Polyurethane moisture-curable hot-melt edge sealing adhesive, and preparation method and application thereof

A moisture-curing, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., to achieve the effect of suitable automatic control and construction, full of elasticity, and good peeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

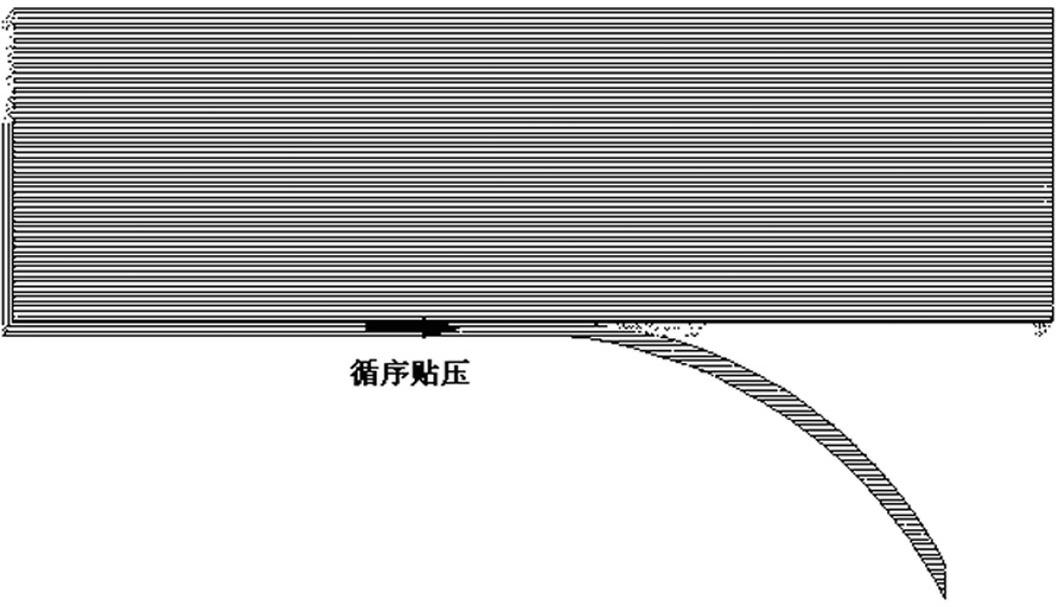

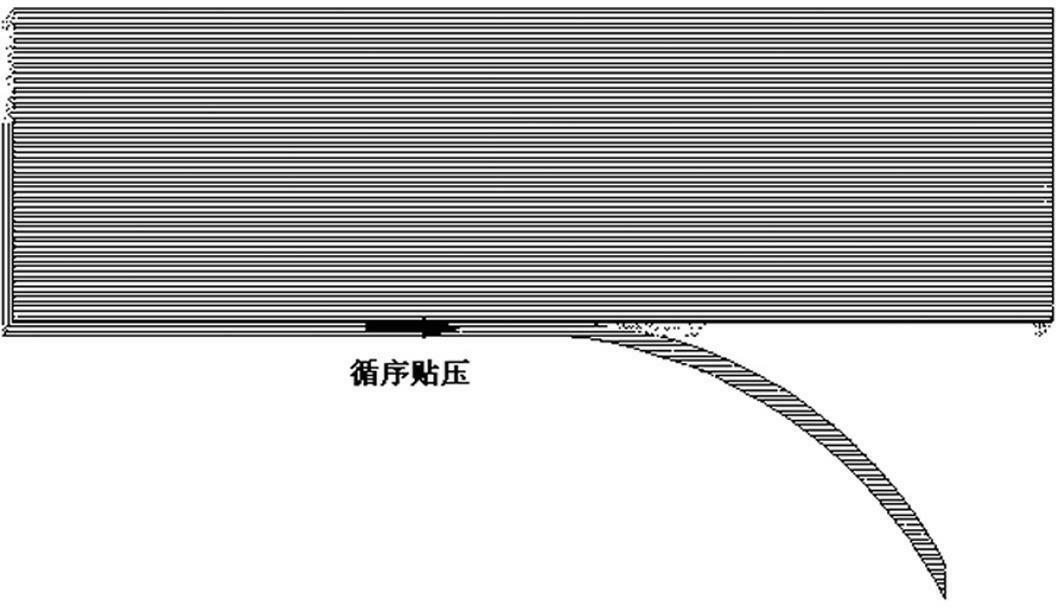

Image

Examples

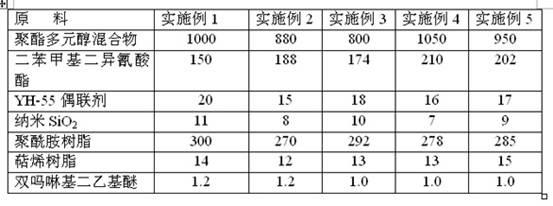

Embodiment 1

[0037] (1) Weighing and compounding polyester polyol mixture, its composition and weight ratio are:

[0038] Grade PHL-1600 18 parts

[0039] Grade PH-2000 2 copies

[0040] Grade CMA-1044 5 copies

[0041] Grade CMA-44 33 copies;

[0042] (2) Weigh 1000 parts of polyester polyol mixture, 300 parts of polyamide resin, 14 parts of terpene resin, 20 parts of YH-55 coupling agent, nano-SiO 2 Add 11 parts into the reaction kettle, heat up to 120°C under the pressure of -0.08~-0.1 MPa to melt, dehydrate until the liquid material has no bubbles escape, cool down to 90°C, and then weigh 150 parts of diphenylmethyl diisocyanate, Add it into the reaction kettle for 3.5 hours of polymerization reaction until the molar percentage of residual isocyanate reaches 0.6%, then add 1.2 parts of bismorpholino diethyl ether, continue to stir and disperse for 30 minutes, cool down to 60°C, filter while hot, Discharge, seal and package immediately to obtain polyurethane moisture-curing ho...

Embodiment 2

[0045] (1) Weighing and compounding polyester polyol mixture, its composition and weight ratio are:

[0046] Grade PHL-1600 25 parts

[0047] Brand CMA-44 55 copies;

