Patents

Literature

45 results about "Radial Force Variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

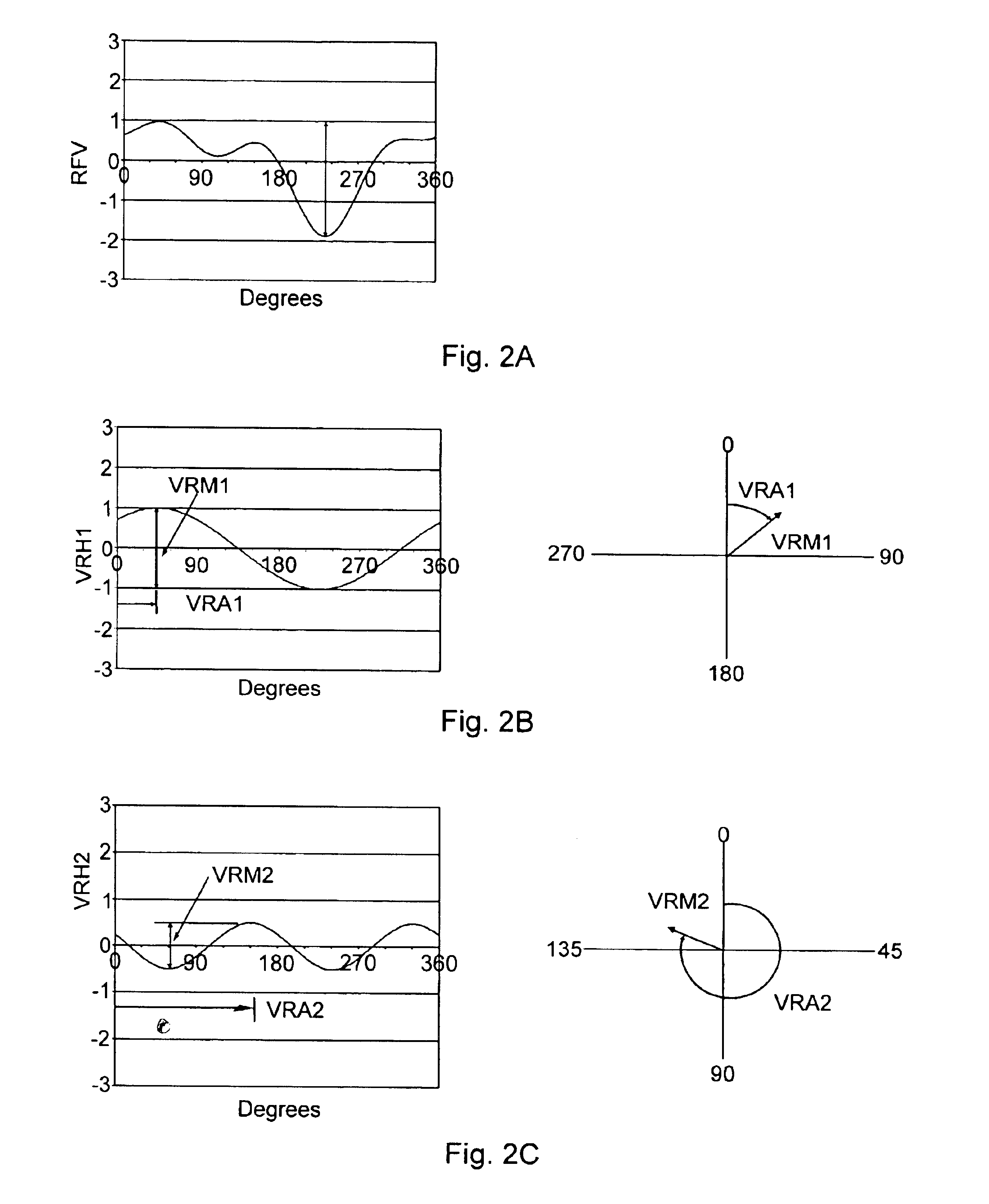

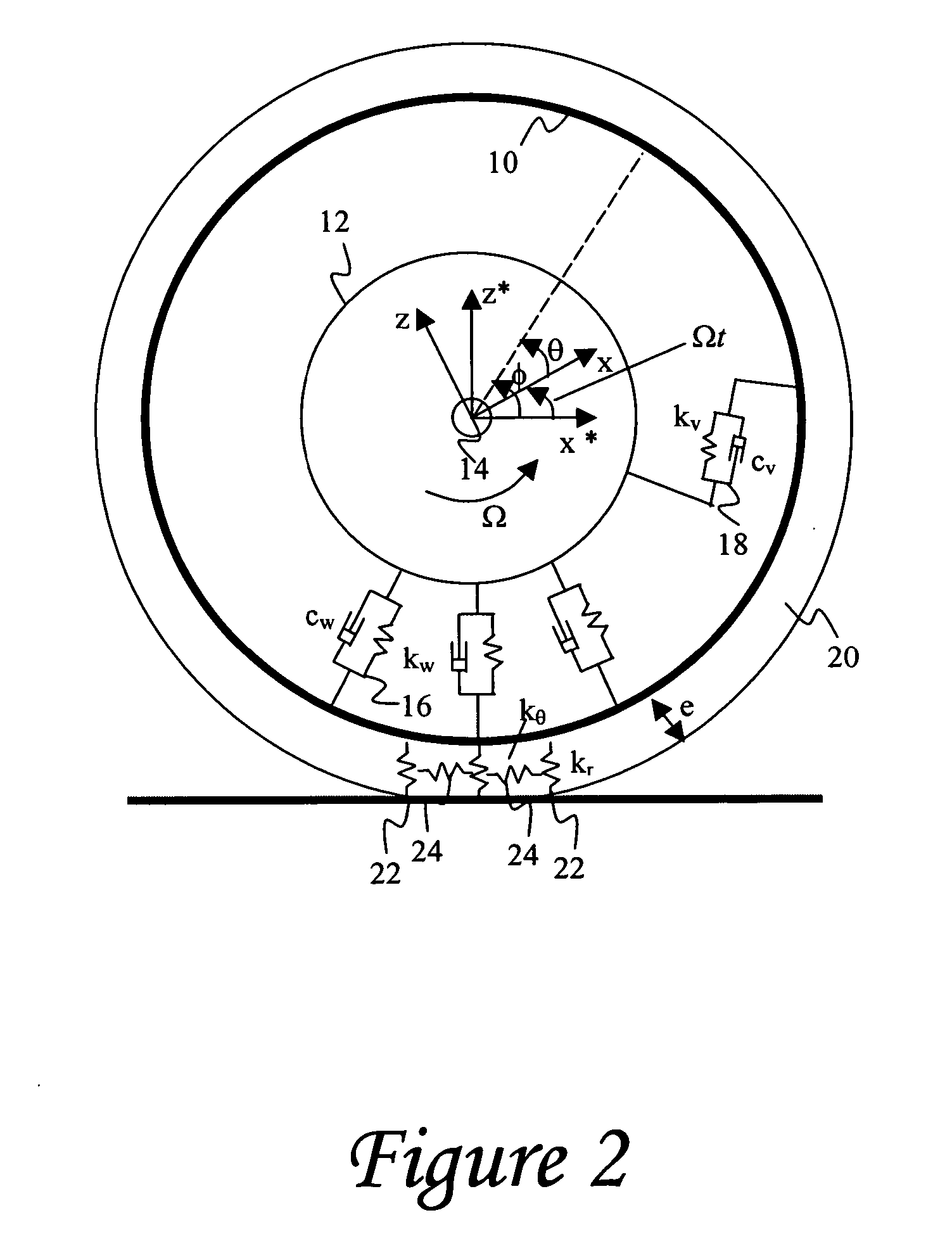

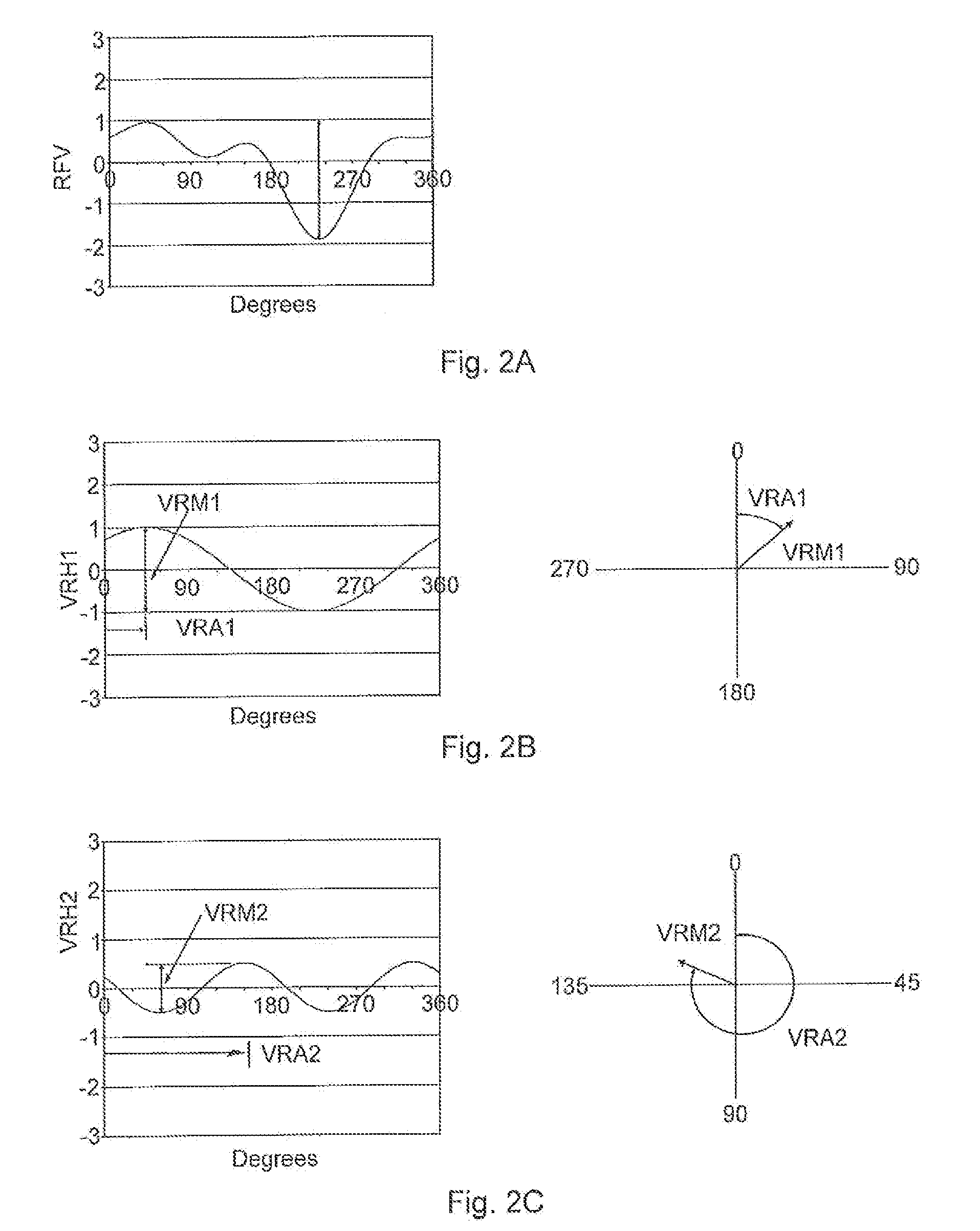

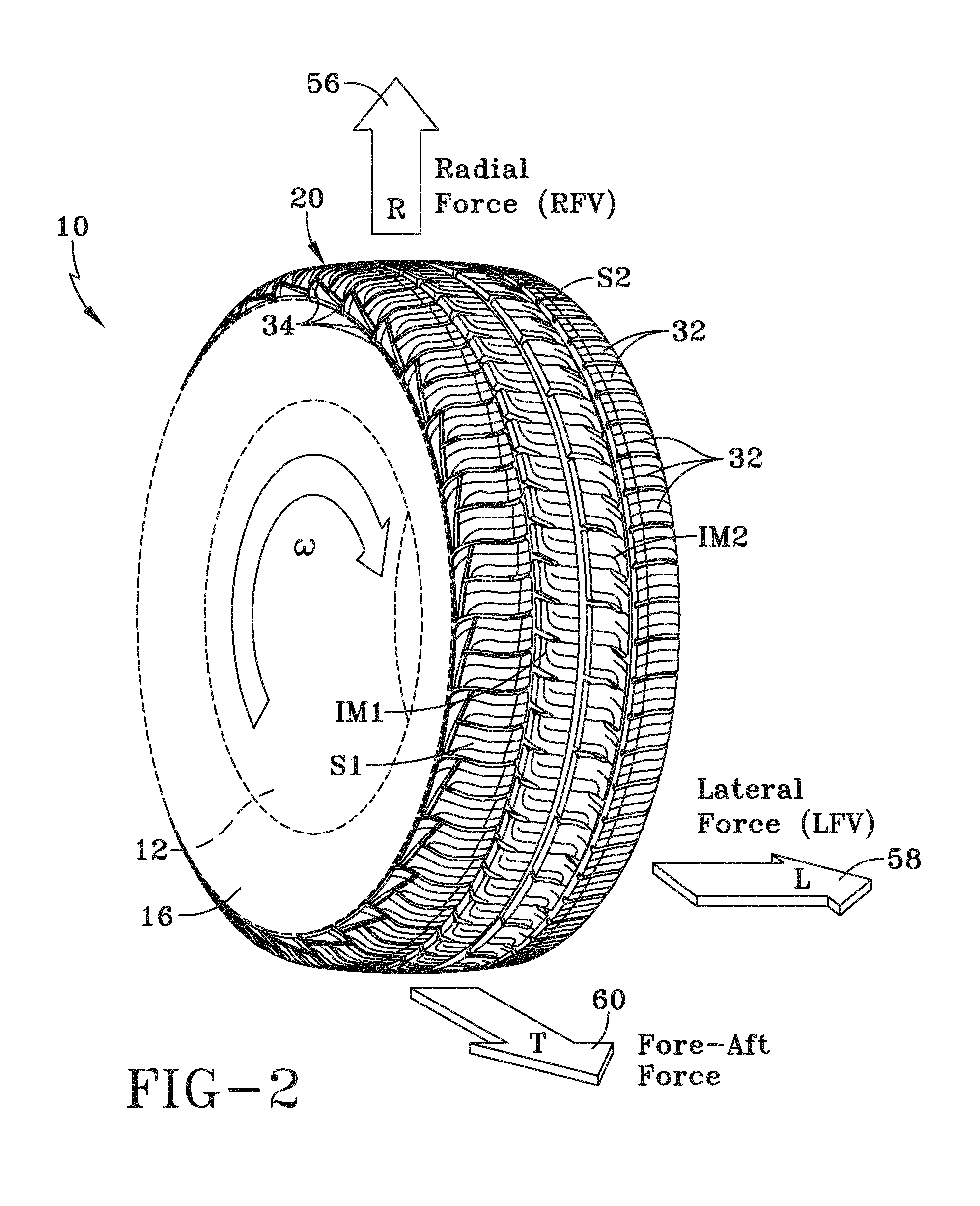

Radial force variation or road force variation (RFV) is a property of a tire that affects steering, traction, braking and load support. High values of RFV for a given tire reflect a high level of manufacturing variations in the tire structure that will impart ride disturbances into the vehicle in the vertical direction. RFV is measured according to processes specified by the ASTM International in ASTM F1806 – Standard Practice for Tire Testing.

