Labeling mechanism

A technology for labeling and fixing plates, which is applied in labeling machines, labels, packaging, etc., can solve problems that affect work efficiency, consume a lot of manpower, and barcodes are not beautiful, and achieve the goals of improving work efficiency, simple operation, and ensuring the appearance of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

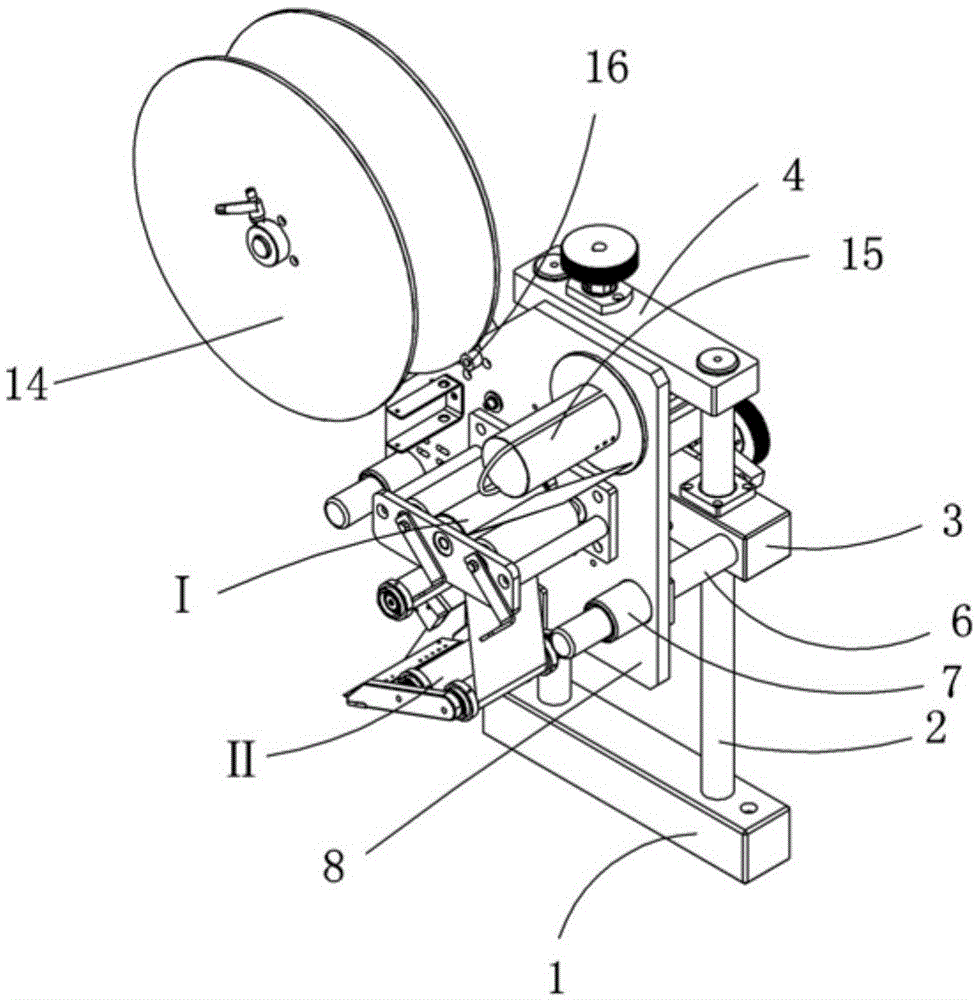

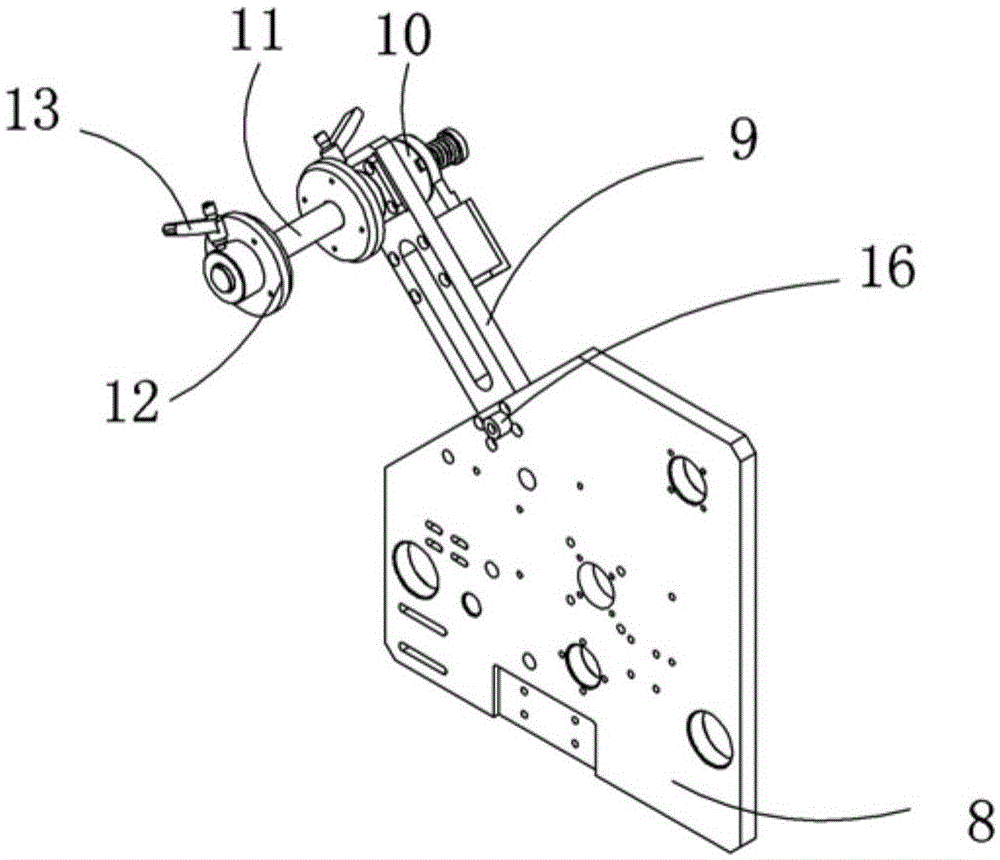

[0024] Examples, see attached Figure 1~5 , a labeling mechanism, which includes a labeling connecting bracket, a material tray assembly, a pressing wheel assembly II and a labeling mechanism II, the feeding tray assembly is installed on the labeling connecting bracket; the pressing wheel assembly and the outputting mechanism The marking mechanism is installed on the tray assembly respectively.

