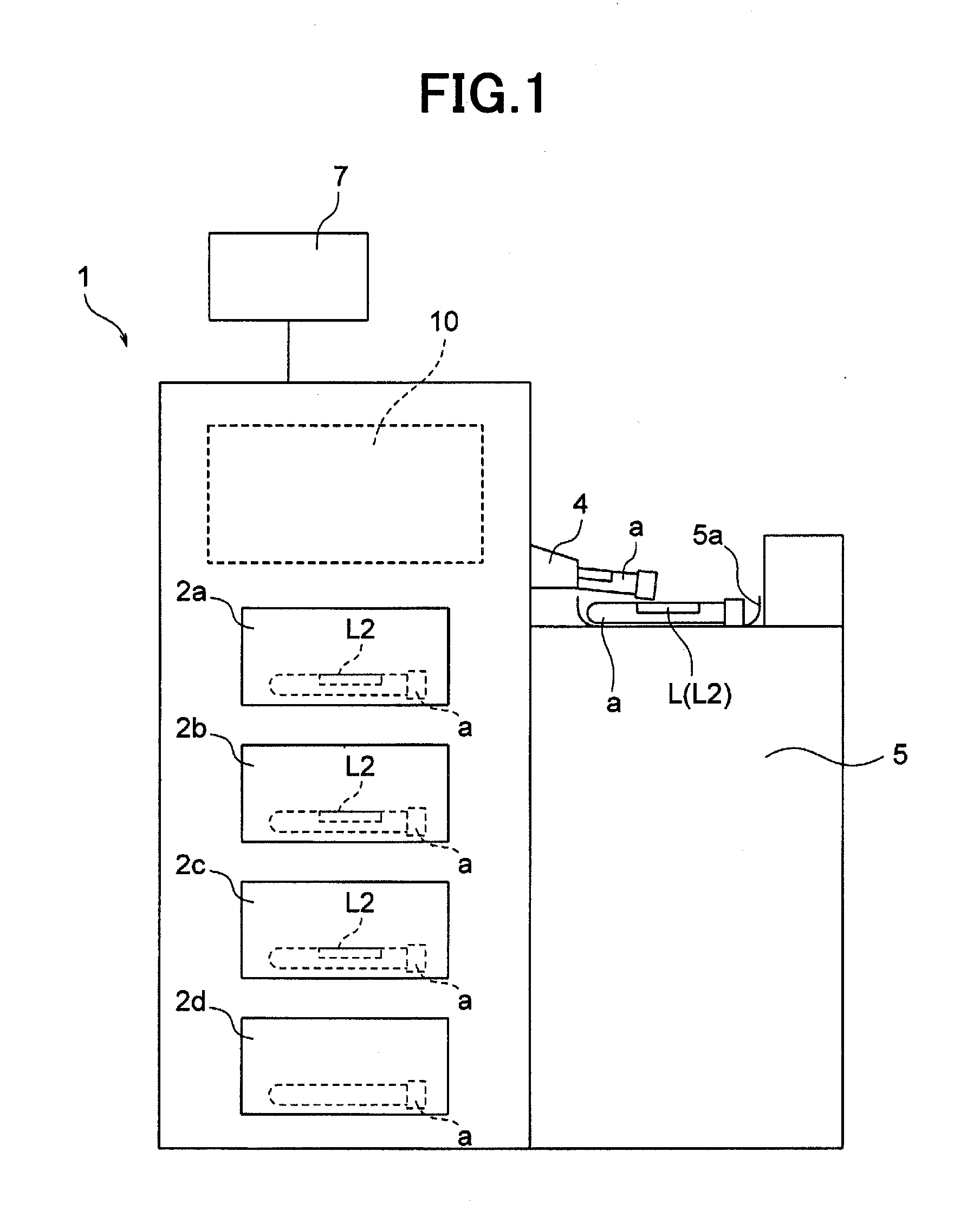

Lifting type AGV automatic guide transport cart system based on two-dimension code positioning

InactiveCN104036212AExact searchPaste accuratelySensing record carriersRemote controlTransport engineering

The invention discloses a lifting type AGV automatic guide transport cart system based on two-dimension code positioning. The lifting type AGV automatic guide transport cart system based on two-dimension code positioning comprises a remote control computer, a lifting AGV, two-dimension code marks, a vehicle-mounted two-dimension code scanning instrument and a goods shelf, wherein the vehicle-mounted two-dimension code scanning instrument is installed on a lifting AGV lifting mechanism, the two-dimension code marks include goods shelf two-dimension code marks and goods position two-dimension code marks, and the goods shelf two-dimension code marks are stuck to a lateral surface of the bottom layer of the goods shelf, the goods position two-dimension code marks are stuck under each goods station of the goods shelf, and the remote control computer is connected with the lifting AGV in a wireless communication mode. By means of an automatic goods storage and taking system and method, target goods can be rapidly and accurately positioned in a complex route, operation is simple, and cost is low.

Owner:GUANGXI UNIV

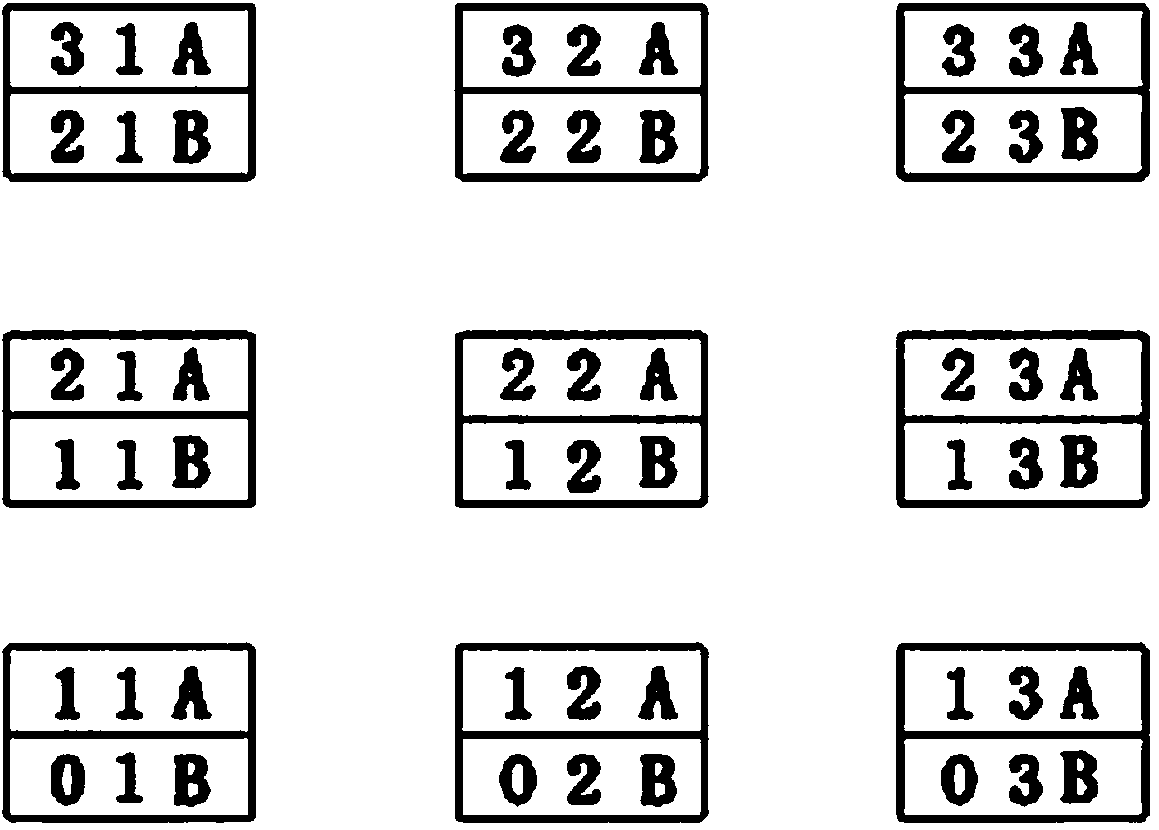

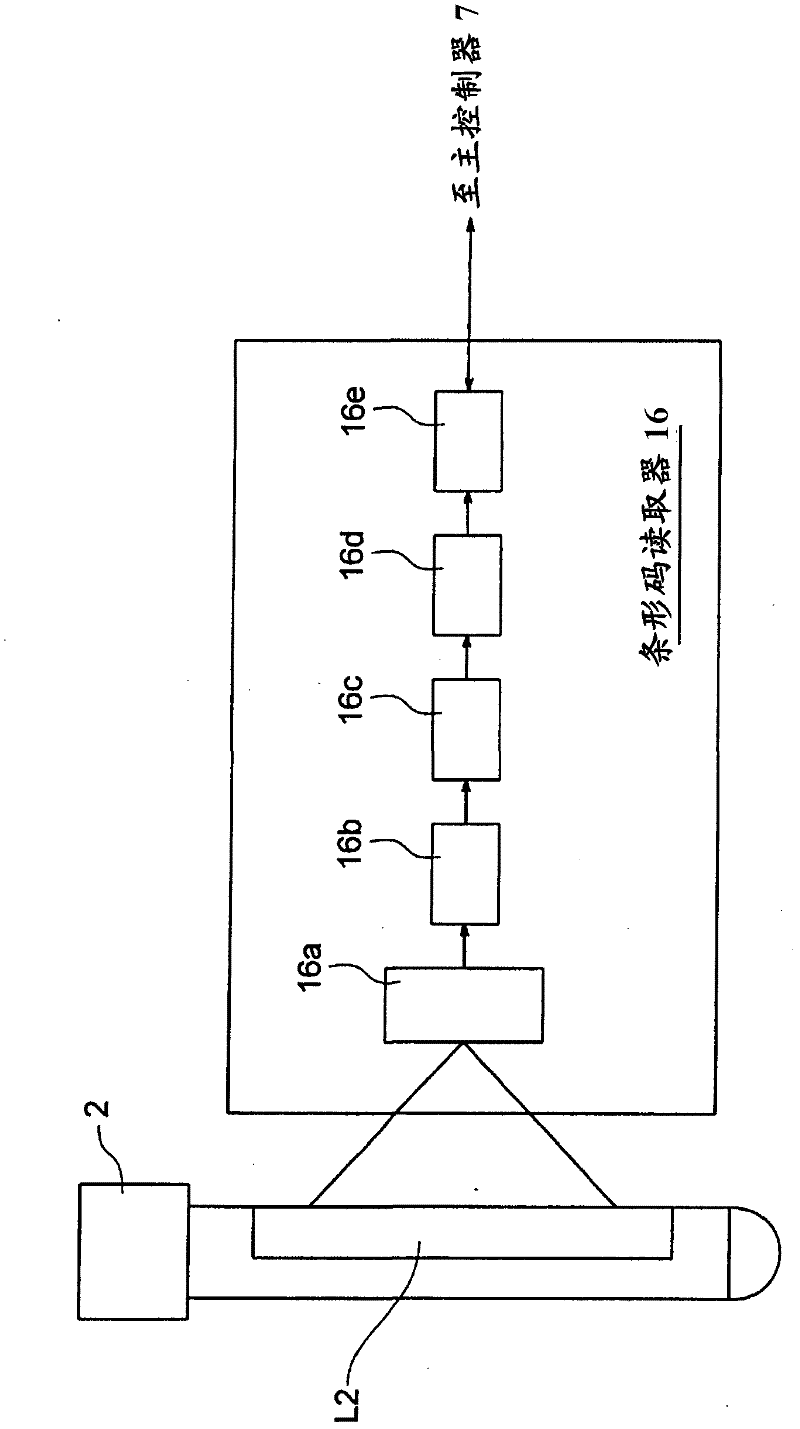

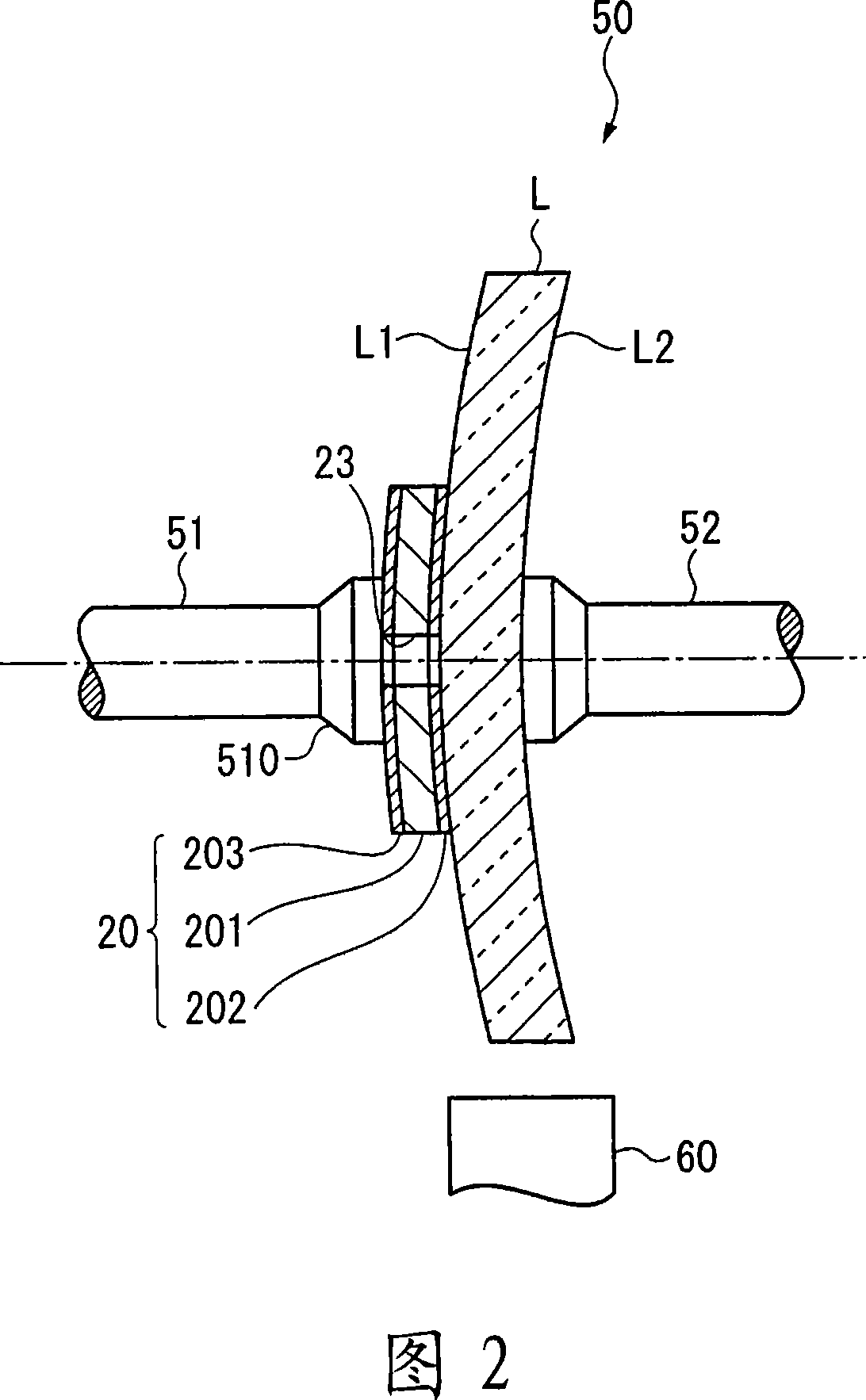

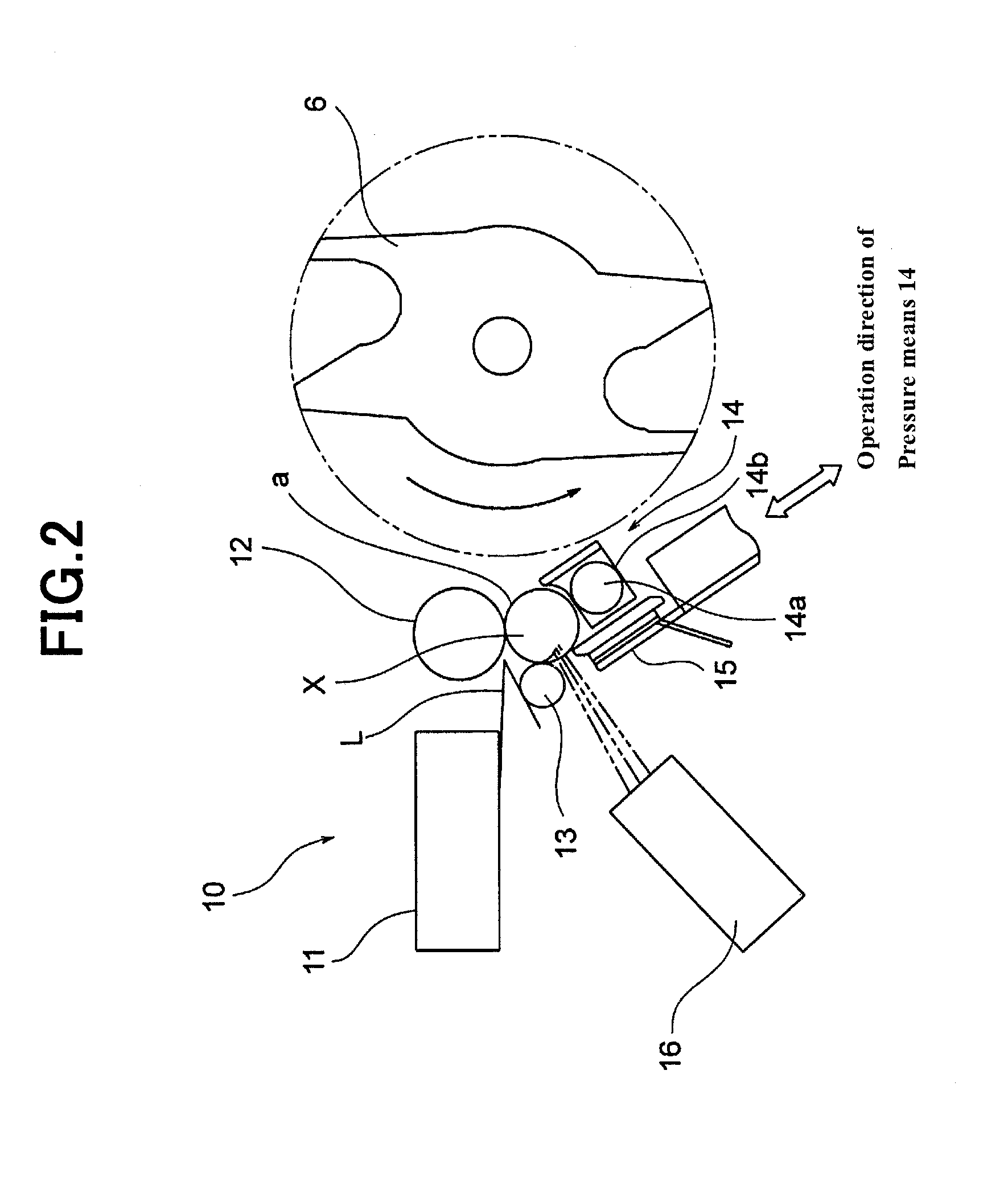

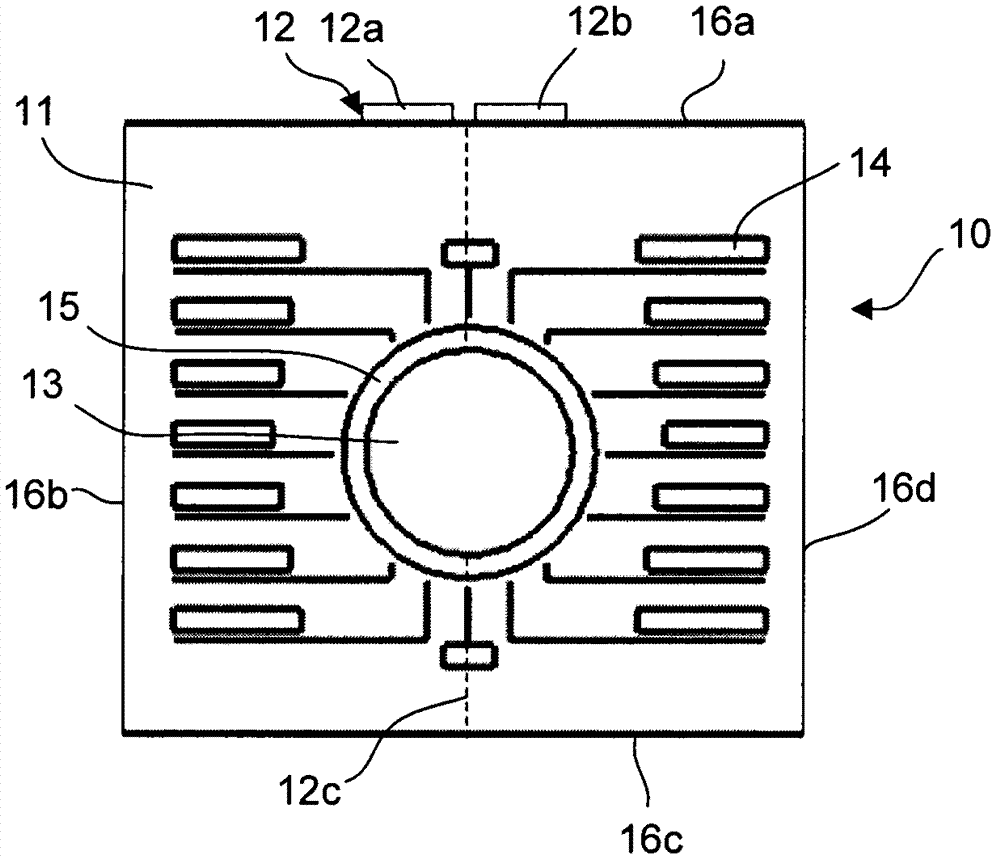

Labeling device for automatic test-tube setting-up device

ActiveCN102459008ASimple structureSmall sizeLaboratory glasswaresAdhesivesLocation detectionBlood Collection Tube

Provided is a labeling device for an automatic test-tube setting-up device wherein an identification label can be pasted over a product label with a sample structure. A labeling device for an automatic blood-sampling-tube setting-up device comprises a means for taking out a blood-sampling tube based on patient information and supporting the blood-sampling tube at a labeling position, a blood-sampling tube driving means for rotary driving the blood-sampling tube at the labeling position, a label printing means for creating an identification label by printing test information and / or patient information and outputting the identification label to the labeling position, a product label position detecting means for detecting the edge of a product label previously pasted to the outer surface of the blood-sampling tube, and a controller for controlling the operation of the label printing means and the blood-sampling tube driving means such that the identification label is pasted over the product label with a continuous gap left in the axial direction of the blood-sampling tube on the outer surface of a blood-sampling tube based on information about the diameter of a blood-sampling tube corresponding to the blood-sampling tube at the labeling position, and information about the edge of the product label obtained from the product label position detecting means.

Owner:TECHNO MEDICA CO LTD

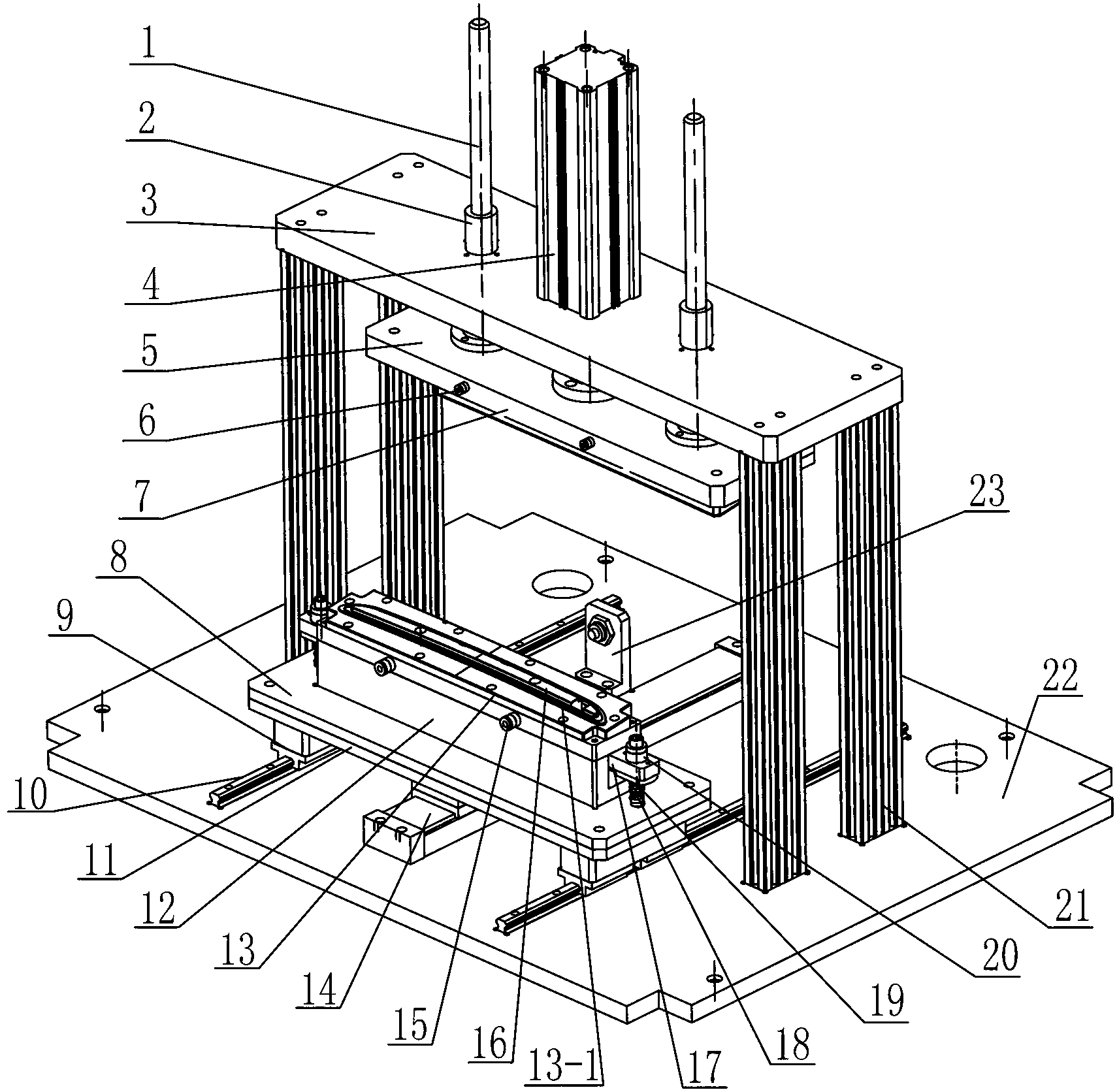

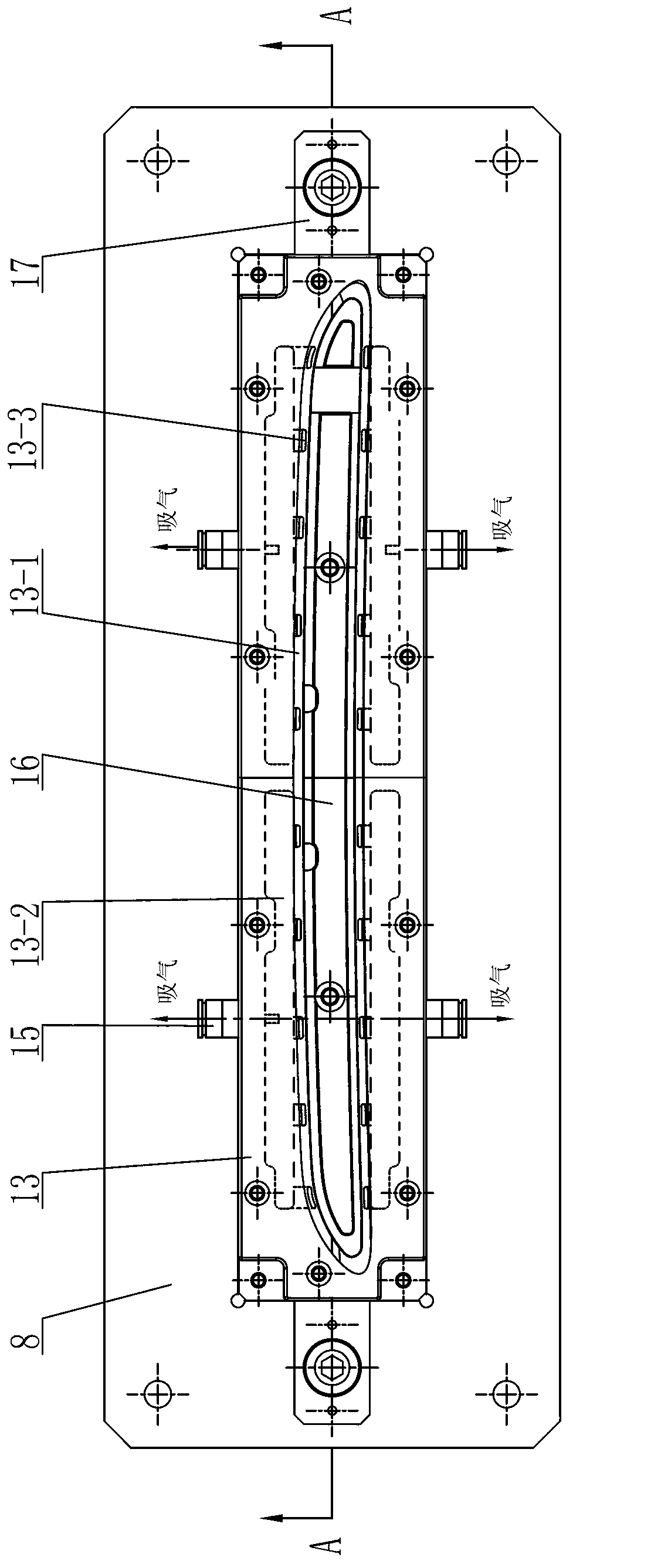

Automatic gluing device for lampshade double-side-glued seal gaskets

The invention relates to an automatic gluing device for lampshade double-side-glued seal gaskets. The automatic gluing device comprises a bottom plate, a lower mould assembly, and an upper mould assembly. A lower positioning plate of the lower mould assembly is mounted on a lower mould fixing plate through a bearing block, two guide shafts are mounted on the lower mould fixing plate, two sides of a floating block are mounted on the guide shafts, one end of a spring wrapping each guide shaft is connected with one floating block while the other end of every spring is abutted to the lower mould fixing plate, a flexible moving block passes through the bearing block and the lower positioning plate, the top of the lower positioning plate is provided with a seal gasket positioning groove in the outer periphery of an upper cavity and a closed gas cavity inside, and the gas cavity is communicated with the seal gasket positioning groove through at least four suction holes. A lifting cylinder of the upper mould assembly is mounted on an upper mould fixing plate while a moving side of the lifting cylinder is connected with a top plate, the upper positioning plate is mounted below the top plate, at least two vacuum suckers are mounted on the top plate, and suction holes of the vacuum suckers are located in a lampshade cavity of the upper positioning plate. The automatic gluing device for lampshade double-side-glued seal gaskets is convenient to operate and enables assembly quality and production efficiency to be improved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Prolate automatic silk-screen machine

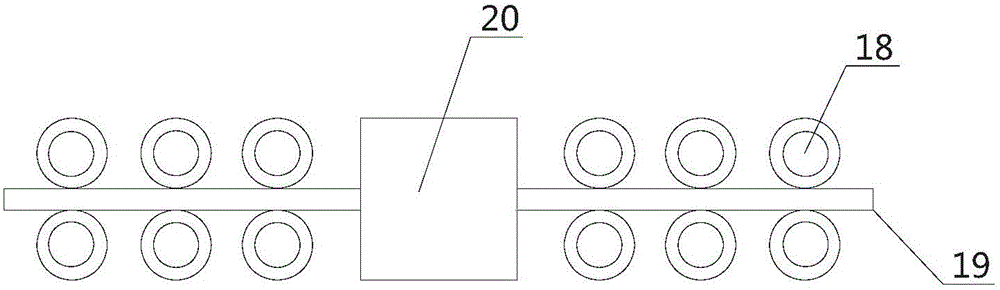

InactiveCN101186141APaste accuratelyFully automatedScreen printersWebs handlingEngineeringAutomation

The invention relates to a printing machine in umbrella manufacture filed, in particular to a long-breadth umbrella surface automatic screen printer. The invention changes the umbrella surface processing type of first-cutting and printing of the prior art; the existing umbrella surface automatic screen printer is provided with a fabric frame feeding mechanism mainly consisting of a fabric frame and a material feeding roller, and a material collecting mechanism mainly consisting of an intermittent rotary collection core shaft, thus thoroughly implementing the automation of the umbrella surface printing. Matched with long rolling fabrics, the invention can implement automatic printing without people on duty for a long time, thus greatly saving manpower resources.