Prediction and control of mass unbalance and high speed uniformity

ActiveUS20050081614A1Little effectAdvanced technologyRoads maintainenceVehicle tyre testingLow speedHarmonic

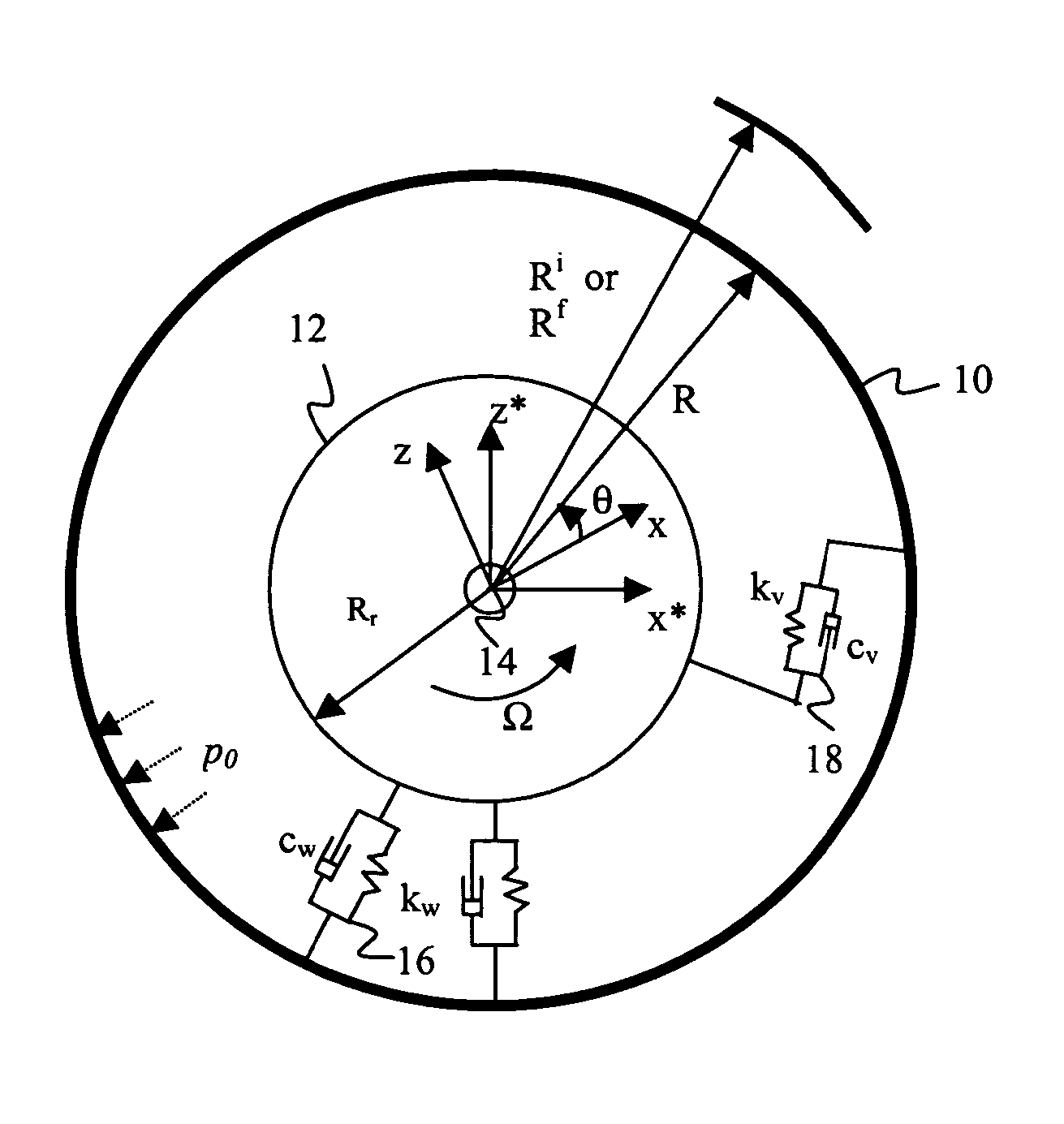

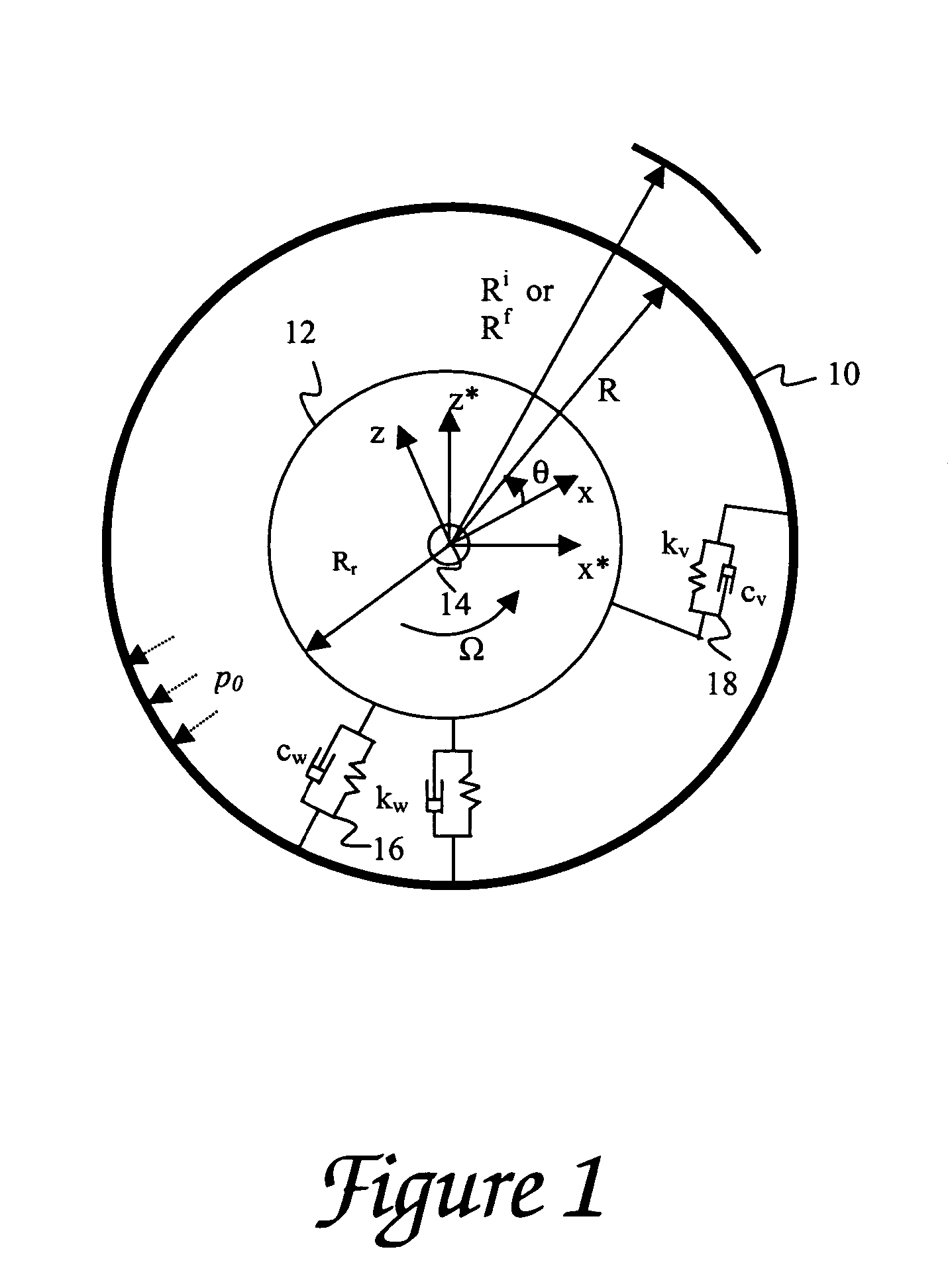

