Method and equipment for quantitatively distributing adhesion agent onto heat radiator fin, and positioning adhesion therefor

A heat sink and adhesive technology, which is applied in the direction of surface coating liquid devices, coatings, electrical components, etc., can solve the problem of difficult control of the amount of adhesive 2 coating, skewed angle of heat sink 1, position shift, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

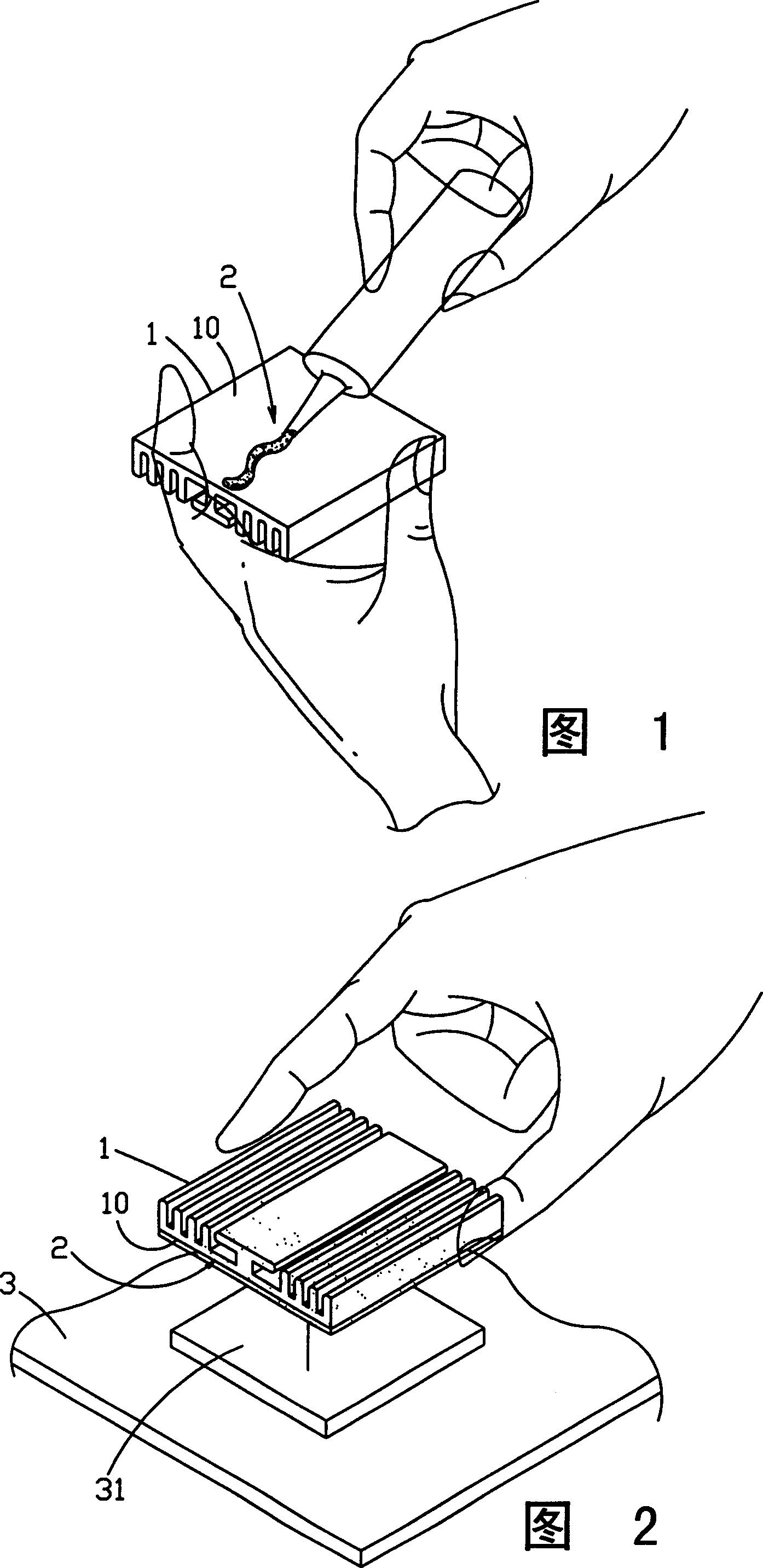

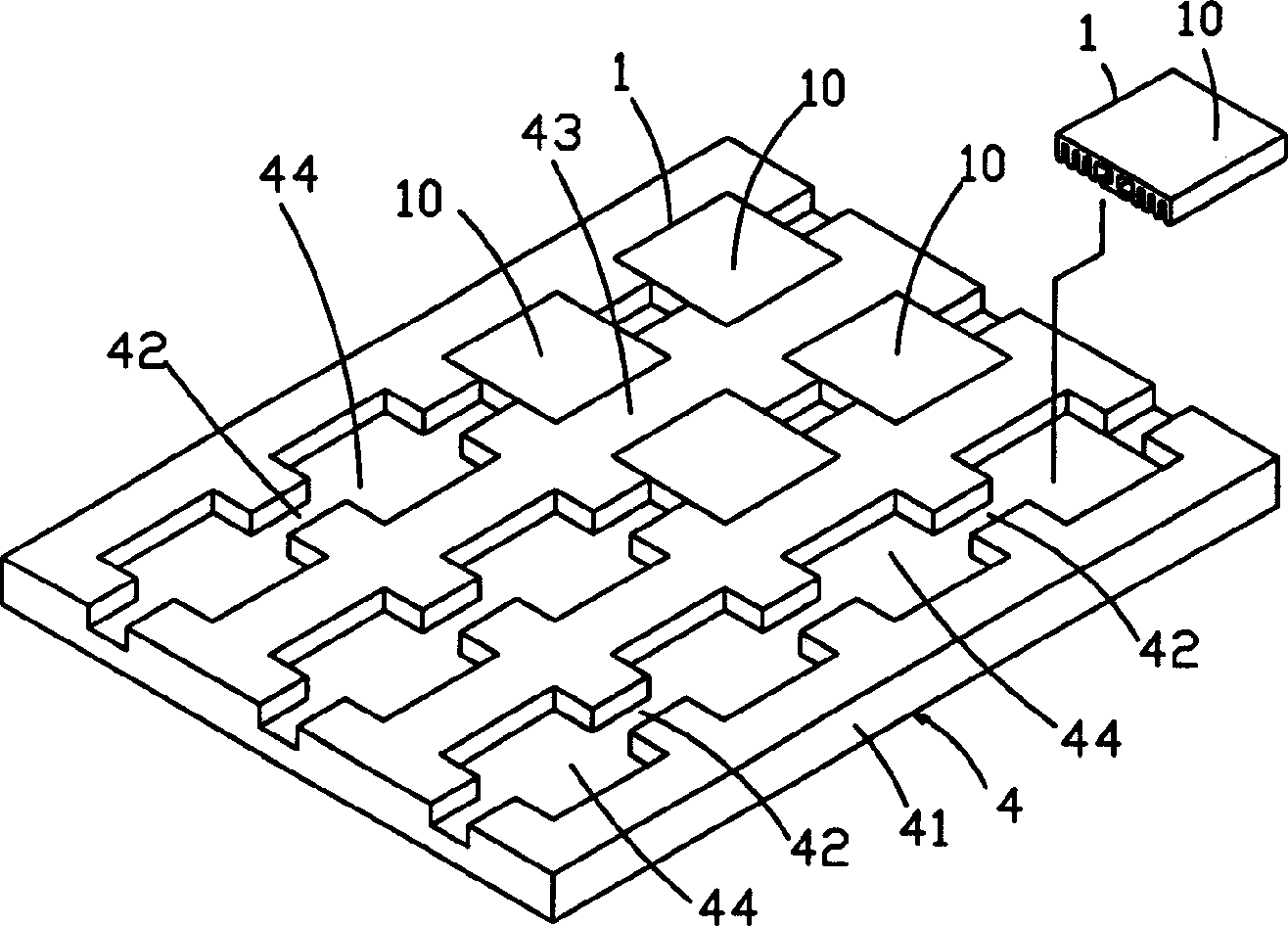