Owner:HANGZHOU PARADISE UMBRELLA GROUP

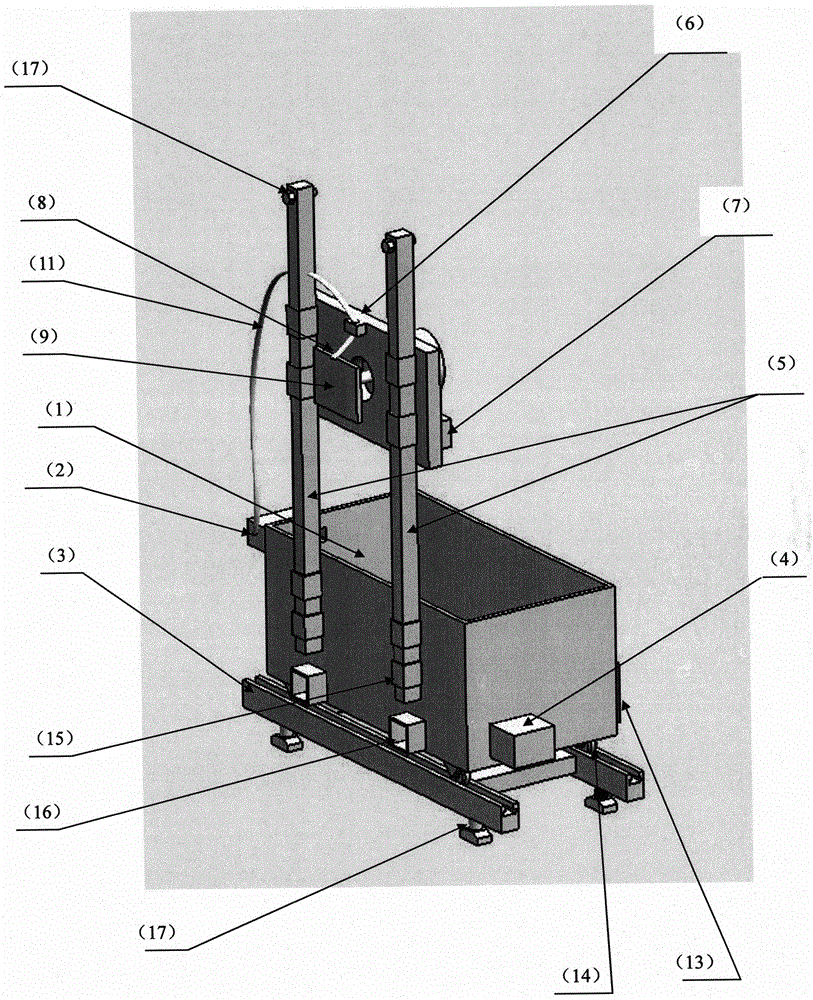

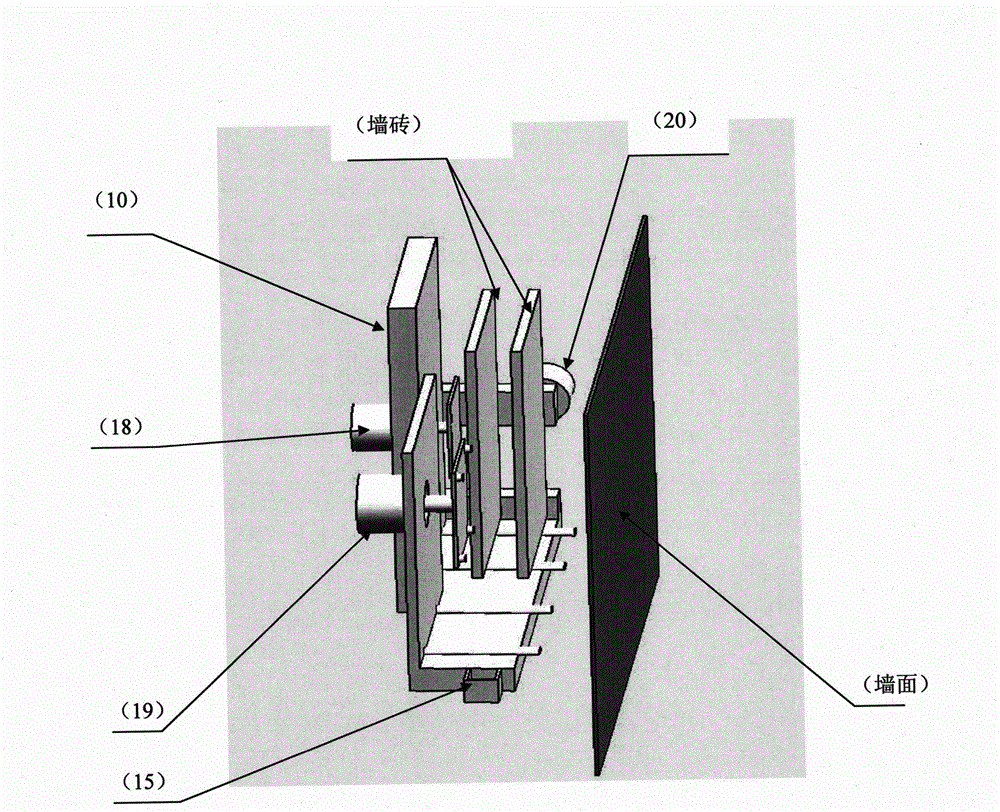

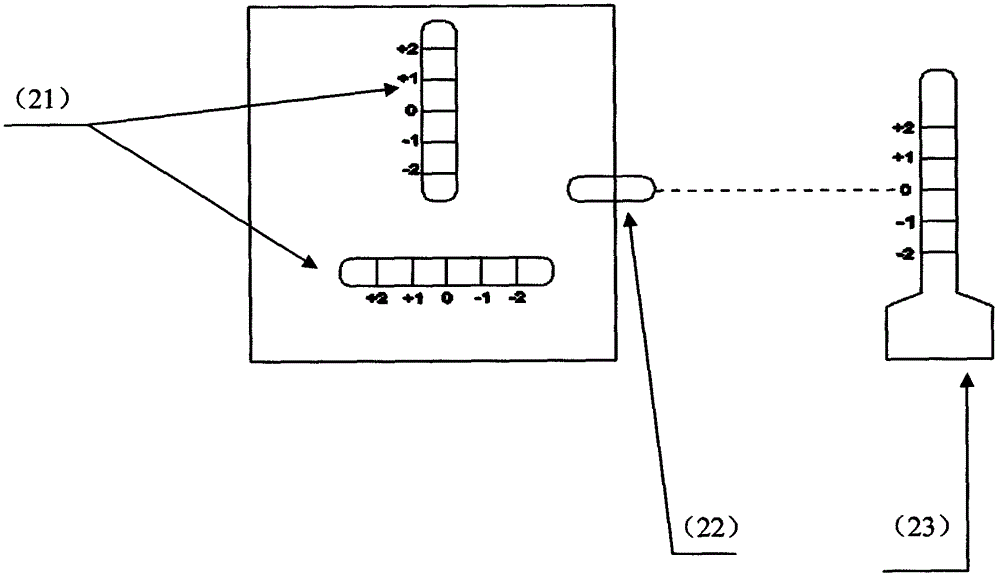

Full-automatic wall tile and floor tile laying machine

The invention discloses a full-automatic wall tile and floor tile laying machine. The full-automatic wall tile and floor tile laying machine comprises a blender, a slurry pump, a mobile lead rail, a guide post, an upper drive mechanism, a lower drive mechanism, a mounting base, a pouring hole, a vibrating mechanism, a wall tile and floor tile laying rack, a conduit, a multi-directional gradienter and a control system; the blender is arranged on the mobile lead rail, the lower drive mechanism and slurry pump are fixed at two sides of the blender, the guide post is fixed at the front side of the blender, the mounting base is arranged on the guide post, and the upper drive mechanism is fixed in the mounting base; the pouring hole is formed in the upper part of the mounting base, and the middle is provided with the vibrating mechanism and the changeable wall tile and floor tile laying rack. Compared with the prior art, the full-automatic wall tile and floor tile laying machine uses an execution mechanism controlled by a control program, the smearing consistency between the wall surface and floor to be bonded with wall tiles and floor tiles is very good, the positions of the wall tiles and floor tiles can be precisely located through machinery, die and digital locating, and the bonding is precise. Through using the machinery to replace manpower, the efficiency is improved, the manpower resource is saved, the bonding cost is lowered, and the economical benefit and social benefit are obvious.

Owner:SHAOXING COUNTY LONGHUA TOOLS

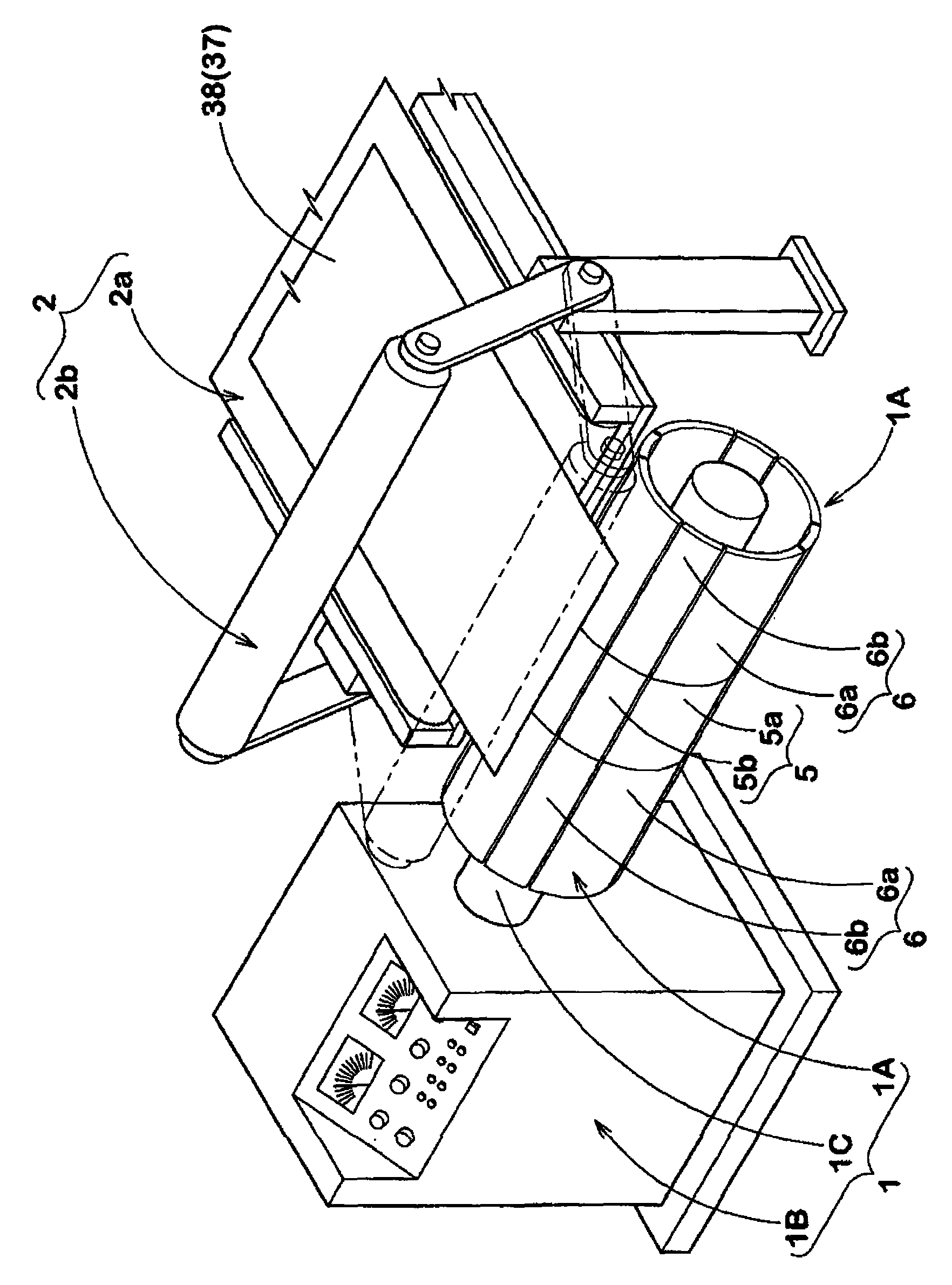

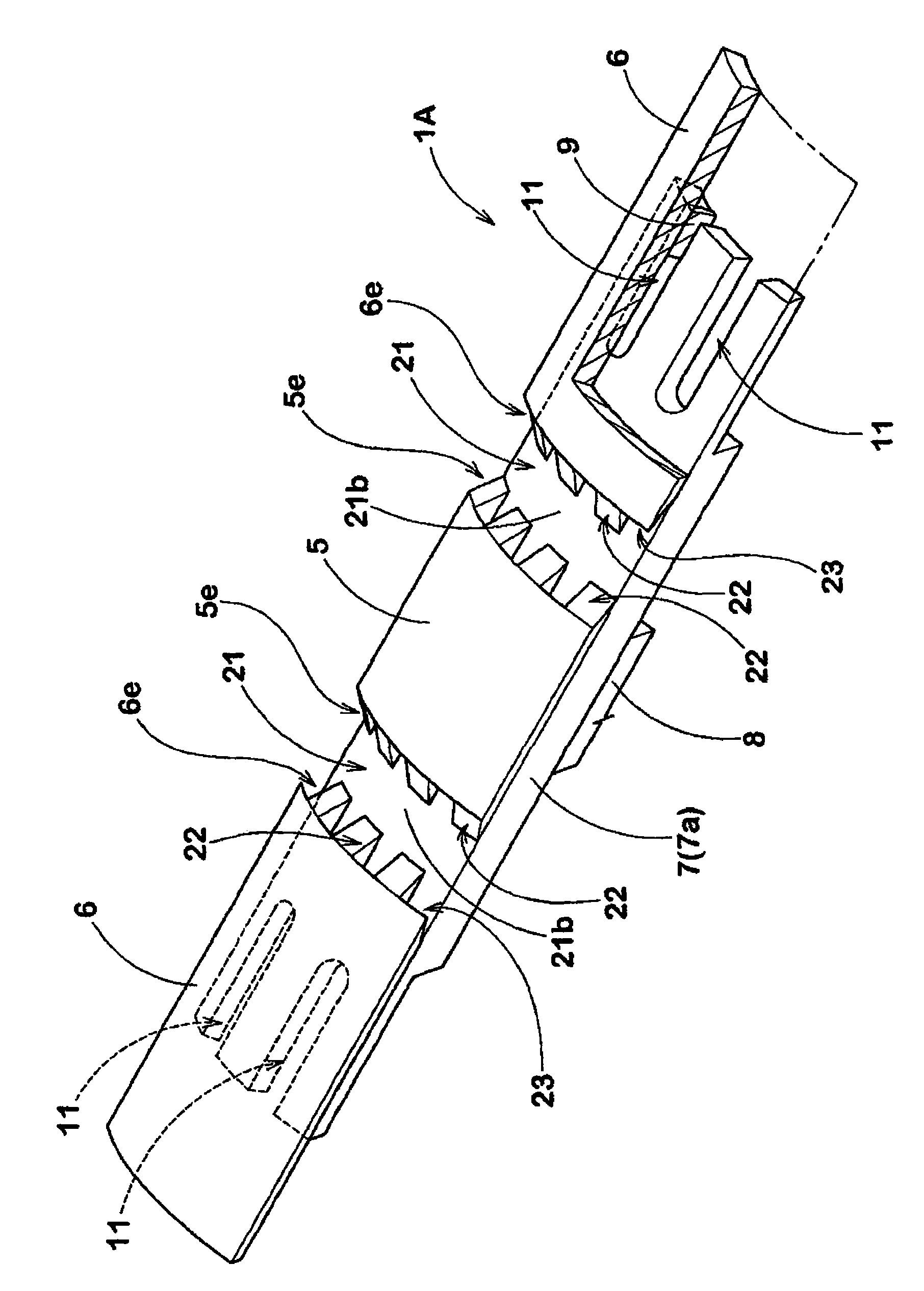

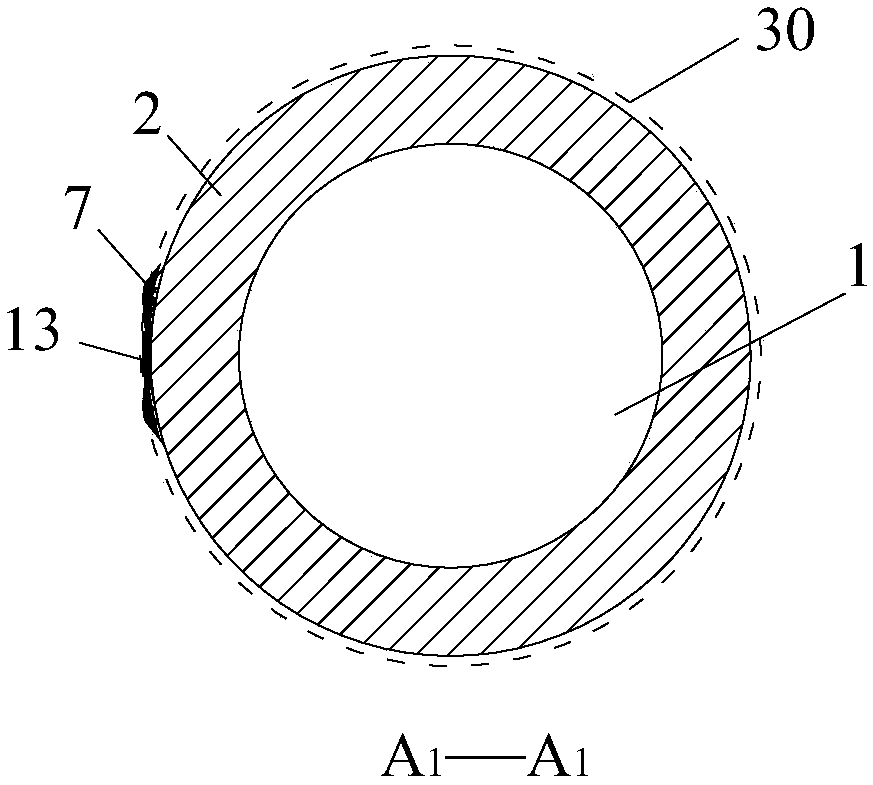

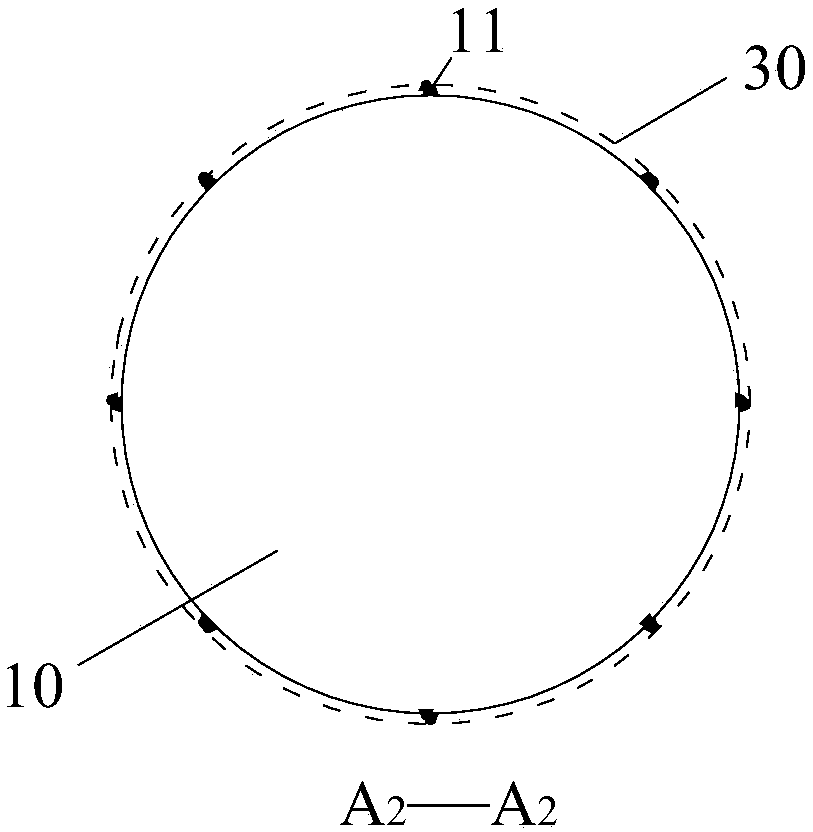

Method for making run-flat tire and assembly drum device for same

ActiveCN101659127AImprove pasting accuracyUniform elasticityTyresPneumatic tyre reinforcementsBand shapeEngineering

The invention can improve the homogeneity of a run-flat tire. A method for making the run-flat tire of which a tire side part is provided with a tire side reinforcing glue with the cross section approximately in the crescent shape is provided. The method includes: winding flaky inner lining glue on the external circumstance of a cylindrical drum main body; winding and sticking band-shaped tire side reinforcing glue in the region of the external circumstance of the cylindrical inner lining glue equivalent to a pair of tire sides to form a first cylindrical object; arranging a pair of circumferential channels on the external circumstance of the drum main body and the inner side of the tire side reinforcing glue, expanding the drum main body, thereby the portion of the first cylindrical object, reinforced with the tire side reinforcing glue goes down into the circumferential channels; and winding the flaky carcass cord fabric by means of the external circumstance of the sinking and flat first cylindrical object to form a basal body of the tire.

