Adhesive tape and method for adhering the adhesive tape

A kind of adhesive tape, one-party technology, applied in the direction of transportation and packaging, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of immersion, adhesive tape to reduce the adhesion of eyeglass lenses, etc., to achieve adhesion does not reduce the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0141] Next, the present invention will be described in more detail through examples, but the present invention is not limited by these descriptions.

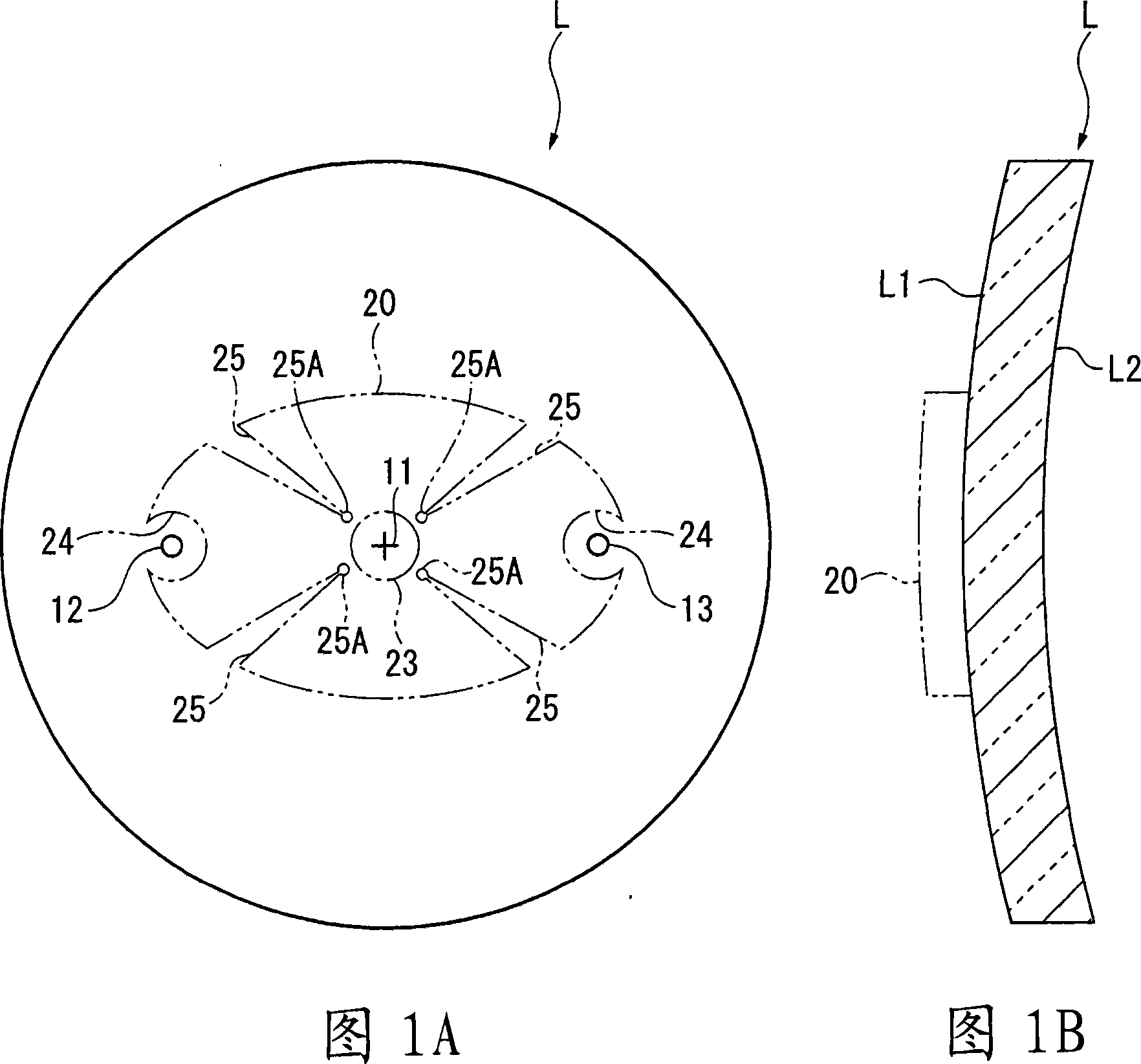

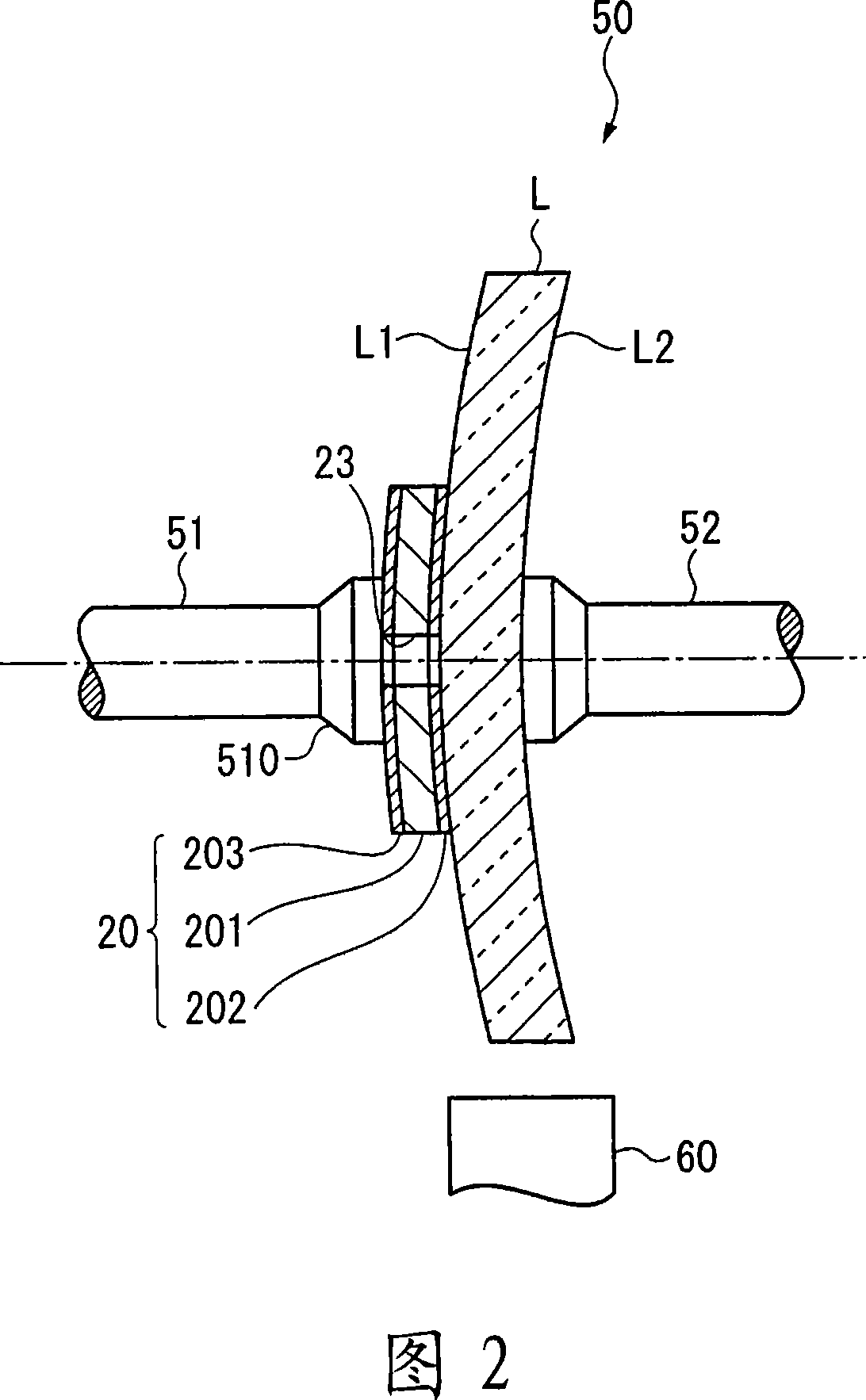

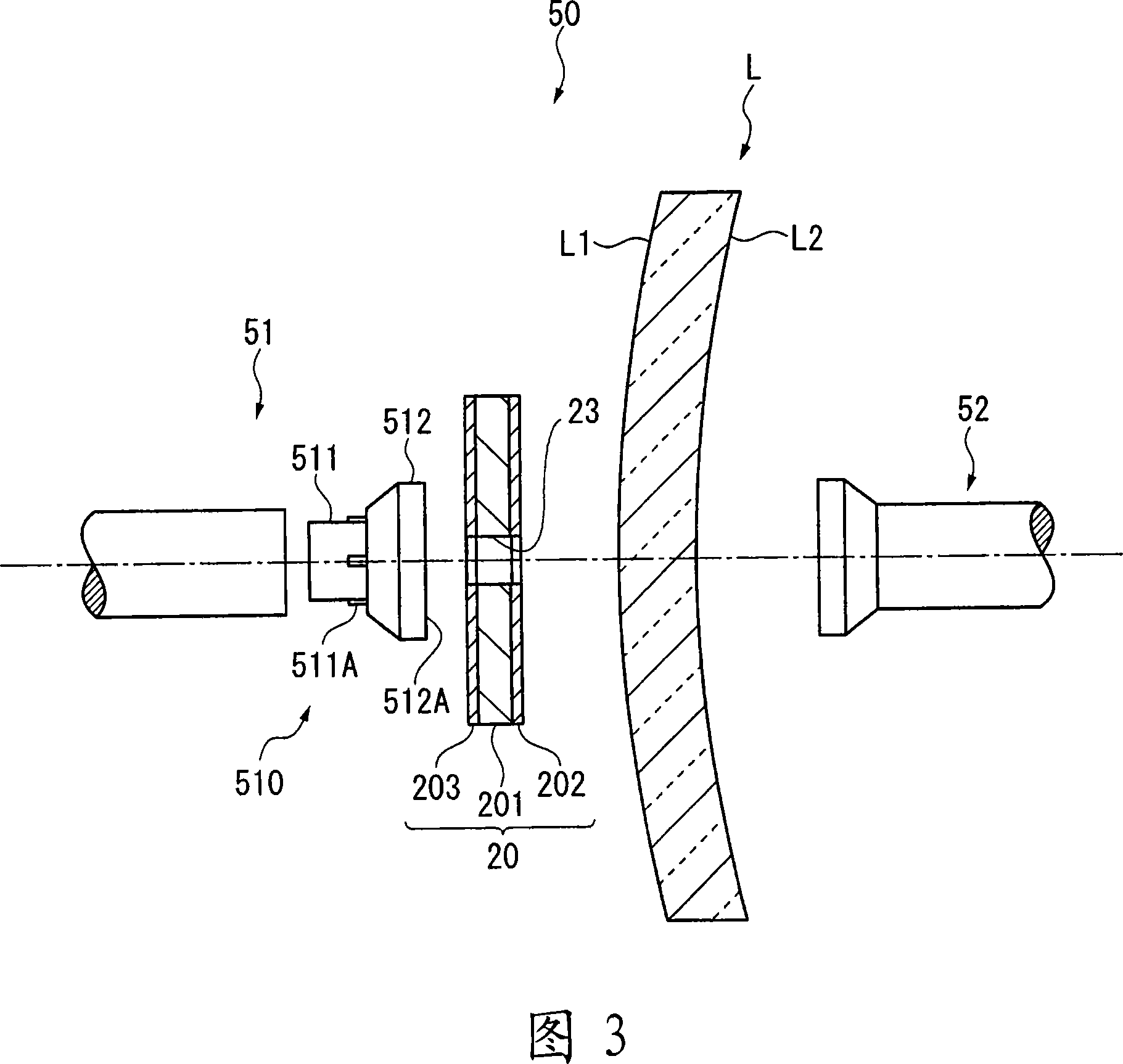

[0142] Specifically, as shown below, after adhering an adhesive tape to a predetermined convex surface of a spectacle lens, the spectacle lens is clamped with a pair of chucks, edged, and the degree of axial deviation of the spectacle lens is observed. In addition, the present embodiment is basically in accordance with the above-mentioned embodiments, and specific parts that are not considered to be particularly repeated are omitted.

[0143] (1) Spectacle lenses for edging:

[0144] As a plastic lens (Seiko Lucious manufactured by Seiko Epson Co., Ltd.) used for eyeglasses, a lens having powers of S=+3.50D and C=+0.50D was used.

[0145] In addition, an antifouling layer is formed on the surface of the lens, and the antifouling layer contains the above-mentioned fluorine-containing silane compound of the general formula (1) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com