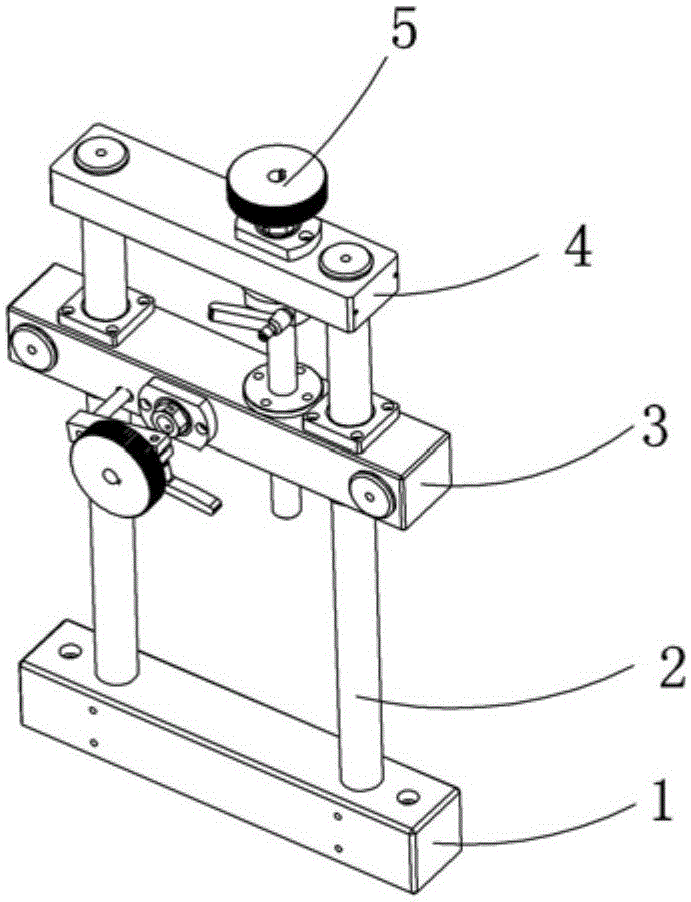

[0025] The labeling connection bracket includes a labeling fixing seat 1, a guide post 2, an adjusting fixing plate 3, a nut fixing plate 4 and an adjusting nut 5, two guide posts are installed on the labeling fixing seat, and the two guide posts pass through The upper end of the adjustable fixing plate is connected with the nut fixing plate, and an adjusting nut is installed between the adjusting fixing plate and the nut fixing plate, and the up and down position of the adjusting fixing plate can be adjusted through the adjusting nut, and finally the up and down position of the tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com