Owner:SUMITOMO RUBBER IND LTD

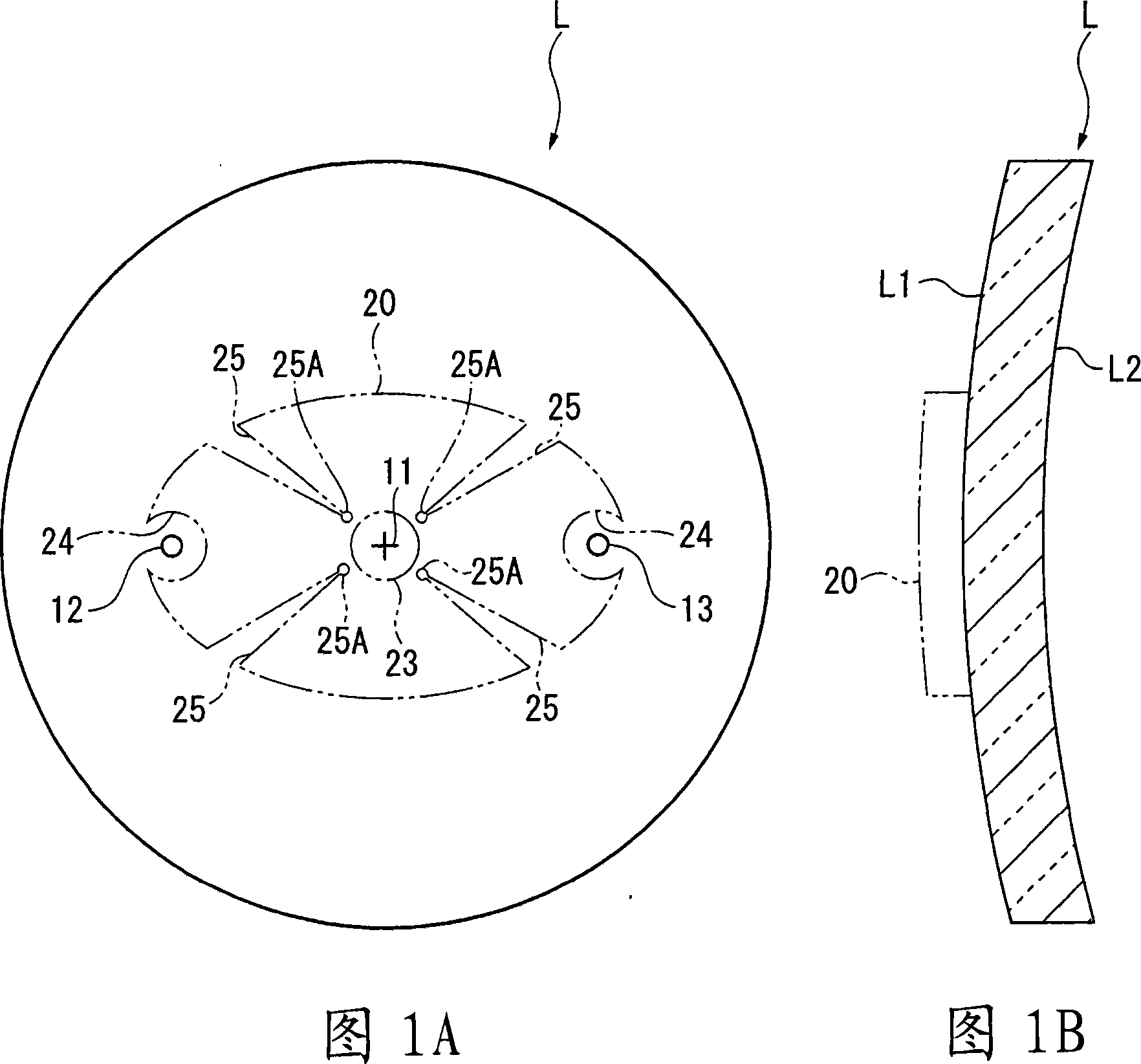

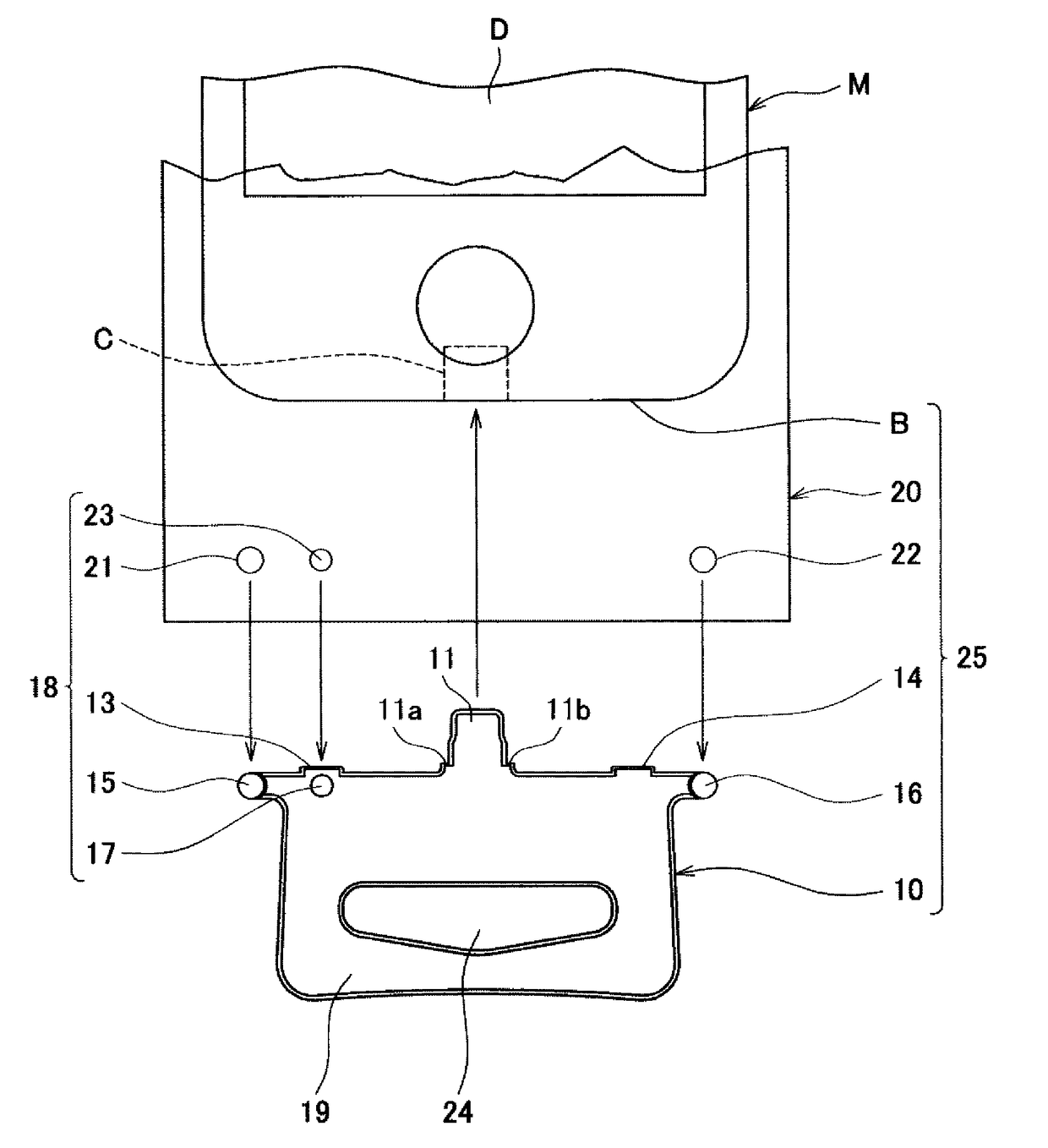

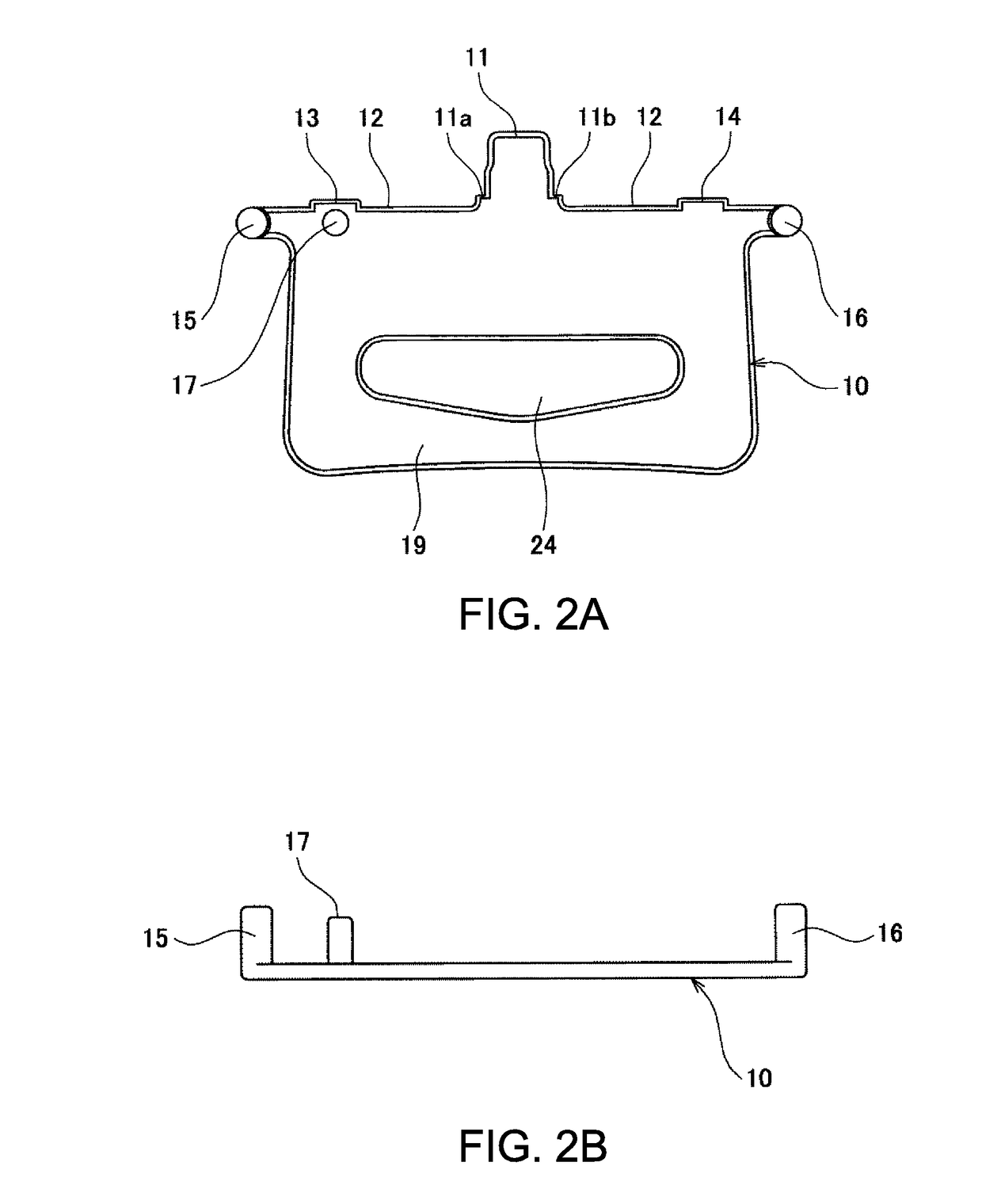

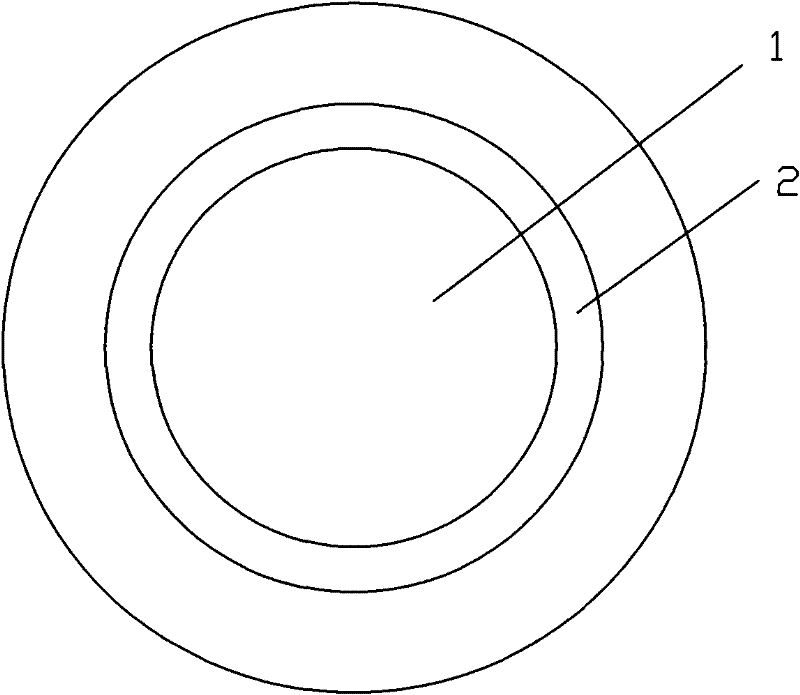

Adhesive tape and method for adhering the adhesive tape

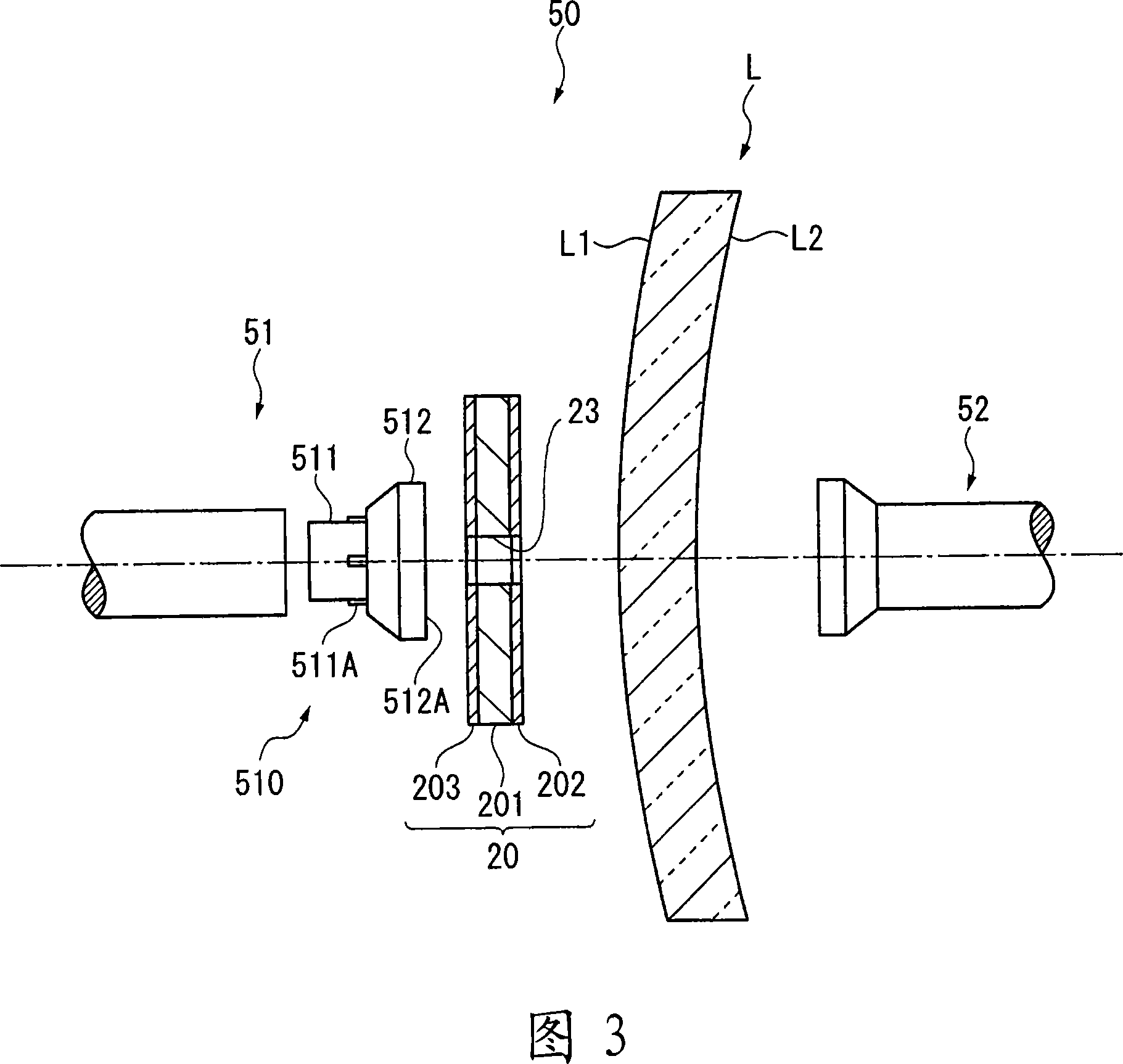

InactiveCN101204785APaste accuratelyEdge grinding machinesOptical surface grinding machinesAdhesive beltEngineering

The present invention provides an adhesive tape and a method for adhering the adhesive tape. A cutout (25) extending from a periphery toward a center portion of the adhesive tape (20) is formed. The cutout (25) have a shape of approximate sector with width becoming wide from center portion to periphery of the adhesive tape (20). Thus, the adhesive tape can be adhered onto the lens surface without drape generation no matter what is the curvature of the lens surface. Thus the adhesive force of the adhesive tape (20) to the lens may not reduce even spraying water for cooling or removing grinding material in edge grinding machining.

Owner:SEIKO EPSON CORP

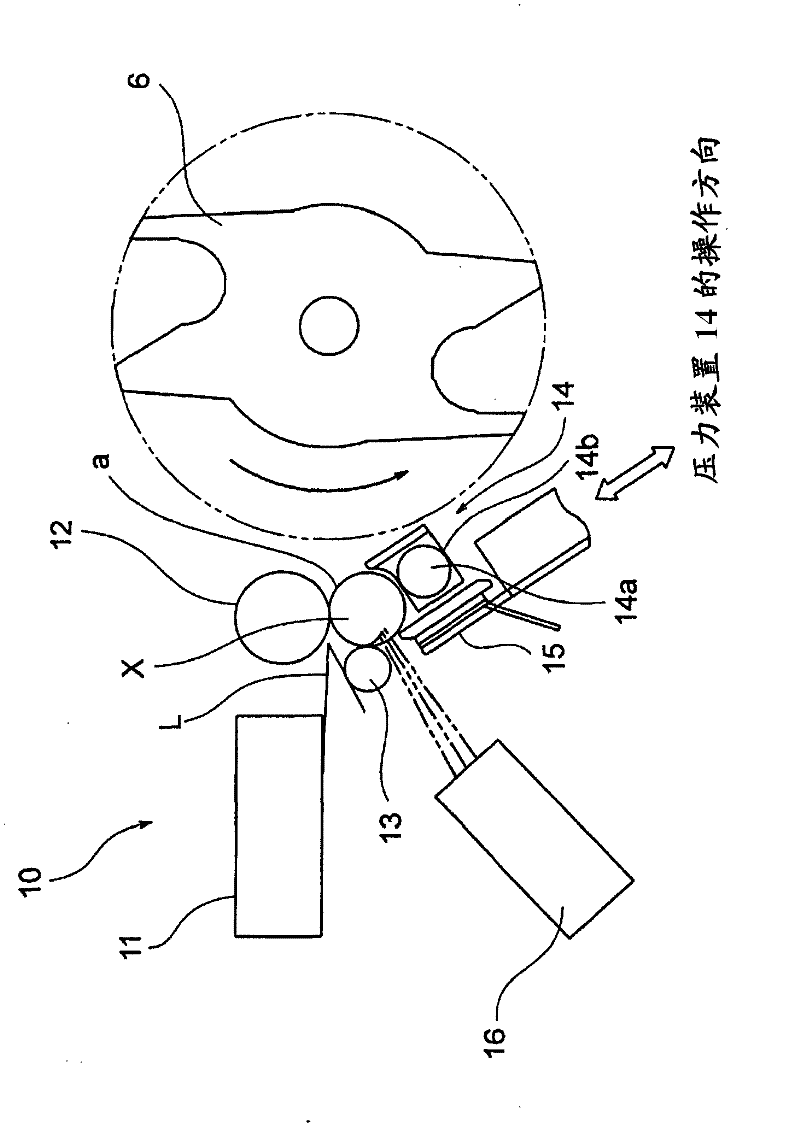

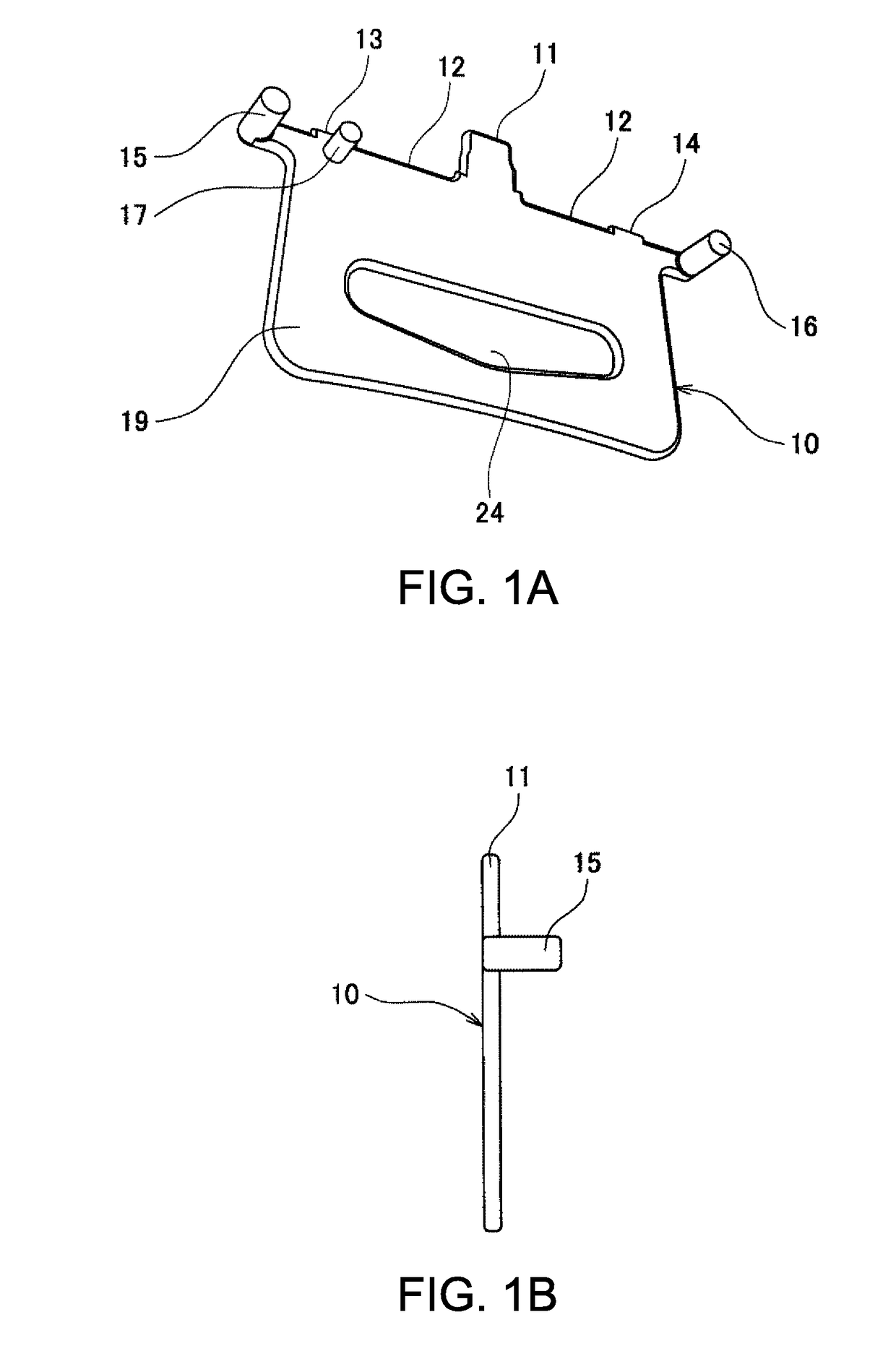

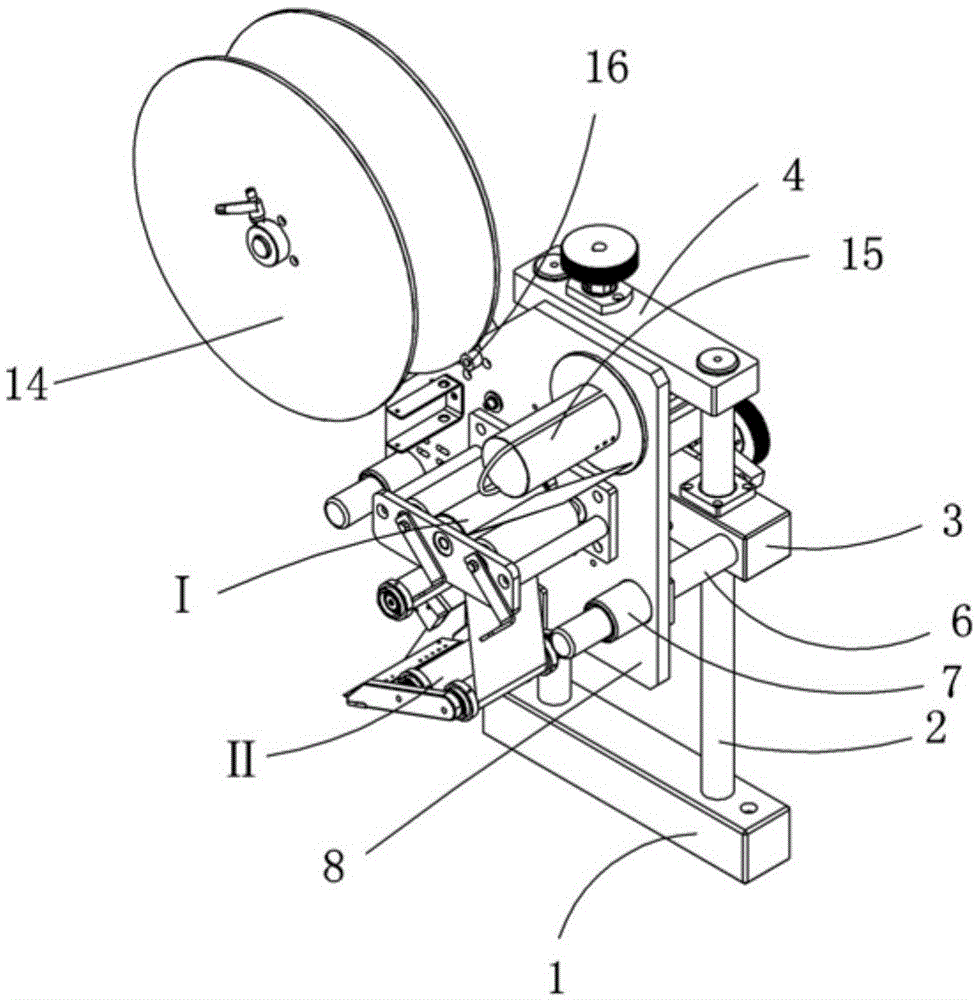

Label sticking device for handrial belt

InactiveCN101066710AEasy to assemble and disassembleReduce disassemblyLabelling flat rigid surfacesLabelling machinesHandrailEngineering

The label sticking device for handrail belt includes a frame, a label supplier, a separating roller, a label guiding wheel, a pair of stripped layer guide wheel, a compressing unit, a stripped layer exhausting unit and a holding unit. The frame includes two parallel borders, portal supports, fixing unit, forcer and other parts; and the label supplier includes label spool and label spool shaft. The present invention can stick label to required portions, and has simple structure, light weight, easy installation and easy disassembling.

Owner:田恩国

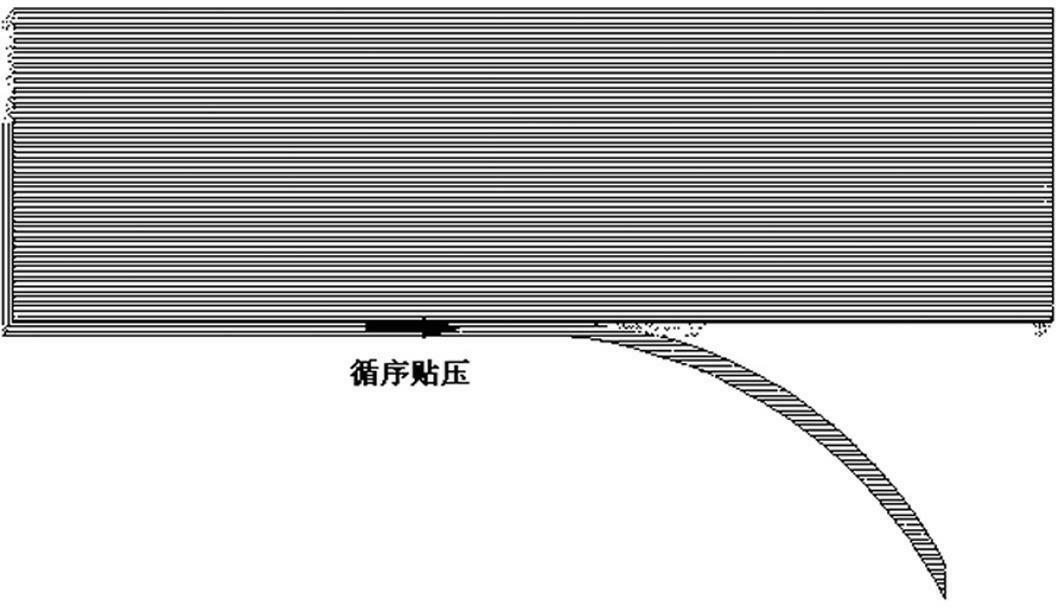

Polyurethane moisture-curable hot-melt edge sealing adhesive, and preparation method and application thereof

InactiveCN102690625AImprove material utilizationLow shrinkagePolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention belongs to the technical field of chemical adhesives, and relates to a polyurethane moisture-curable hot-melt edge sealing adhesive and a preparation method thereof. Based on weight part, the polyurethane moisture-curable hot-melt edge sealing adhesive comprises the following components: a polyester polyol mixture, diphenylmethyl diisocyanate, a plasticizer, a chain extender and a tackifying resin, wherein the polyester polyol mixture has the relative molecular weight of 1,000-7,000 and is one or more of PHL-1600, PH-2000, CMA-1044 and CMA-44; and the polyurethane moisture-curable hot-melt edge sealing adhesive does not contain any organic solvent, has the solid content of 100 percent, is short in positioning time, quickly and accurately adhere between a decorative film and a to-be-decorated base material, has high adhesive strength and high peel strength, can prevent the influence of water and other adverse environmental factors, has a flexible and elastic adhesive layer and can resist mechanical impact of edge parts in the subsequent polishing decoration process.

Owner:舒跃辉

Labeling machine for blood-sampling tube automatic preparation device

ActiveUS20120138231A1Small sizePaste accuratelyControlling laminationLaminationTest tubePatient information

Provided is a labeling device for an automatic test-tube setting-up device wherein an identification label can be pasted over a product label with a simple structure. A labeling device for an automatic blood-sampling-tube setting-up device comprises a means for taking out a blood-sampling tube based on patient information and supporting the blood-sampling tube at a labeling position, a blood-sampling tube driving means for rotary driving the blood-sampling tube at the labeling position, a label printing means for creating an identification label by printing test information and / or patient information and outputting the identification label to the labeling position, a product label position detecting means for detecting the edge of a product label previously pasted to the outer surface of the blood-sampling tube, and a controller for controlling the operation of the label printing means and the blood-sampling tube driving means such that the identification label is pasted over the product label with a continuous gap left in the axial direction of the blood-sampling tube on the outer surface of a blood-sampling tube based on information about the diameter of a blood-sampling tube corresponding to the blood-sampling tube at the labeling position, and information about the edge of the product label obtained from the product label position detecting means.

Owner:TECHNO MEDICA CO LTD

Device for sticking film on display screen

ActiveUS20180117892A1Avoid positioningSimple configurationLaminationLamination apparatusMobile deviceElectrical and Electronics engineering

A device for sticking a film on a display screen of a mobile device, the device including: a film holder for sticking a film main body on the display screen, the film holder having a protruding engagement piece which is inserted into and fixed to a connector on the side of the mobile device which serves as an engagement partner and a positioning means for the film main body, the film holder has at least two positioning projections and the film main body has the same number of positioning holes which are commensurate with the positioning projections.

Owner:TRINITY

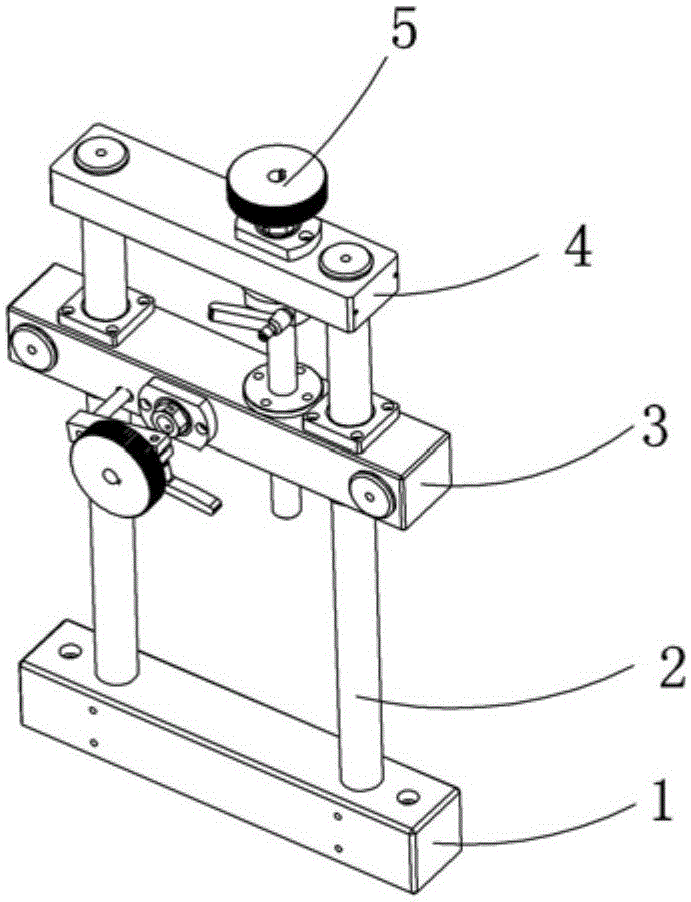

Labeling mechanism

InactiveCN105000239AEasy to operateImprove work efficiencyLabelling machinesFeed pressurePulp and paper industry

The invention relates to a labeling mechanism. A material tray assembly is installed on a label connecting support. A material-press wheel assembly and a label outlet mechanism are respectively installed on the material tray assembly. A roll of label-carrying adhesive paper strip is installed on a material tray, and the paper strip successively twines around a feeding pressure wheel, an idle wheel a and a label pressing roller so as to guarantee that the paper strip will not be too tight or too loose during the motion process. In addition, a label is pasted onto a product by the use of the label pressing roller when the product passes by, and simultaneously, the pasted label undergoes rolling by the label pressing roller so as to guarantee the pasting quality of the label. Then, the paper strip passes through a stripping knife of the label outlet mechanism to strip and separate the label from the paper strip, and the paper strip then passes through two idle wheels b of the label outlet mechanism, the material-press wheel assembly, an idle wheel c and a roller. Finally, material receiving is conducted by the use of a material receiving wheel. By the labeling mechanism, labels can be automatically pasted in front of products. Thus, work efficiency is enhanced, and appearance aesthetics of products is ensured.

