Device and method for installing automobile glass rearview mirror seat and bracket

A technology for automotive glass and rearview mirrors, which is used in motor vehicles, transportation and packaging, manipulators, etc., can solve problems such as the inability to meet the bonding position accuracy, and achieve the effects of accurate bonding, high stability and high installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The content of the present invention will be further described below in conjunction with the accompanying drawings.

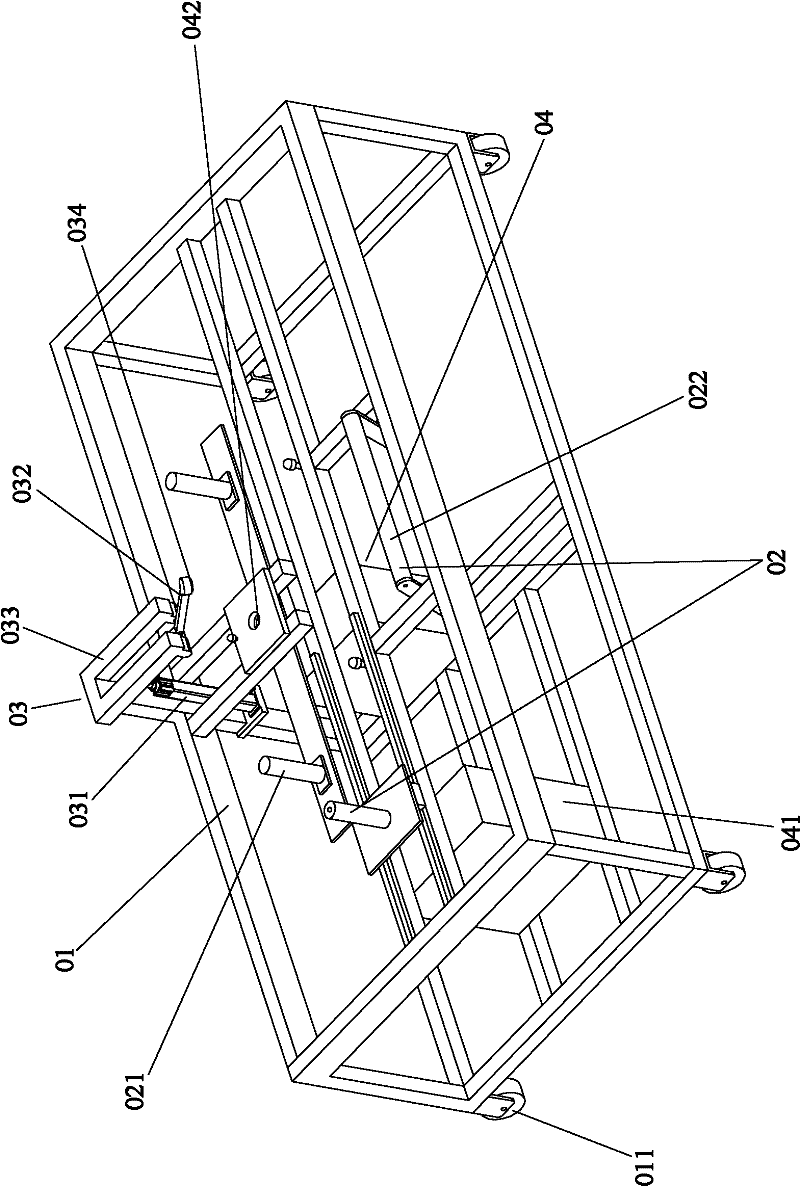

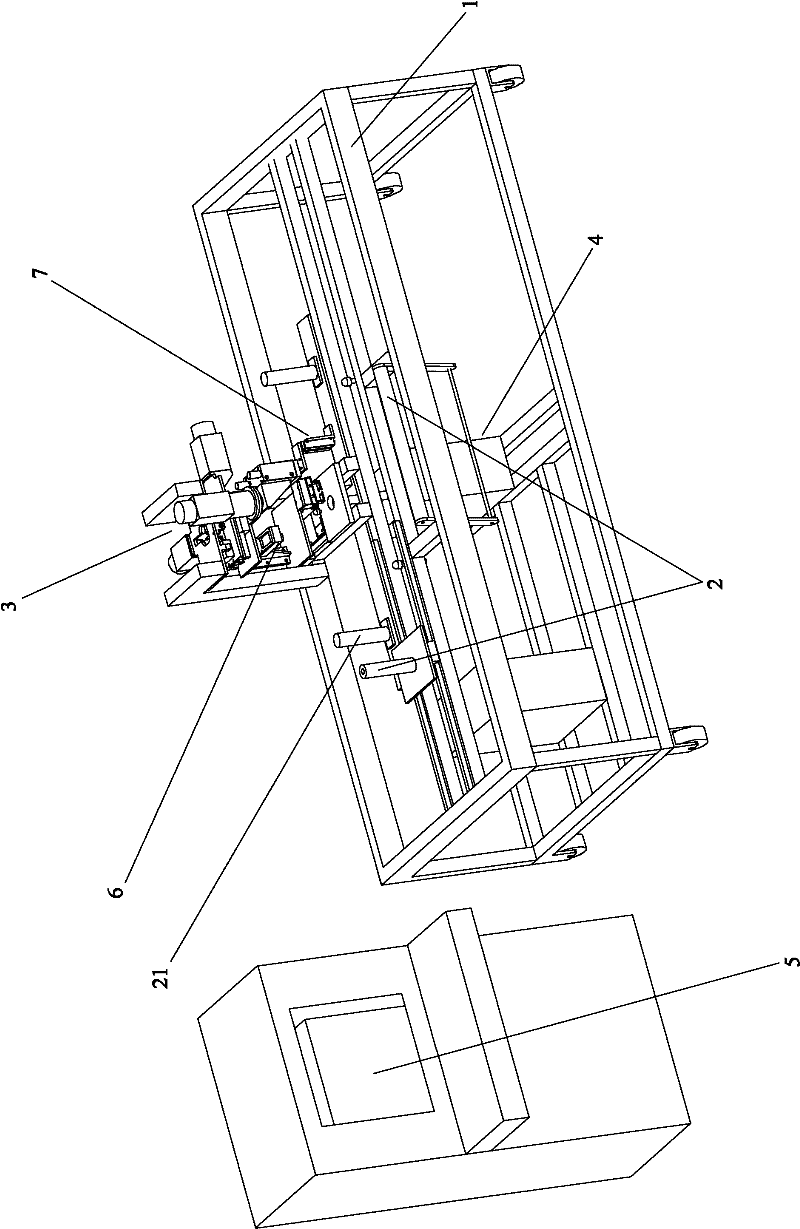

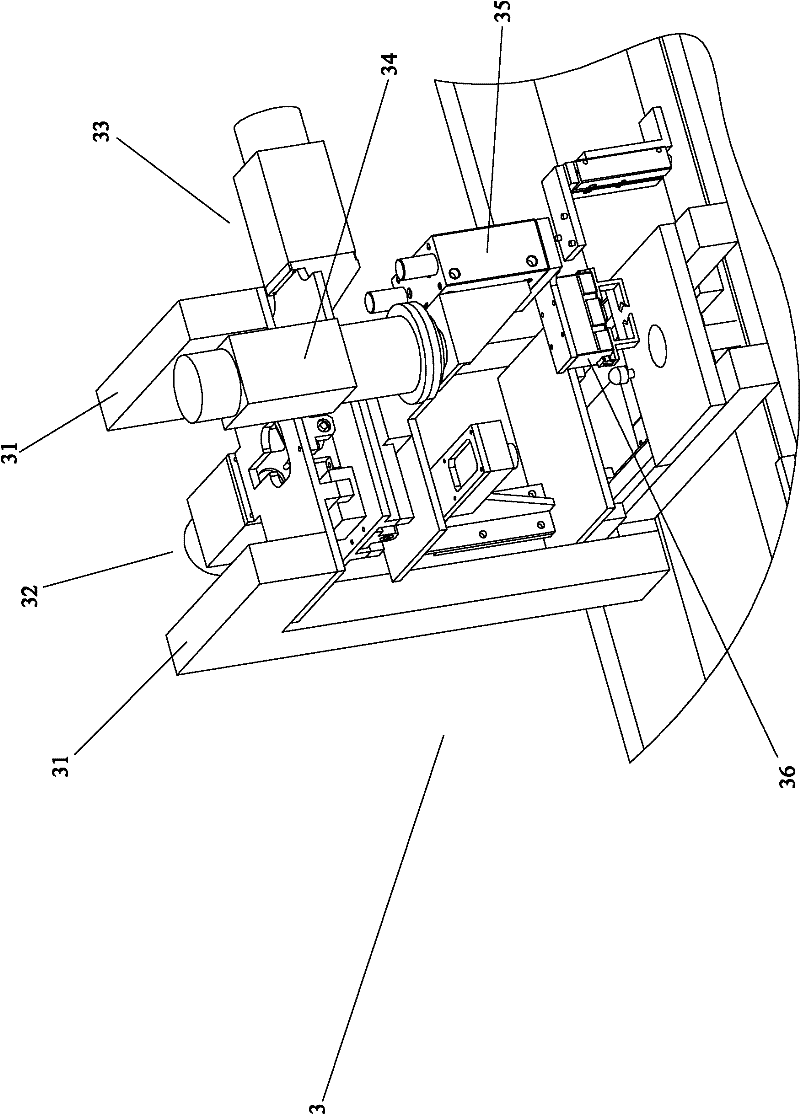

[0045] Such as figure 2 As shown, a device for installing automobile glass rearview mirror bases and brackets includes a frame 1, a pre-positioning mechanism 2, a bonding mechanism 3, a heating mechanism 4, a computer 5, an image acquisition mechanism 6, and a placement mechanism 7.

[0046]The computer 5 is integrated with a data transmission port and a motion control card and an analysis control program is installed, wherein the data transmission port is a data transmission interface, the motion control card is a control interface, and the analysis control program has a positioning analysis function for the bonding mechanism 3 and Automatic adjustment control function, the computer 5 is mainly used to receive and store image data, compare and analyze the received image data through the analysis program, and send and receive control instructions to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com