Vehicle nameplate gluing machine

A technology for pasting machines and nameplates, which is applied to mechanical equipment, vehicle parts, connecting components, etc., and can solve problems such as unfavorable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

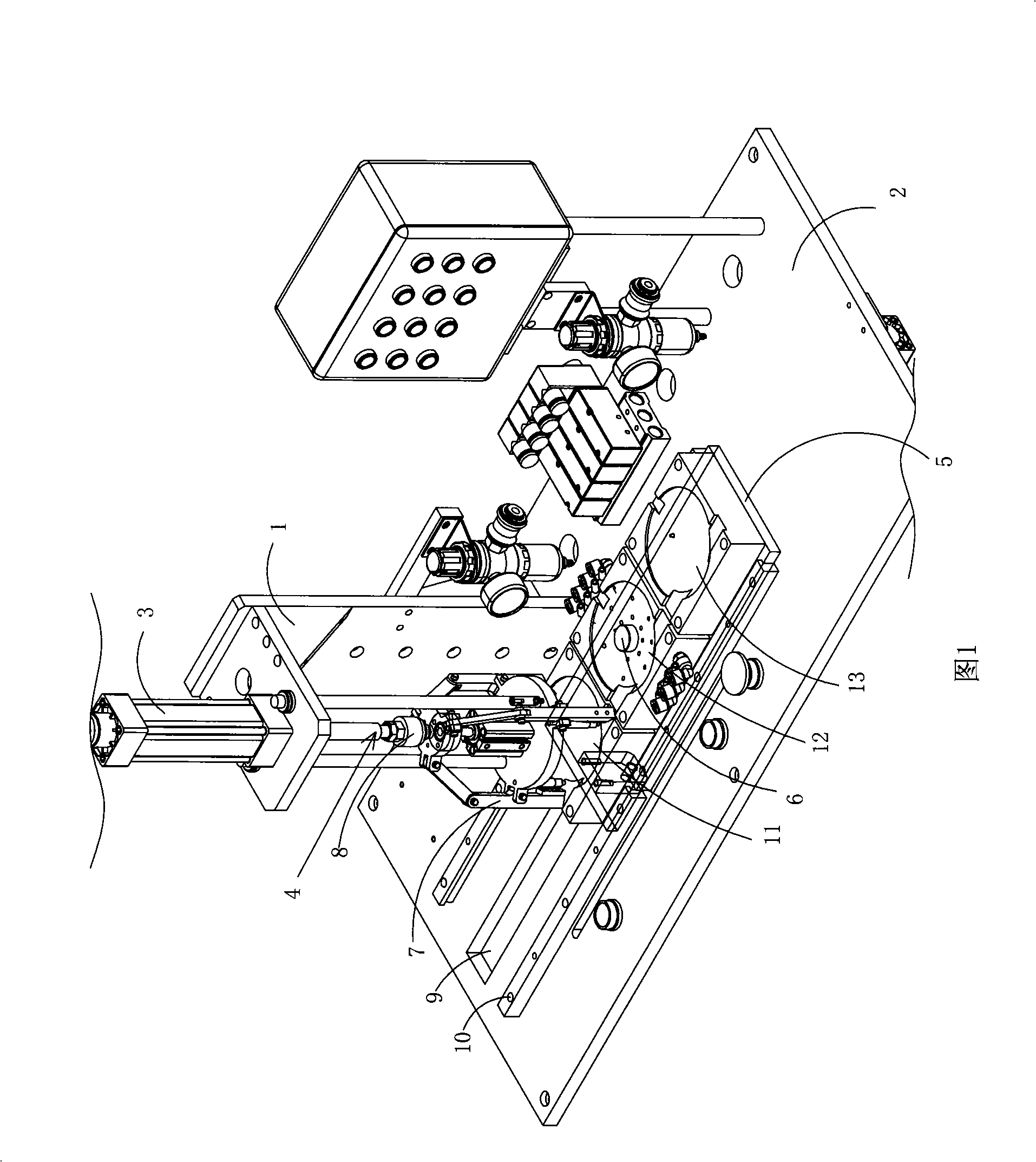

[0010] Embodiment: A car nameplate sticking machine, comprising a bracket 1 and a base 2, a pressing and lifting cylinder 3 is fixed on the bracket 1, and the piston of the pressing and lifting cylinder 3 is fixedly connected to a clamping device 4 that can clamp the handle cover , the clamping device 4 can be longitudinally positioned and slid on the support 1, and a material seat 5 is fixed on the base 2, the material seat 5 is under the clamping device 4, and the material seat 5 can be horizontally slid and positioned on the base 2, the material seat The first position 11 for putting the handle cover, the second position 12 for putting the double-sided adhesive tape and the third position 13 for putting the nameplate are separately arranged on the 5, and the vacuum suction port 6 is established below the second position 12.

[0011] The clamping end of the clamping device 4 is provided with a mechanical clamp 7, and the mechanical clamp 7 is controlled by the mechanical clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com