Owner:BOZHON PRECISION IND TECH CO LTD

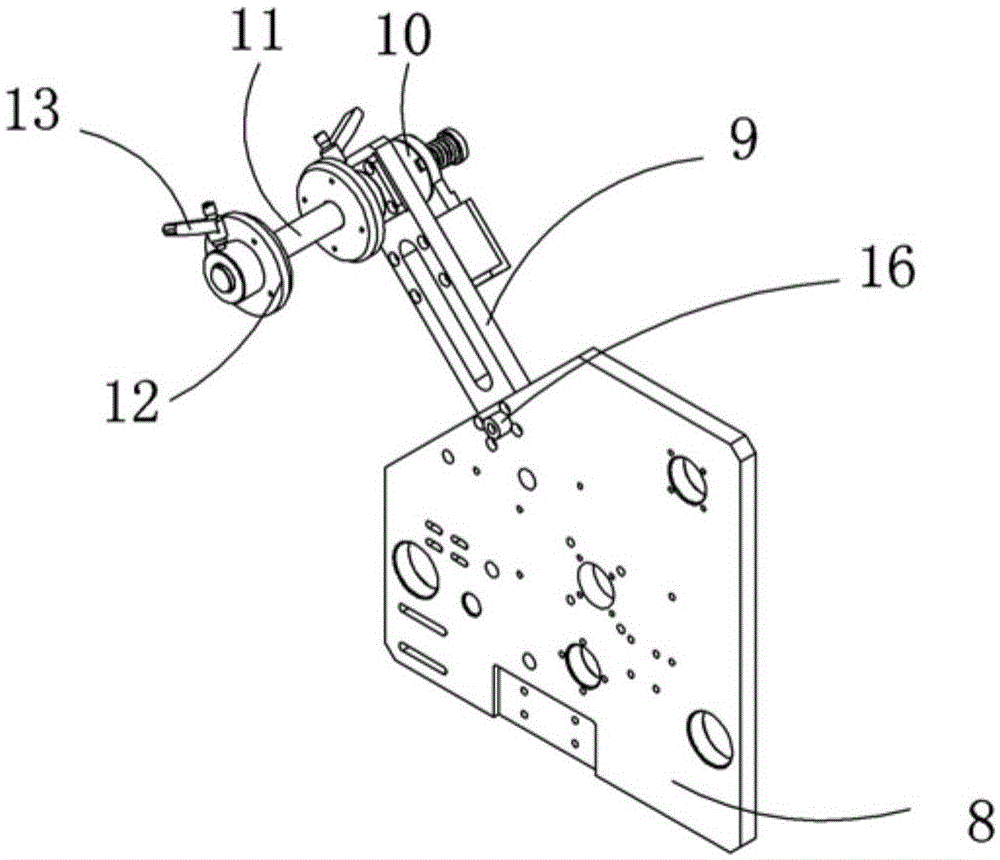

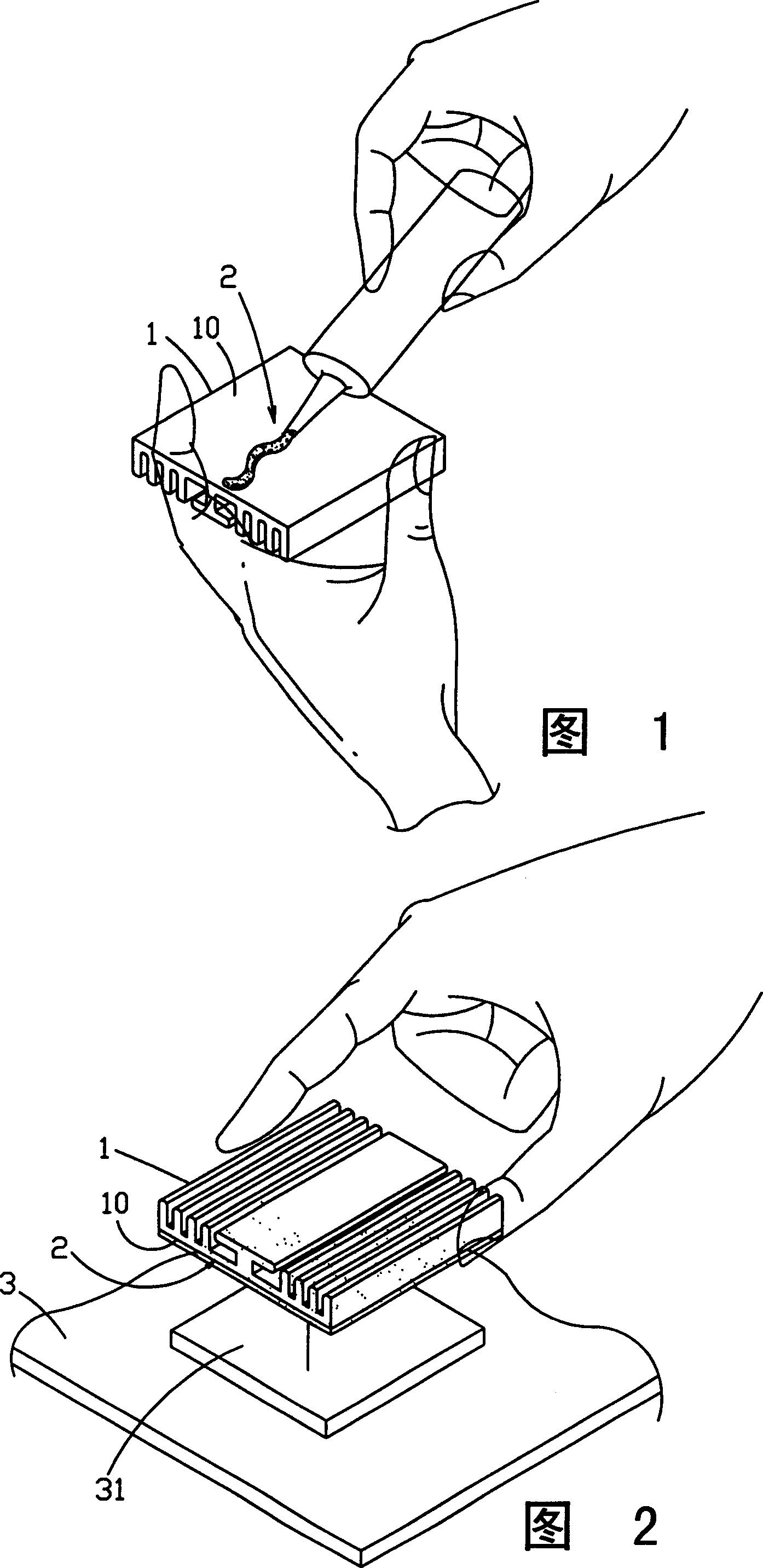

Method for pasting strain foil and equipment for pasting strain foil

InactiveCN102221428APaste accuratelyForce measurement using piezo-resistive materialsEngineeringStrain gauge

The invention is suitable for the field of a method for manufacturing a micro-fusion semiconductor silicon strain foil sensor, which provides a method for pasting a strain foil. The method provided by the invention comprises the following steps: 1) coating viscose on at least one fixing glue which is coated on a pressure film; 2) placing the strain foil on the fixing glue by means of the viscose,thereby enabling the strain foil and the fixing glue to be pasted; and 3.) moving the strain foil in the specified position of the fixing glue. After the technical scheme is adopted, one strain foil is pasted on another strain foil through the three steps; the viscose is pasted on the fixing glue; the strain foil is fixed on the fixing glue; the strain foil and the fixing glue are pasted; and thestrain foil is moved to the specified position of the fixing glue, thereby better realizing the technical effect that the strain foil is accurately pasted in the specified position of the fixing glue. The invention also provides equipment for pasting the strain foil.

Owner:MEASUREMENT SPECIALTIES CHINA

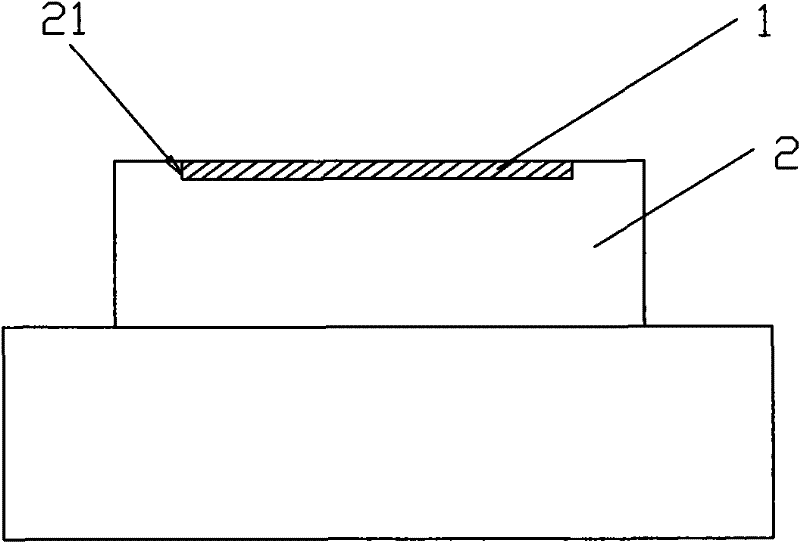

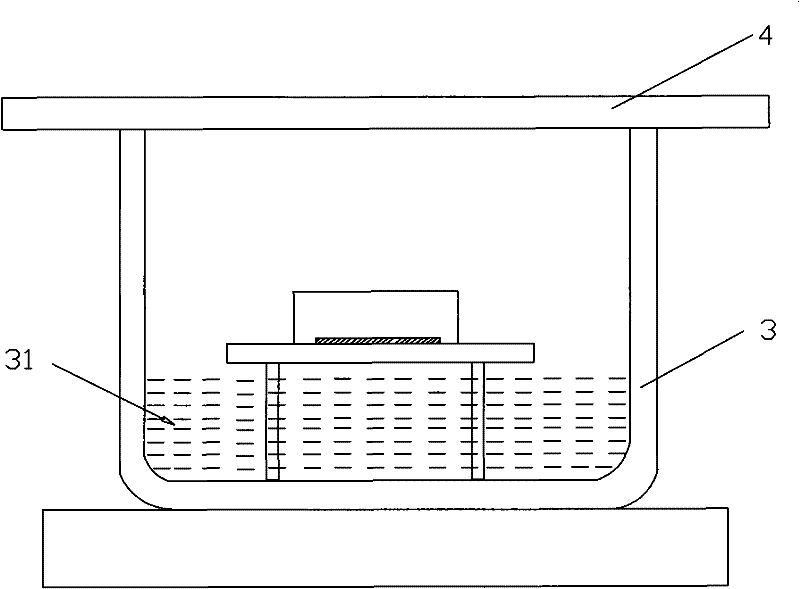

Method and equipment for quantitatively distributing adhesion agent onto heat radiator fin, and positioning adhesion therefor

InactiveCN1459338AAccurate bondingPrecise positioningSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A method for quantitatively coating adhesive on heat radiator and its locating and adhering includes such steps as sprading several heat radiators on a first locating implement, putting a perforated coating template on the first locating implement, coating, adhesive via the through holes of template, removing the said template, putting a slug in a second locating implement with notch on top wall, and adhering the radiator to the slug via the said notch.