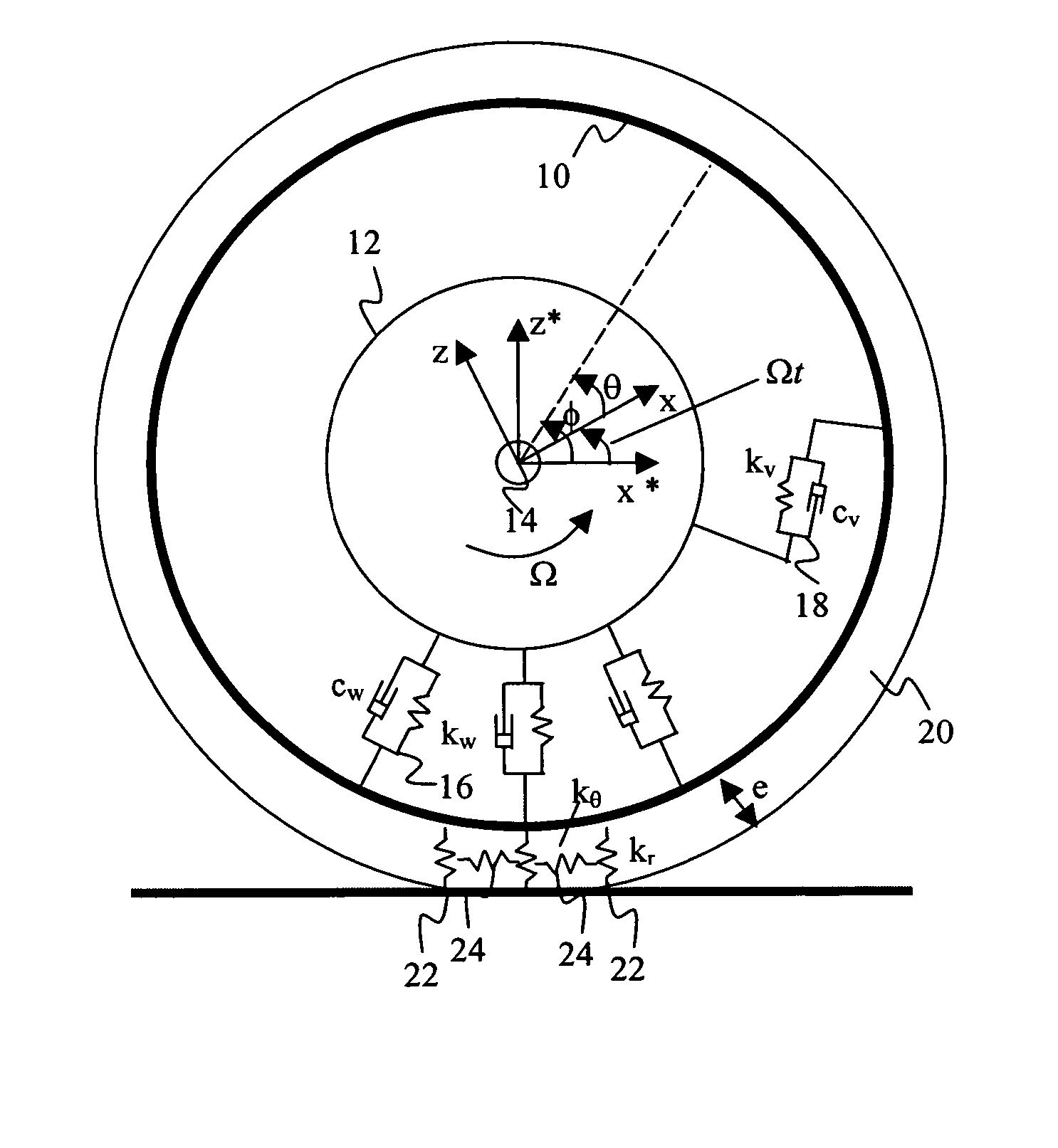

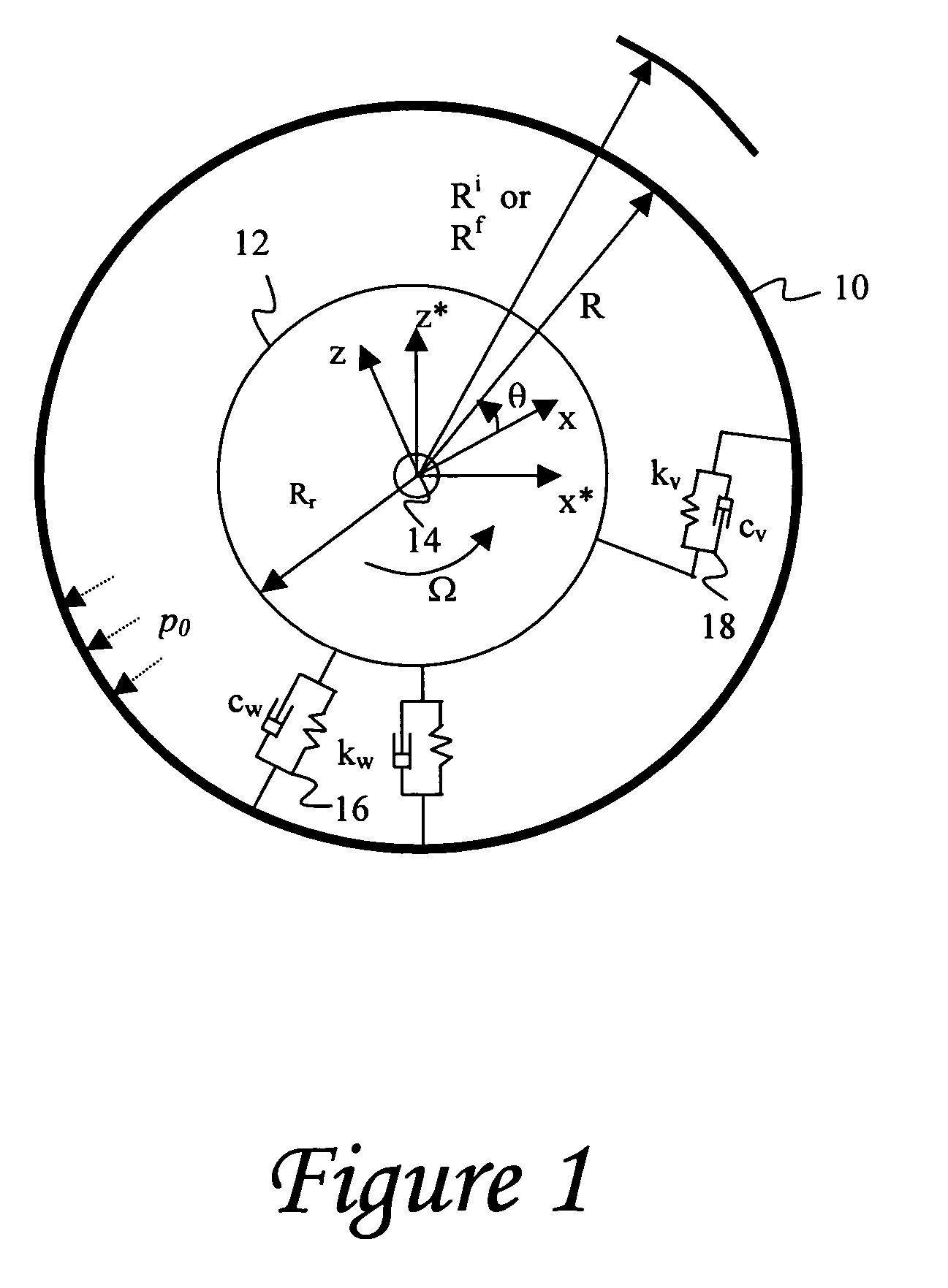

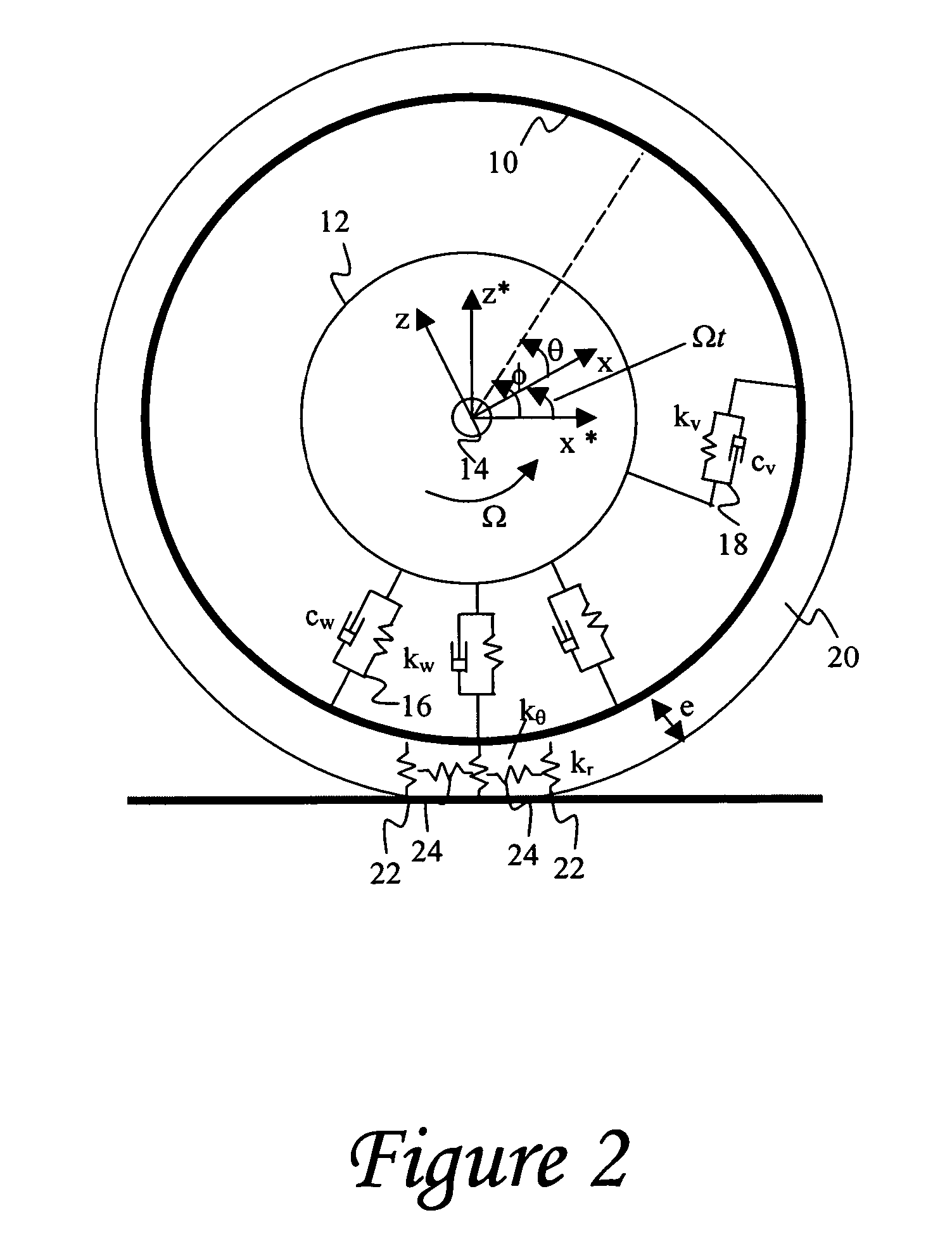

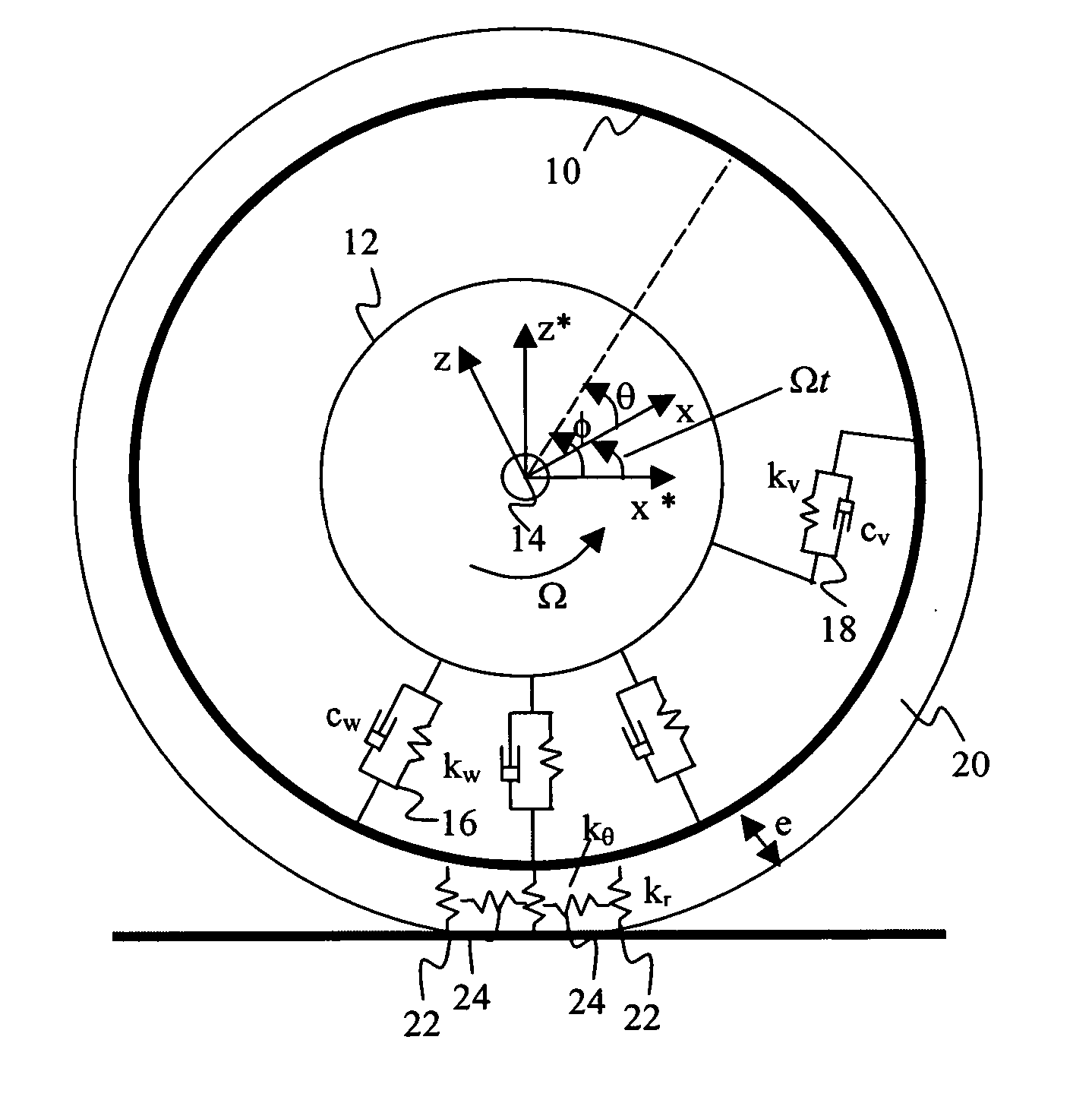

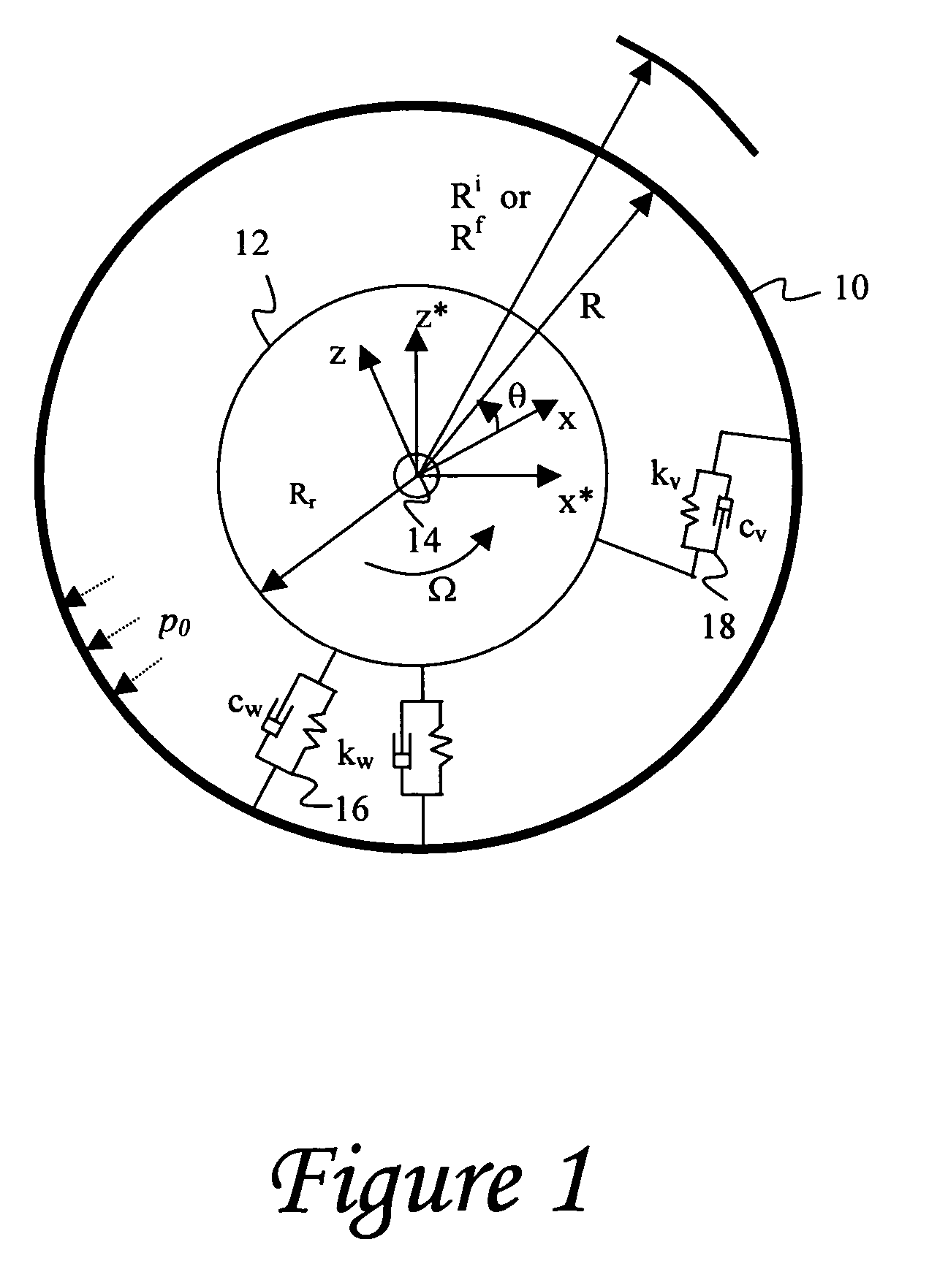

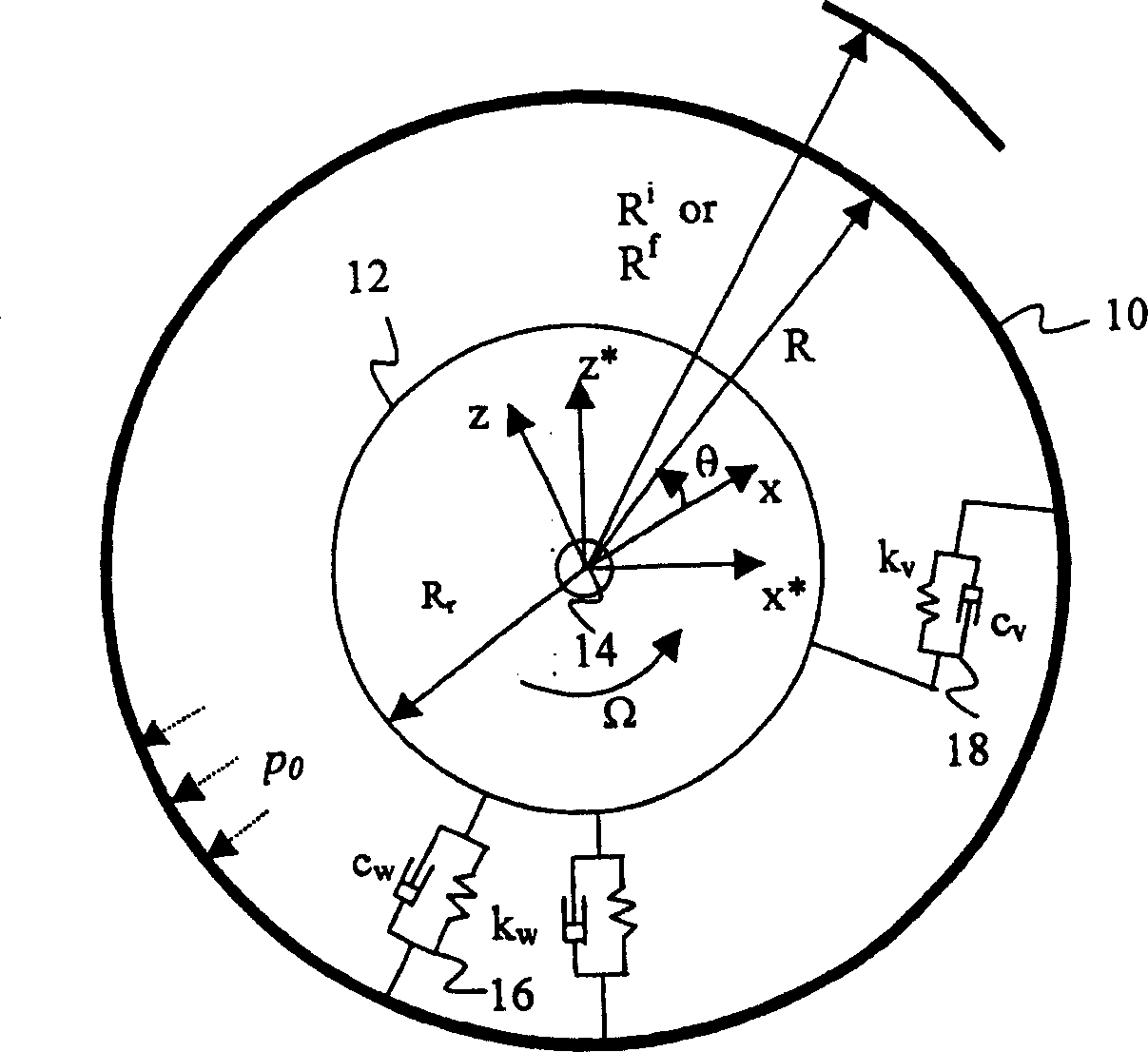

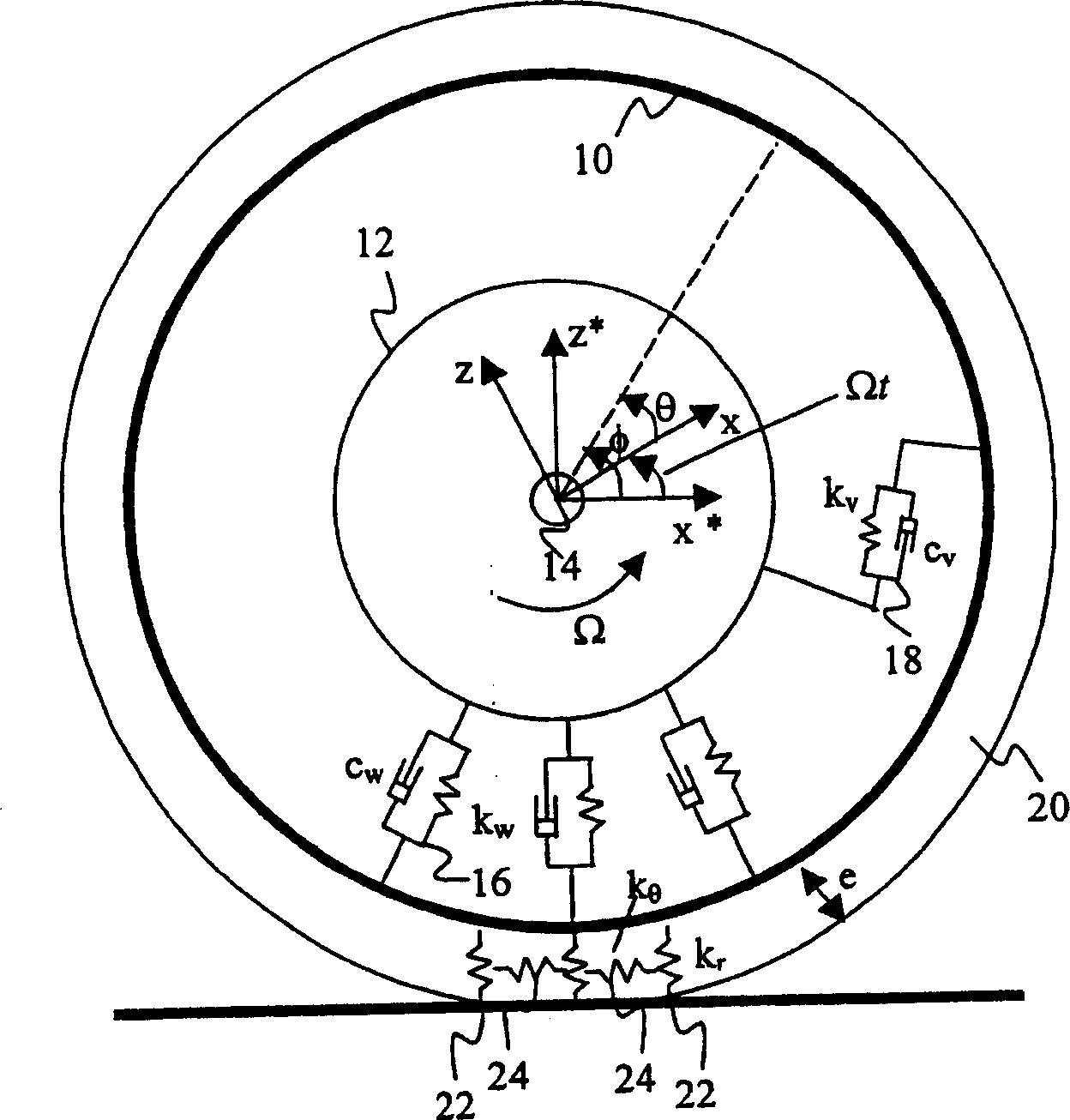

