Electrode plate winding apparatus

A winding device and pole piece technology, applied in sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve the problems of low pass rate, position deviation, low battery production efficiency, etc., to improve production efficiency , The effect of improving the process speed and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

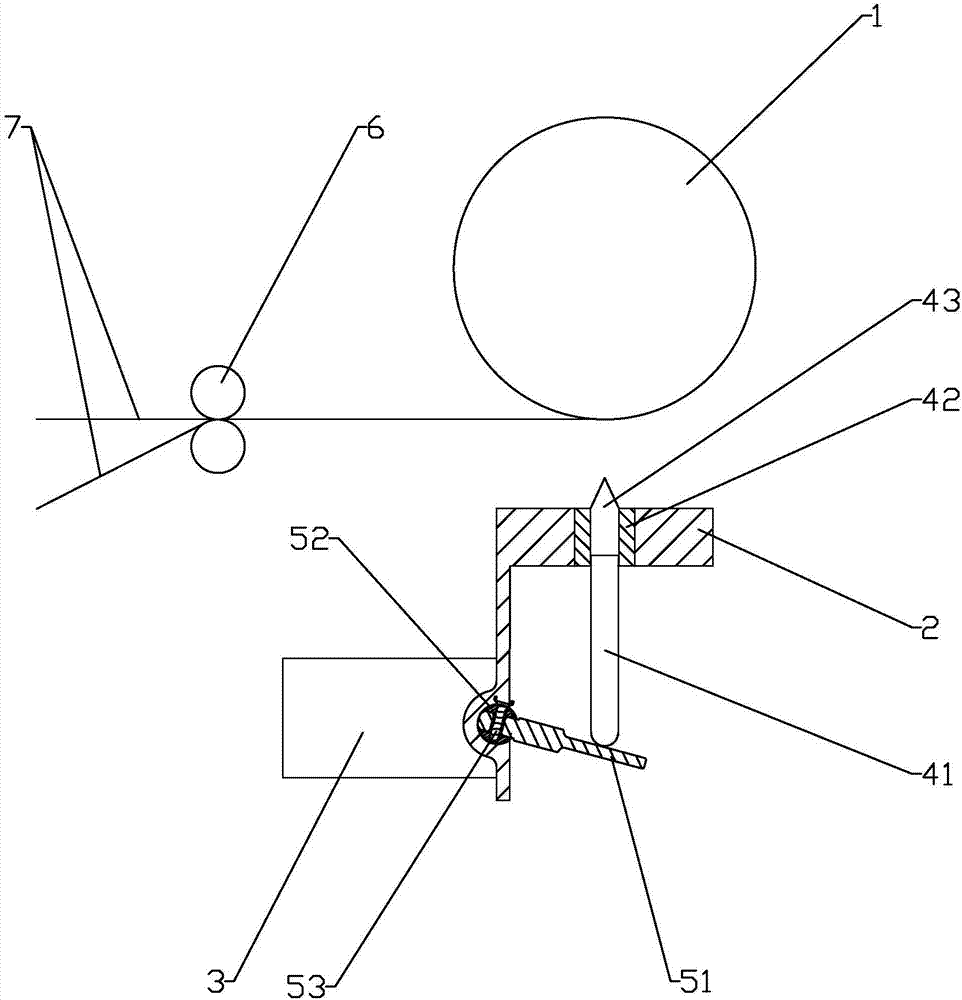

[0014] Such as figure 1 As shown, a pole piece winding device includes a winding machine, and the winding machine includes a mandrel 1 for winding a positive pole piece, a separator 7 and a negative pole piece, and also includes a mounting bracket 2, a driving mechanism 3 and a The diaphragm 7 is bonded on the surface of the mandrel 1 by means of heating and welding. The mandrel 1 is arranged horizontally. 42 and a hot iron head 43, the hot iron head 43 is fixed on the end of the guide rod 41 facing the mandrel 1, the heating ring 42 is installed on the mounting bracket 2 and used to heat the hot iron head 43, the installation The support 2 is provided with a guide through hole, and the guide rod 41 is inserted in the guide through hole; the output end of the drive mechanism 3 is provided with a push rod mechanism, and the push rod mechanism includes a bouncing guide rail for driving the guide rod 41 to move up and down 51 and a rotating shaft 52 that drives the bouncing guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com