Owner:MITAC INT CORP

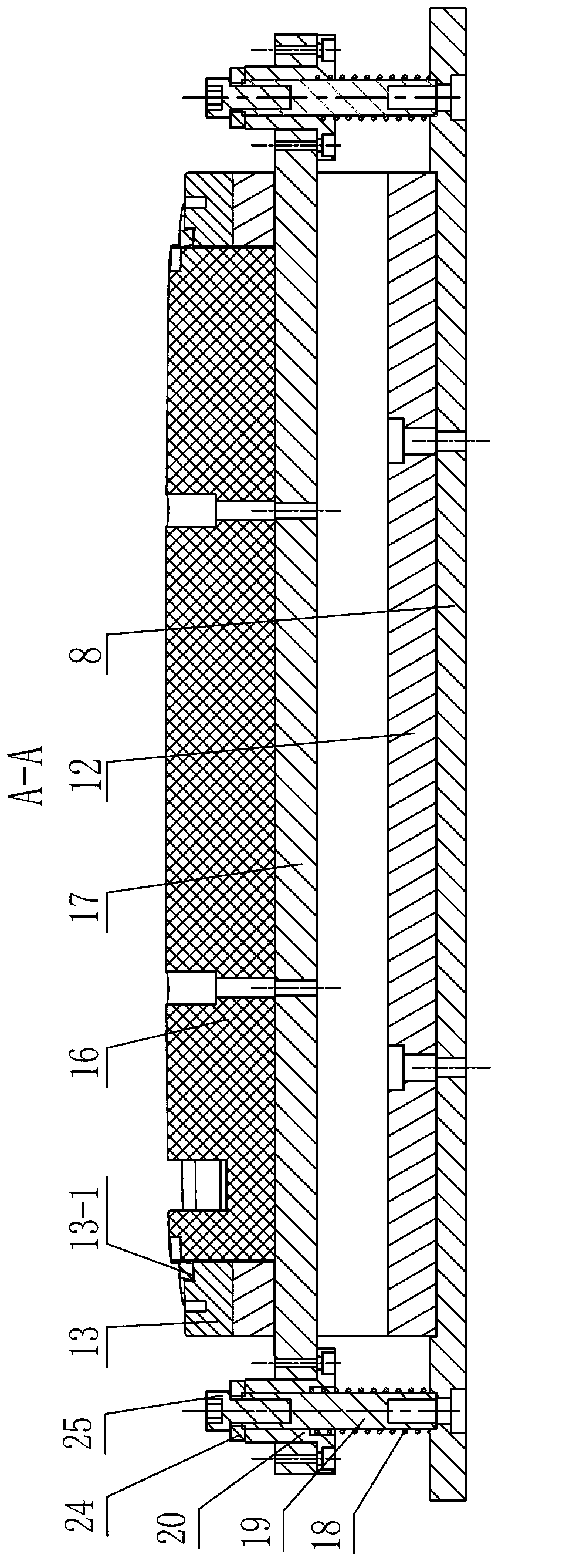

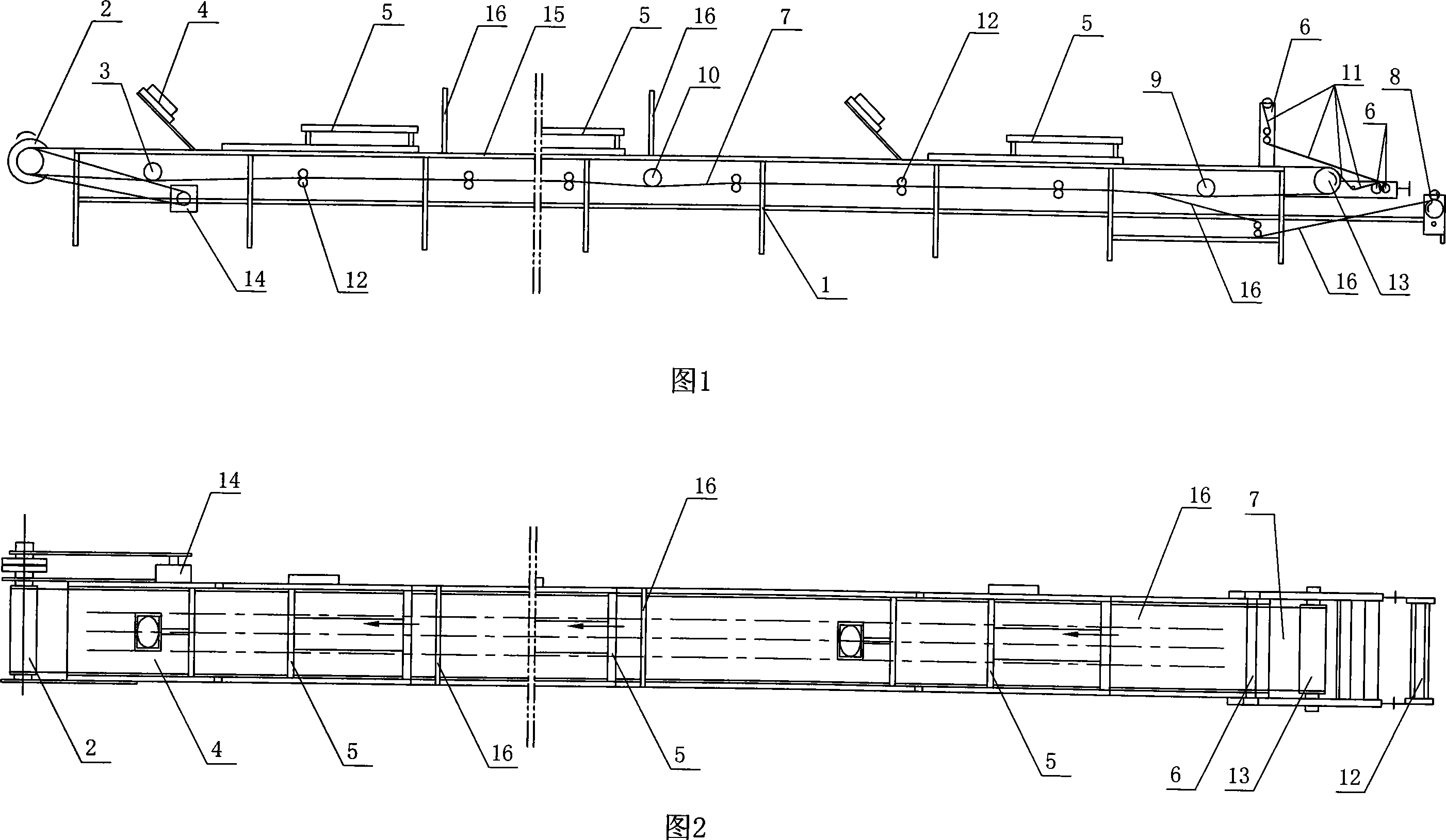

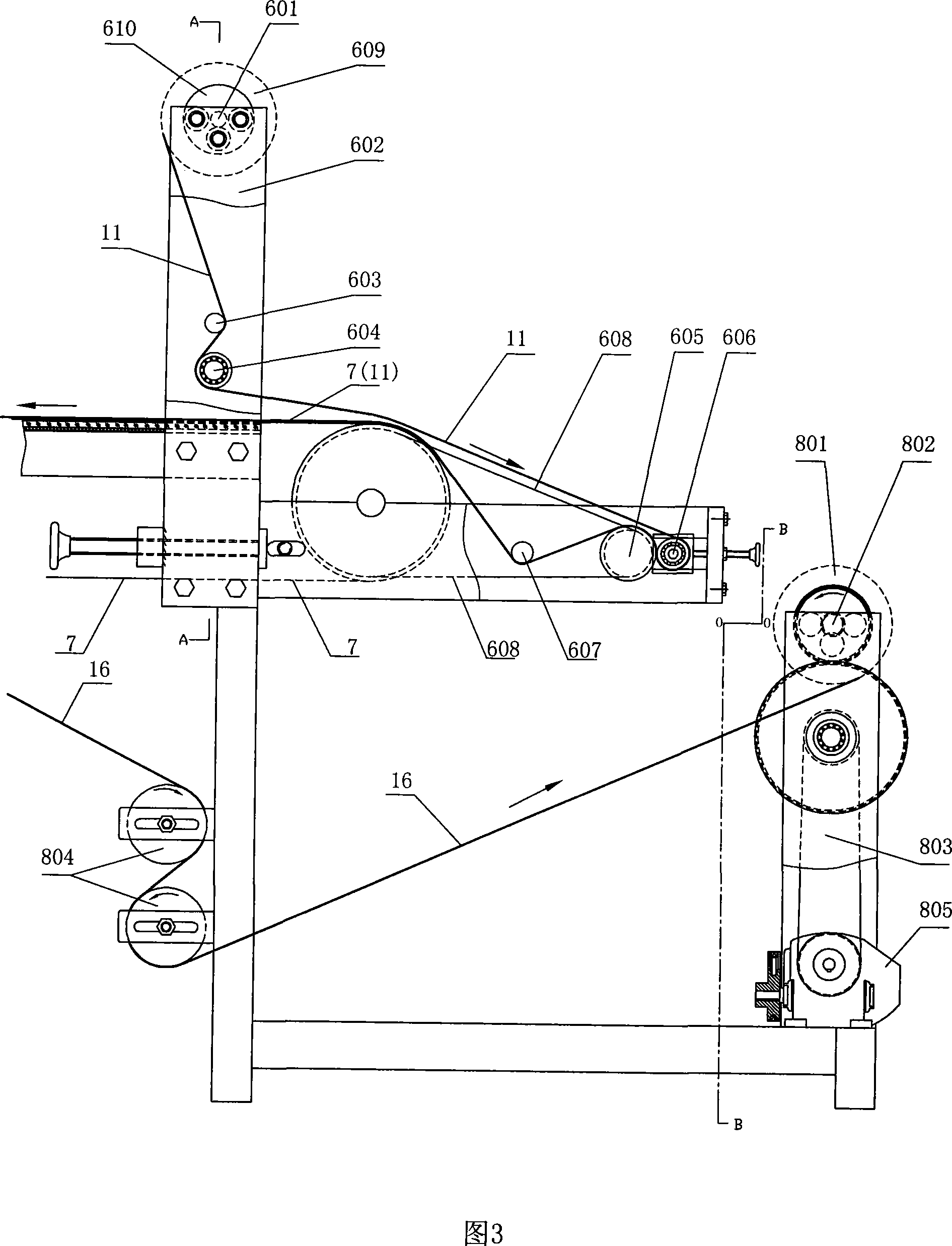

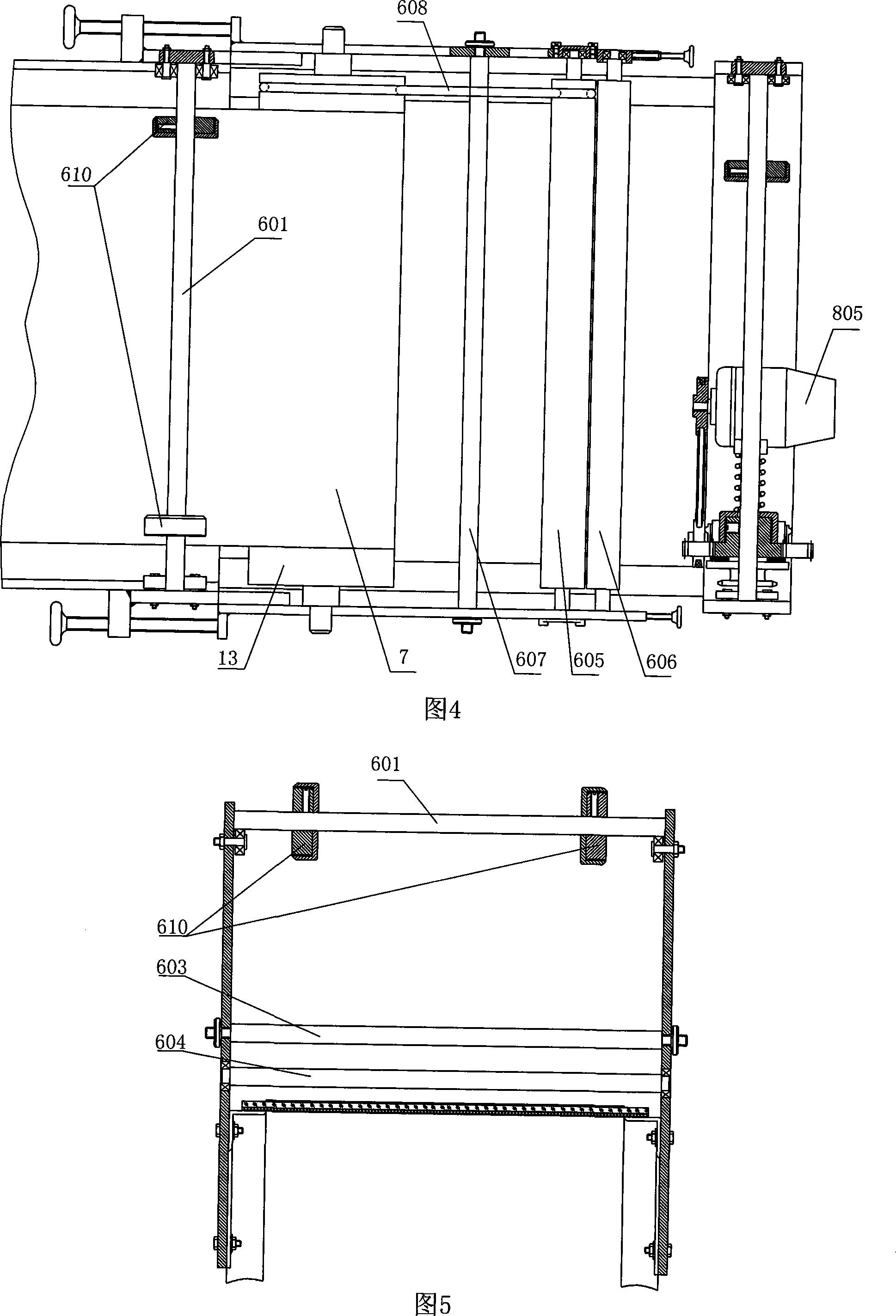

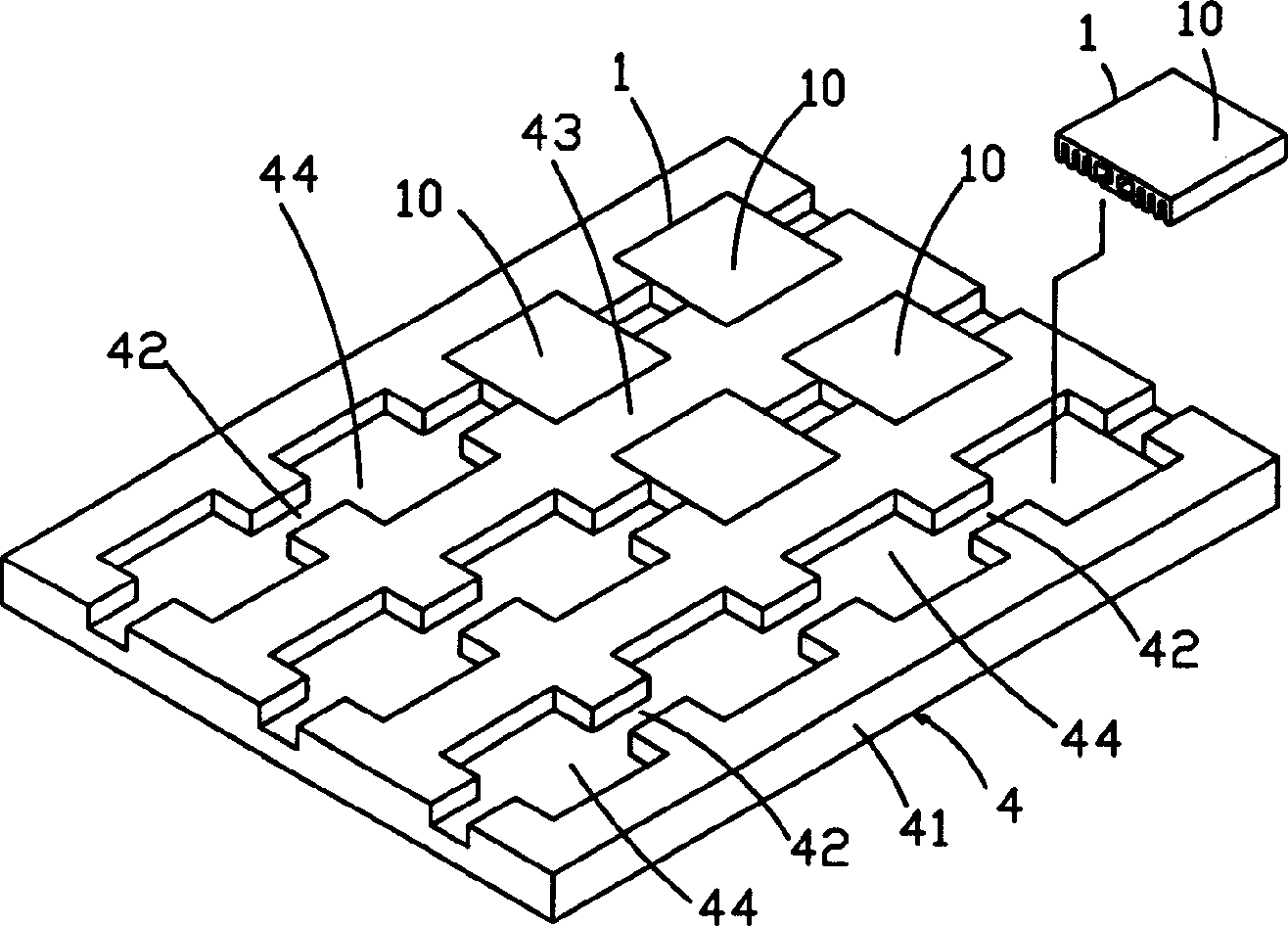

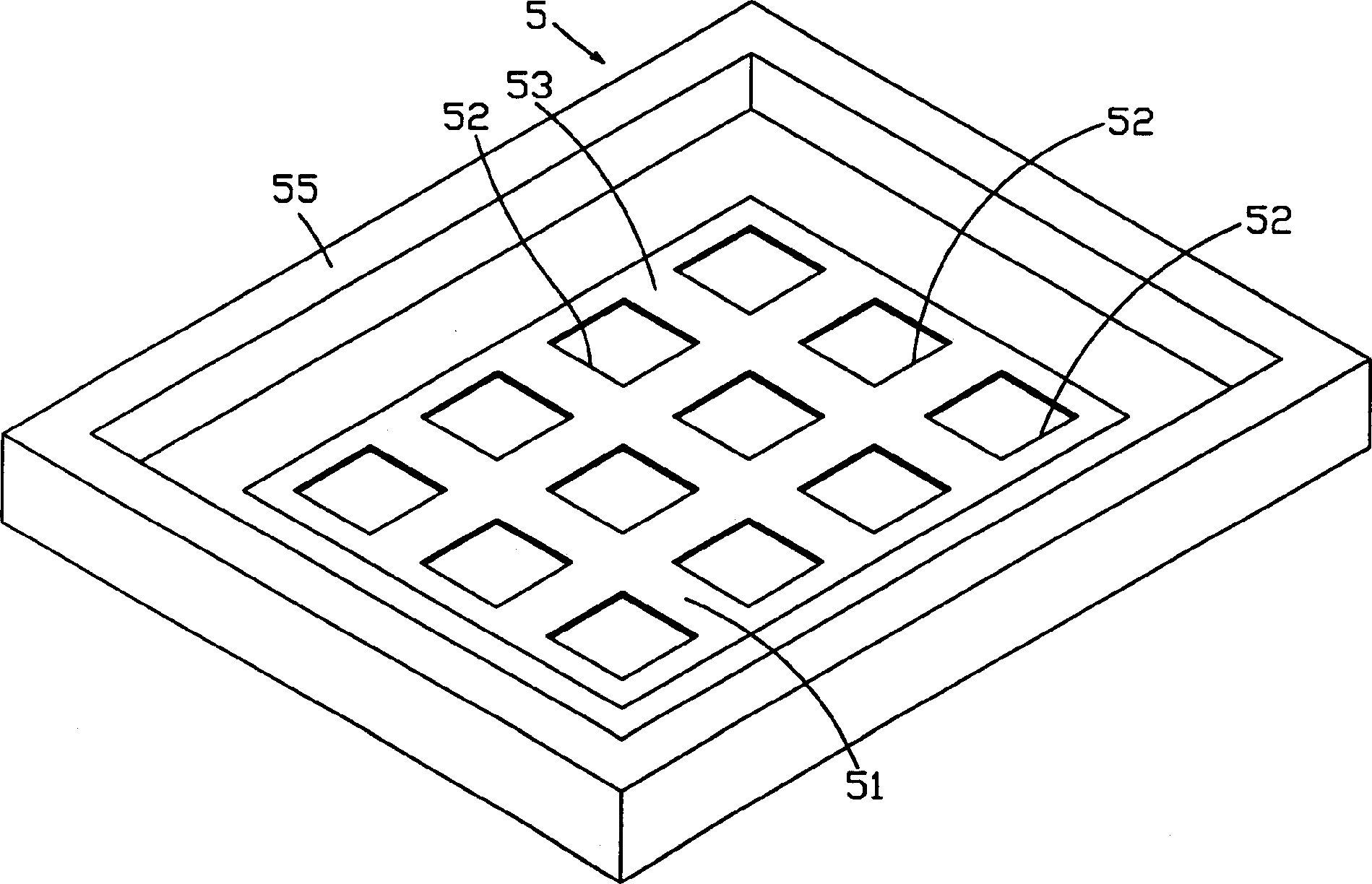

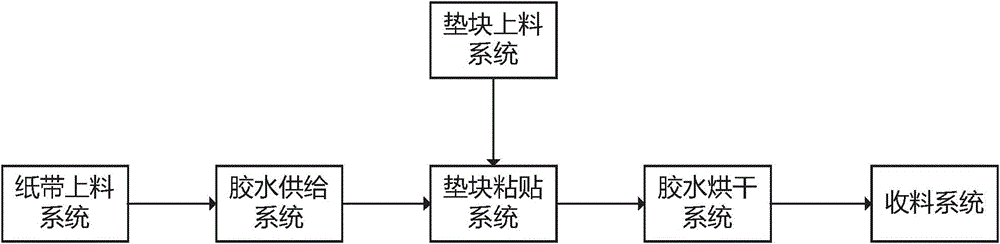

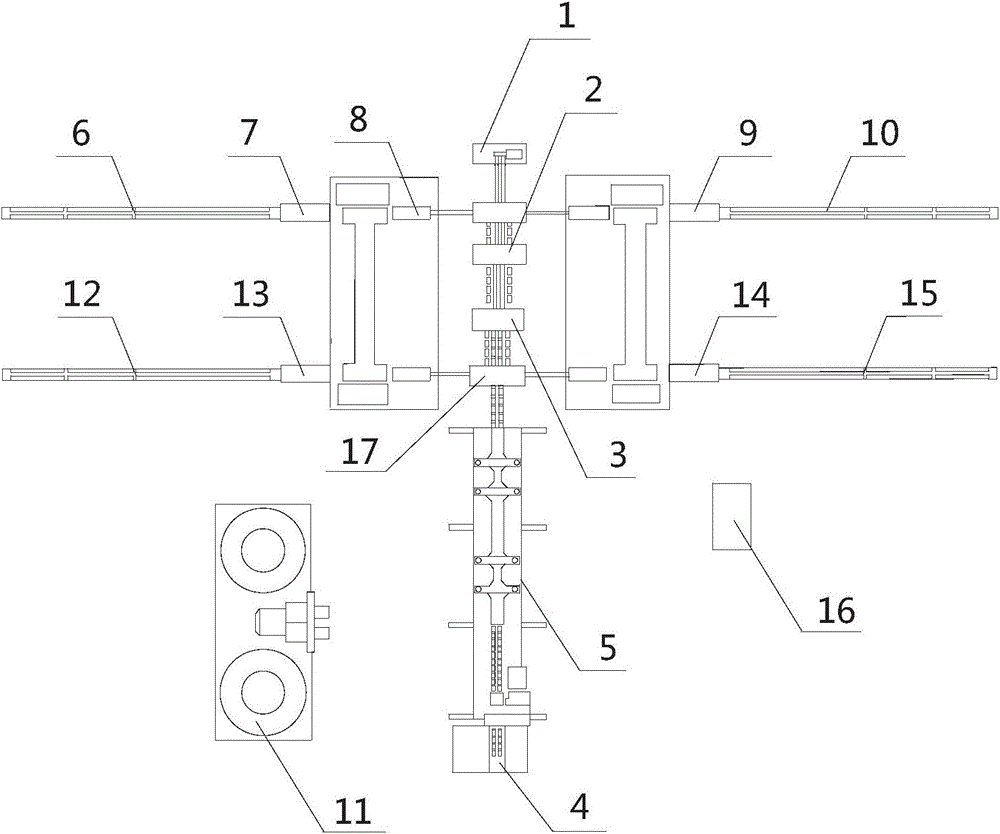

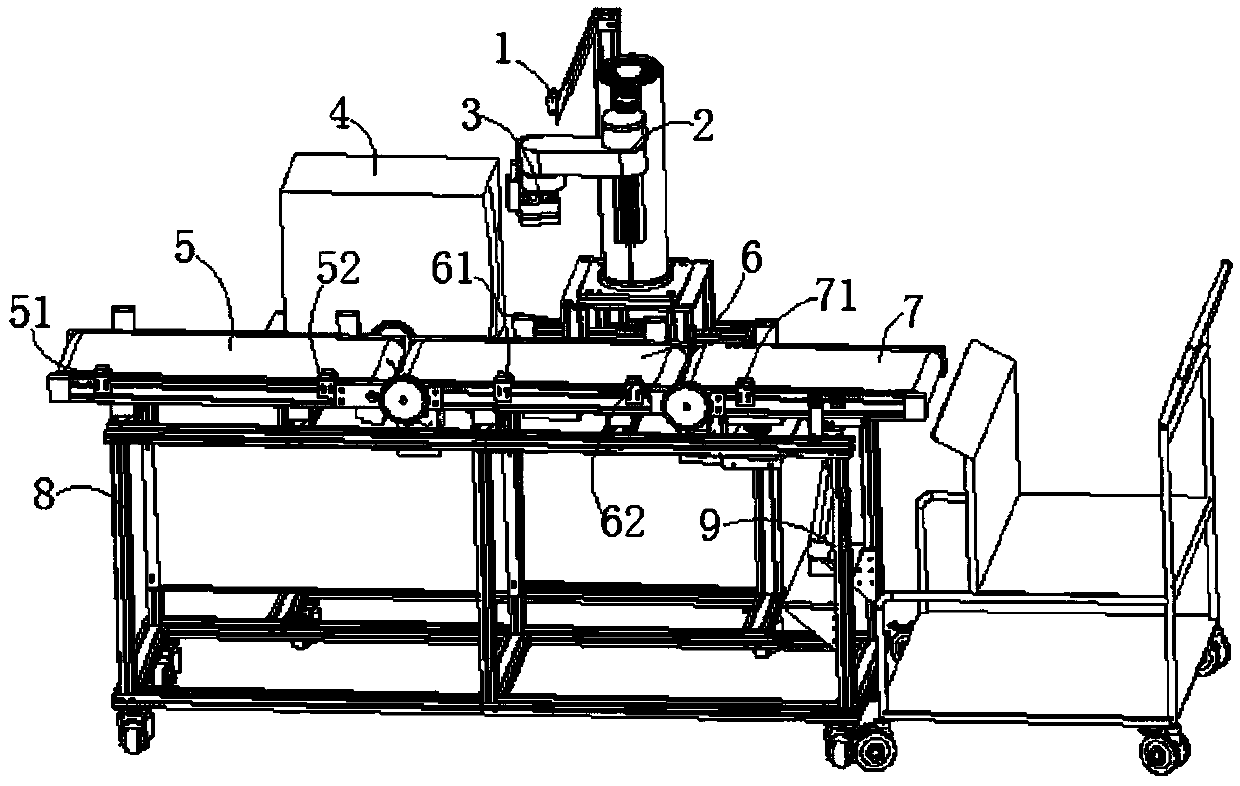

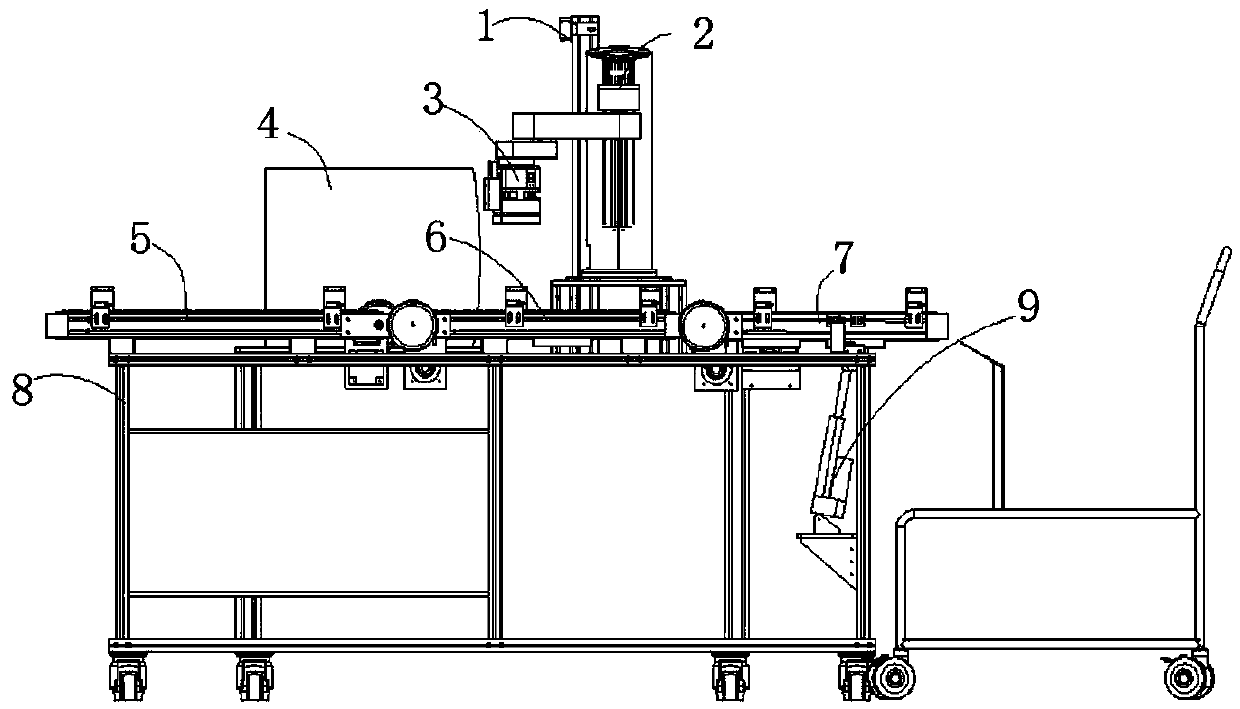

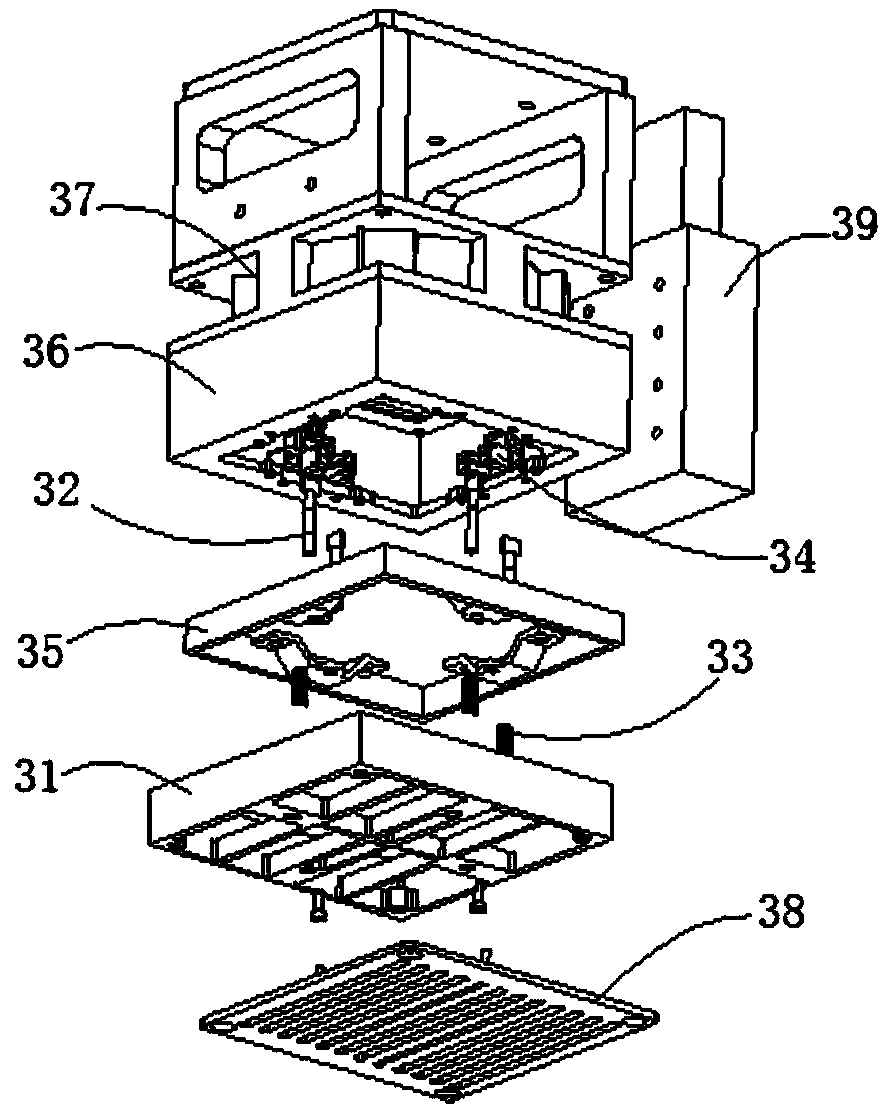

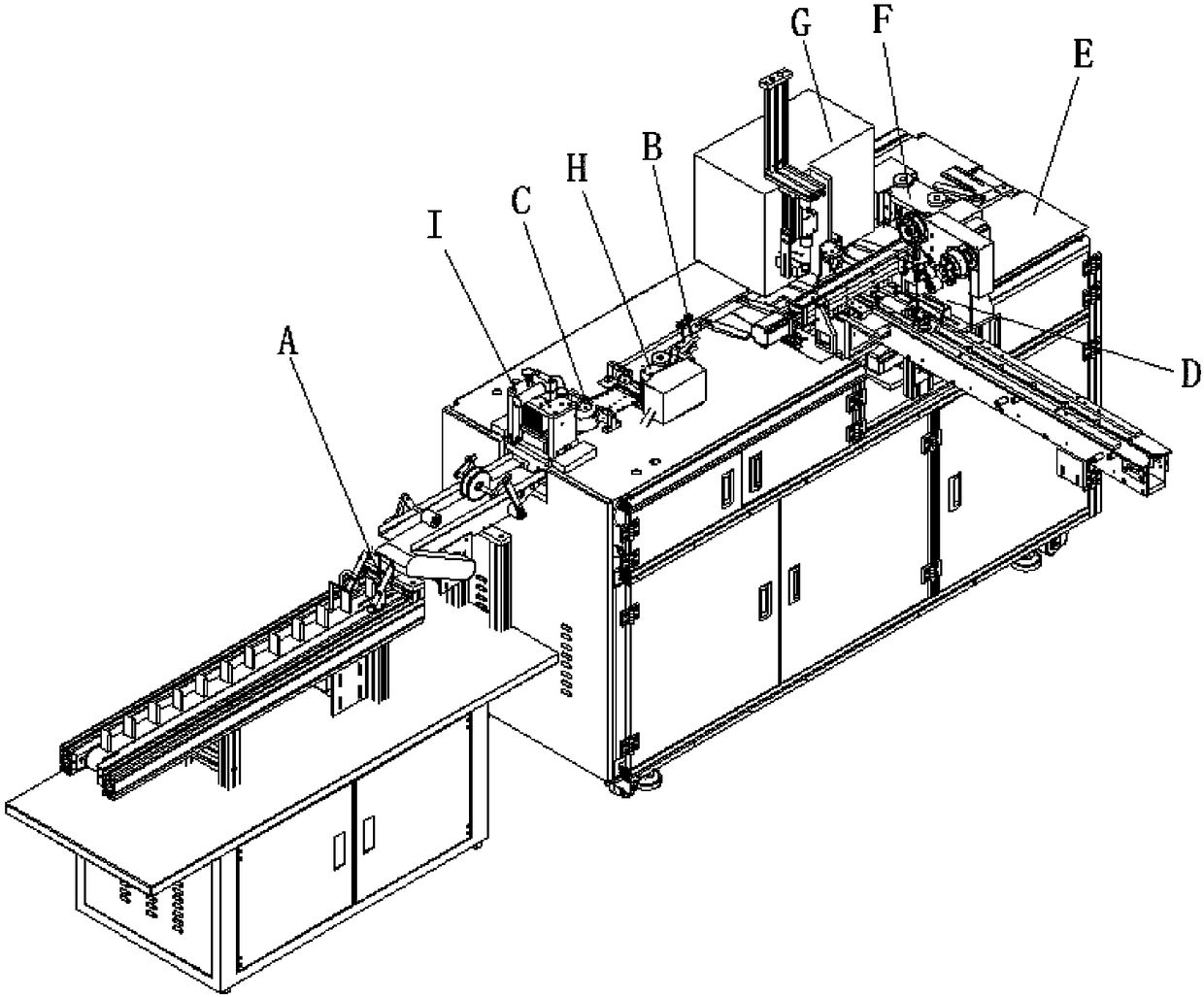

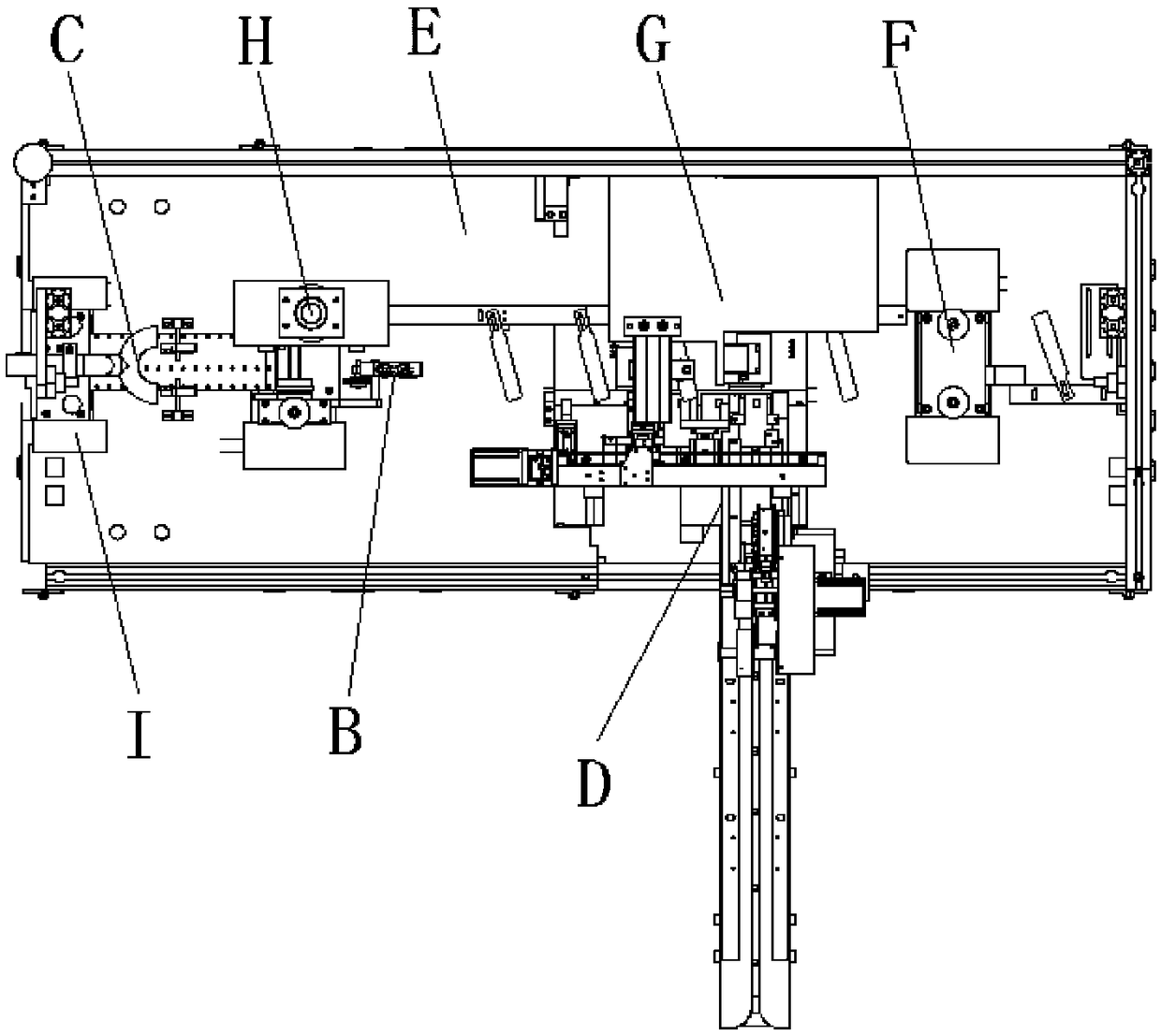

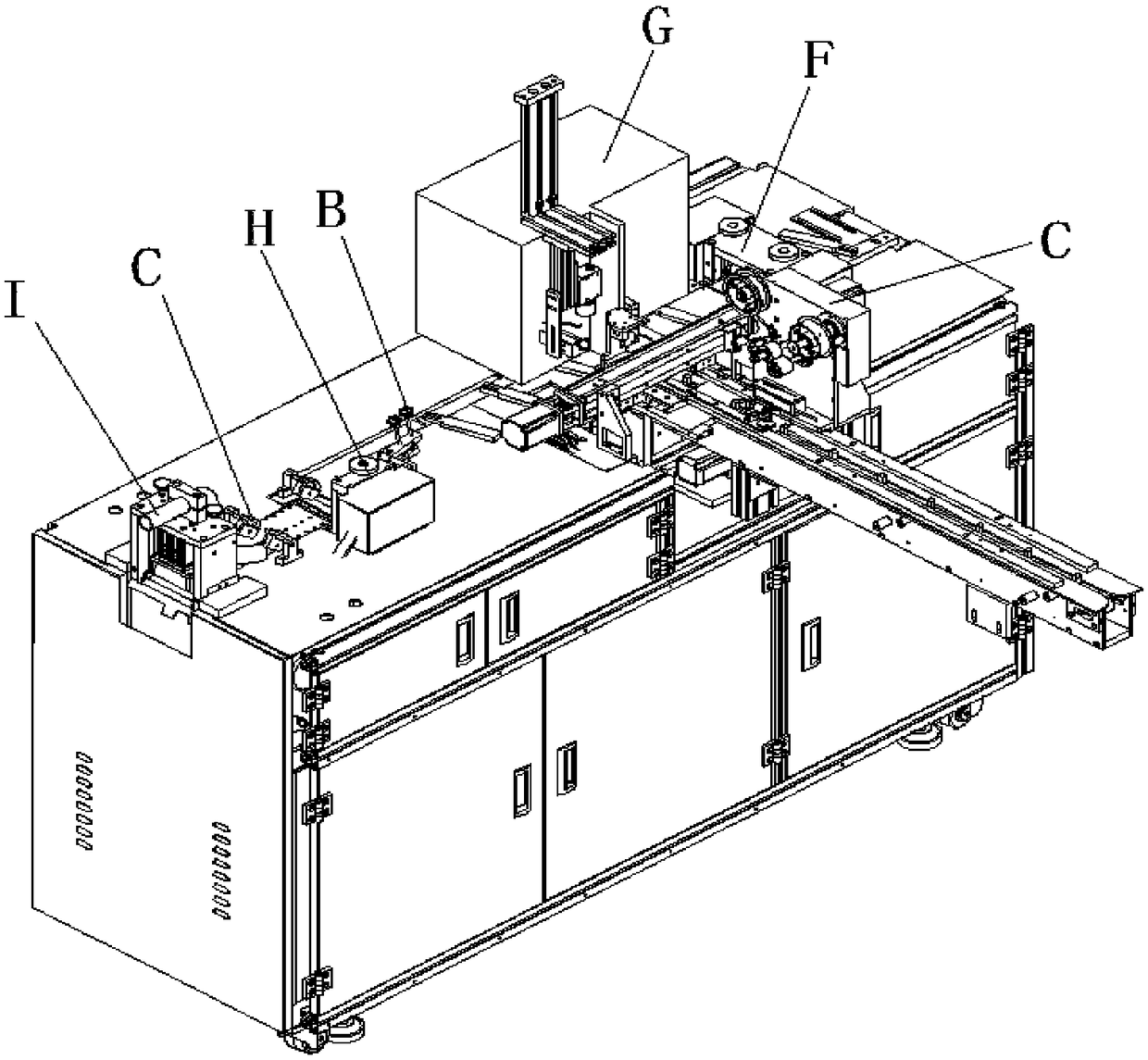

Automatic production line for insulation oil passage of transformer

InactiveCN105097257AReduce personal injuryReduce labor burdenInductances/transformers/magnets manufactureArticle deliveryProduction lineTransformer

The invention belongs to the technical field of production of an insulation oil passage of a transformer, and in particular relates to an automatic production line for the insulation oil passage of the transformer. The automatic production line comprises a control system, and a paper tape feeding system, a cushion block feeding system, a glue supply system, a cushion block pasting system, a drying system and a receiving system which are connected with the control system, wherein the cushion block feeding system, the glue supply system and the cushion block pasting system are arranged on the side surface of the paper tape feeding system, the drying system and the receiving system are sequentially arranged at the front end of the paper tape feeding system along a paper tape transmission direction, the glue supply system is used for glue dispersing on a paper tape on the paper tape feeding system, the cushion block pasting system is used for pasting a cushion block transmitted on the cushion block feeding system at a tape pasting part on the paper tape to form the insulation oil passage of the transformer, and the insulation oil passage of the transformer enters the receiving system after drying by the drying system. The automatic production line has the advantages that mass production is realized, automatic degree is high, product quality is high, and cushion blocks with certain shapes and sizes can be automatically and accurately pasted on the paper tape one by one.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Film guiding device for guiding positioning of films

InactiveCN101935855AHeight adjustableStable positionEngineeringElectrical and Electronics engineering

The invention relates to a film guiding device for guiding the positioning of films, which is arranged on one side of an extruding wheel, and comprises a frame and a film guiding assembly arranged on the frame. The film guiding assembly comprises film guiding blocks used for guiding the films and film guiding check blocks used for positioning the films, which are alternately arranged; the surfaces of the film guiding blocks used for guiding the films are set to be guiding surfaces; the surfaces of the film guiding check blocks, positioned on the same side as the guiding surfaces of the film guiding blocks, are set to be positioning surfaces; and the positioning surfaces of the film guiding check block is higher than the guiding surfaces of the film guiding blocks. The film guiding device for guiding the positioning of the films can simultaneously guide and position a plurality of films, and can accurately adjust the integral height of the films to keep relative positions of the films not changed.

Owner:苏骞

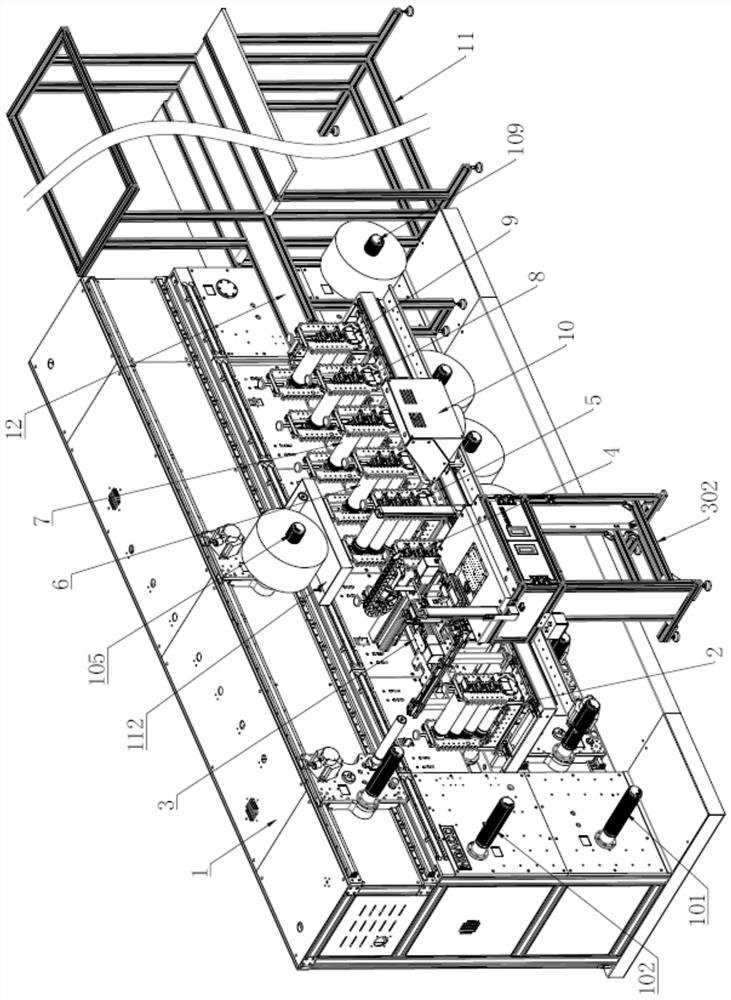

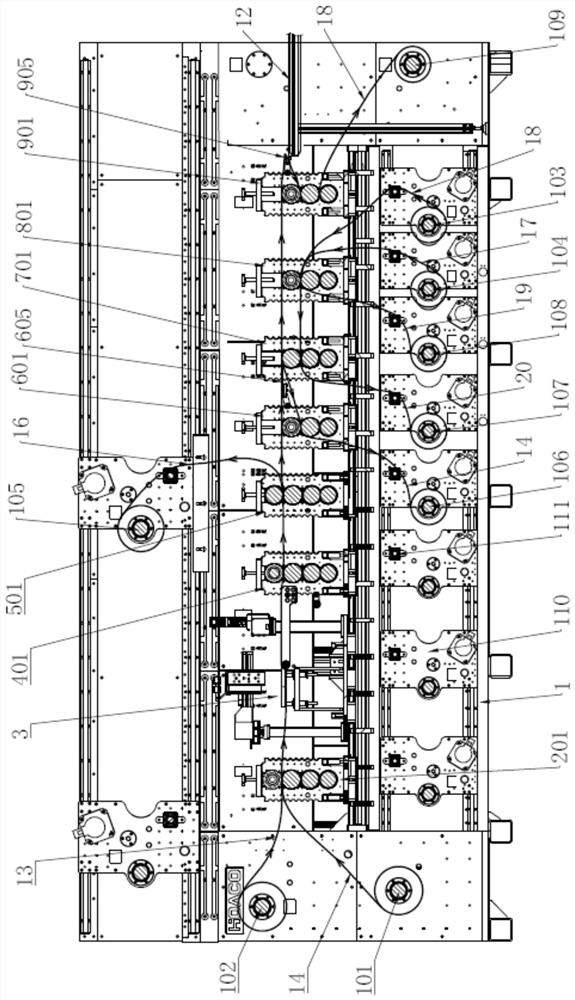

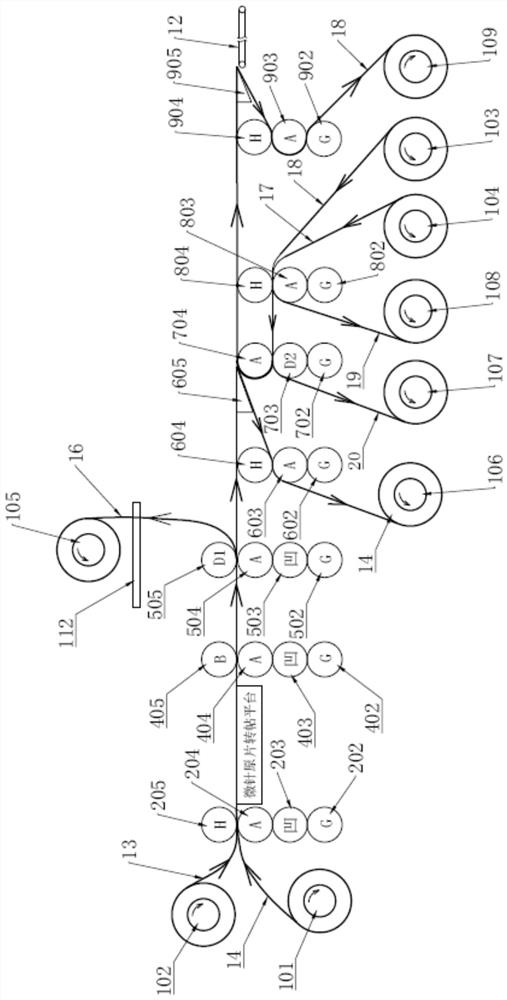

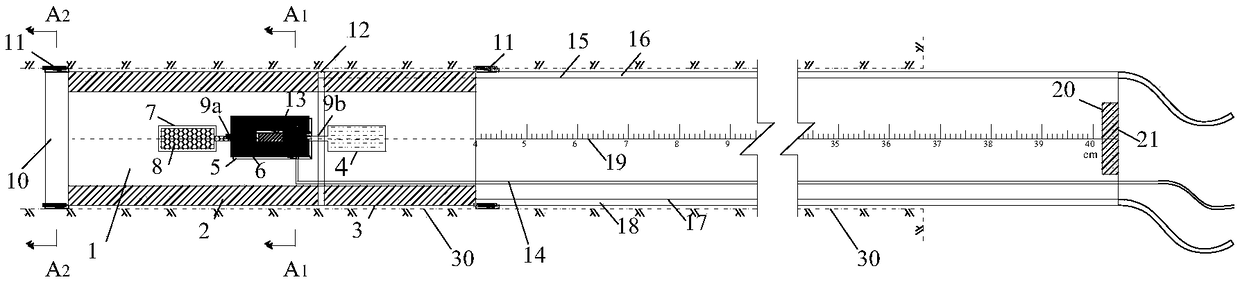

Micro-needle eye patch processing equipment and processing method thereof

ActiveCN113548511AImprove processing efficiencyImprove processing qualityMicroneedlesPharmaceutical delivery mechanismWaste materialDie cutting

The invention belongs to the technical field of micro-needle eye patch processing, and provides micro-needle eye patch processing equipment and a processing method thereof. The micro-needle eye patch processing equipment comprises an eye patch sheet making machine and an eye patch conveyor, and the eye patch sheet making machine comprises a sheet making machine rack provided with a plurality of material belt discharging shafts and waste material rolling shafts; a first traction composite device, a micro-needle original sheet repasting device, a traction conveying device, a micro-needle original sheet die cutting device, a first low-viscosity film waste collecting device, a medical rubber strip die cutting device, a second traction composite device and a second low-viscosity film waste collecting device are sequentially arranged from one end to the other end of the sheet making machine rack; the micro-needle original sheet repasting device comprises an original sheet feeding base platform installed on the sheet making machine rack, a bonding supporting plate and an original sheet moving mechanism are arranged on the original sheet feeding base platform, and an original sheet feeding mechanism is arranged on the upstream of the original sheet moving mechanism. According to the micro-needle eye patch processing equipment and the processing method thereof, the processing efficiency and the processing quality of micro-needle eye patches are greatly improved, and micro-needle eye patch products obtained through processing are convenient to use and good in attaching effect.