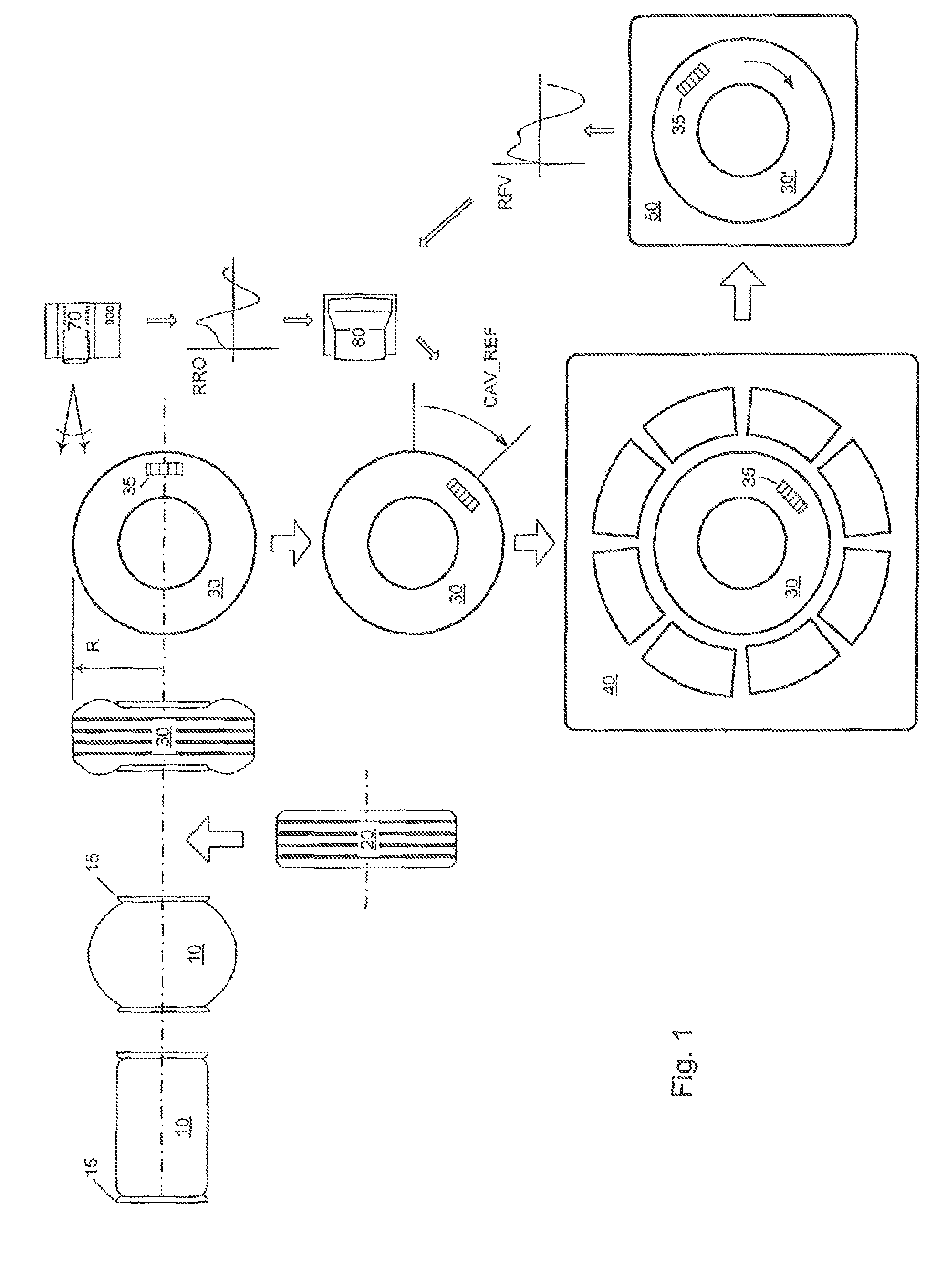

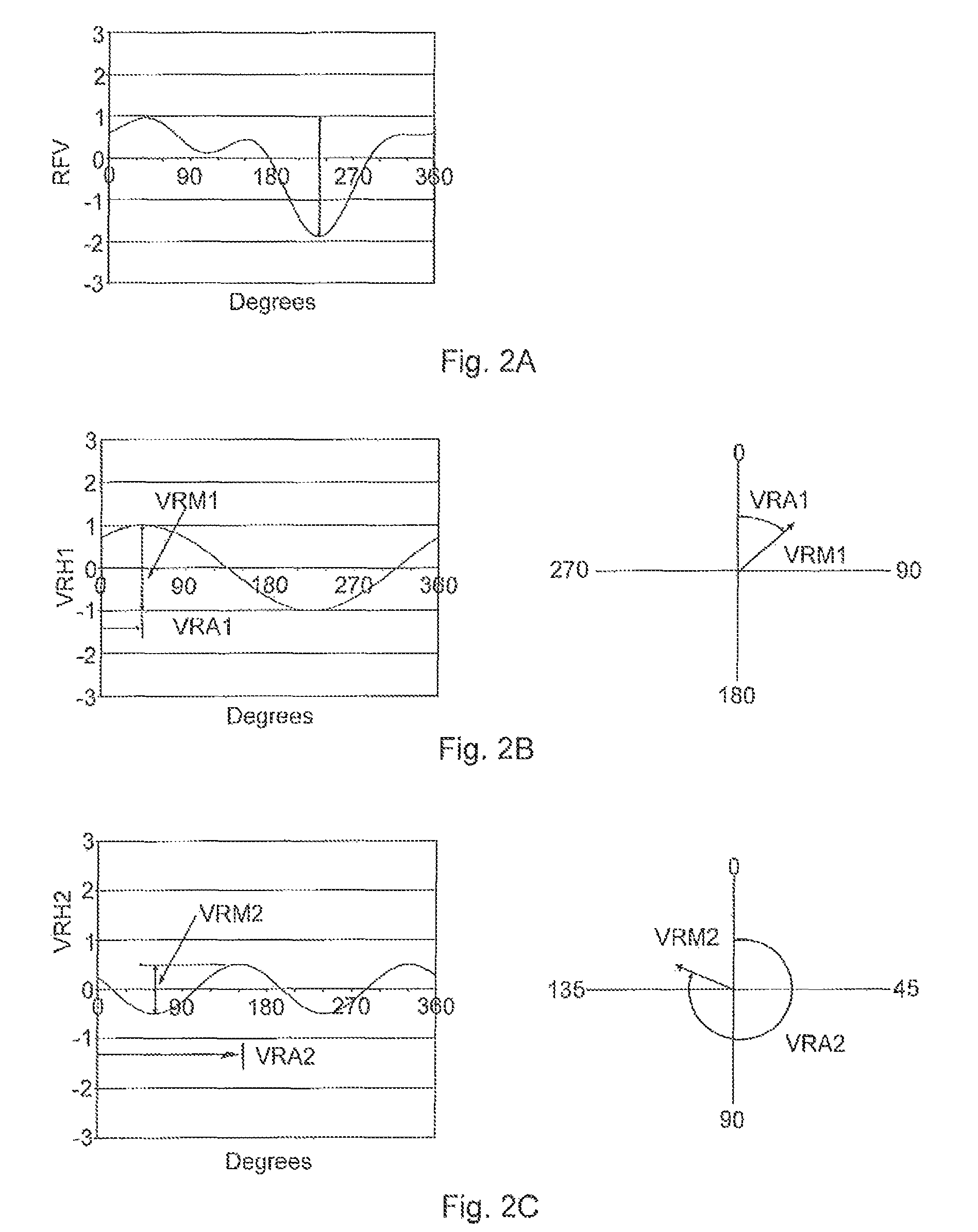

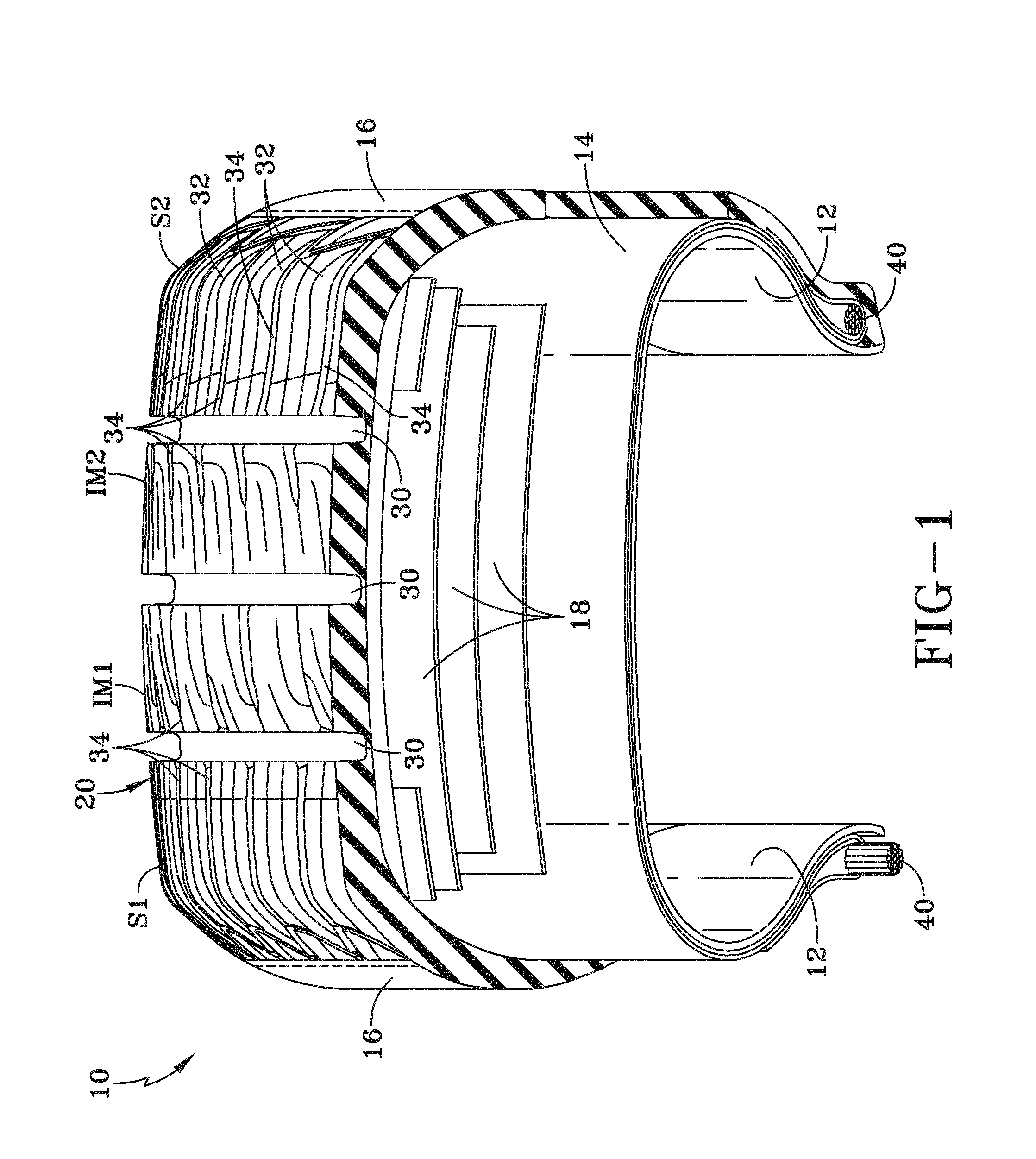

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

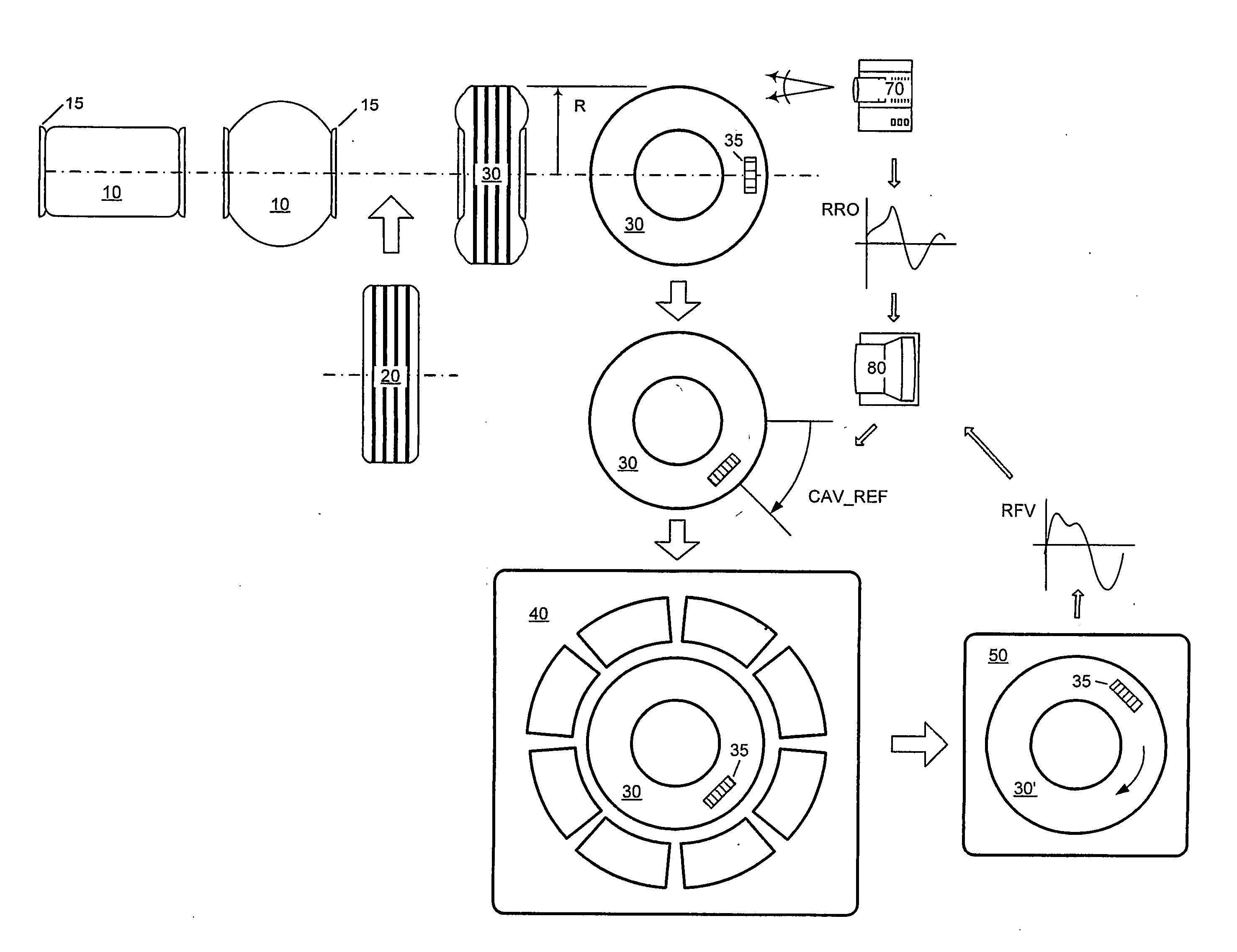

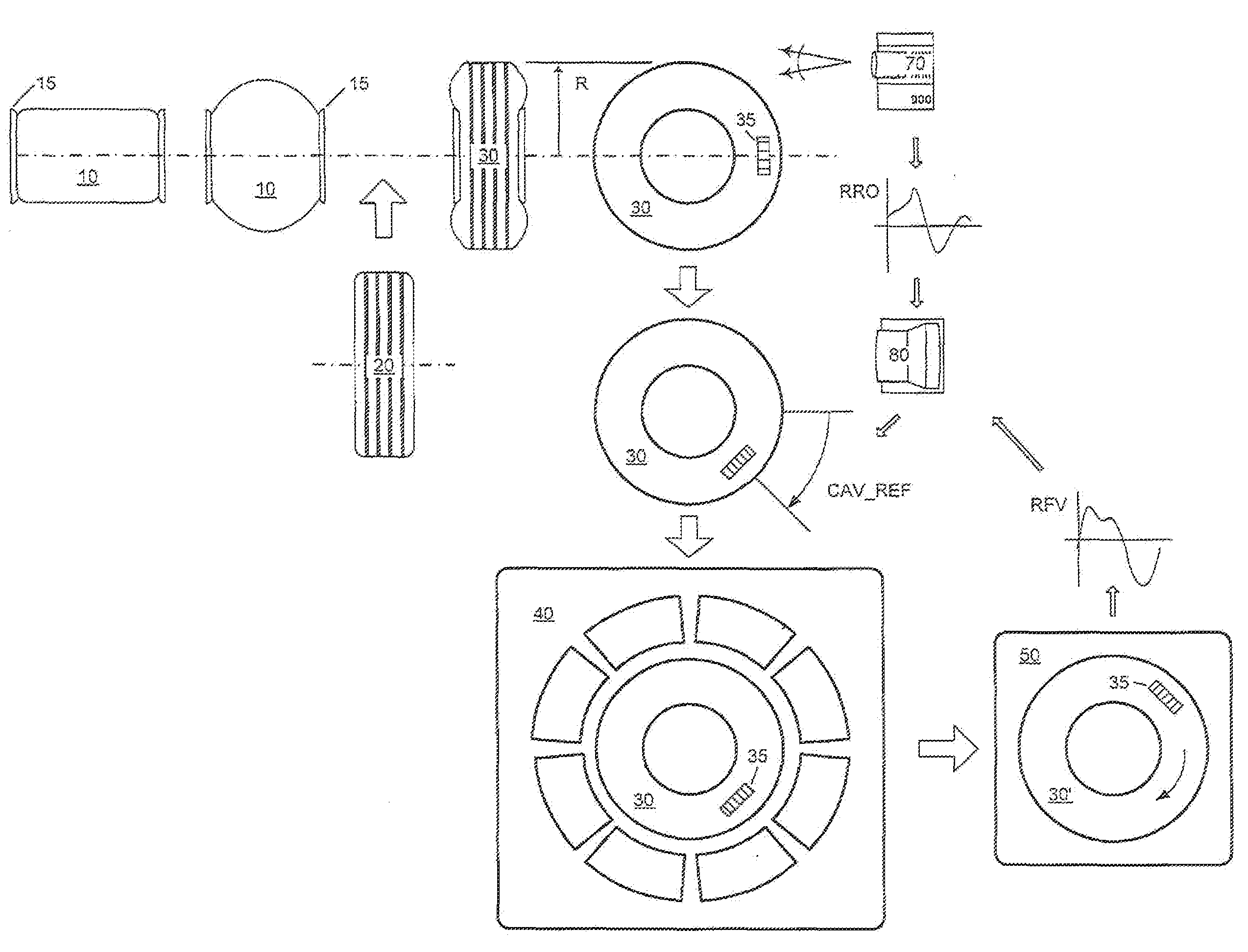

