Automatic production line for insulation oil passage of transformer

An automated production line and transformer technology, applied in the manufacture of inductors/transformers/magnets, electrical components, delivery objects, etc., can solve the problems of unstable product quality, low labor intensity, low labor productivity, etc., to reduce the labor burden of workers, The effect of good product quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

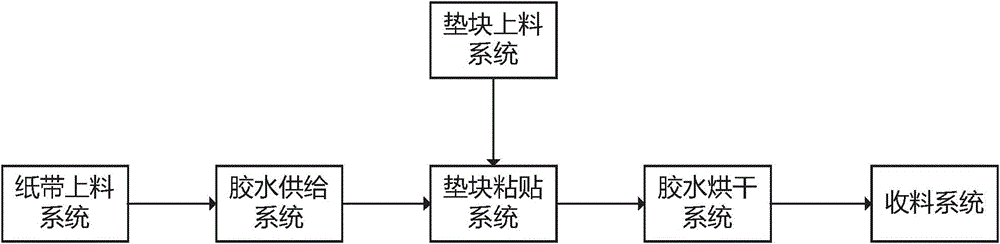

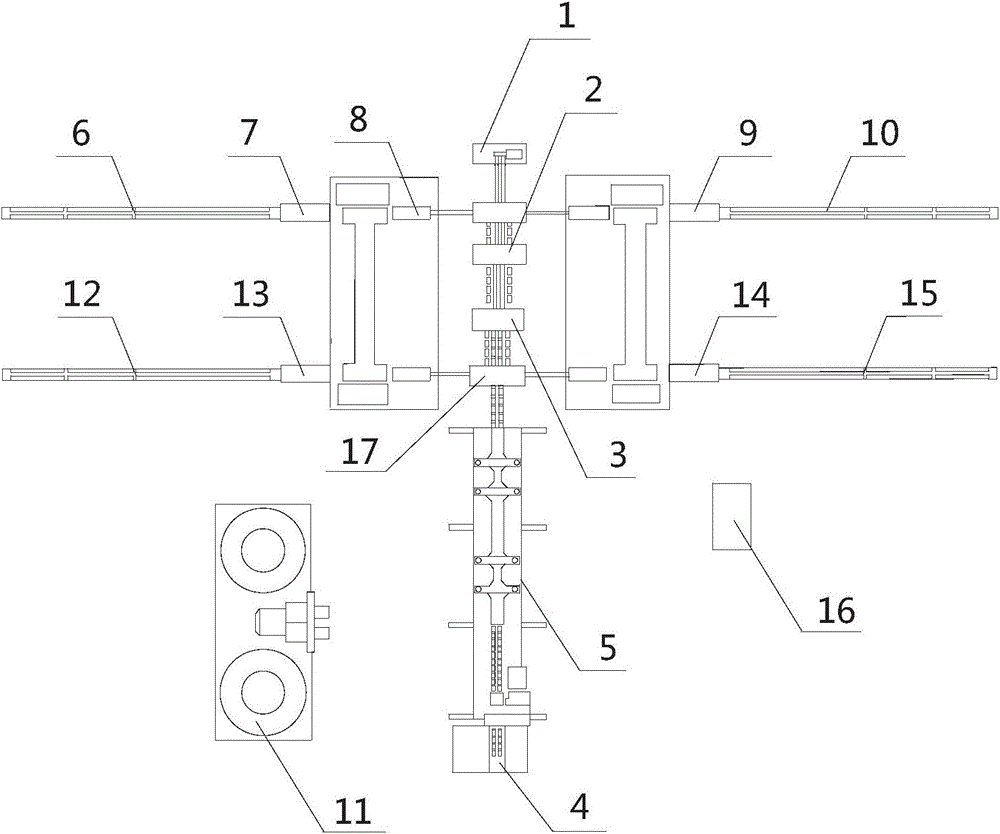

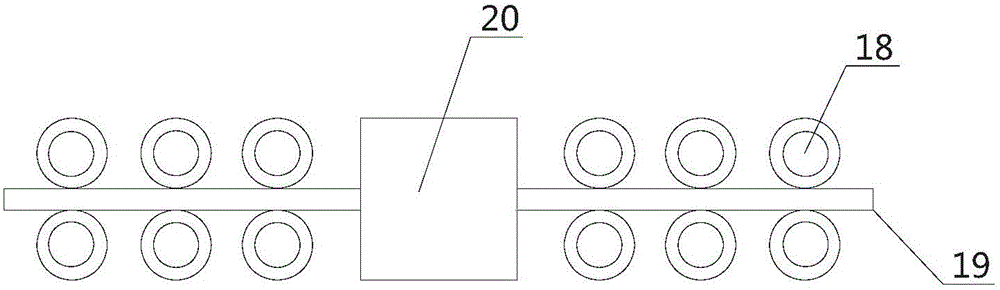

[0027] Such as figure 1 , figure 2 As shown, the present invention includes a control system 16 and a paper tape feeding system, a pad feeding system, a glue supply system 2, a pad sticking system 3, a drying system 5 and a receiving system 4 that are all connected to the control system 16, Wherein the side of paper tape feeding system is provided with pad feeding system, glue supply system 2 and pad pasting system 3, and the front end of described paper tape feeding system is provided with drying system 5 and receiving system successively along paper tape conveying direction Material system 4; the glue supply system 2 is used to glue the paper tape on the paper tape feeding system, and the pad sticking system 3 sticks the pad 22 conveyed by the pad feeding system on the paper tape The tape pasting part forms the transformer insulating oil passage, and the transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com