Owner:SHANDONG HOACO AUTOMATION TECH

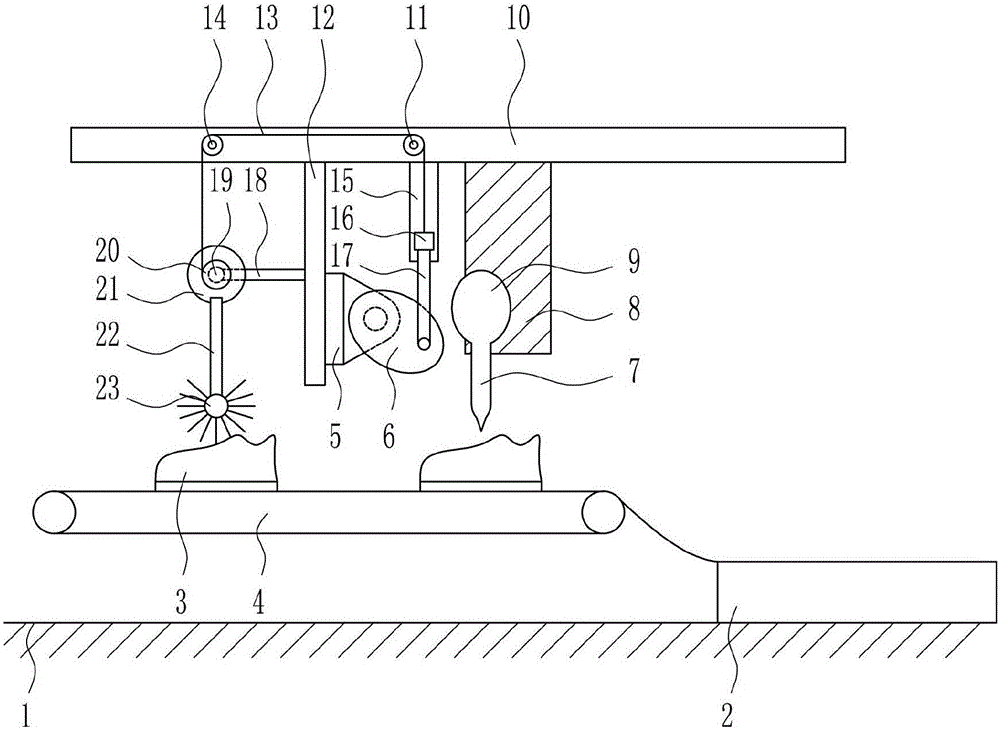

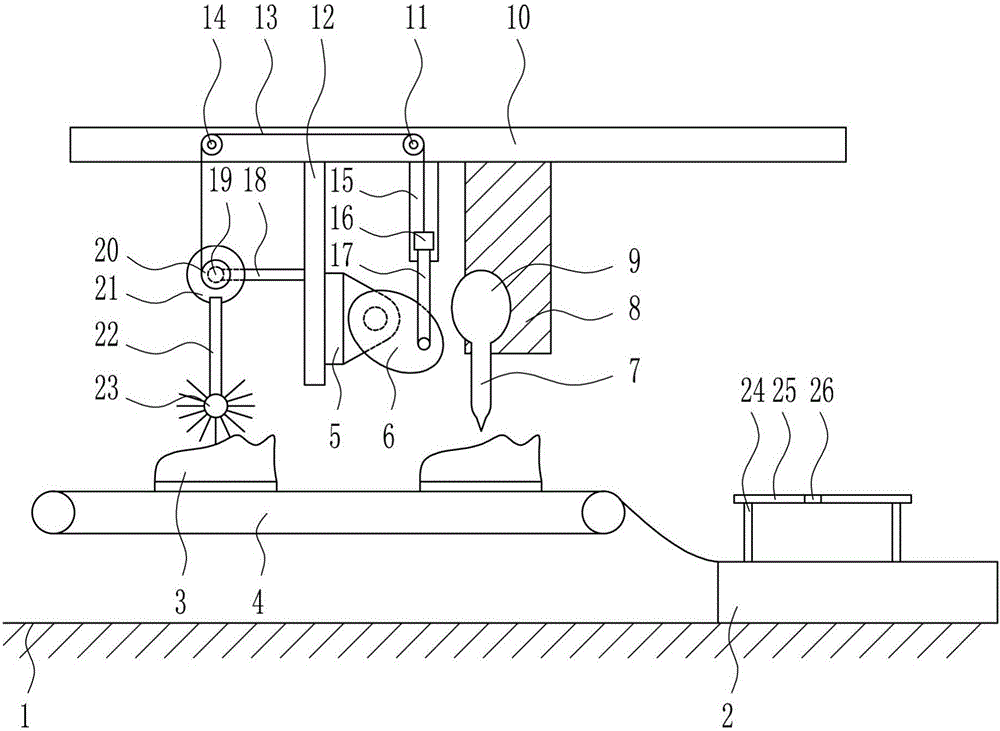

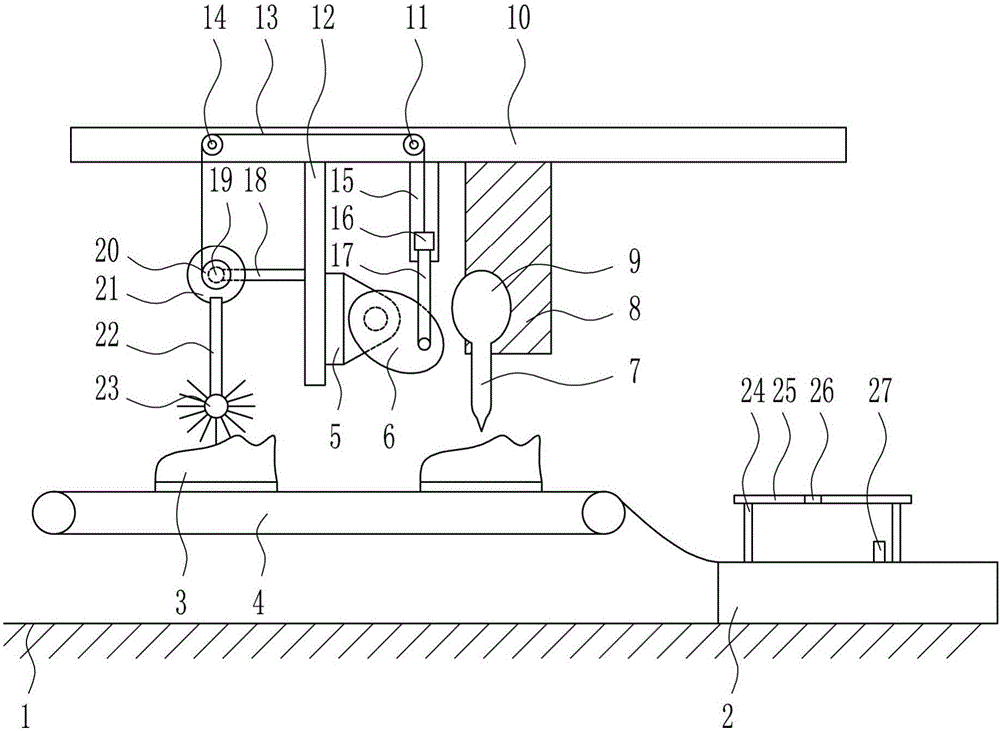

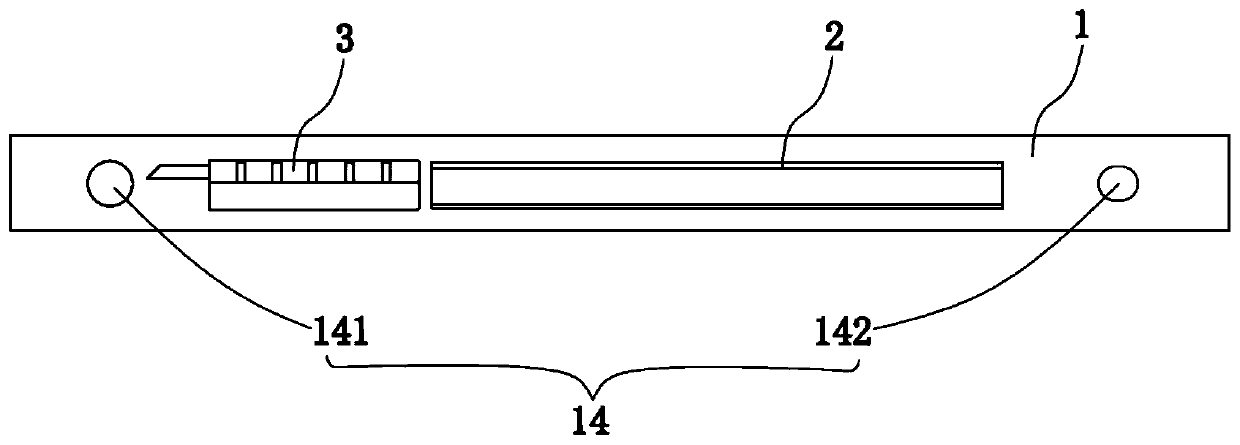

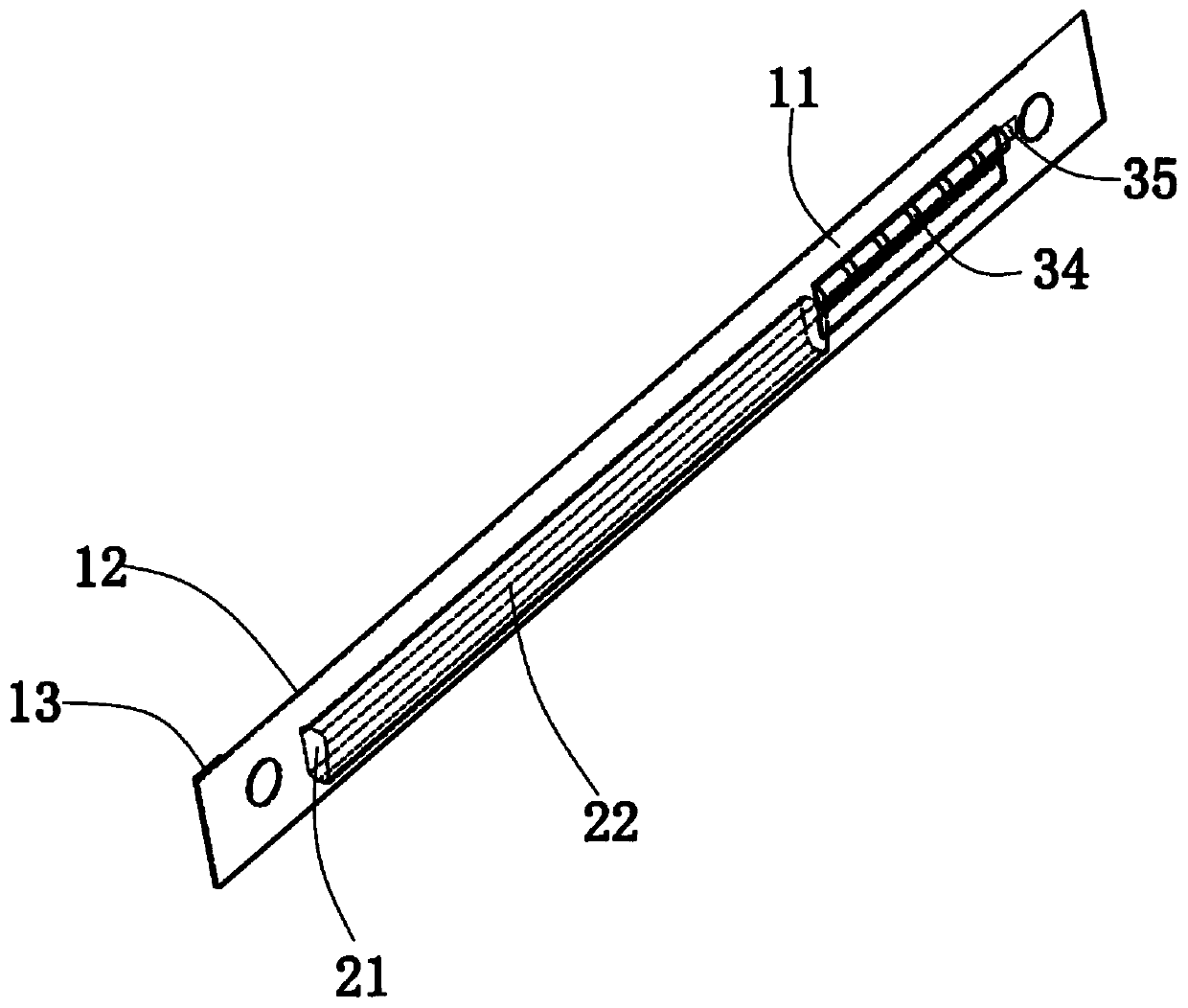

Ornament adhesion device for shoe making

The invention relates to an ornament adhesion device and especially relates to an ornament adhesion device for shoe making. The technical problem to be solved by the invention is to provide the ornament adhesion device for the shoe making, wherein adhesion efficiency is high and ornament adhesion is accurate. In order to solve the technical problem, the invention provides the ornament adhesion device for the shoe making. The device comprises a working table, a transmission device, a sway base, an ellipsoid cam, an adhesive dripping bottle, a fixation trough, an adhesive cap, a top plate, a second fixed pulley, a fixation plate, a pull wire, a first fixed pulley, a slide rail, a slide block, a connecting rod, a first strut, an electric motor, a winding wheel, a round disk, a sway rod and a duster, wherein the transmission device and the working table are disposed on the ground, and the transmission device is located above the left part of the working table. According to the invention, ornaments can be adhered on a shoe rapidly; by a limiting block, a second strut and a positioning plate, the ornaments can be adhered on the shoe more easily; and ornament adhesion positions are more accurate.

Owner:广东亮丰达实业有限公司

Multi-functional integrated conductive tape

PendingCN109694673AIncrease flexibilityEnsure structural stabilityFilm/foil adhesive release linersAdhesiveElectromagnetic shielding

The invention discloses a multi-functional integrated conductive tape comprising a release film. A conductive shock absorption assembly and a conductive shielding assembly are arranged on a first sideof the release film side by side. The conductive shock absorption assembly comprises shock absorption foamed cotton and first conductive cloth covering the side face of the shock absorption foamed cotton. The end face, facing to the release film, of the conductive shock absorption assembly is coated with a conductive adhesive layer; the conductive shielding assembly comprises a shielding channel,and the end face, facing to the release film, of the conductive shielding assembly is partially or totally provided with a double-sided adhesive. The multi-functional integrated conductive tape is exquisite in design and simple in structure; two different assemblies integrate into a whole, so that when the multi-functional integrated conductive tape is used, and the two assemblies can be arrangedsimultaneously at one time; therefore, the assembly efficiency is effectively improved and the operation errors caused by step-by-step connection are effectively avoided; meanwhile, different assemblies have the functions of electric connection, electromagnetic shielding and shock absorption and dust prevention, and multi-functional integration is effectively achieved.

Owner:苏州佳值电子工业有限公司

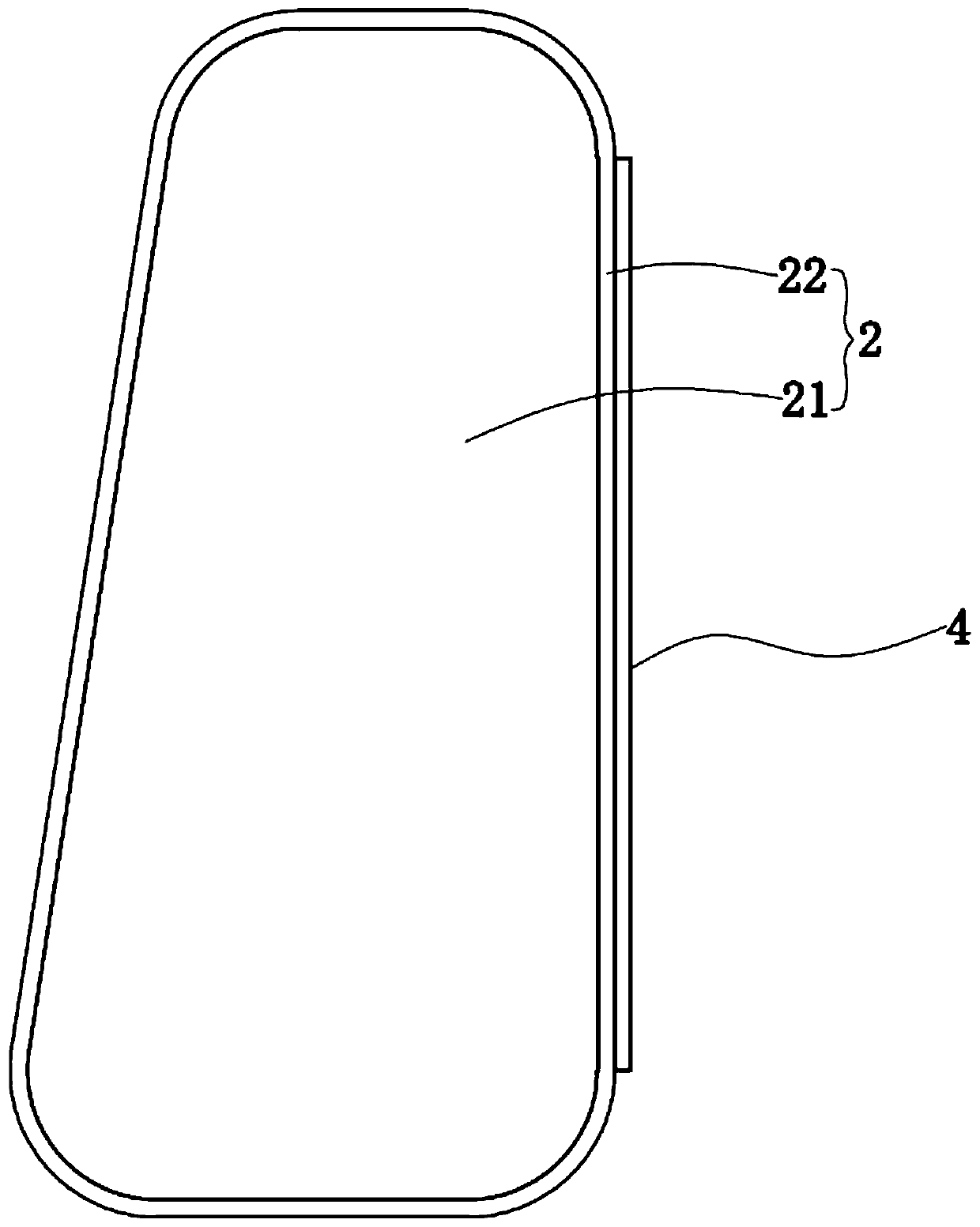

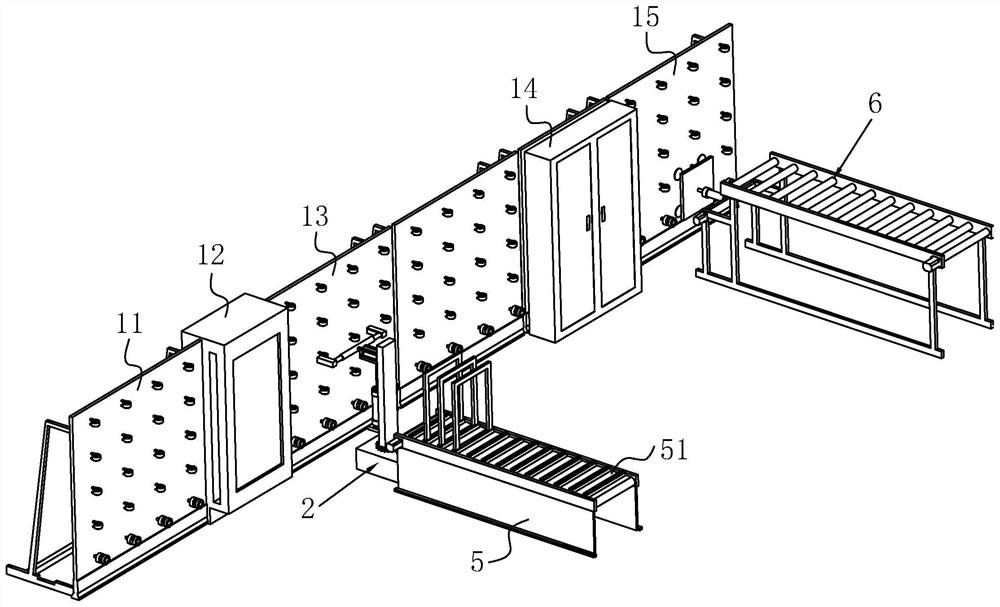

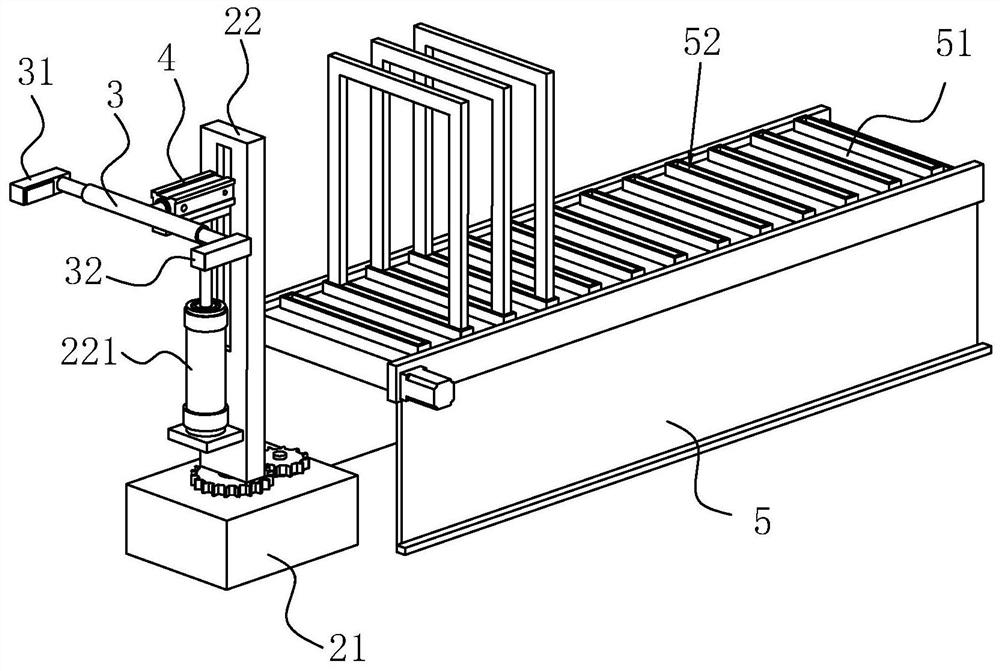

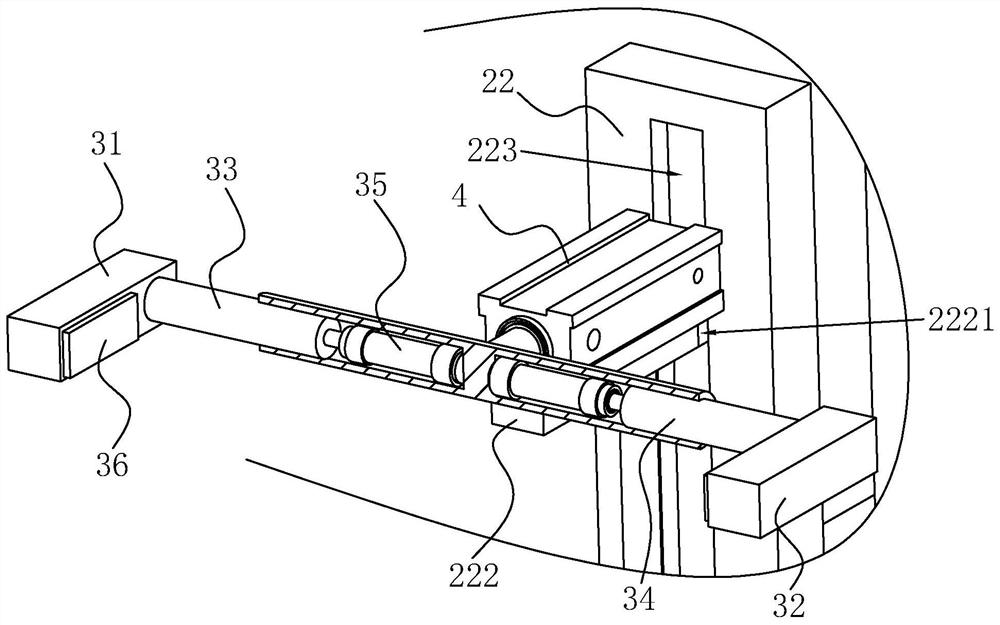

Hollow glass production line

PendingCN111732347APaste accuratelySave human effortCharge manipulationUnits with parallel planesPhysicsElectric machinery

The invention relates to a hollow glass production line, and belongs to the field of glass production equipment. The production line comprises a feeding section, a cleaning chamber, a pasting section,a pressing chamber, a discharging section and a conveying device used for conveying glass, wherein a pasting device for pasting an aluminum frame is arranged at the position of the pasting section; the pasting device comprises a base; a supporting column is rotationally connected to the base; a clamping device used for clamping the aluminum frame is arranged on the supporting column; a pushing device is arranged between the supporting column and the clamping device and used for enabling the clamping device to move towards or away from the supporting column; and a first motor used for drivingthe supporting column to rotate is arranged on the base. The production line has the effects that an aluminum frame can be conveniently pasted to glass, and manpower is saved.

Owner:四川安能玻璃有限公司

Labeling machine

The invention provides a labeling machine, and relates to the technical field of labeling equipment. The labeling machine comprises a conveying module, a visual system, a manipulator and a labeling head; the conveying module comprises a labeling area; the visual system is arranged above the labeling area, and can detect the information and the position of infusion bags; the manipulator is arrangedbeside the conveying module; and the labeling head is mounted on the manipulator, and can be driven by the manipulator to paste labels on the infusion bags. The labeling machine solves the technicalproblems of regular placement of the infusion bags during loading of a labeling machine in the prior art and incapability of identifying consistence between the information of the infusion bags with the labels and the information on the labels extracted by the labeling head by the labeling machine.

