Sheet adhering apparatus

A chip sticking device and chip technology, applied to adhesives, electrical components, circuits, etc., can solve the problems of chip waste, inappropriateness, and easily broken chips, and achieve the effect of precise pasting and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

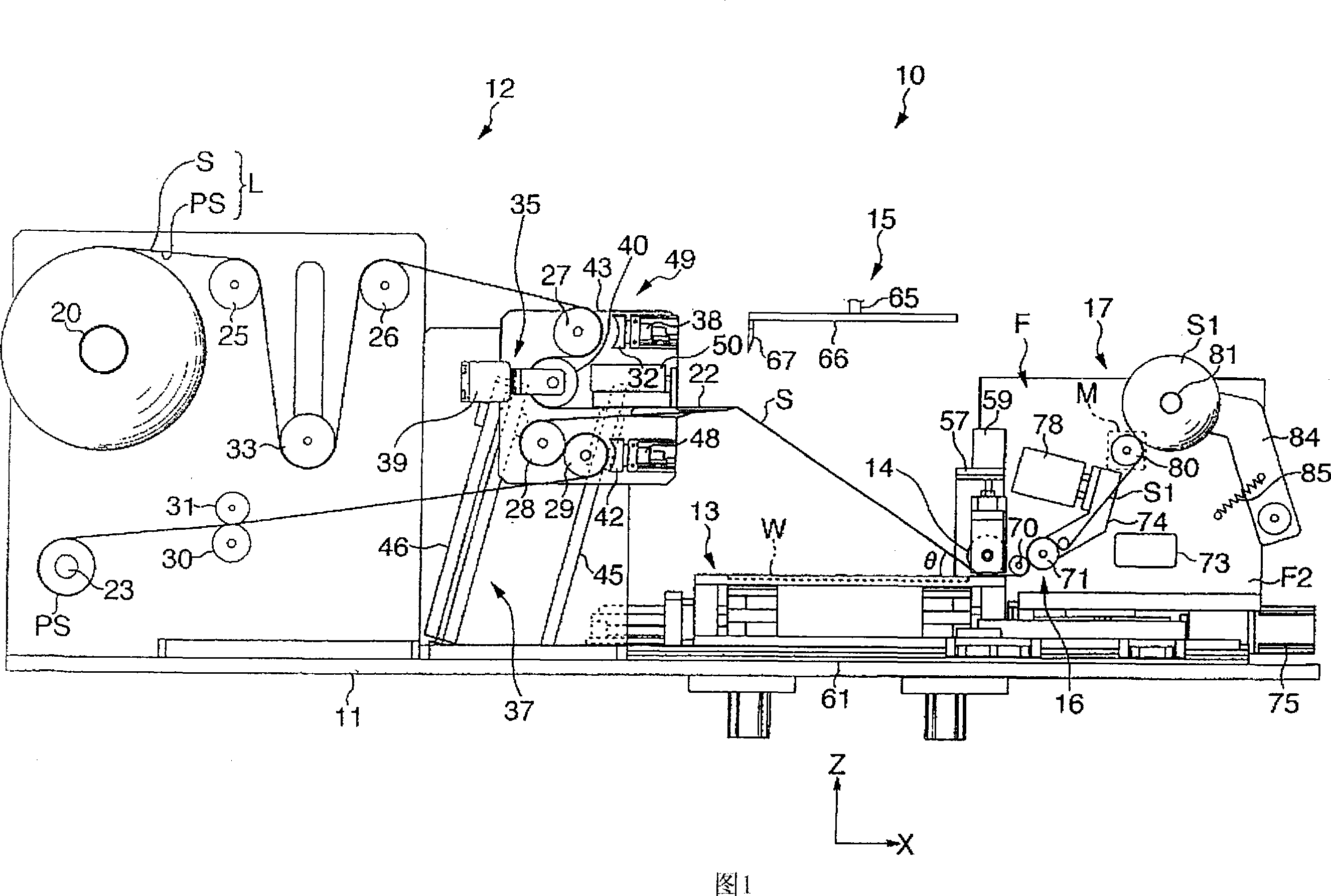

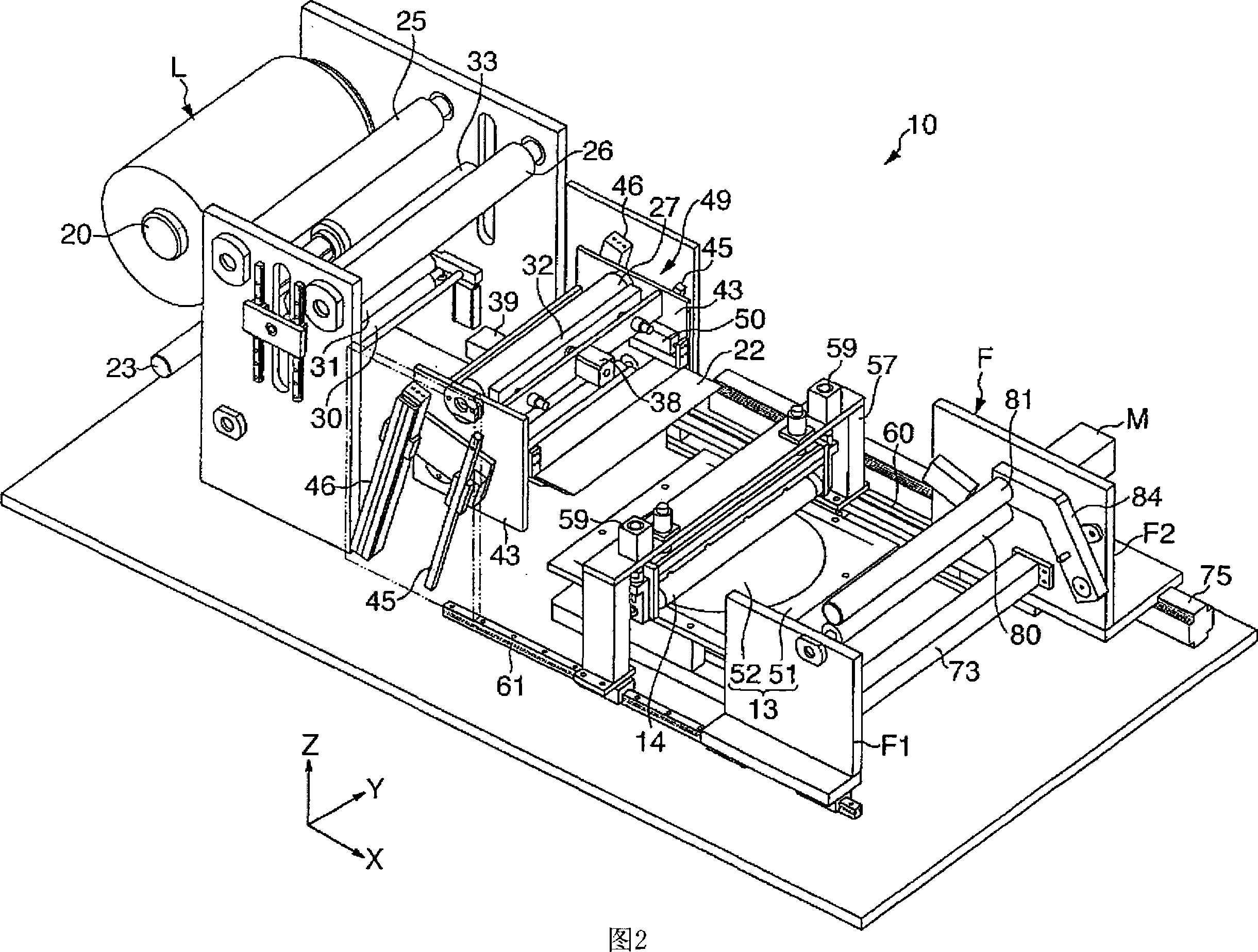

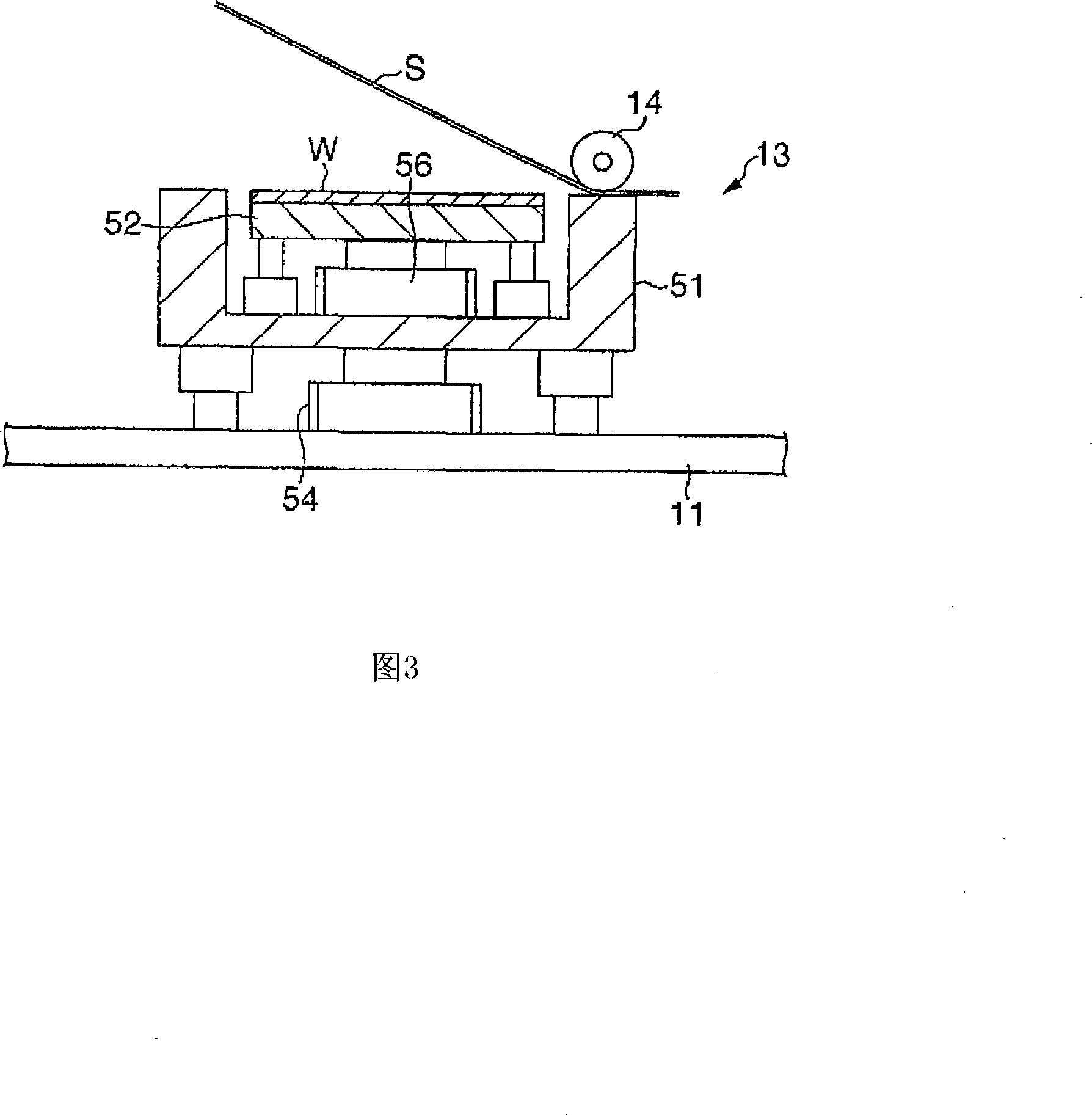

[0032] FIG. 1 shows a schematic front view of the sheet sticking device according to this embodiment, and FIG. 2 shows a schematic perspective view thereof. In these figures, the sheet sticking apparatus 10 is composed of the following components: a sheet guide unit 12 arranged on the upper part of the base 11; a table 13 supporting a wafer W as a plate-shaped member; The pressure roller 14 that sticks the adhesive sheet S on the upper side to the wafer W by applying a pressing force; and the cutter 15 that cuts the adhesive sheet S along the outer edge of the wafer W after the adhesive sheet S is attached to the wafer W; and a peeling device 16 for peeling the unnecessary adhesive sheet S1 on the outer side of the wafer W from the upper surface of the table 13; and a take-up device 17 for winding the unnecessary adhesive sheet S1.

[0033] The above-mentioned sheet gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com