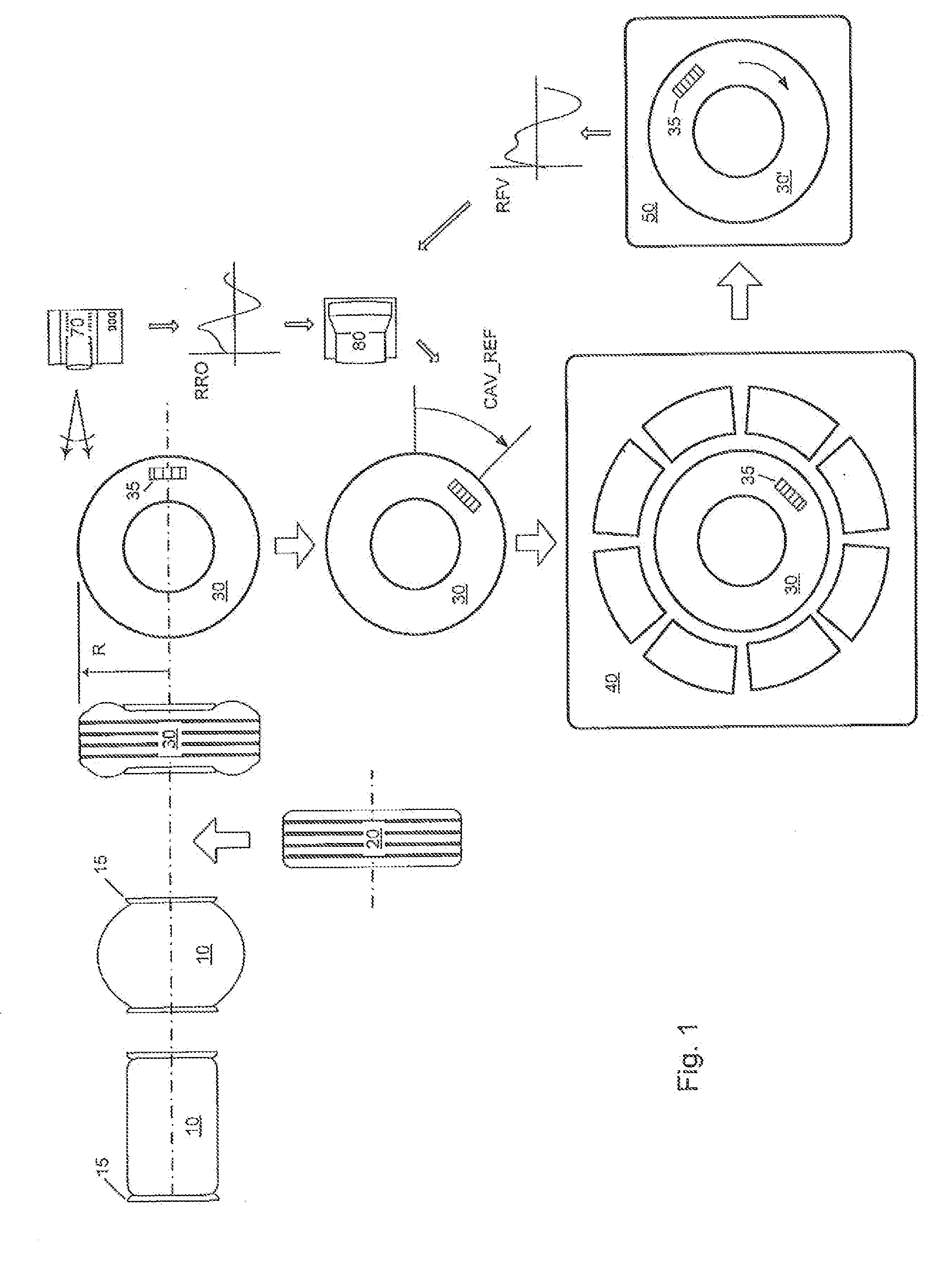

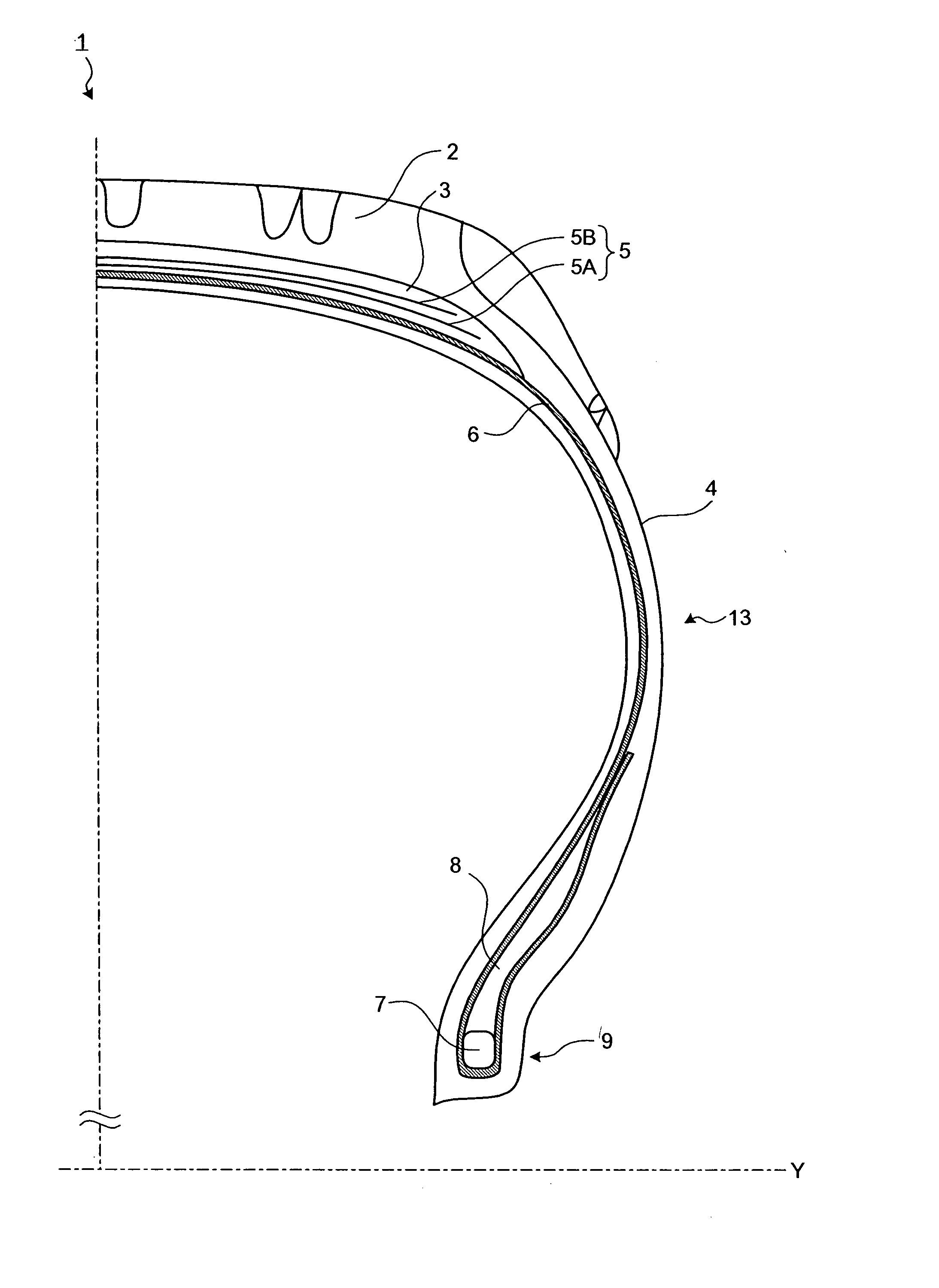

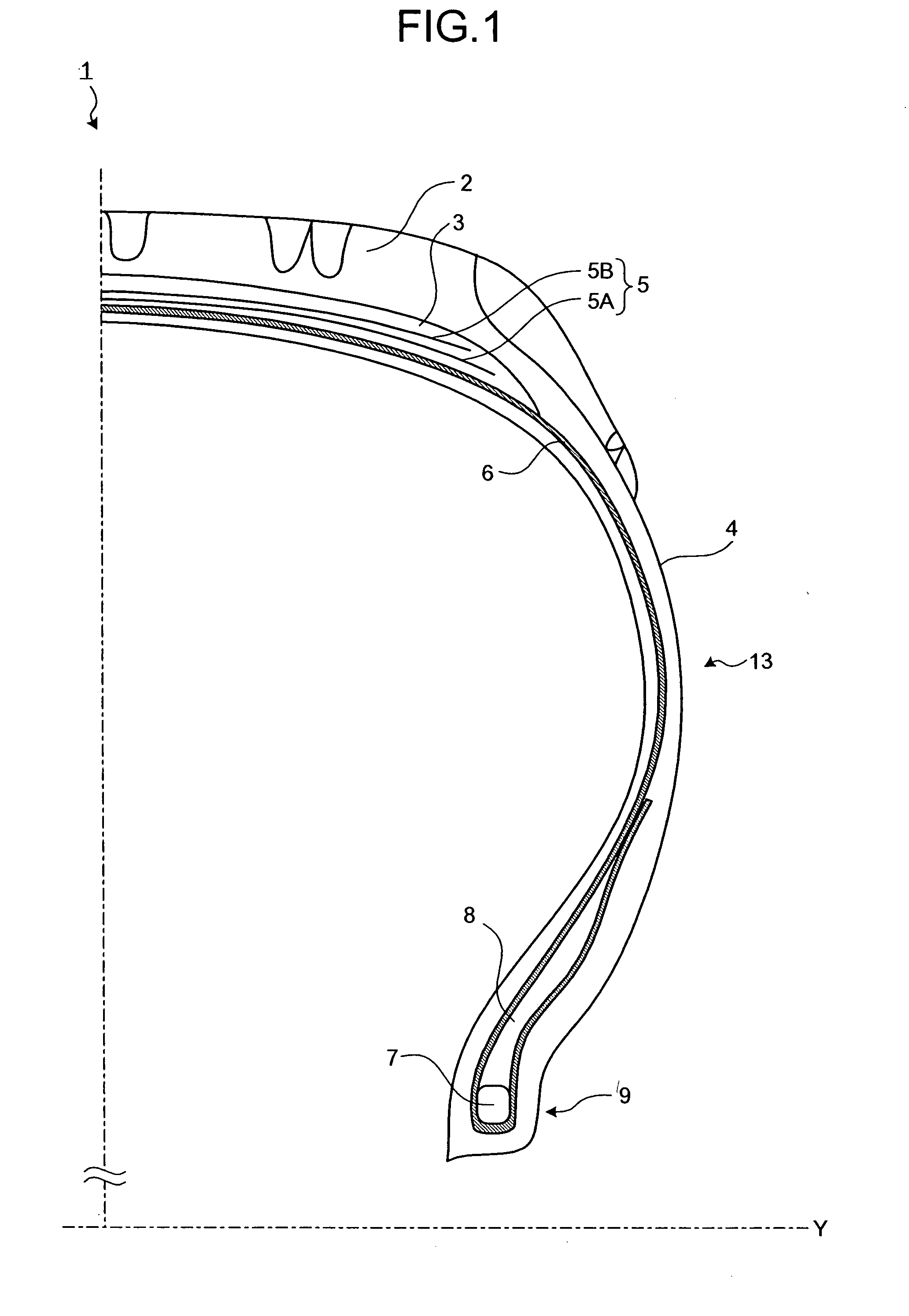

Tire manufacturing method for improving the uniformity of a tire

ActiveUS6856929B1Easy to calculateTyresSpecial data processing applicationsTire uniformityVulcanization