Owner:海尔生物医疗科技(苏州)有限公司

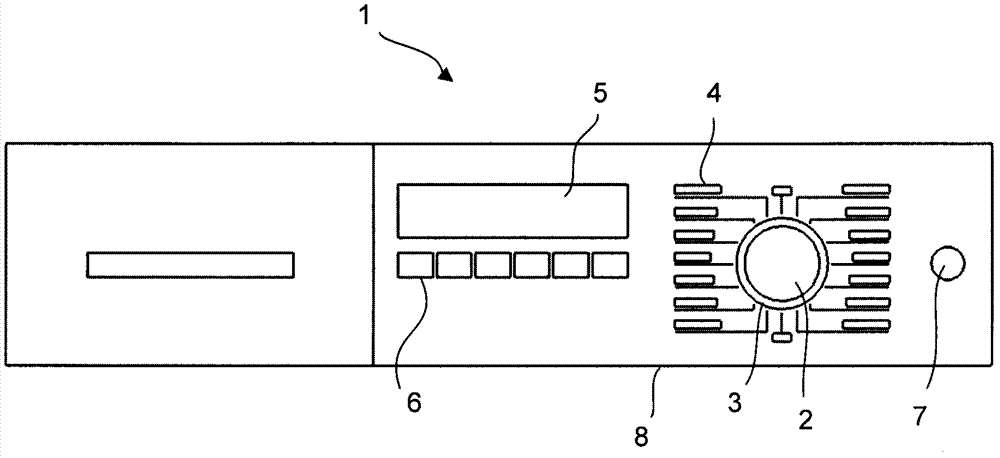

Film for control panel of household appliance and pasting method of film

ActiveCN103361936APaste accuratelyPaste convenient and accurateOther washing machinesTextiles and paperEngineering

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

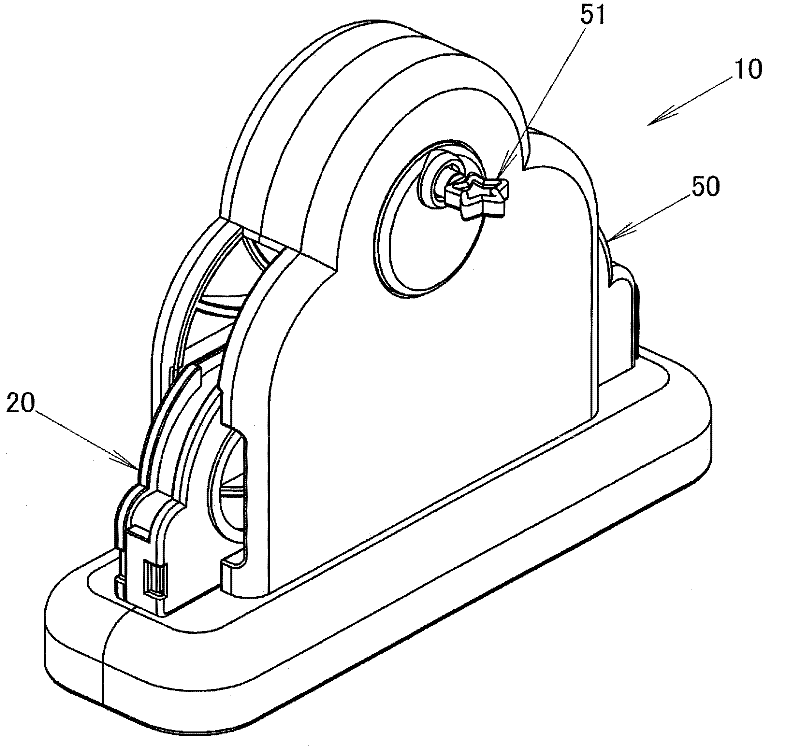

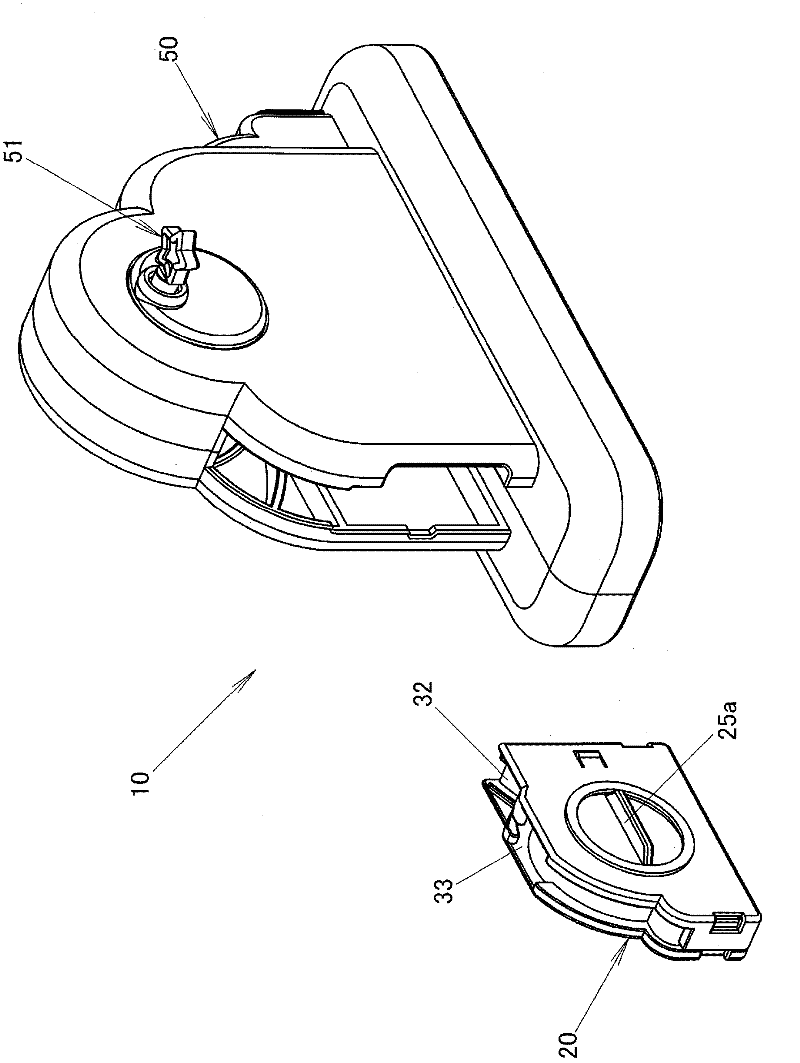

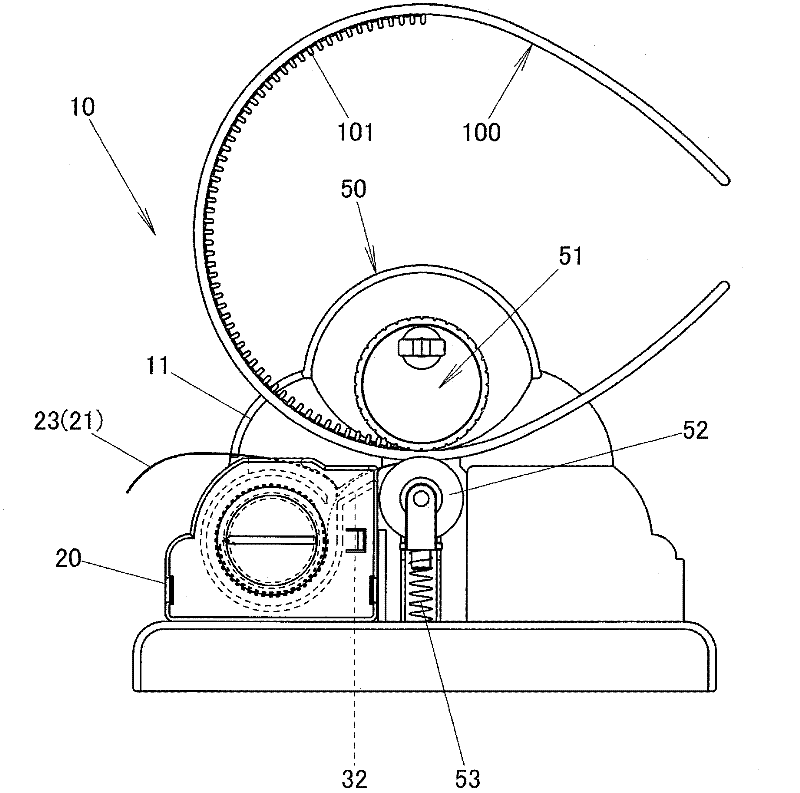

Tape affixing apparatus for band-shaped accessory

InactiveCN102602576AEasy to installPaste accuratelyManual label dispensersDecorative surface effectsBand shapeEngineering

Owner:EPOCH CO

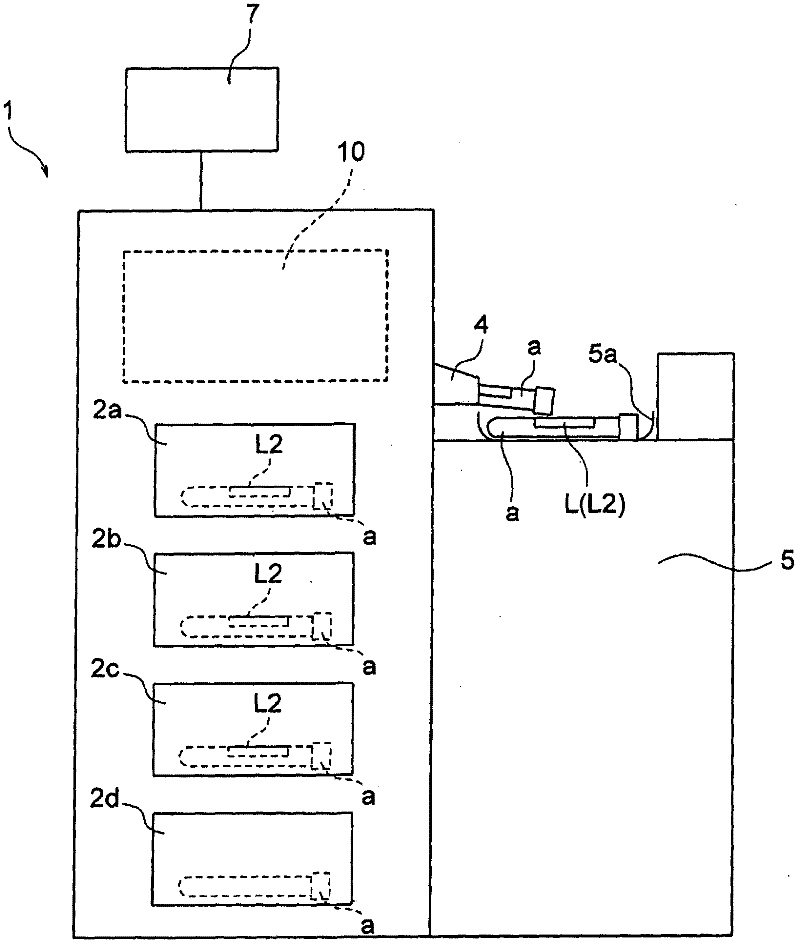

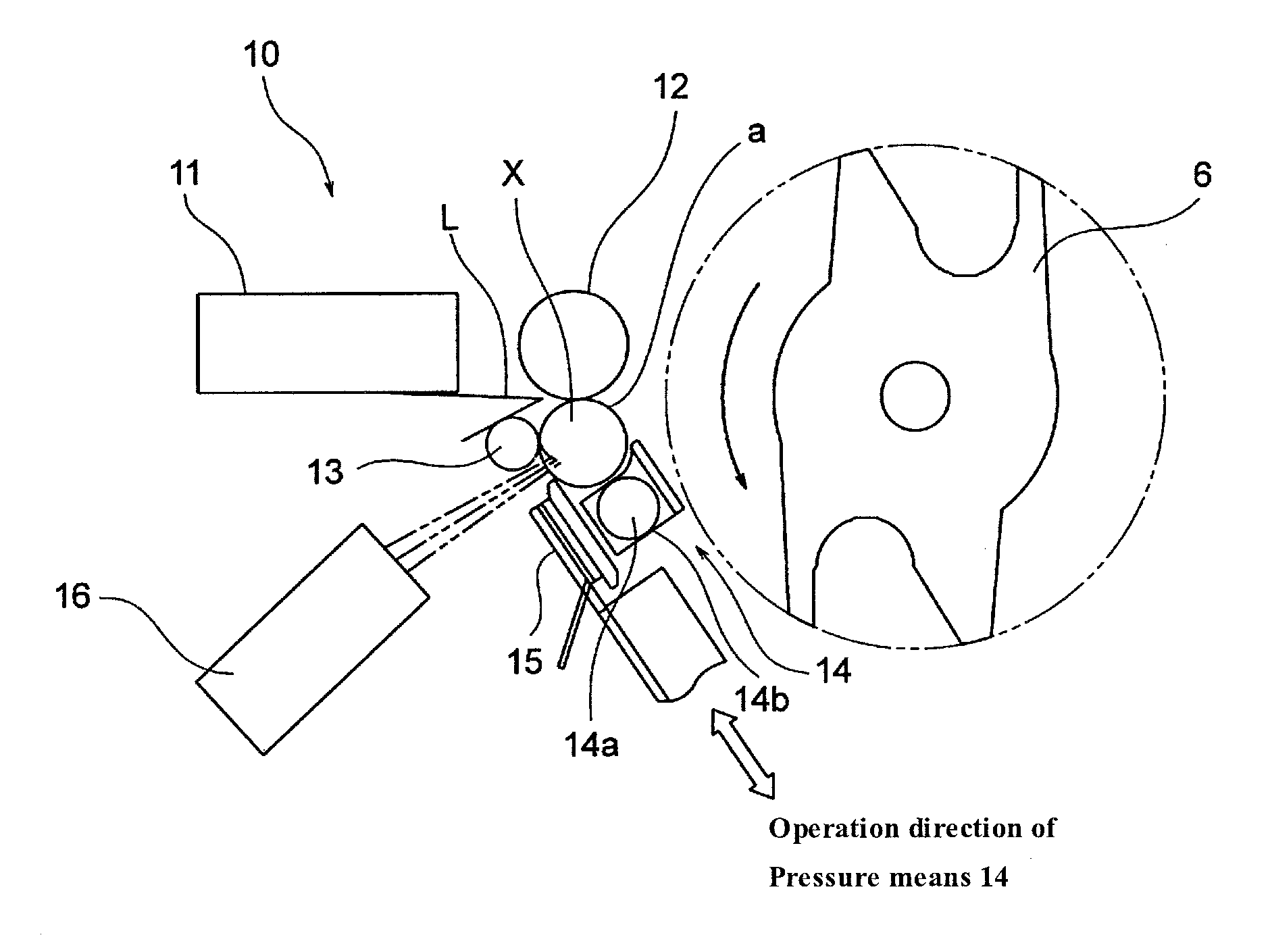

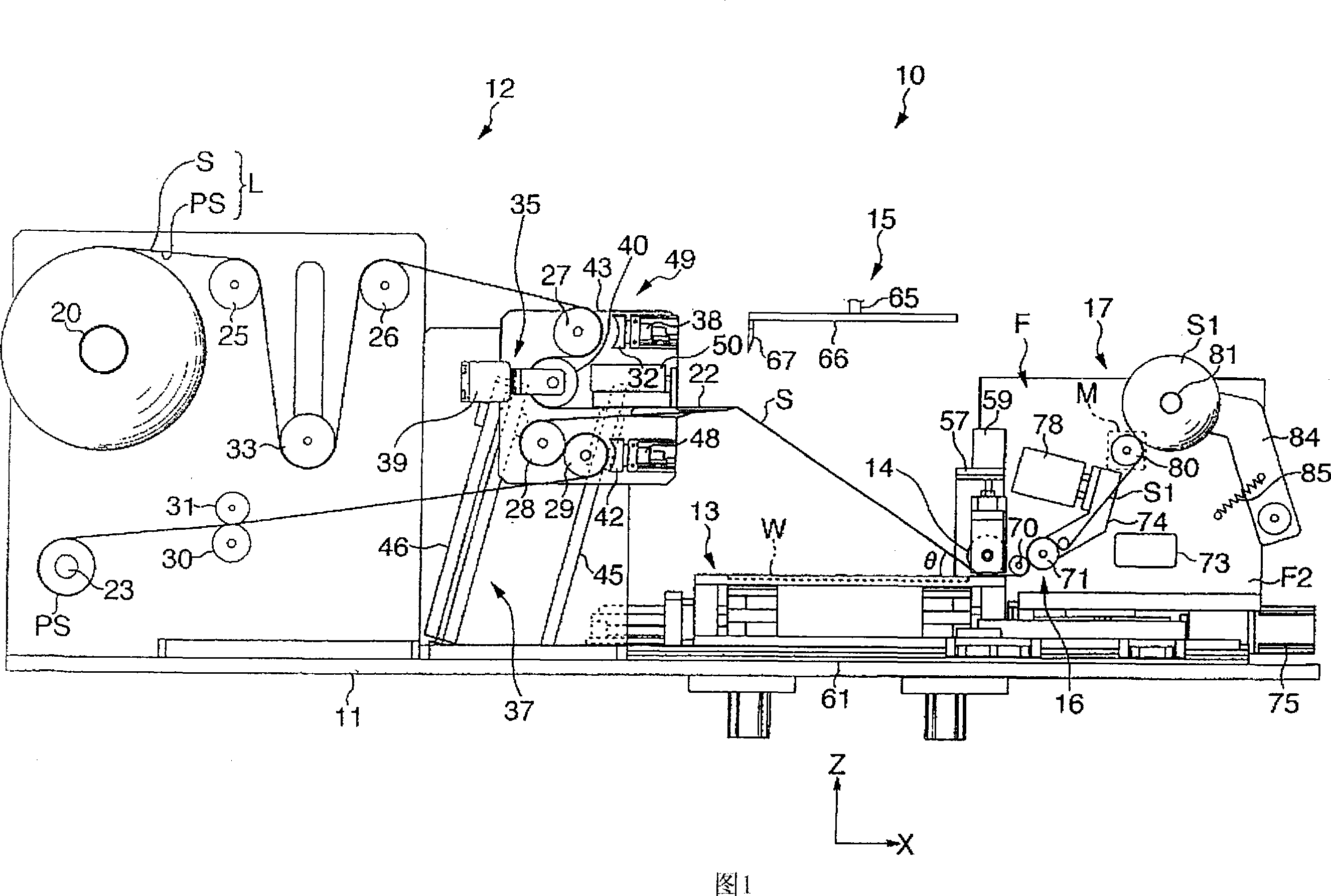

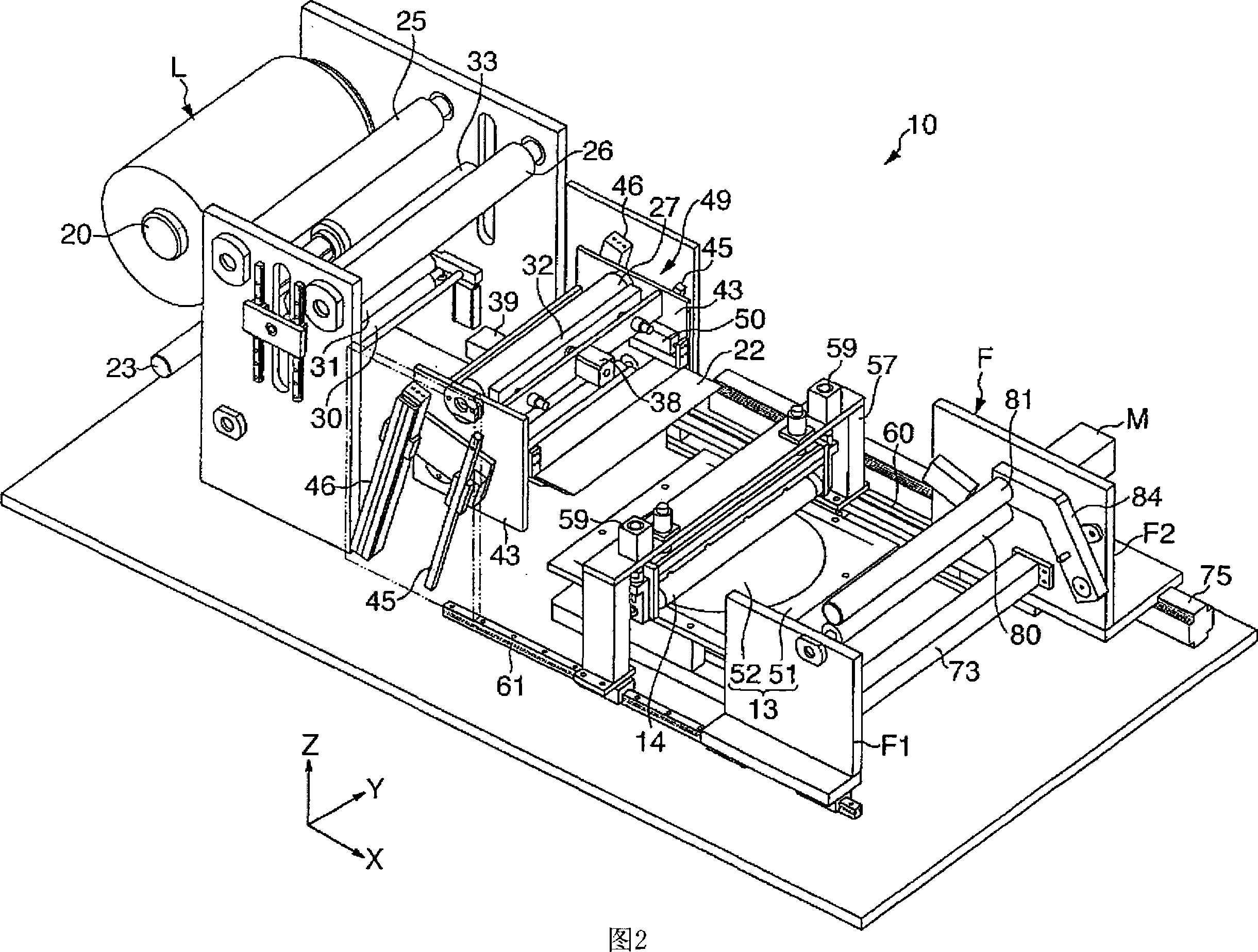

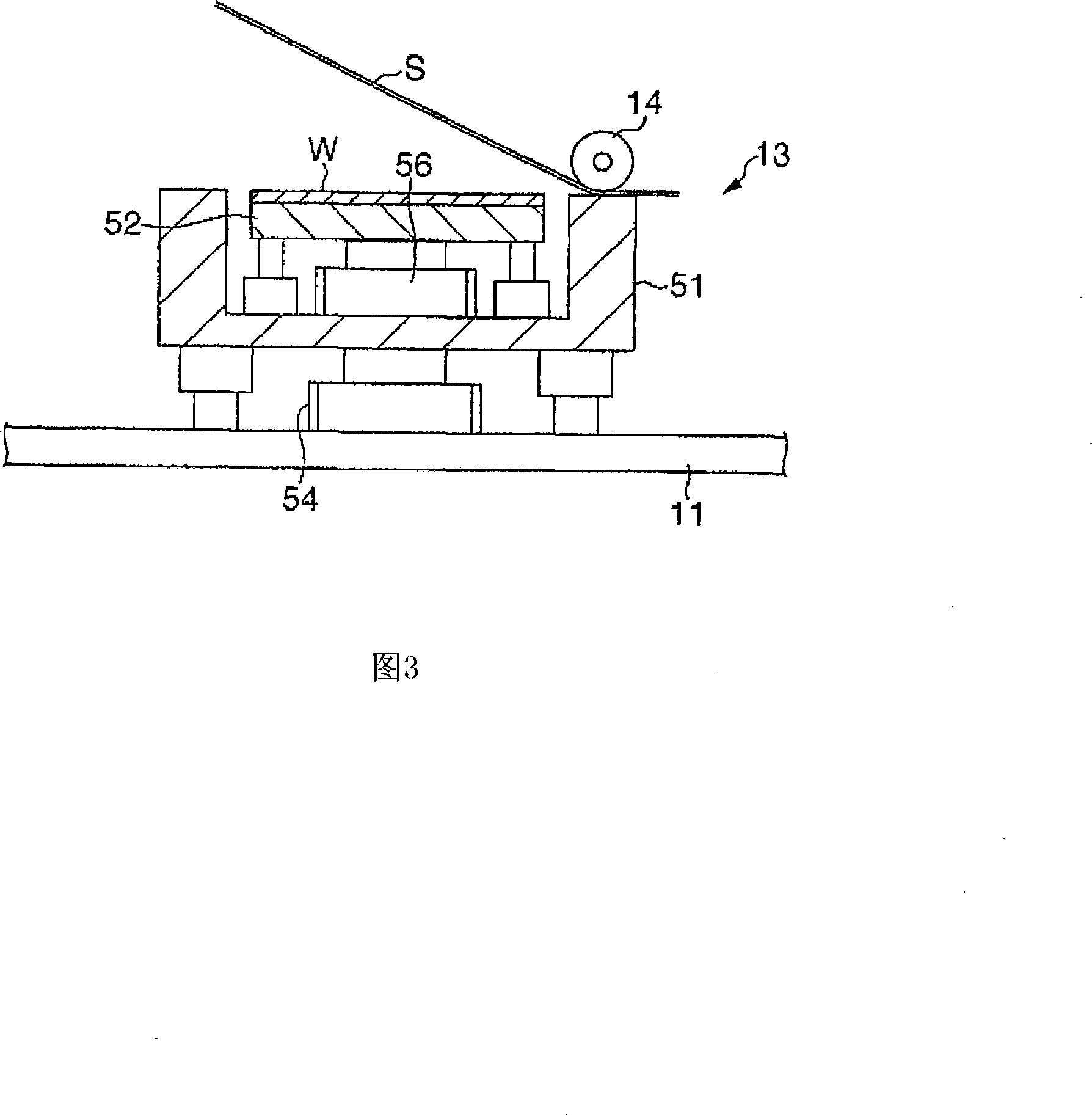

Sheet adhering apparatus

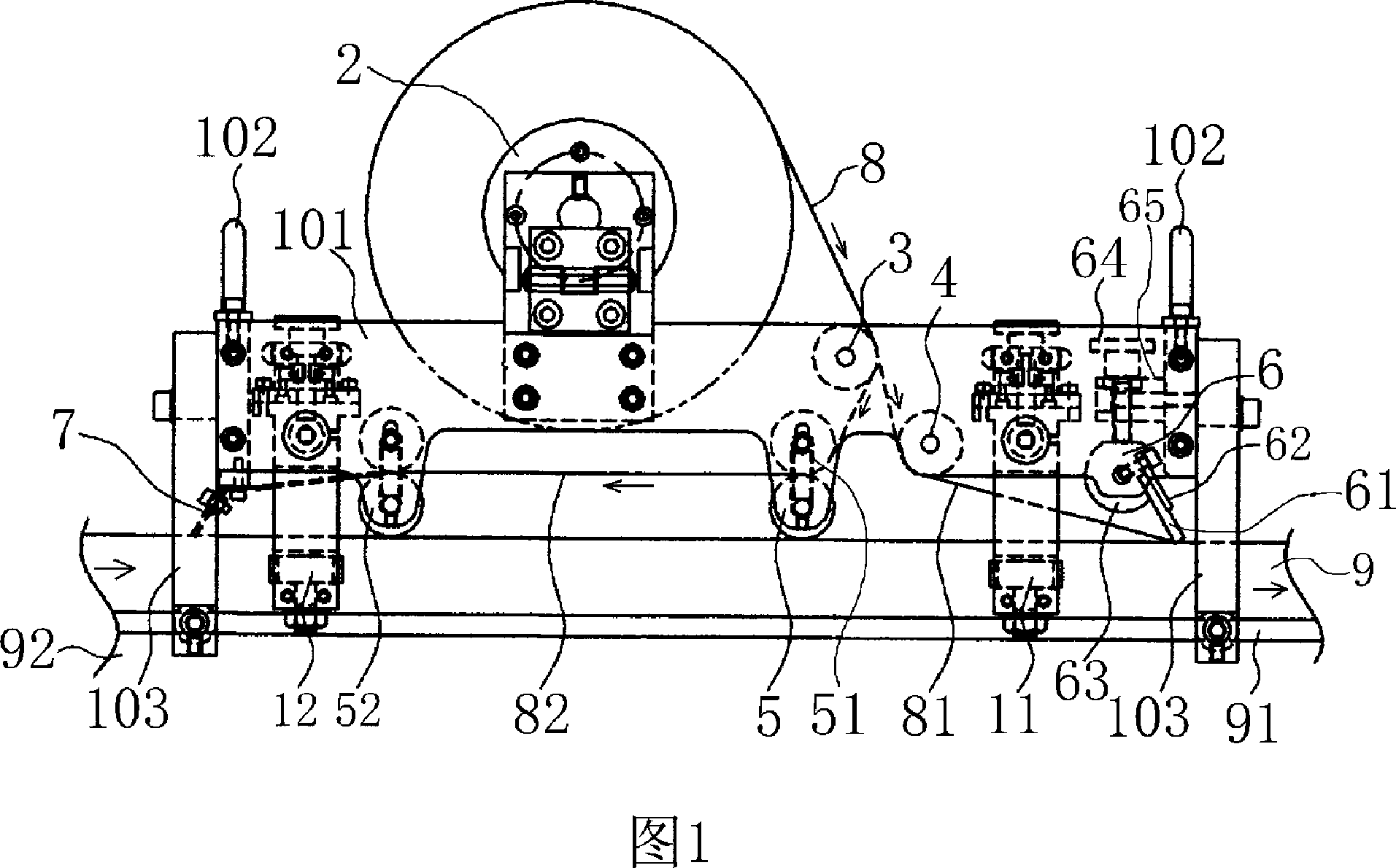

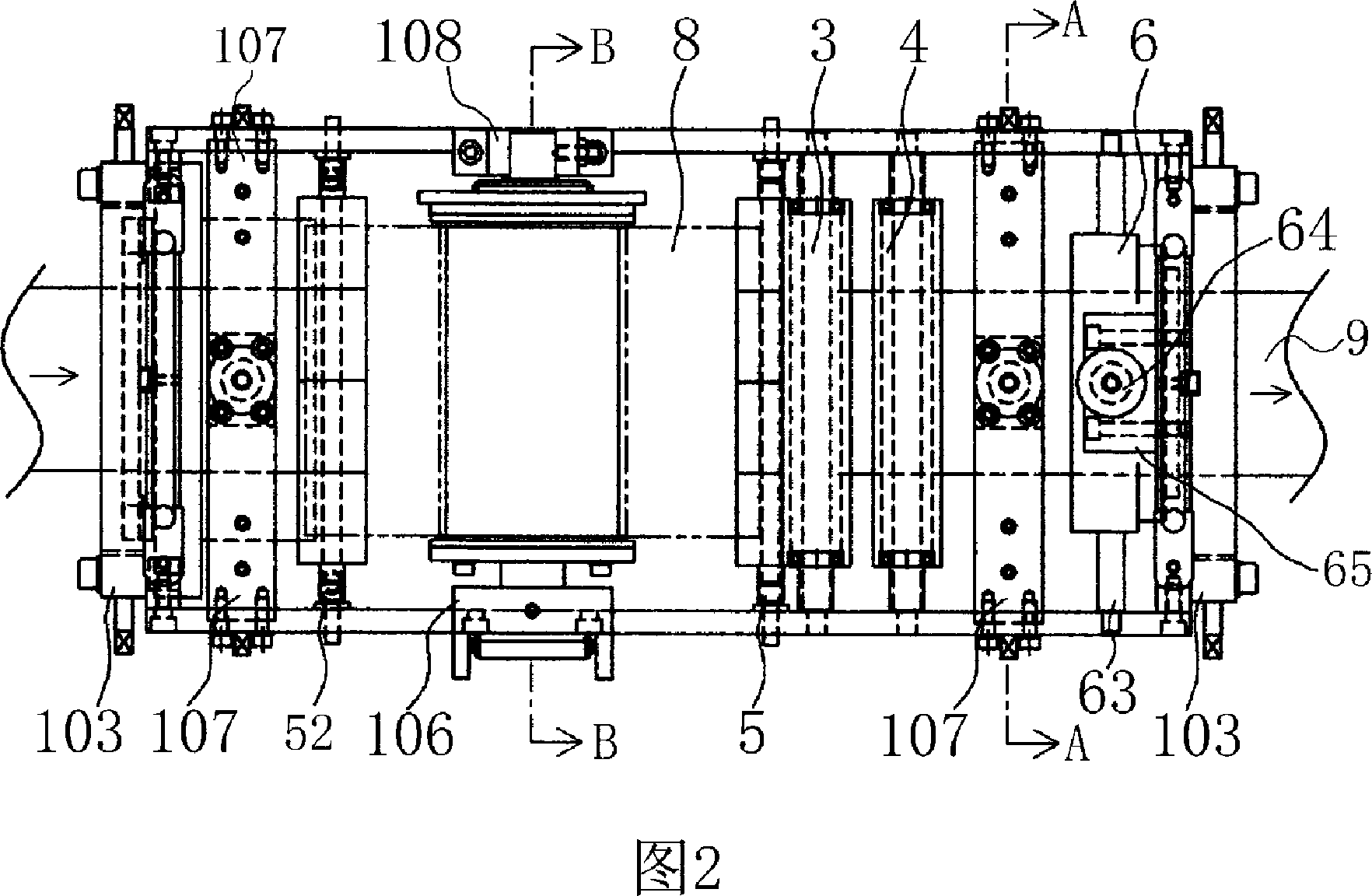

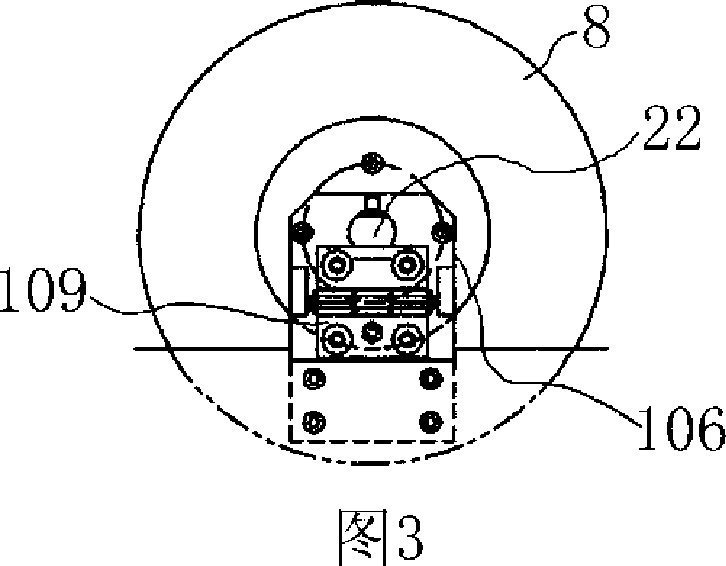

ActiveCN101213646AImplement bootstrap actionAvoid wastingSemiconductor/solid-state device manufacturingAdhesivesEngineeringMechanical engineering

A sheet adhering apparatus is provided with a sheet feeding unit (12) which includes a peel plate (22) for peeling an adhesive sheet (S) from a peeling sheet (PS), and a pressing roller (14) for pressing and adhering the adhesive sheet (S) to the wafer (W) supported by a table (13). The peel plate (22) is supported to move forward and backward by means of a cylinder (50). The initial position of the leading end of the peel plate (22) is adjusted to the front and rear in accordance with the size of the wafer (W) or the size of the table which supports the wafer (W).

