Prolate automatic silk-screen machine

A screen printing machine, automatic technology, applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve the problems of low precision, time-consuming and labor-intensive, etc., achieve automation, save human resources, and prevent low printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

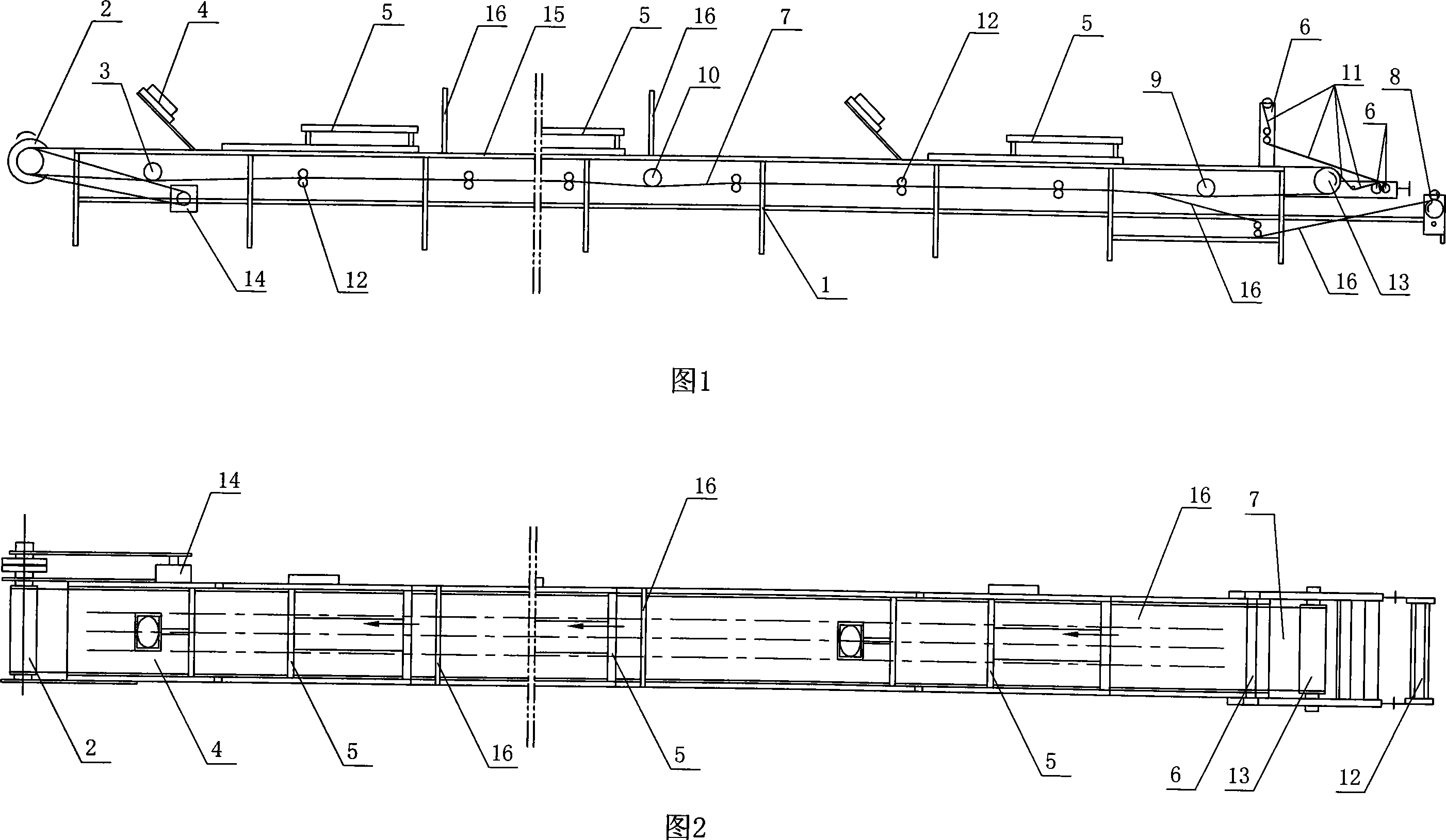

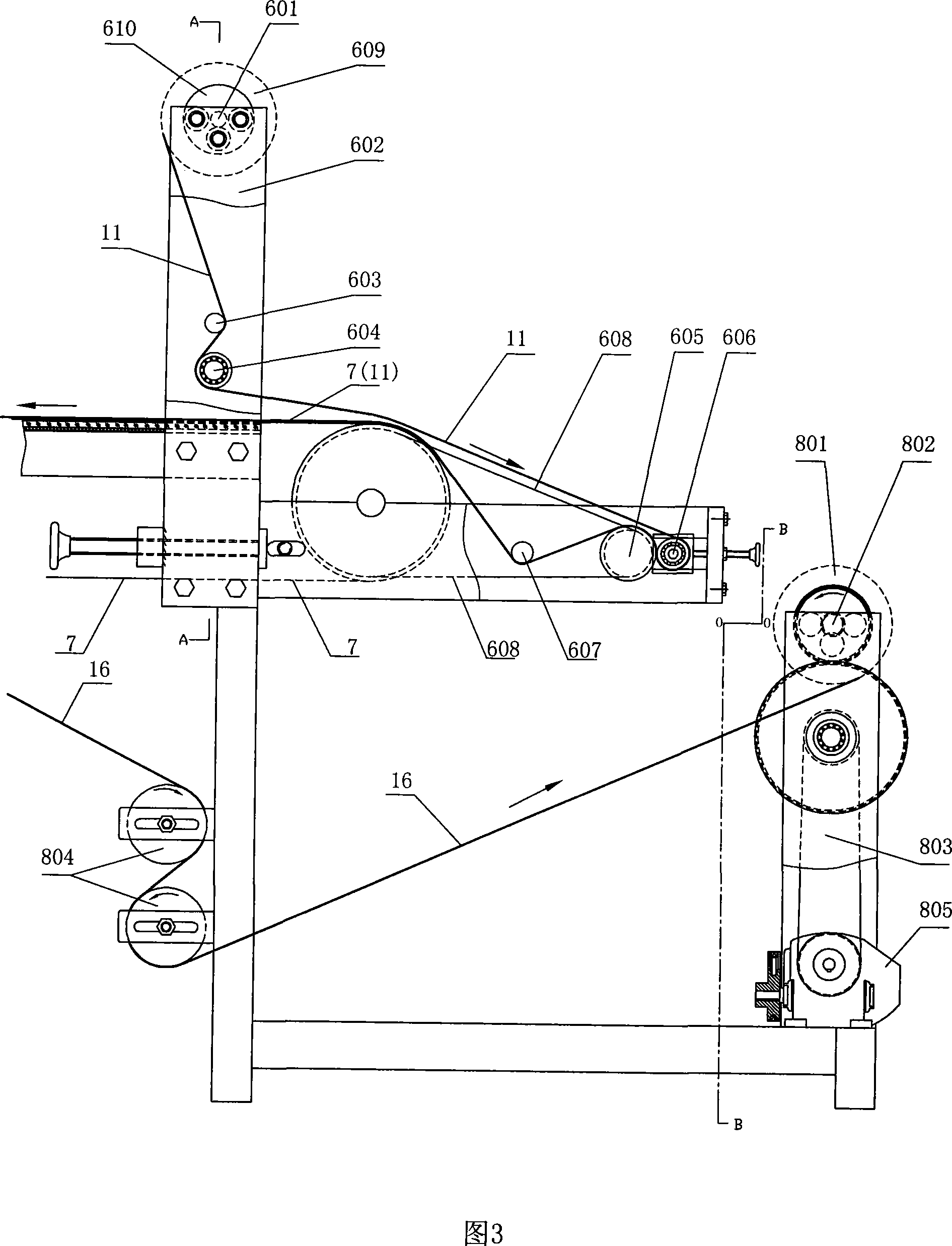

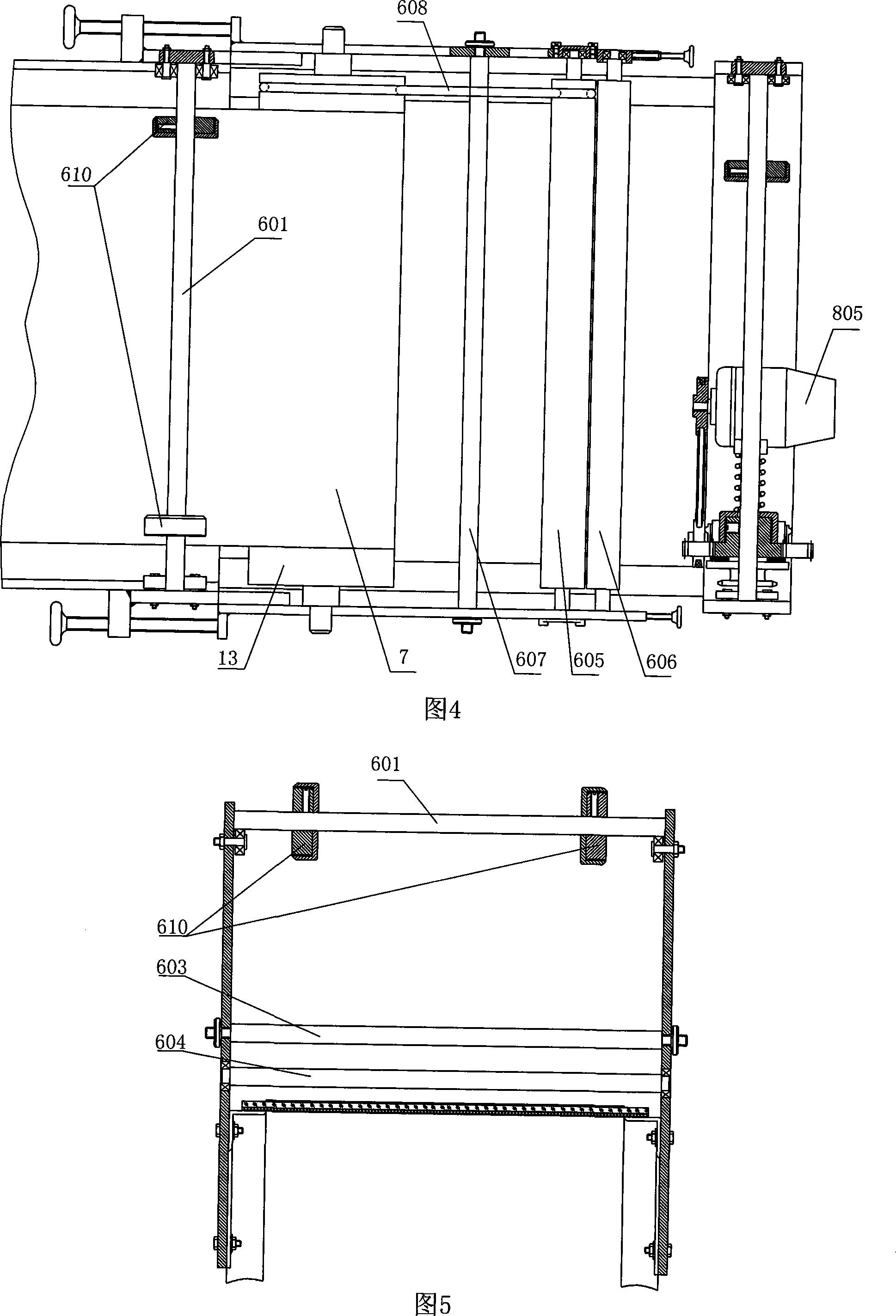

[0022] Referring to Fig. 1 and Fig. 2, the long-format automatic screen printing machine of the present invention comprises a long frame 1, on which a workbench 15 is laid, and two rollers 2, 13 are arranged at both ends of the frame 1, and the two rollers Cover a closed conveyor belt 7 on the cylinder 2,13. The upper belt of the conveyor belt 7 is laid on the top surface of the workbench 15, and its lower belt passes through 13 sets of supporting rollers 12 in sequence, and a tensioning mixing drum 3 is respectively arranged at both ends and in the middle of the lower belt. , 10, 9. The head roller 2 is driven by an electric motor 14 . Four screen printing frames 5 are evenly arranged on the workbench 15 along the length direction of the workbench. The front of each silk screen frame 5 is provided with a blower 4, and a windshield 16 is all provided with other silk screen frame rears except the last one. A feeding mechanism 6 and a receiving mechanism 8 are also provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com