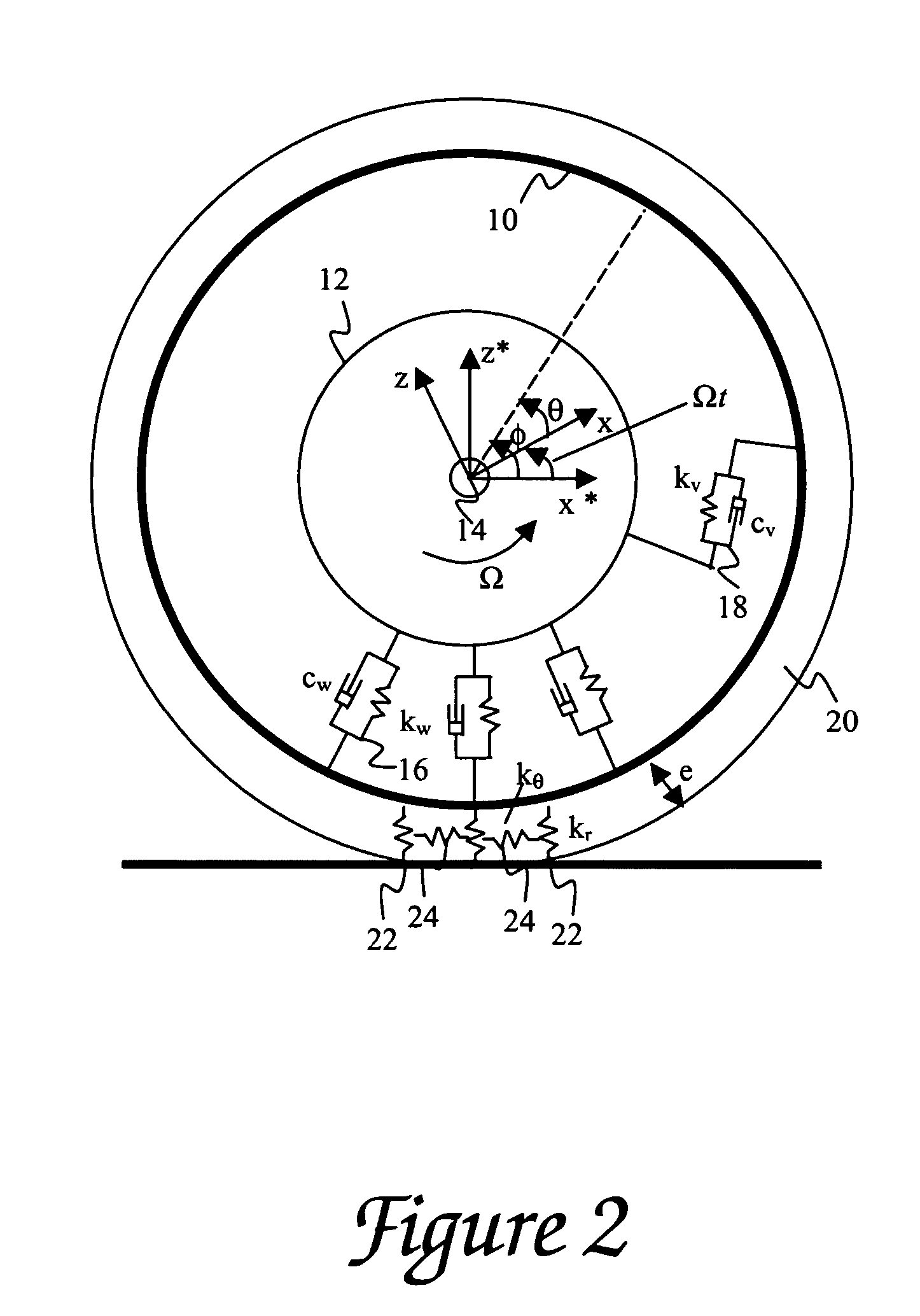

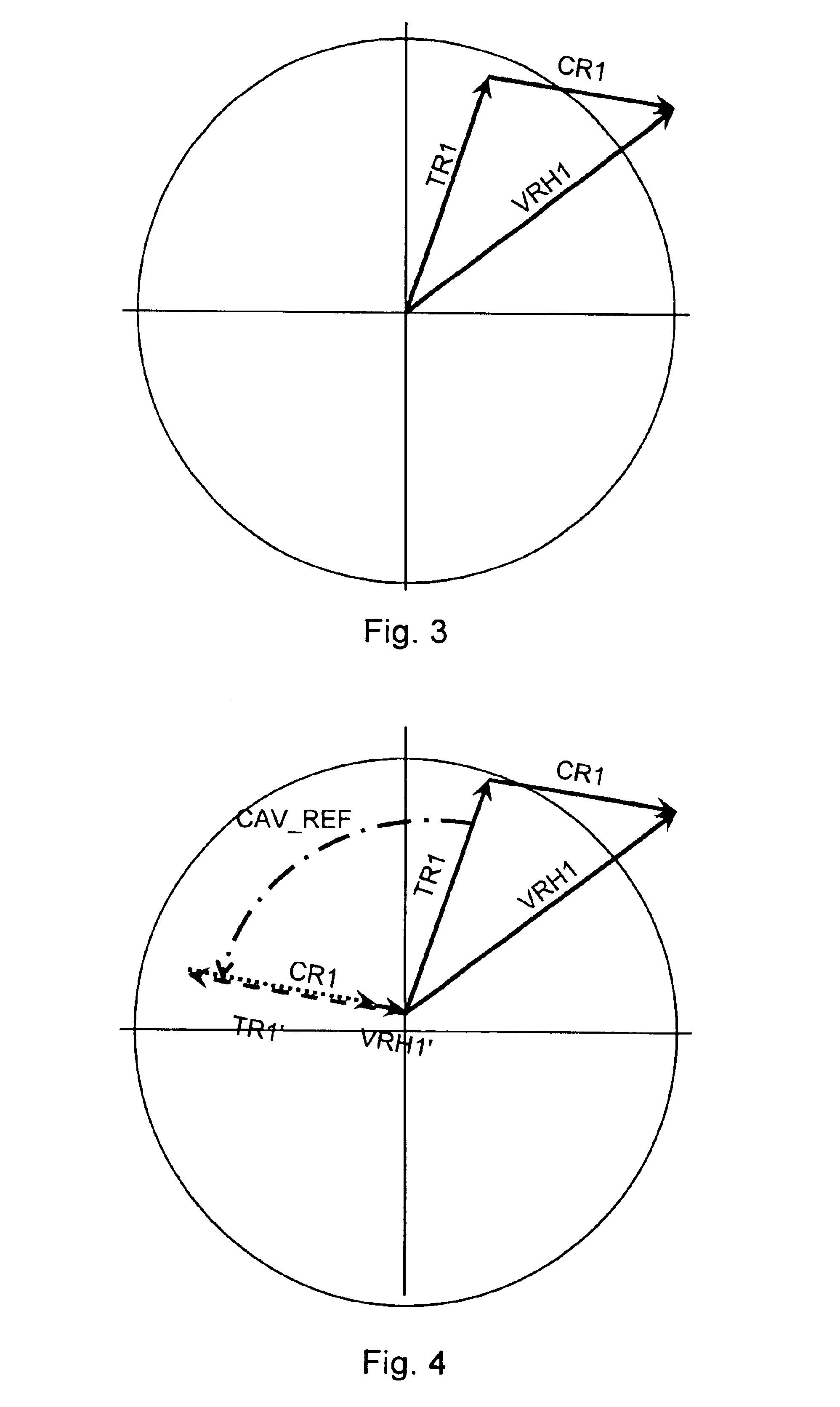

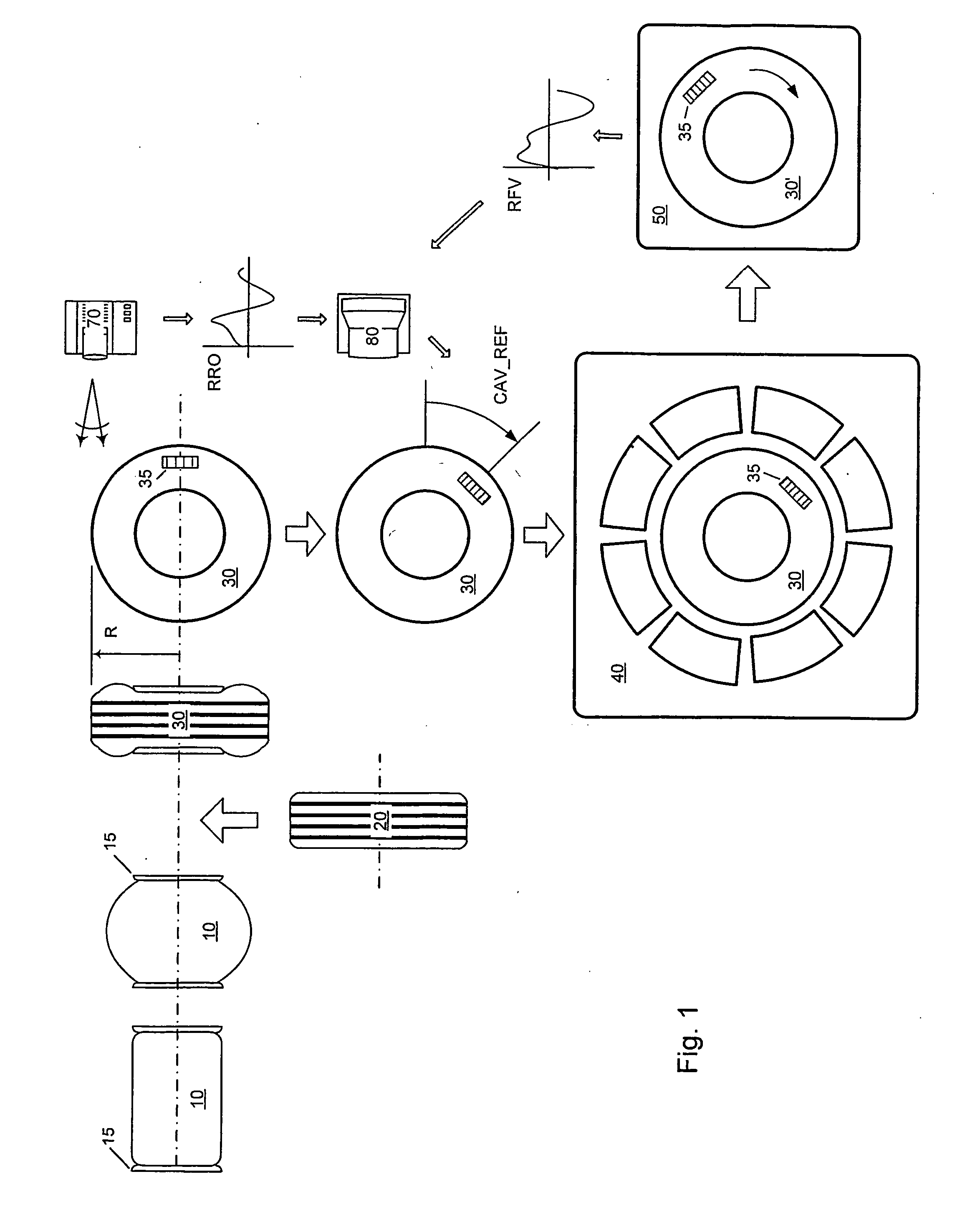

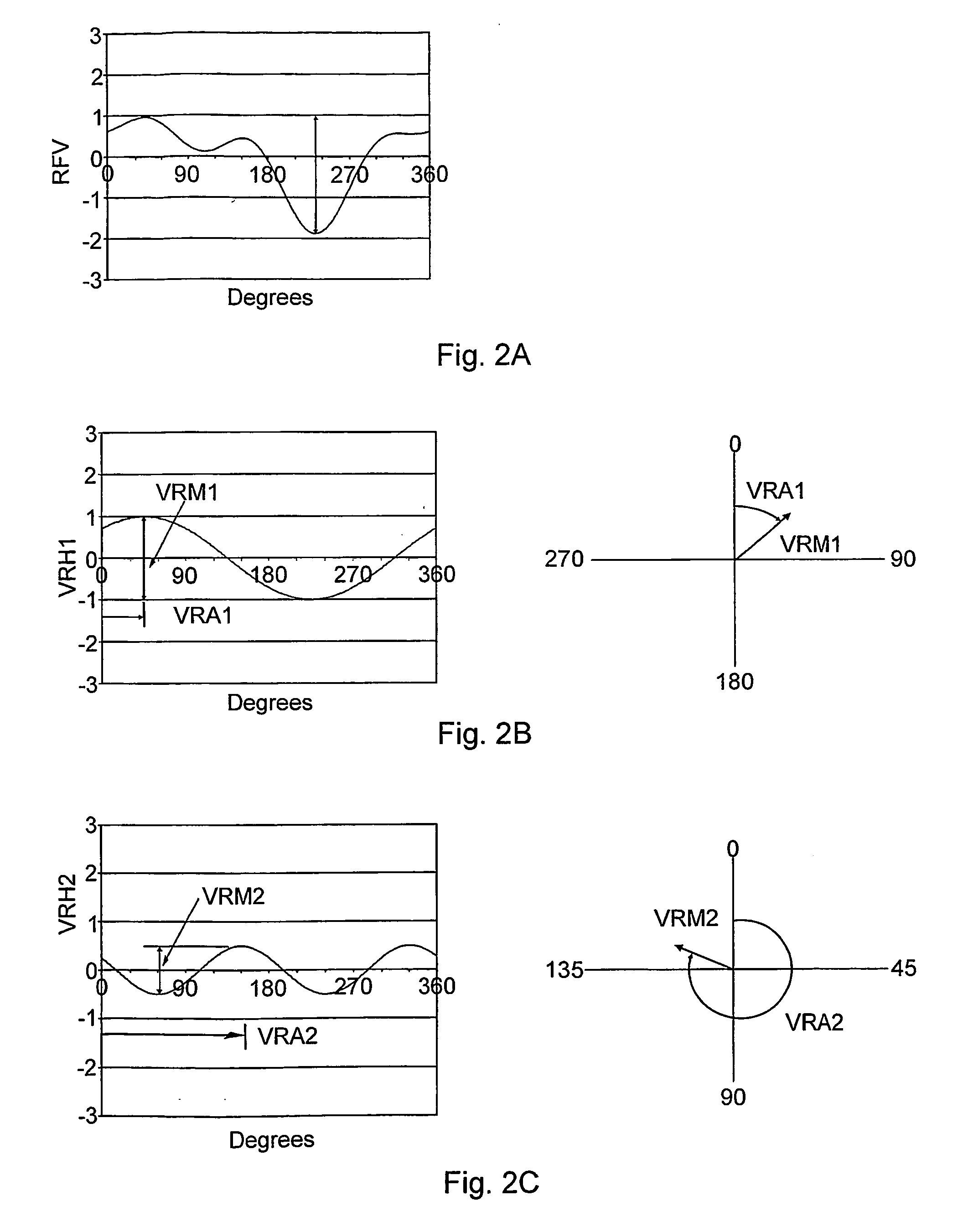

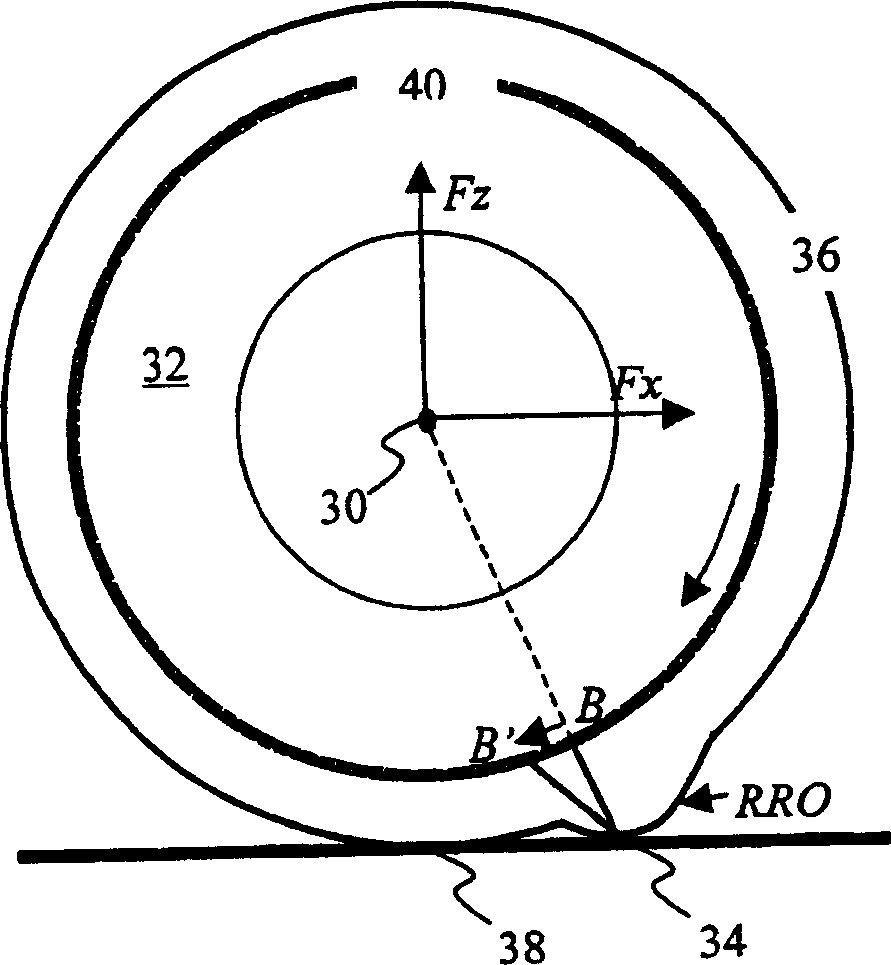

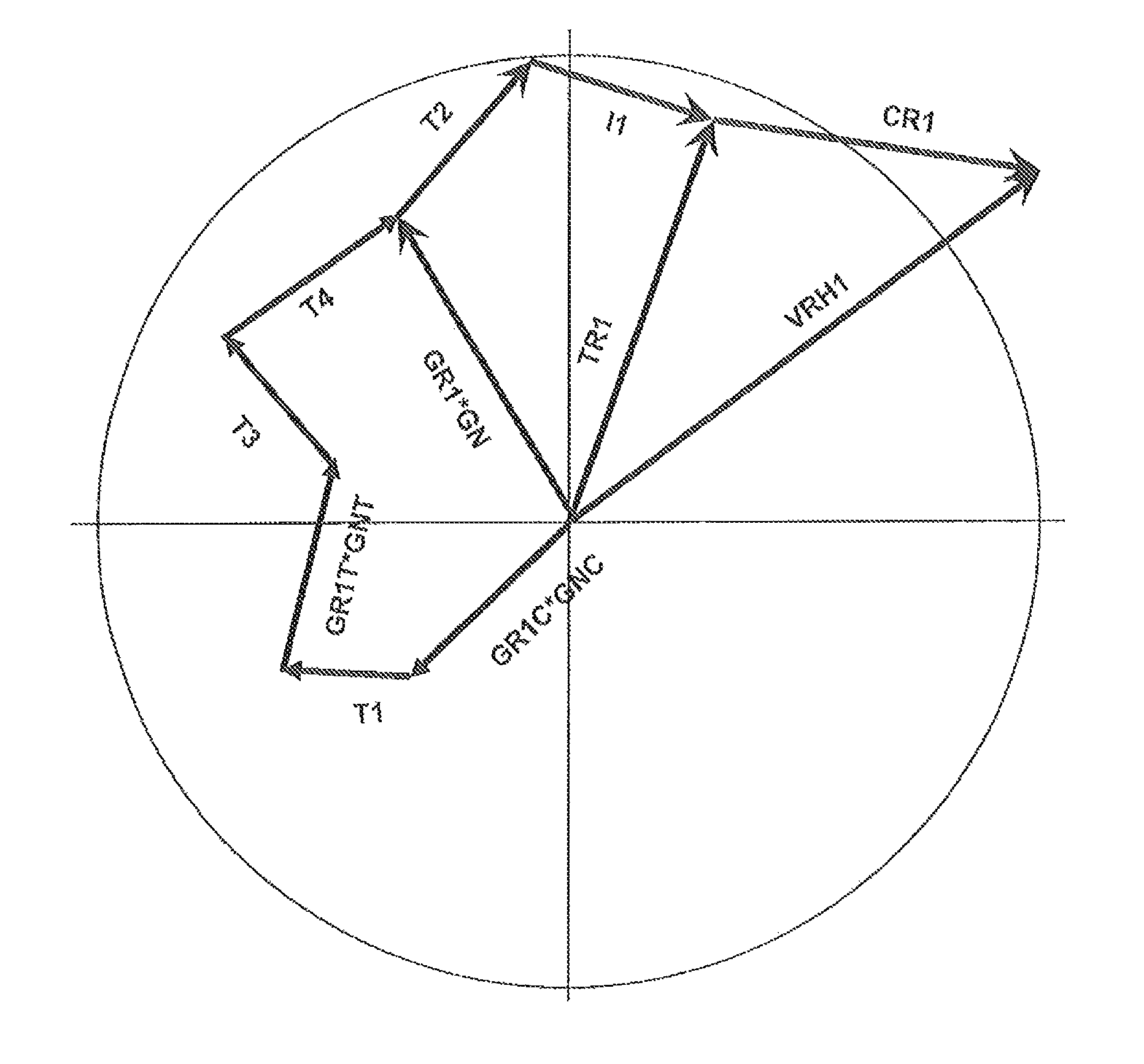

A tire manufacturing method includes a method for optimizing the uniformity of a tire by reducing the after cure radial force variation. The after cure radial force variation vector is modeled as a vector sum of each presenting contributions arising from the tire building steps—the “tire room effect vector” and a vector representing contributions arising from the vulcanization and uniformity measurement steps—the “curing room effect vector.” In further detail, both the tire room and curing room effect vectors can be further decomposed into sub-vectors representing each radial force variation contribution for which a measurable indicator is available. For a series of tires, the method obtains such measurements as the before cure radial runout (RRO) at one or more stages of the building sequence, measurements of loading angles on the tire building equipment, and measurements made during vulcanization process.

