Full-automatic wall tile and floor tile laying machine

A fully automatic, laying machine technology, applied in the direction of construction, building structure, etc., can solve the problems that affect the development and progress of the industry, the perfection is not satisfactory, the overall quality is not high, and achieve significant economic and social benefits, precise paste, The effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

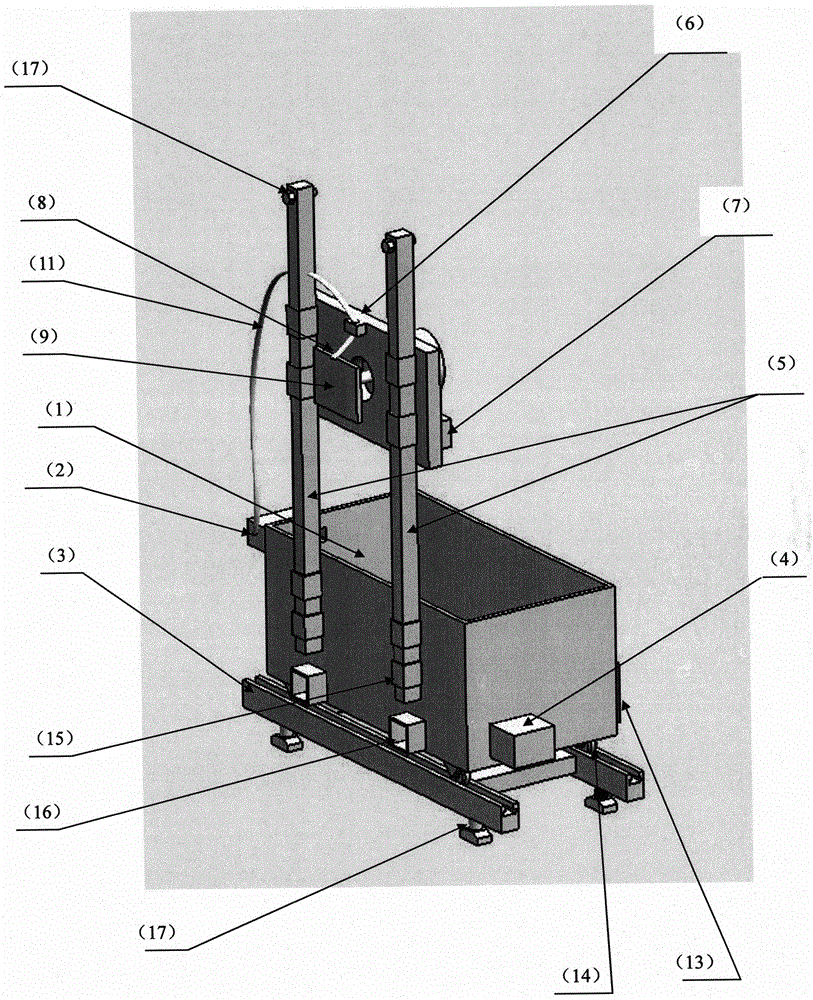

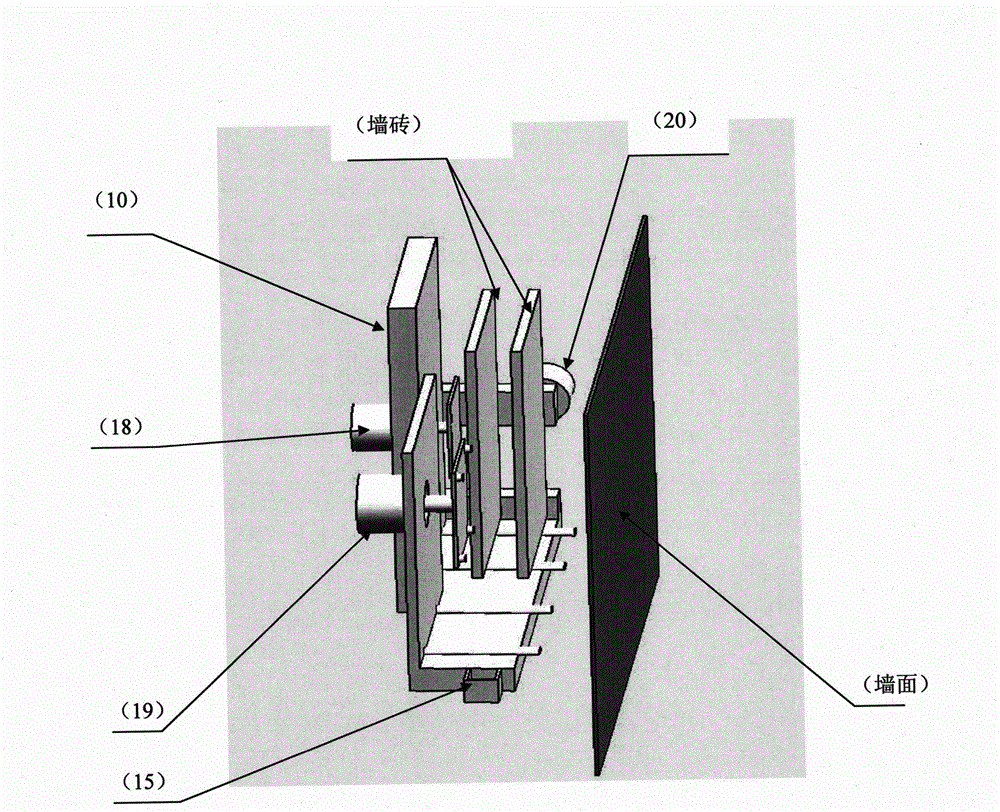

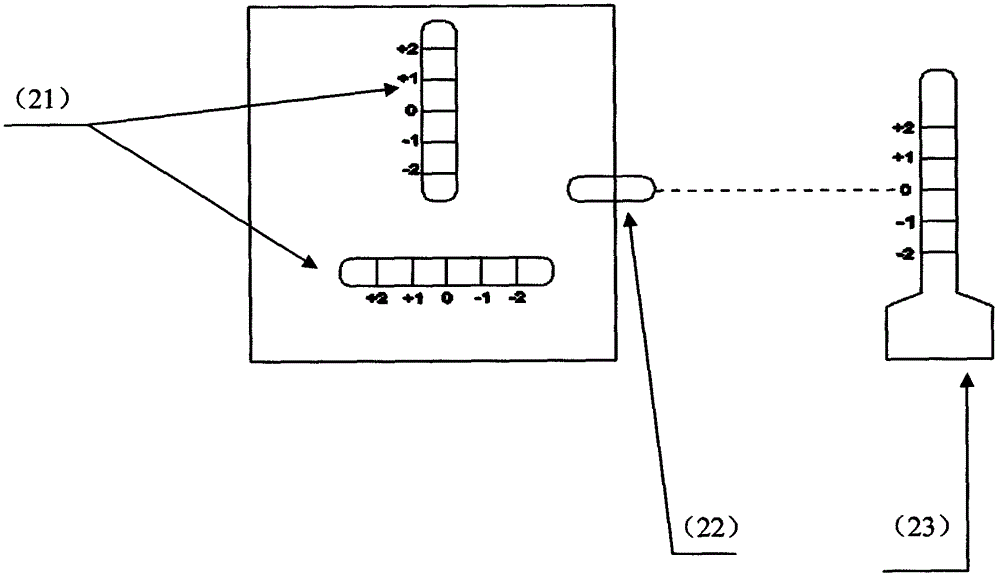

[0015] Such as figure 1 Shown: a fully automatic wall and floor tile laying machine, which includes: mixer 1, mud pump 20, moving guide rail 3, lower driving mechanism 4, guide post 5, mounting seat 6, upper driving mechanism 7, filling port 8, vibration Mechanism 9, wall and floor tile laying frame 10, conduit 11 multidirectional level 12, control system 13; mixer 1 is installed on the moving guide rail 3, the lower driving mechanism 4 and mud pump 2 are fixed on both sides of the mixer 1, and the guide column 5 is fixed On the front side of the mixer 1, the installation seat 6 is installed on the guide column 5, and the upper driving mechanism 7 is fixed in the installation seat 6; the upper part of the installation seat 6 is provided with a filling port 8, and a vibration mechanism 9 and a replaceable wall are arranged in the middle , Floor tile layi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com