[0048] (2) Weigh 880 parts of polyester polyol mixture, 270 parts of polyamide resin, 12 parts of terpene resin, 15 parts of YH-55 coupling agent, nano-SiO 2 Put 8 parts into the reaction kettle, heat up to 115°C under the pressure of -0.08~-0.1 MPa to melt, dehydrate until the liquid material has no bubbles escape, cool down to 80°C, and then weigh 188 parts of diphenylmethyl diisocyanate, Add it into the reaction kettle for polymerization reaction for 4 hours until the molar percentage of residual isocyanate reaches 0.8%, then add 1.2 parts of bismorpholino diethyl ether, continue to stir and disperse for 40 minutes, cool down to 60°C, filter while hot, Discharge, seal and package immediately to obtain polyurethane moisture-curing hot-melt edge banding adhesive.

[0049] The polyurethane moisture-curi...

Embodiment 3

[0051] (1) Weighing and compounding polyester polyol mixture, its composition and weight ratio are:

[0052] Grade PHL-1600 30 parts

[0053] Grade PH-2000 10 parts

[0054] Grade CMA-1044 18 parts

[0055] Brand CMA-44 40 copies;

[0056] (2) Weigh 800 parts of polyester polyol mixture, 292 parts of polyamide resin, 13 parts of terpene resin, 18 parts of YH-55 coupling agent, nano-SiO 2 Add 10 parts into the reaction kettle, heat up to 115°C under the pressure of -0.08~-0.1 MPa to melt, dehydrate until the liquid material has no bubbles escape, cool down to 95°C, and then weigh 174 parts of diphenylmethyl diisocyanate, Add it into the reaction kettle for polymerization reaction for 3 hours until the molar percentage of residual isocyanate reaches 1.5%, then add 1.0 part of bismorpholino diethyl ether, continue stirring and dispersing for 35 minutes, cool down to 60°C, filter while hot, Discharge, seal and package immediately to obtain polyurethane moisture-curing ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com