Owner:MICHELIN RECH & TECH SA

Tire uniformity through compensation between radial run out and stiffness variation

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

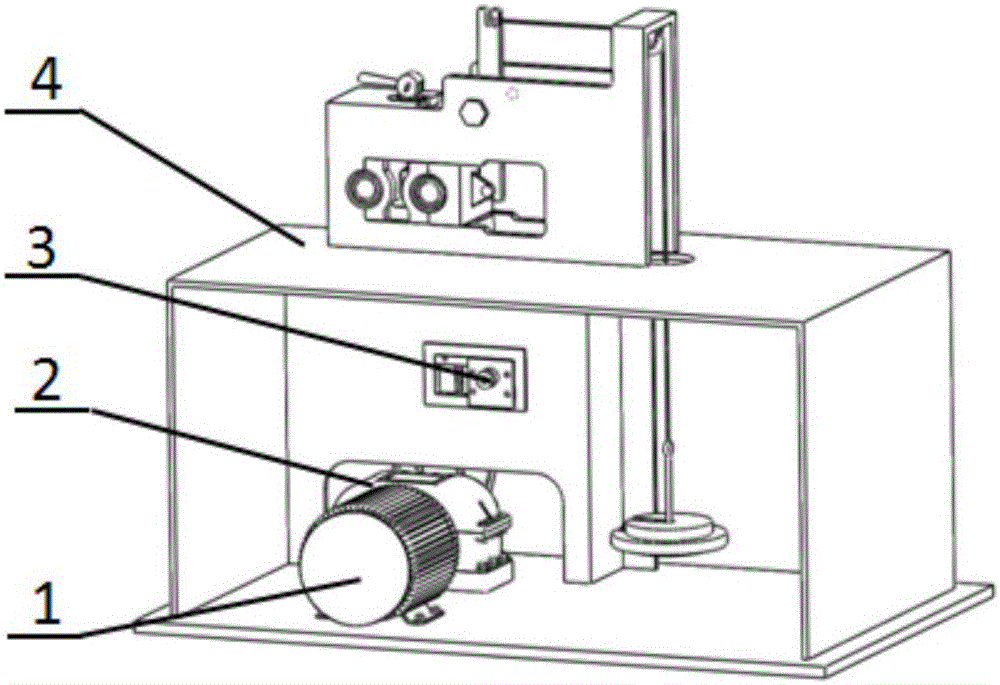

Method for prediction and control of harmonic components of tire uniformity parameters

ActiveUS20130090879A1Static/dynamic balance measurementData acquisition and loggingTire uniformityHarmonic

