Device for mounting sealing strips on vehicle doors

An assembly sealing and functional technology, which is applied in sealing devices, engine sealing, motor vehicles, etc., can solve the problems that the sealing strips cannot be glued accurately, hindering the subsequent processing process of automated production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

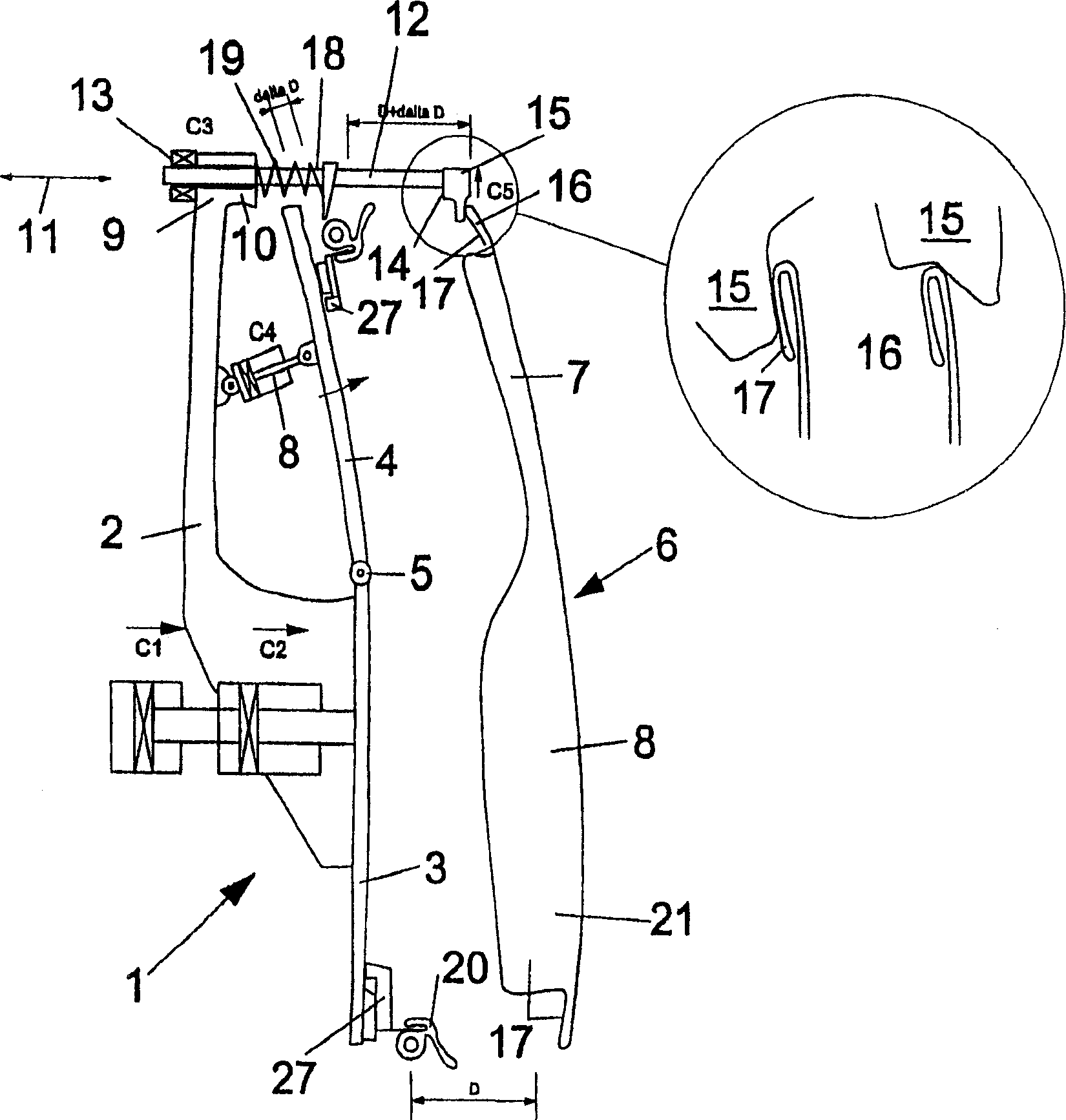

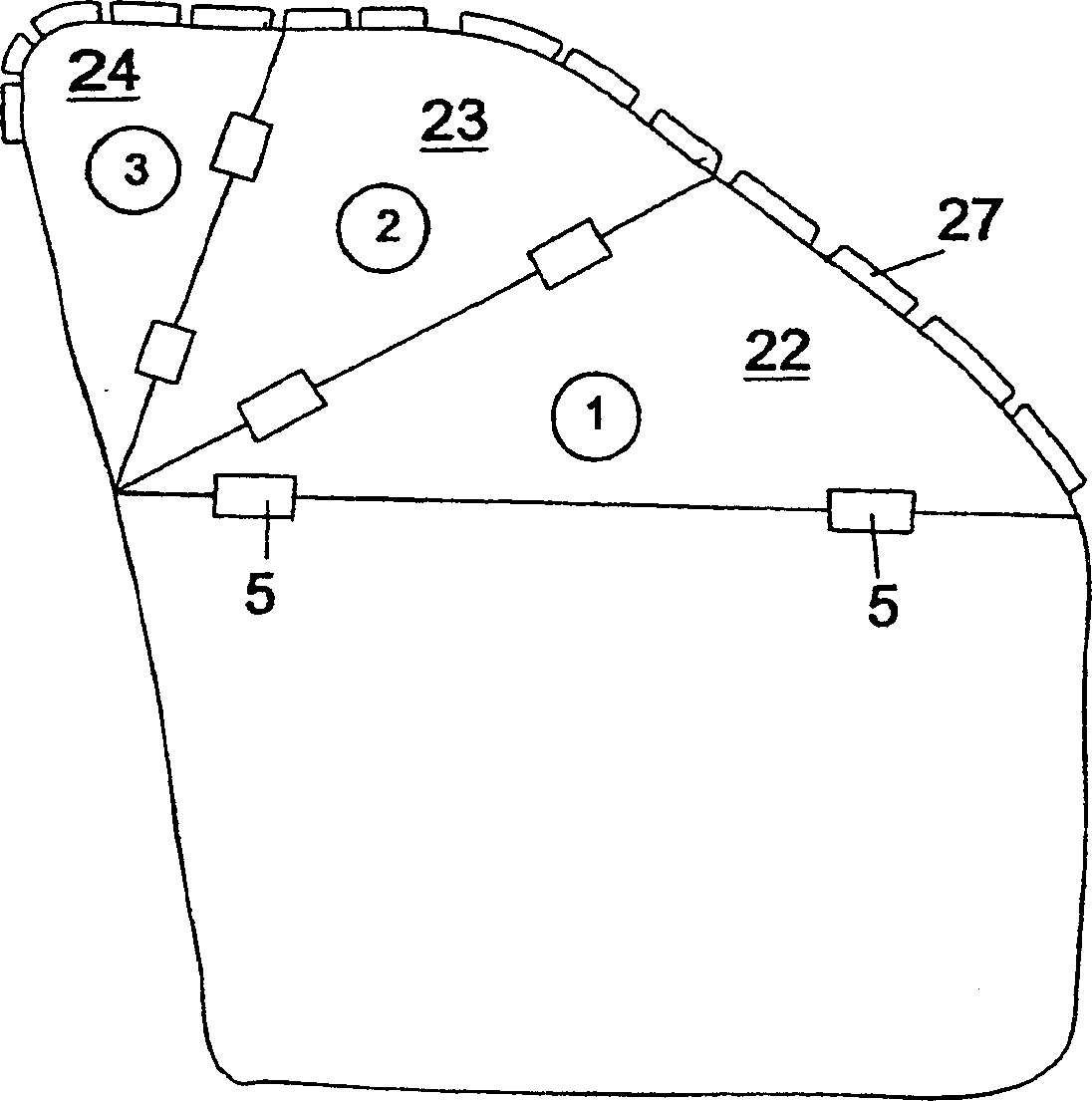

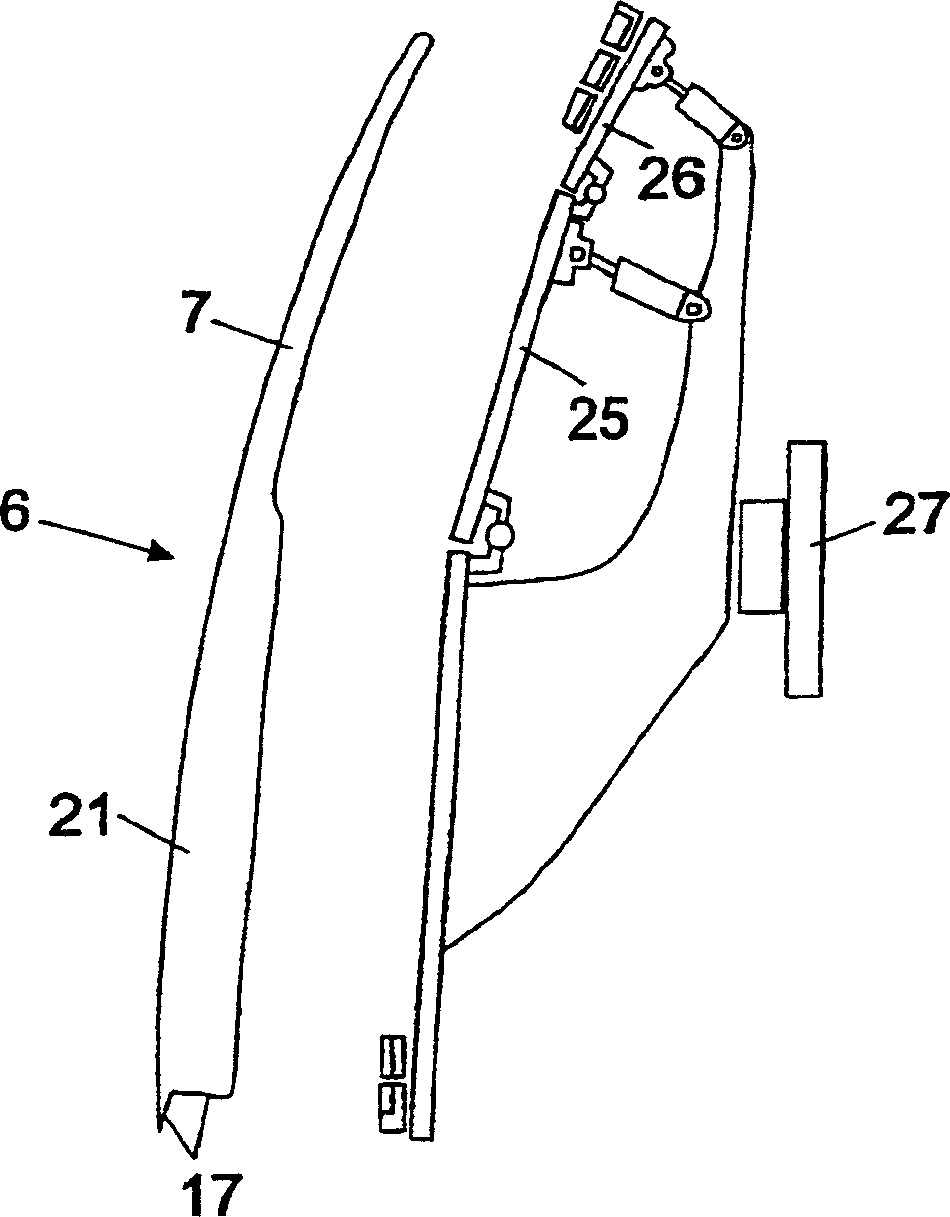

[0021] The device 1 for assembling a sealing strip to an adhesive surface on a vehicle door 6 comprises a base frame 2 to which a mounting plate is fastened. The mounting plate has a fixed plate section 3 relative to the base frame 2 and a movable plate section 4 hinged on the fixed plate section by a hinge 5 , the movable plate section corresponds to the shape of the upper part 7 of the door. A plurality of supports 27 are arranged on the mounting plate in accordance with the shape of the weather strip 20 to be assembled. Between the base frame 2 and the movable panel section 4 there is a pressure medium cylinder 8 for pivoting the panel section 4 about the hinge 5 .

[0022] On the upper edge 9 of the base frame 2 is a sleeve 10, which guides axially a reference push rod 12 corresponding to the plate segment 4, which runs perpendicularly from the surface of the base frame 2 to the movable plate The direction of segment 4 and door 6 extends. The reference push rod 12 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com