Owner:LINTEC CORP

Small bore inner wall strain foil pasting method for rock stress releasing test and apparatus thereof

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Intelligent card packaging machine

The invention discloses an intelligent card packaging machine which comprises a rack, a device for packaging an intelligent card and a specification at the same time, a position detecting mechanism for position detection, an edge cutting device and a card collecting device. The device for packaging the intelligent card and the specification at the same time comprises a specification conveying mechanism, a gluing mechanism and a card conveying mechanism. The position detecting mechanism comprises a fixed frame, a rotary assembly rotationally connected with the fixed frame and a position detecting assembly. The edge cutting device comprises a blade assembly and an air suction belt for sucking a film belt. The card collecting device comprises a card collecting support, a conveying device anda collecting device. The intelligent card packaging machine can put the intelligent card the specification in the film belt to be packaged at the same time, and meanwhile whether the intelligent cardor the specification is located at the proper position in the film belt or not can be detected; and redundant sealing edges at the front end and the rear end of the sealed film belt can be automatically cut off, and finally the packaged intelligent card is folded and collected automatically, and the packaging effect is better.

Owner:GUANGZHOU MINGSEN TECH CO LTD

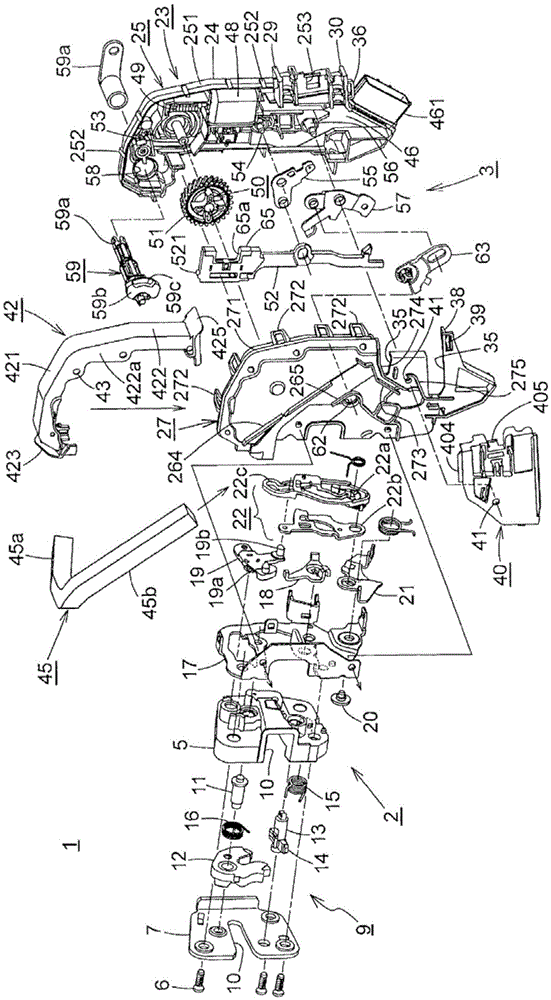

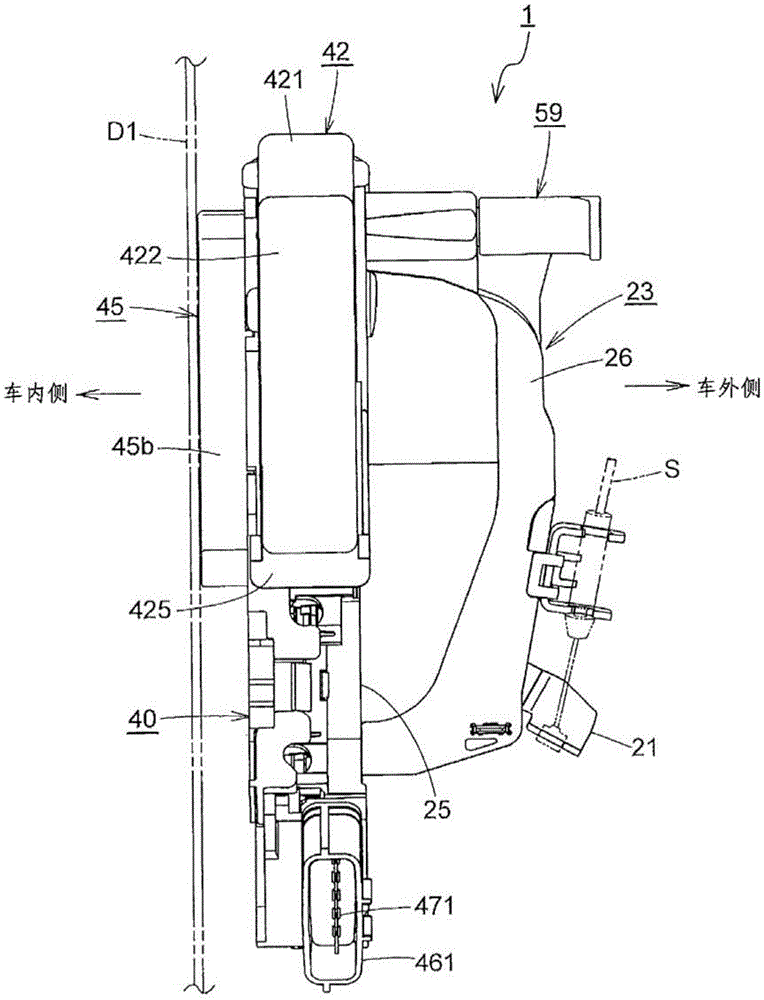

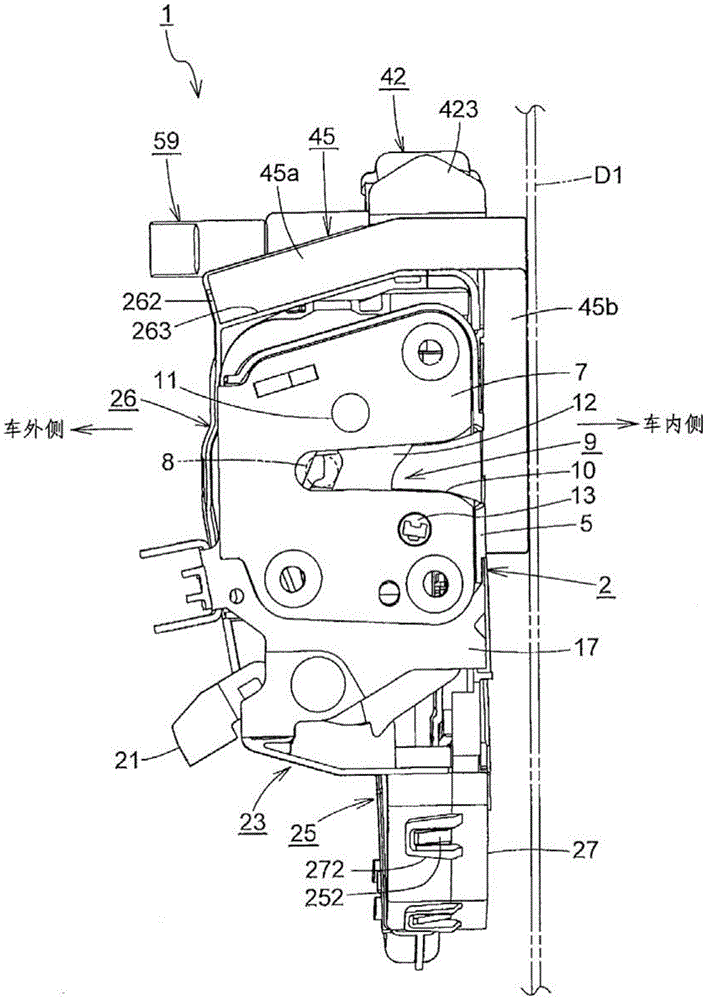

Binding tool

ActiveCN105593443AImprove workabilityPaste clearPower transmission/actuator featuresElectrical locking circuitsEngineering

Owner:MITSUI KINZOKU ACT

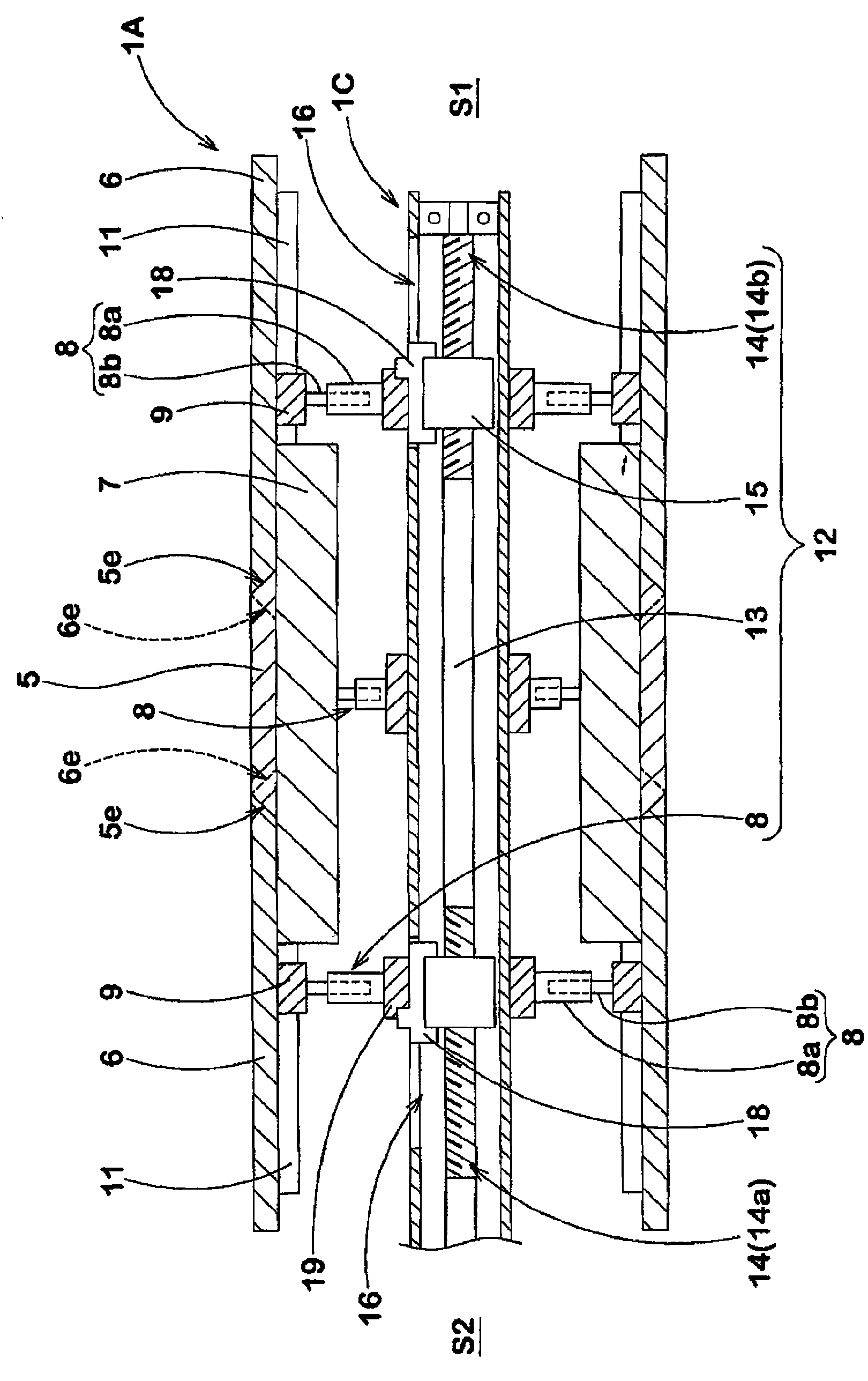

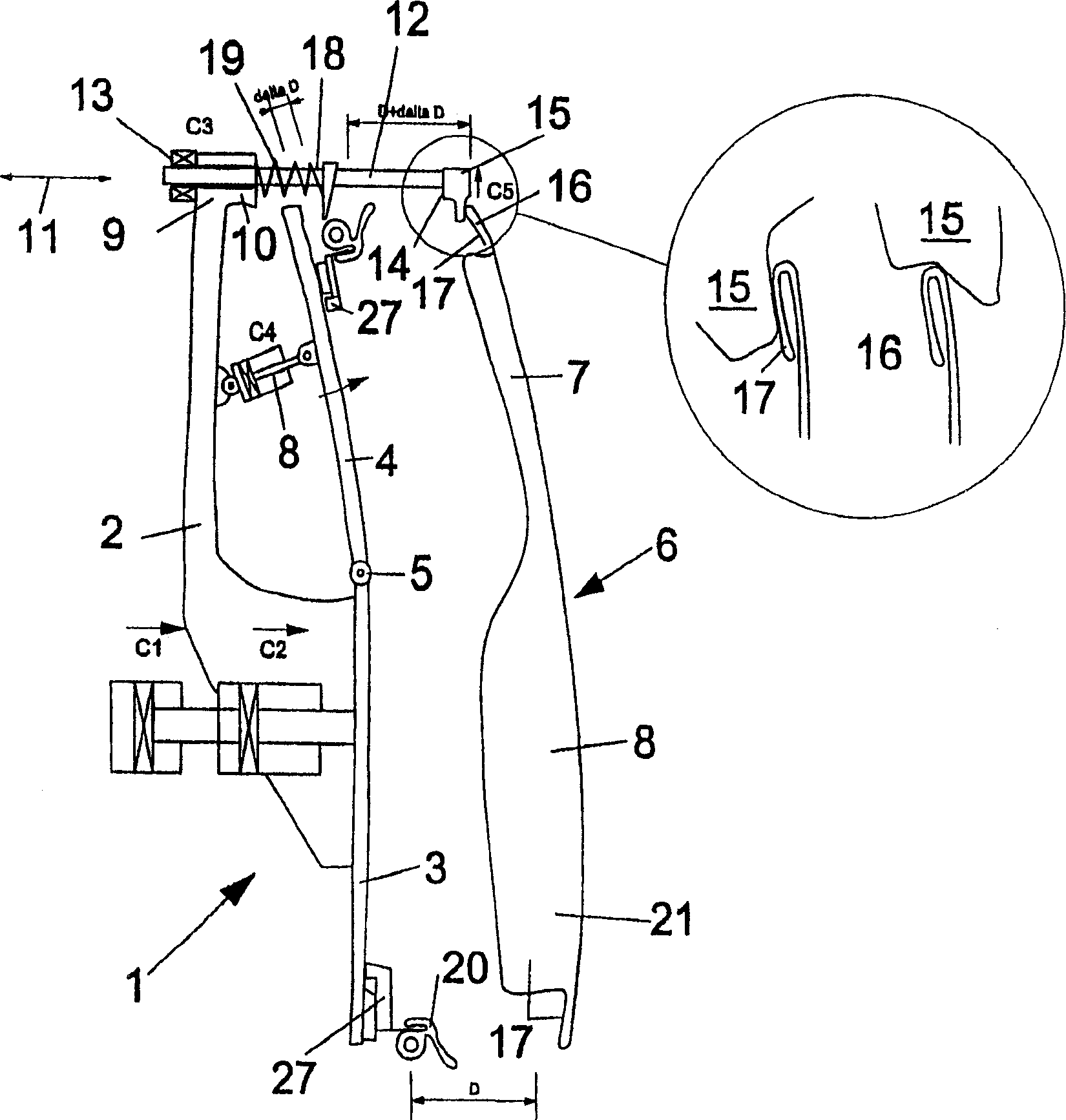

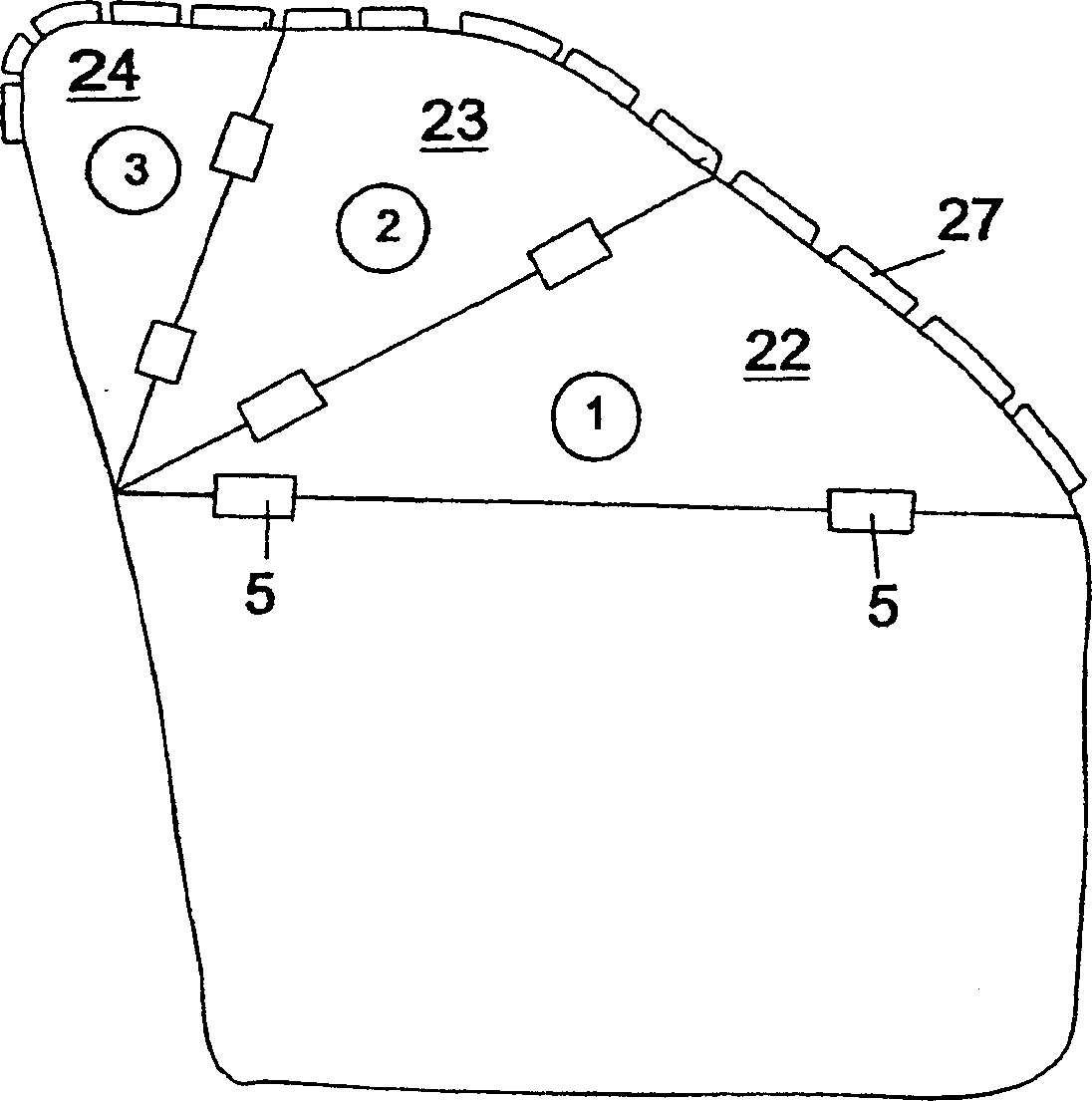

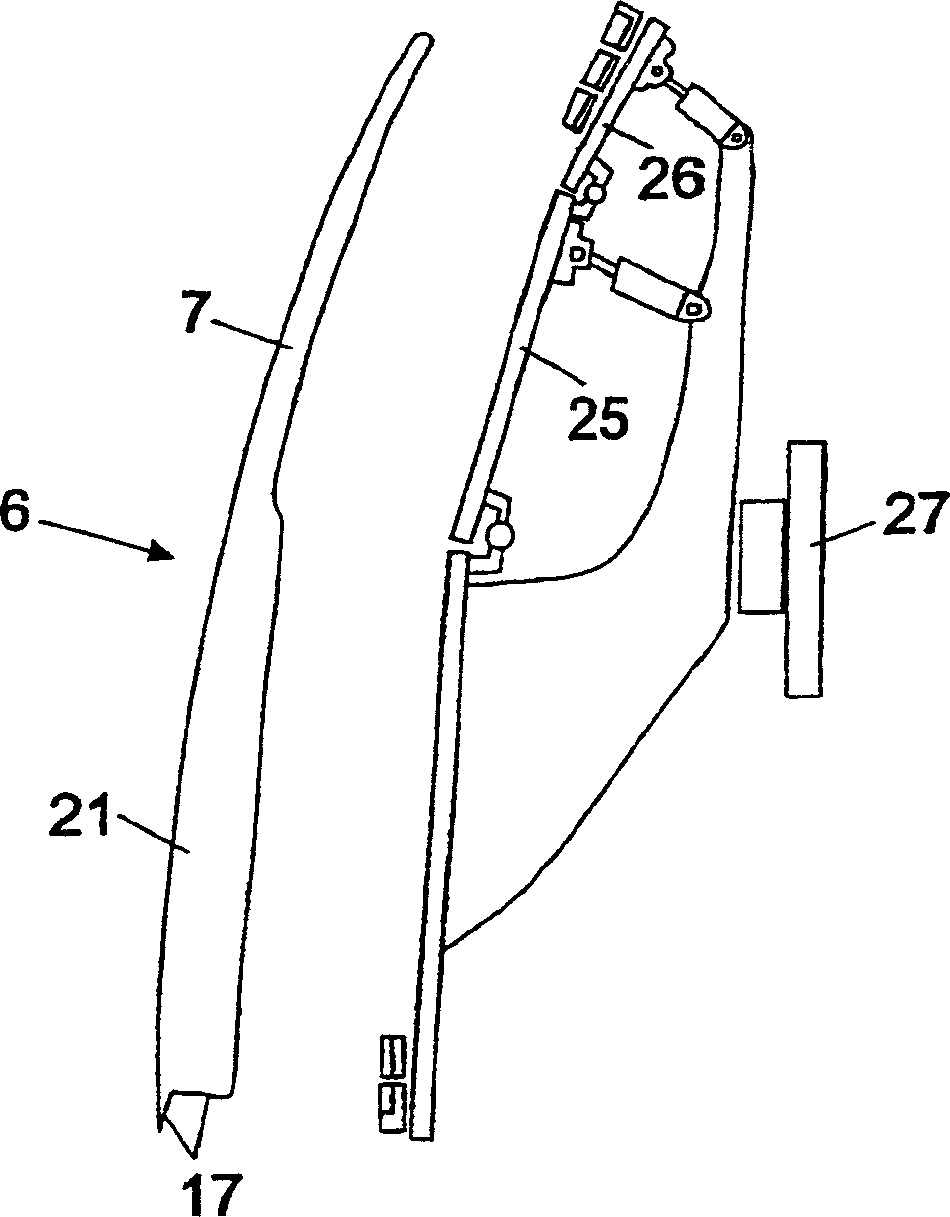

Device for mounting sealing strips on vehicle doors

InactiveCN1298499CPaste accuratelyEngine sealsVehicle sealing arrangementsMotor vehicle partEngineering

At least one installation plate is mounted on a base frame, every installation plate having at least one movable plate segment and means for changing the position of every movable plate segment. In order to exactly position the sealing strip to be bonded relative to the installation surface of the vehicle door, every movable plate segment is associated with a reference plunger that is mounted on the base frame so as to be displaceable in the axial direction. The reference plunger extends from the base frame in the direction of the movable plate segment and can be locked relative to the base frame. The reference plunger has on one end an adjustable cam that can be brought into the released from engagement with the vehicle part. At a distance from the cam, the reference plunger is provided with a stationary stop against which the associated plate segment can be moved.

Owner:特斯拉戈珞曼自动化有限责任公司

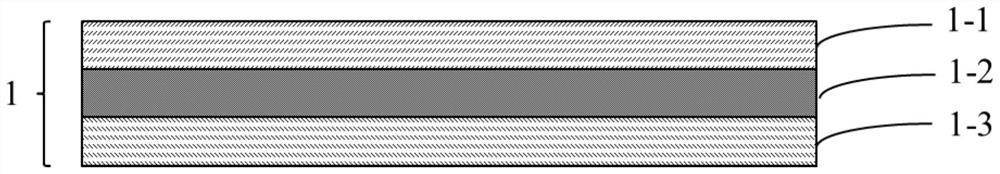

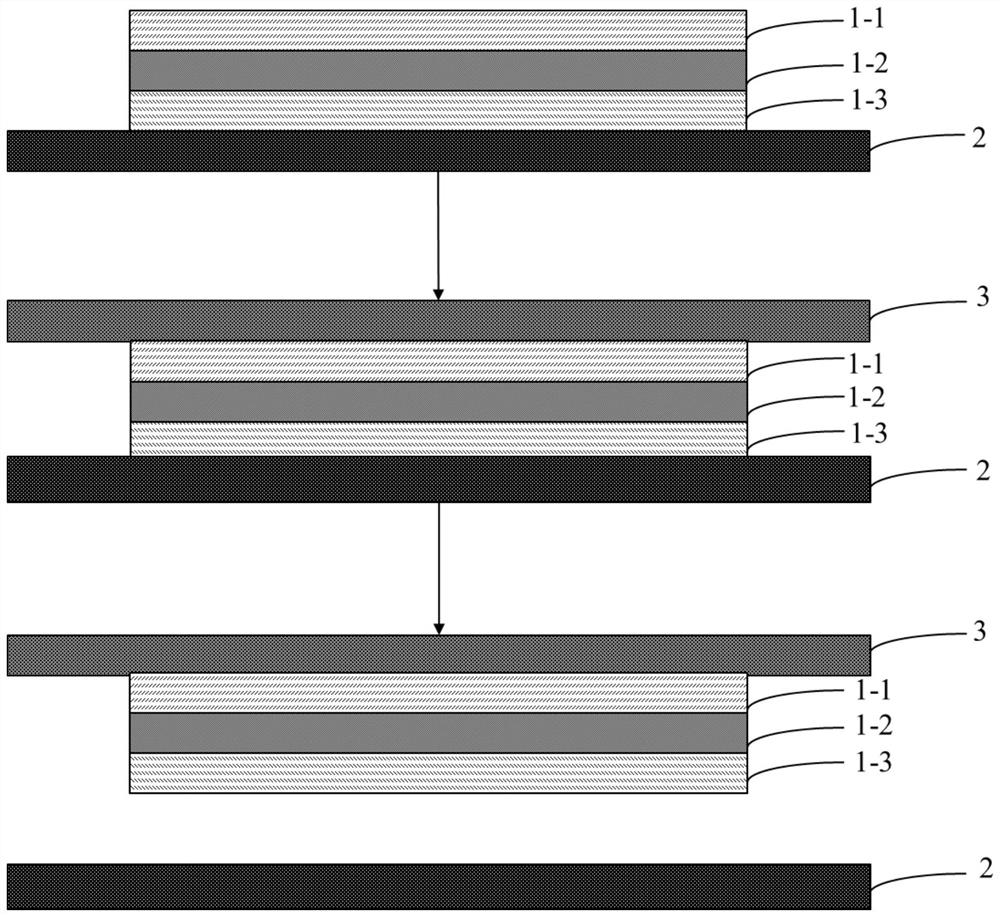

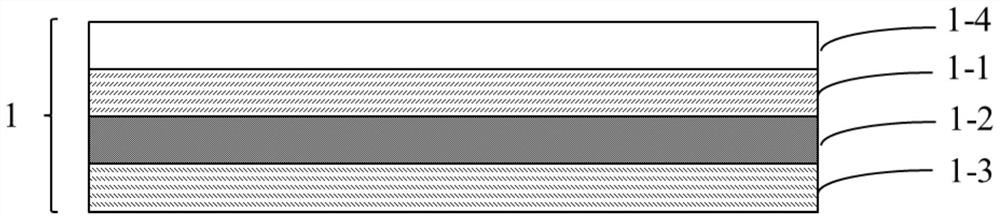

Double-sided adhesive tape and lithium ion battery

PendingCN113683974AEffective pastePaste accuratelyCell component detailsPressure sensitive film/foil adhesivesPhysical chemistrySilicone tape

The invention provides a double-sided adhesive tape and a lithium ion battery. The invention provides a double-sided adhesive tape. The double-sided adhesive tape comprises a first bonding layer, a base material layer and a second bonding layer which are sequentially stacked. The first bonding layer comprises one or more of organic silicon binders, epoxy binders, polyurethane binders, polyacrylic acid binders and rubber binders, and the bonding strength of the first bonding layer is larger than that of the second bonding layer. The double-sided adhesive tape provided by the invention comprises the two bonding layers, and the bonding strength of the first bonding layer is greater than that of the second bonding layer, so that the double-sided adhesive tape can be effectively and accurately bonded on the surface of a light soft material in a manner of transferring an object to assist in adhesive tape bonding, and the problems of wrinkling, poor positioning, bubbles and the like in adhesive tape bonding are effectively solved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com