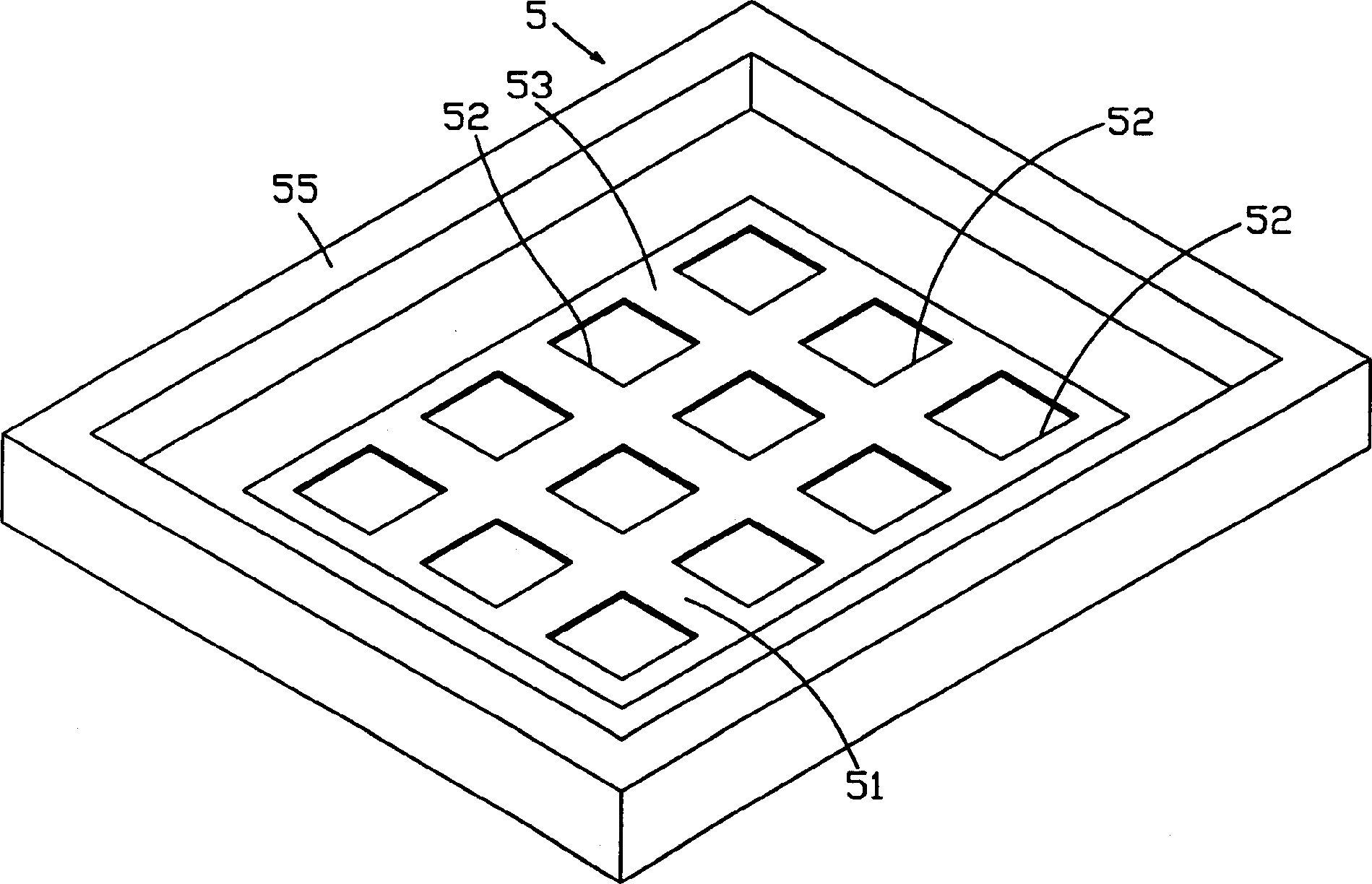

[0019] refer to image 3 , 4 , 5 and 6, the method of quantitatively coating the heat sink 1 with the adhesive 2 and positioning and pasting it on the chip 31 of the circuit board 3 in a preferred embodiment of the present invention includes the following steps:

[0020] Step (1) is to place a plurality of cooling fins 1 with an adhesive surface 10 facing upwards, and arrange them in a tiled manner in a plurality of accommodating spaces 44 of a first positioning tool 4 . The first positioning tool 4 is in the shape of a rectangular plate with a top plane 43, and the accommodating space 44 is formed by recessing downwards on the top plane 43, and the size of each accommodating space 44 is the same as The shape and thickness of the heat sink 1 correspond to accommodate the heat sink 1. In this embodiment, after the heat sink 1 is placed in the accommodating space 44, its adhesive surface 10 is flush with the top plane 43, and A receiving slot 42 is provided between adjacent rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com