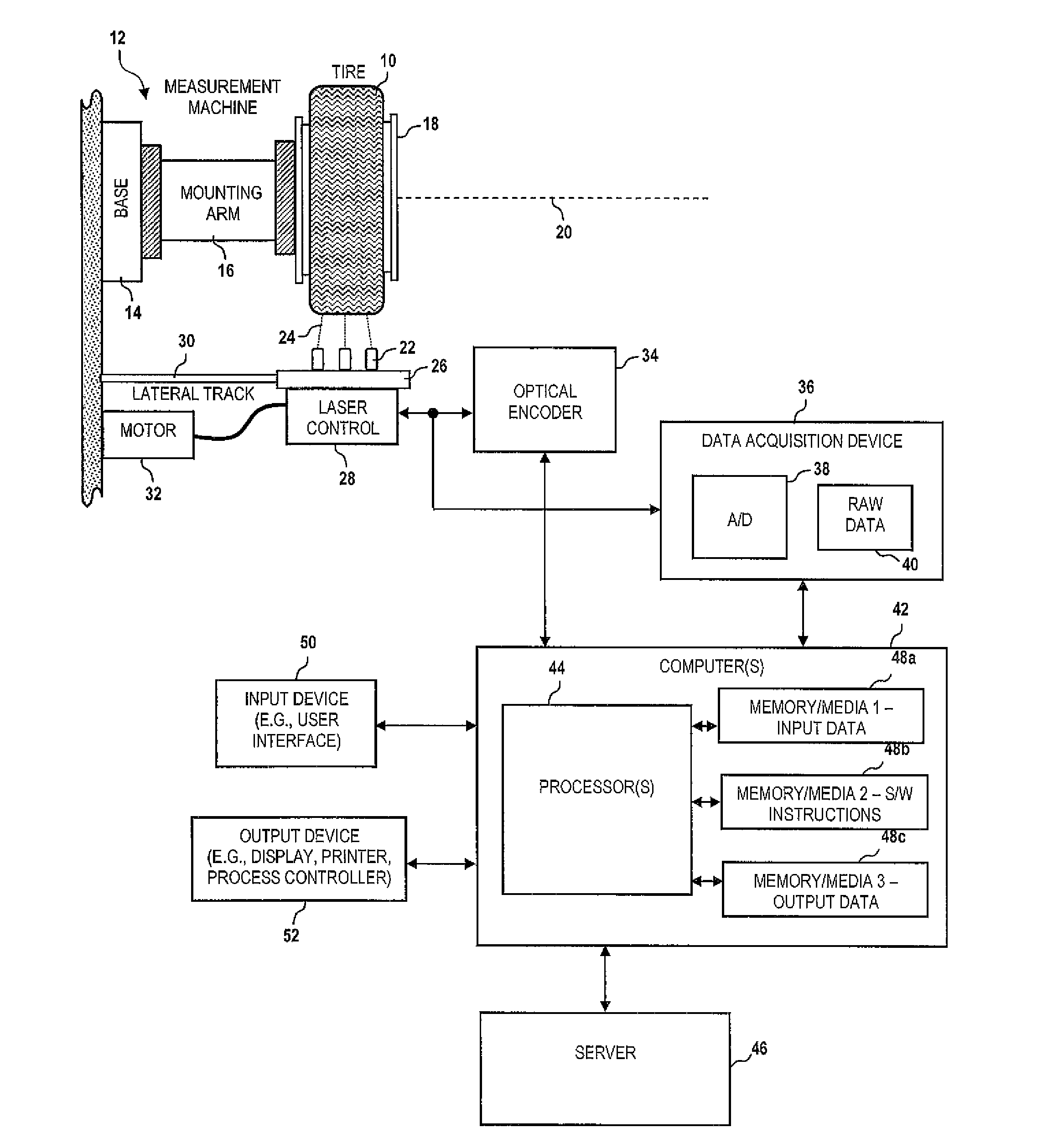

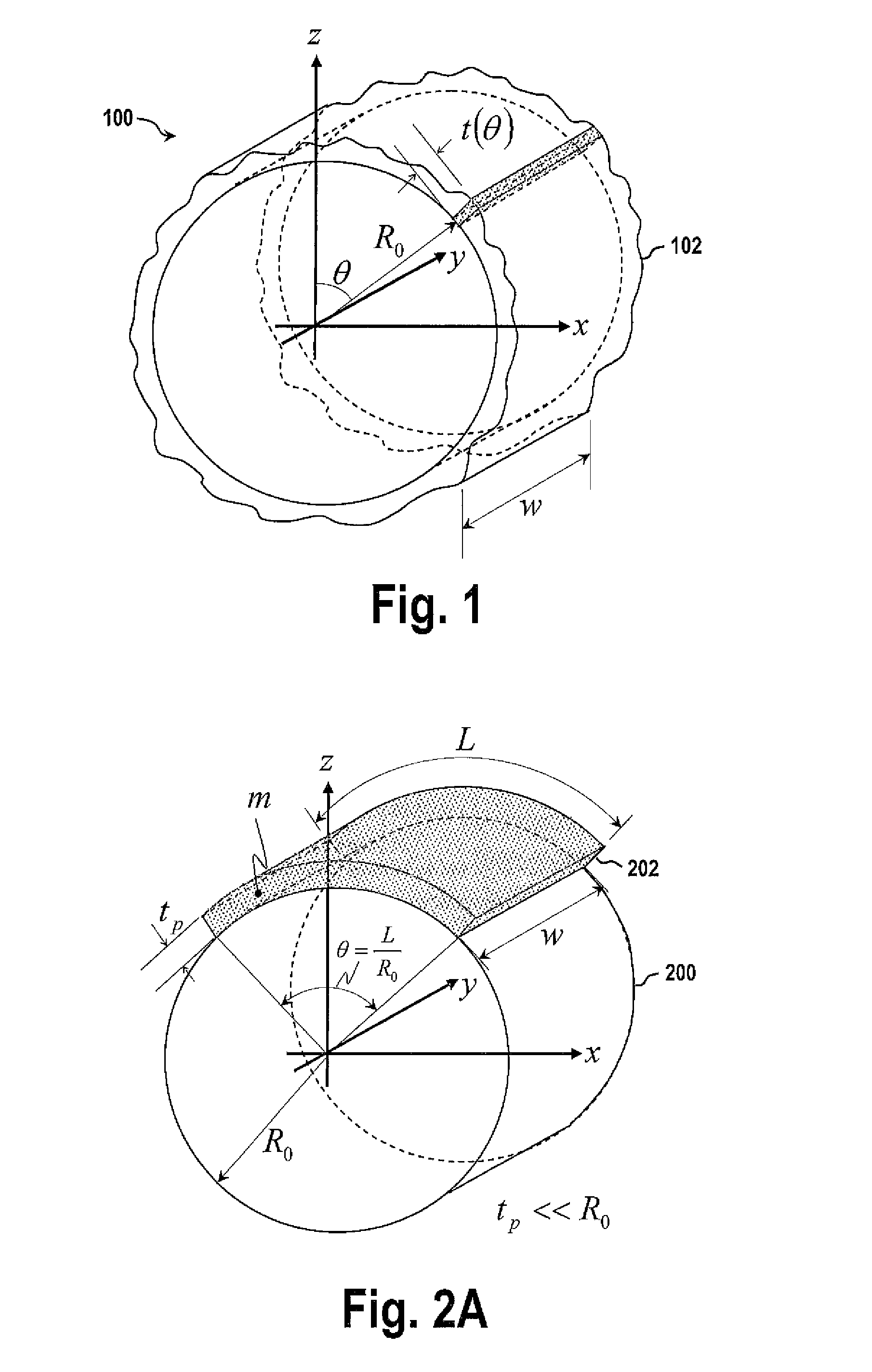

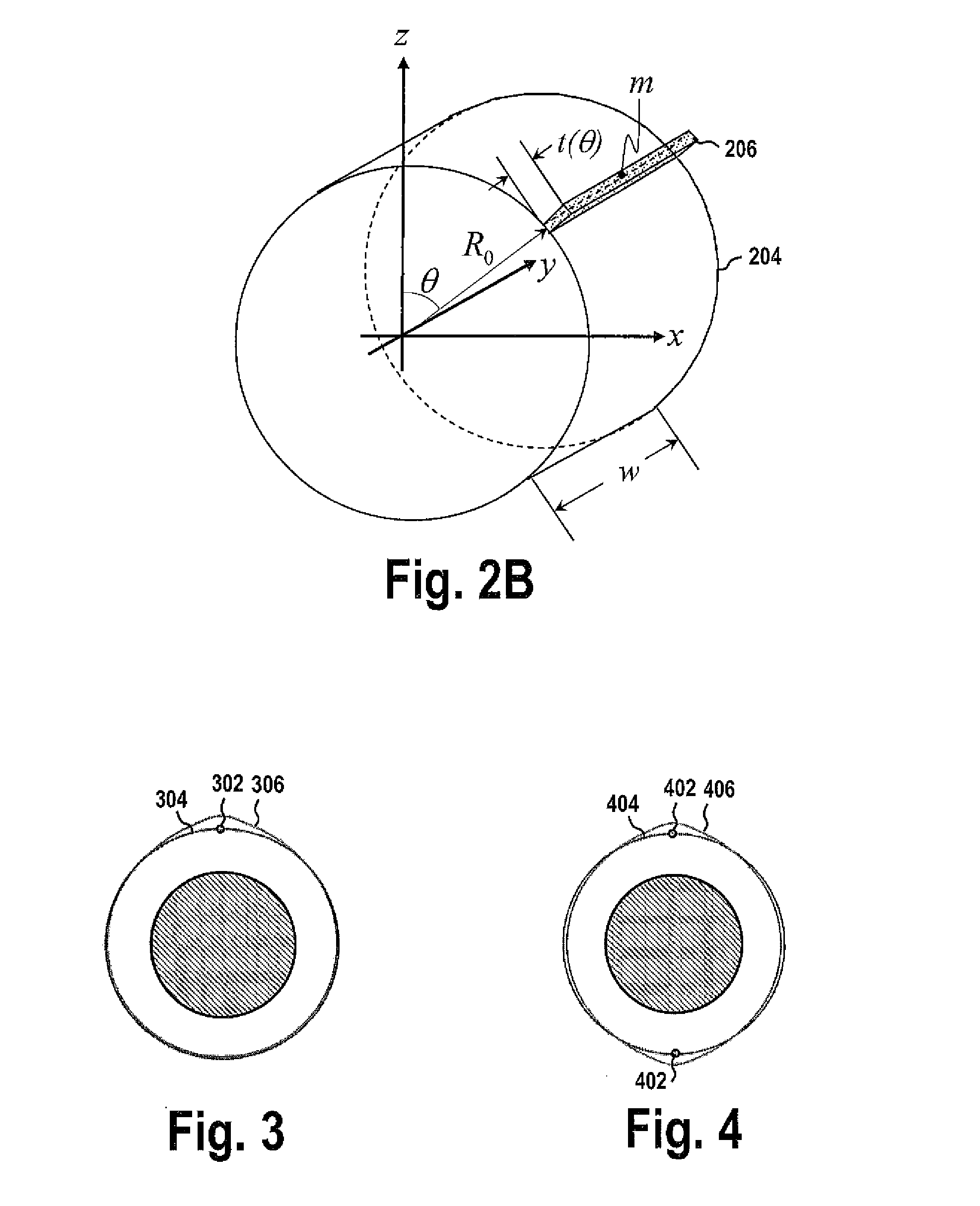

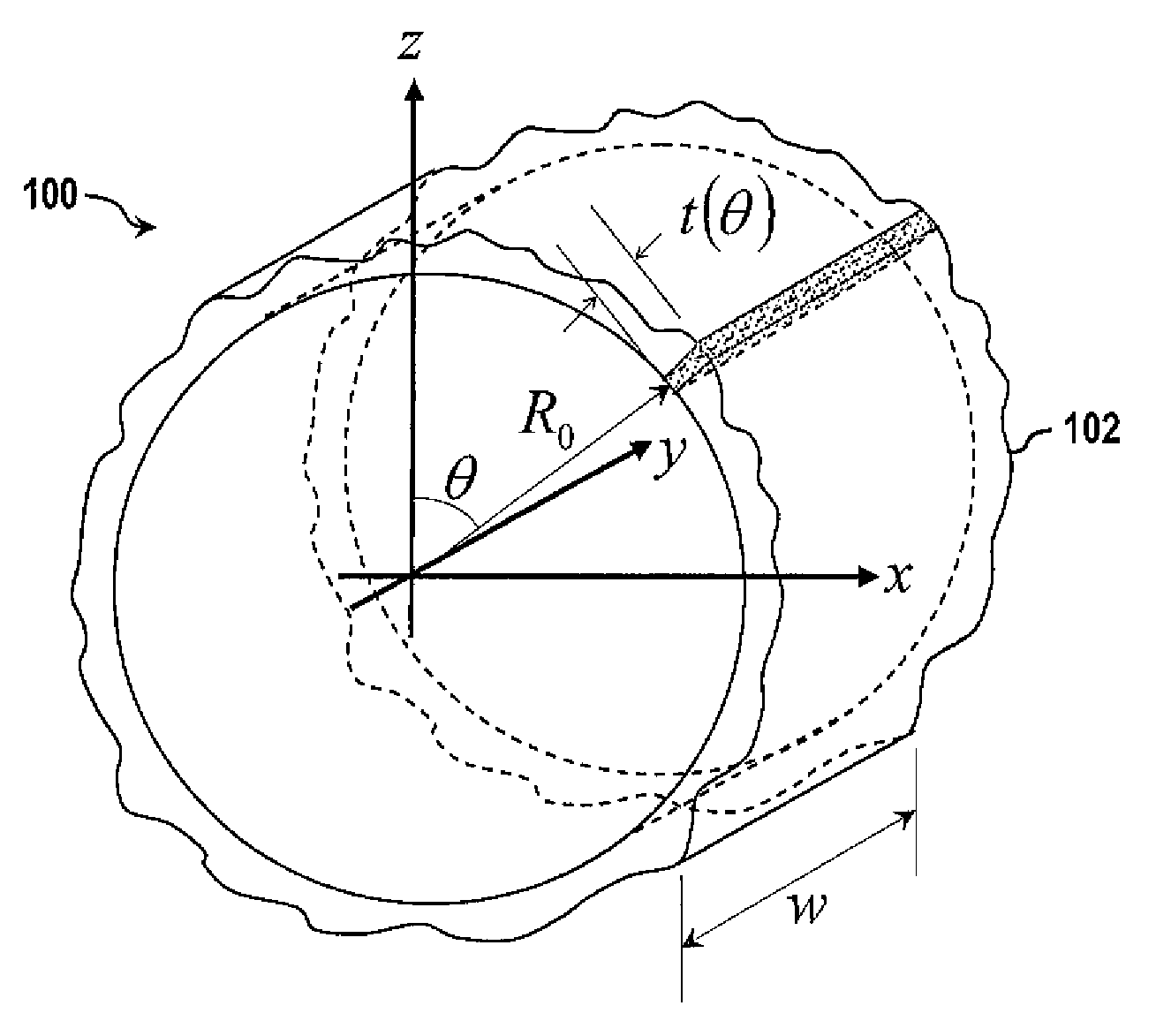

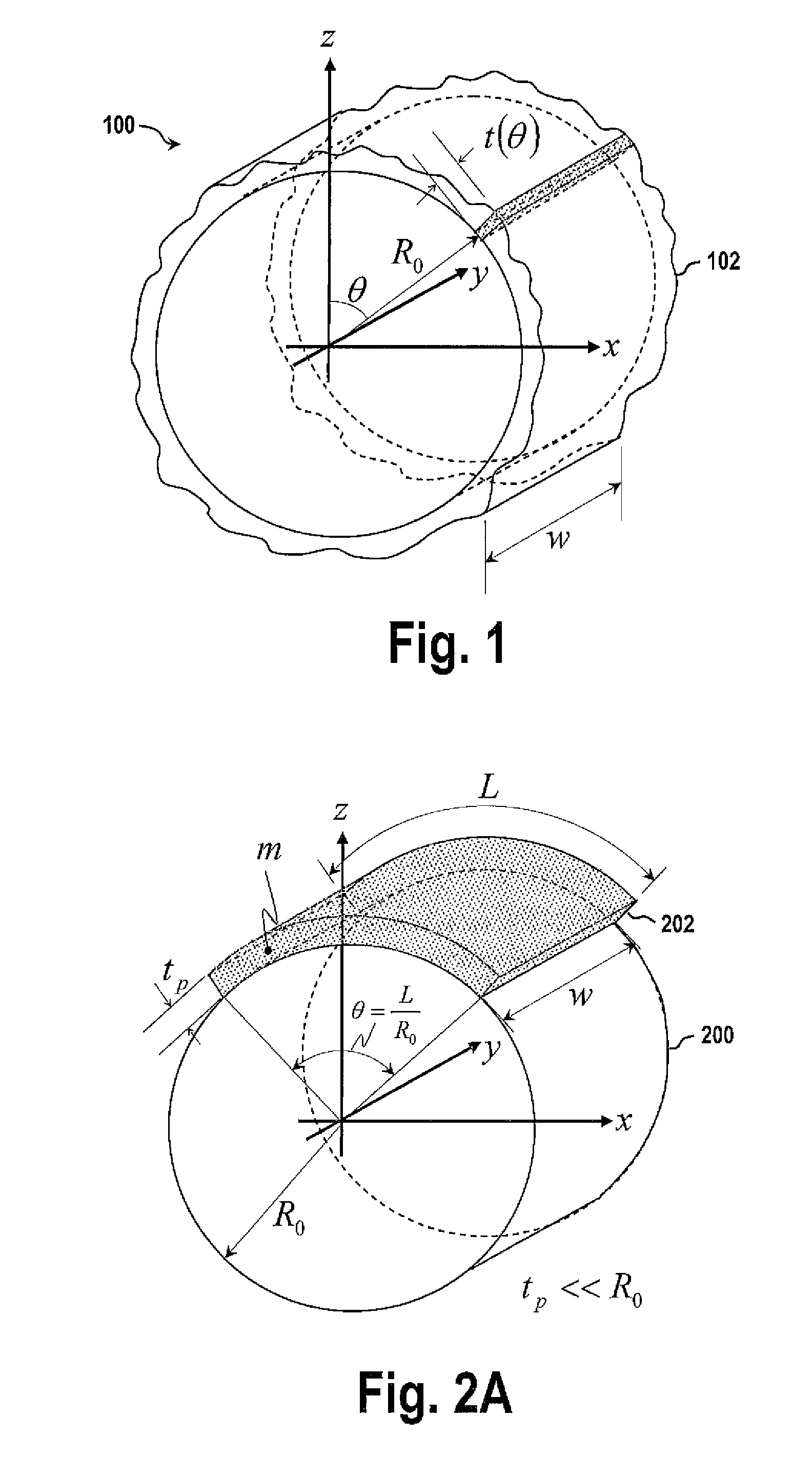

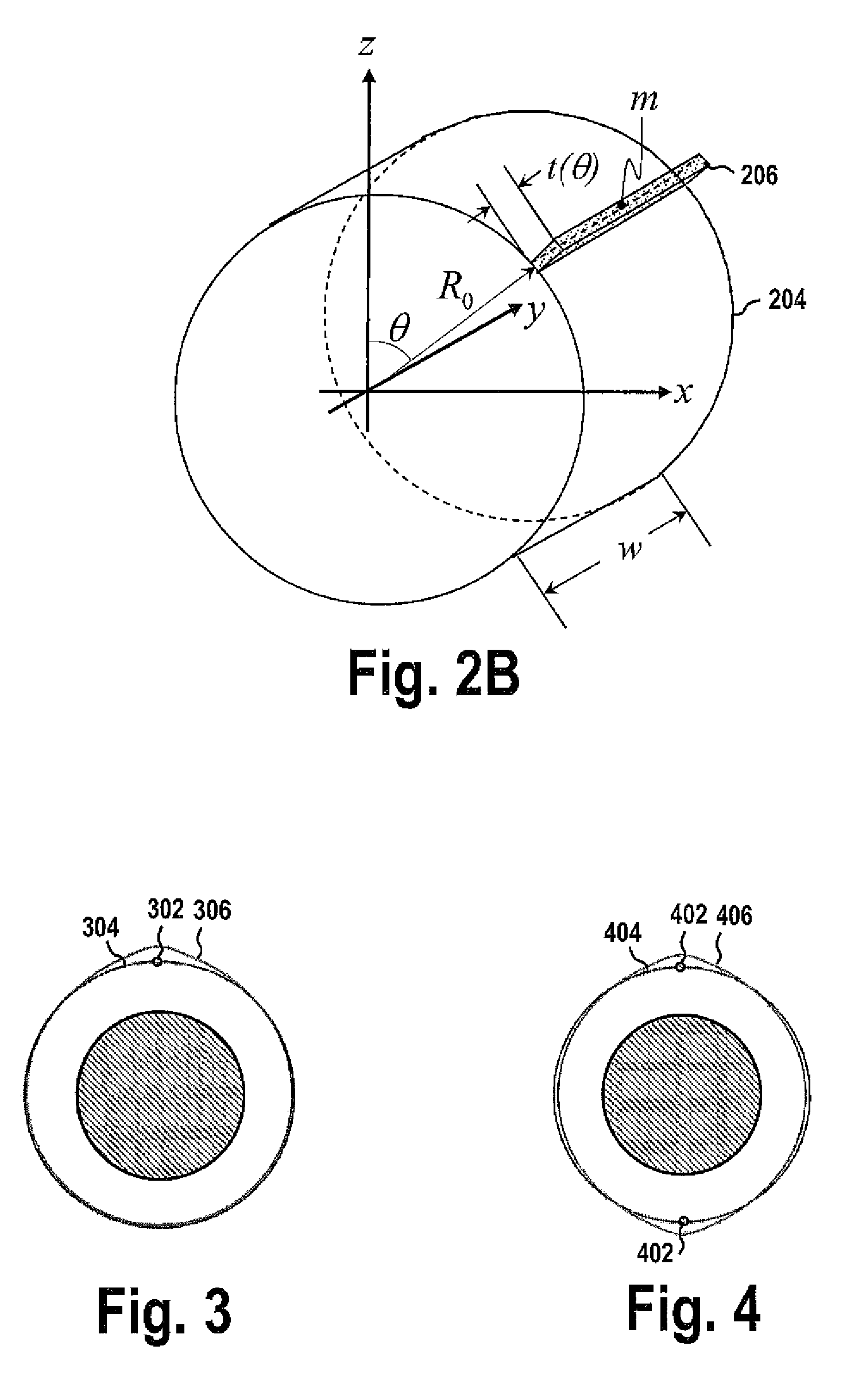

Improved and more easily implemented methods for predicting high speed radial force variation and uneven mass distribution utilize other measurements such as radial nm out and other parameters. The prediction model for high speed radial force variation uses a speed-dependent calibration term for predicting higher harmonic components, while the same or other models can be used for the first harmonic. The uneven mass distribution prediction model accounts for deformation of the tire along multiple tracks, thus employing a more realistic model of crown deformation that accounts for changing tire stiffness levels across different harmonic components of the measured and predicted parameters.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

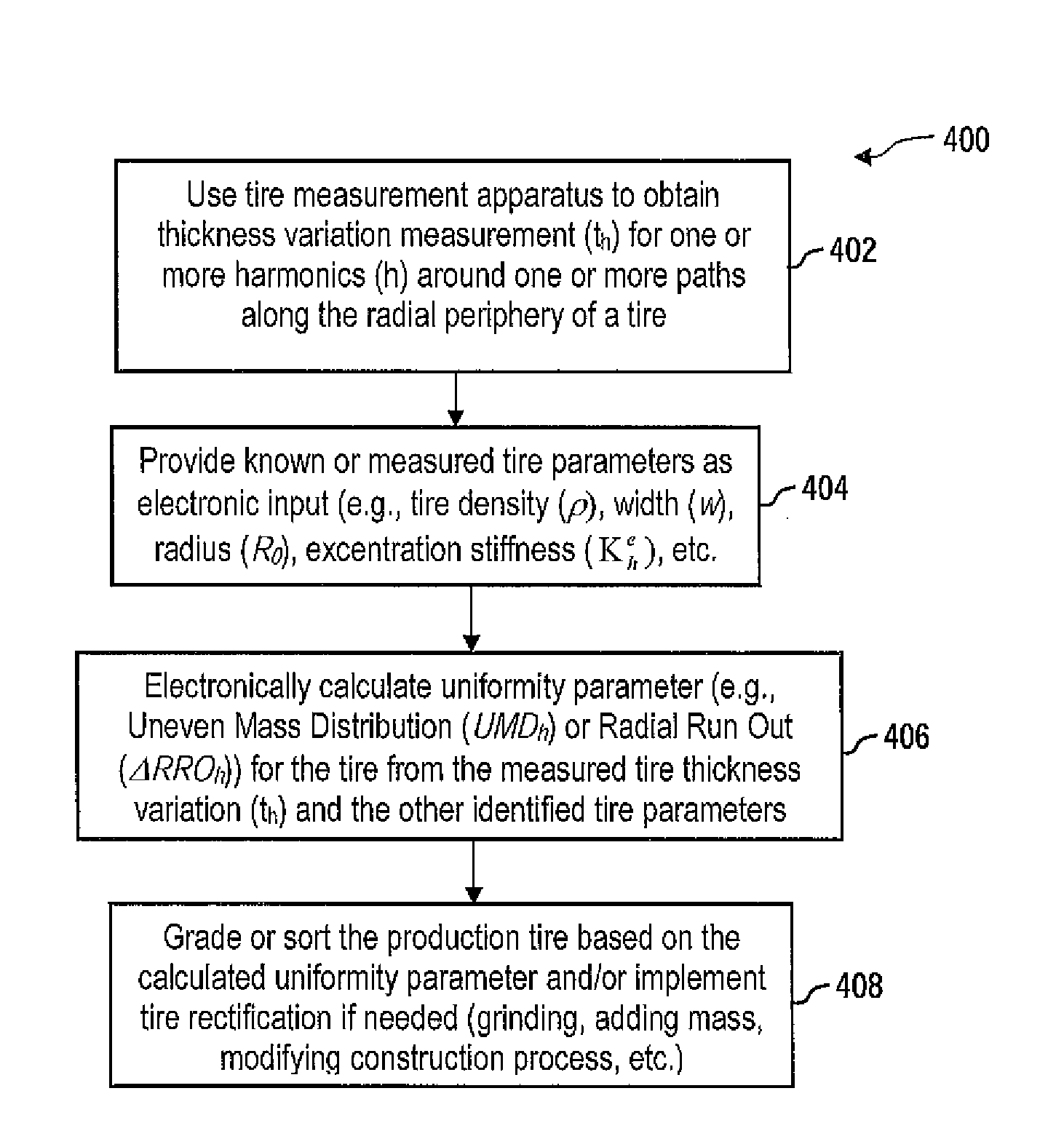

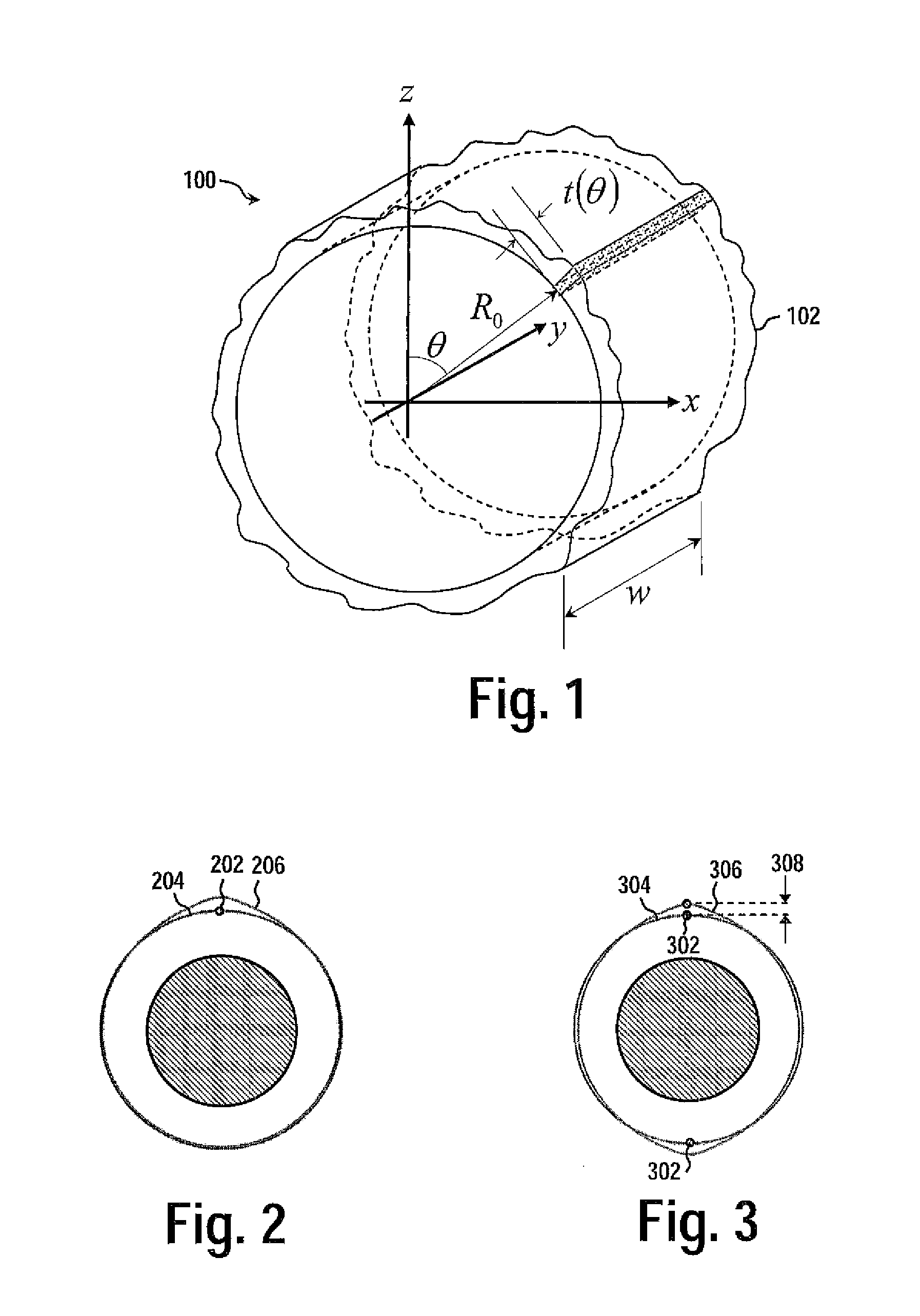

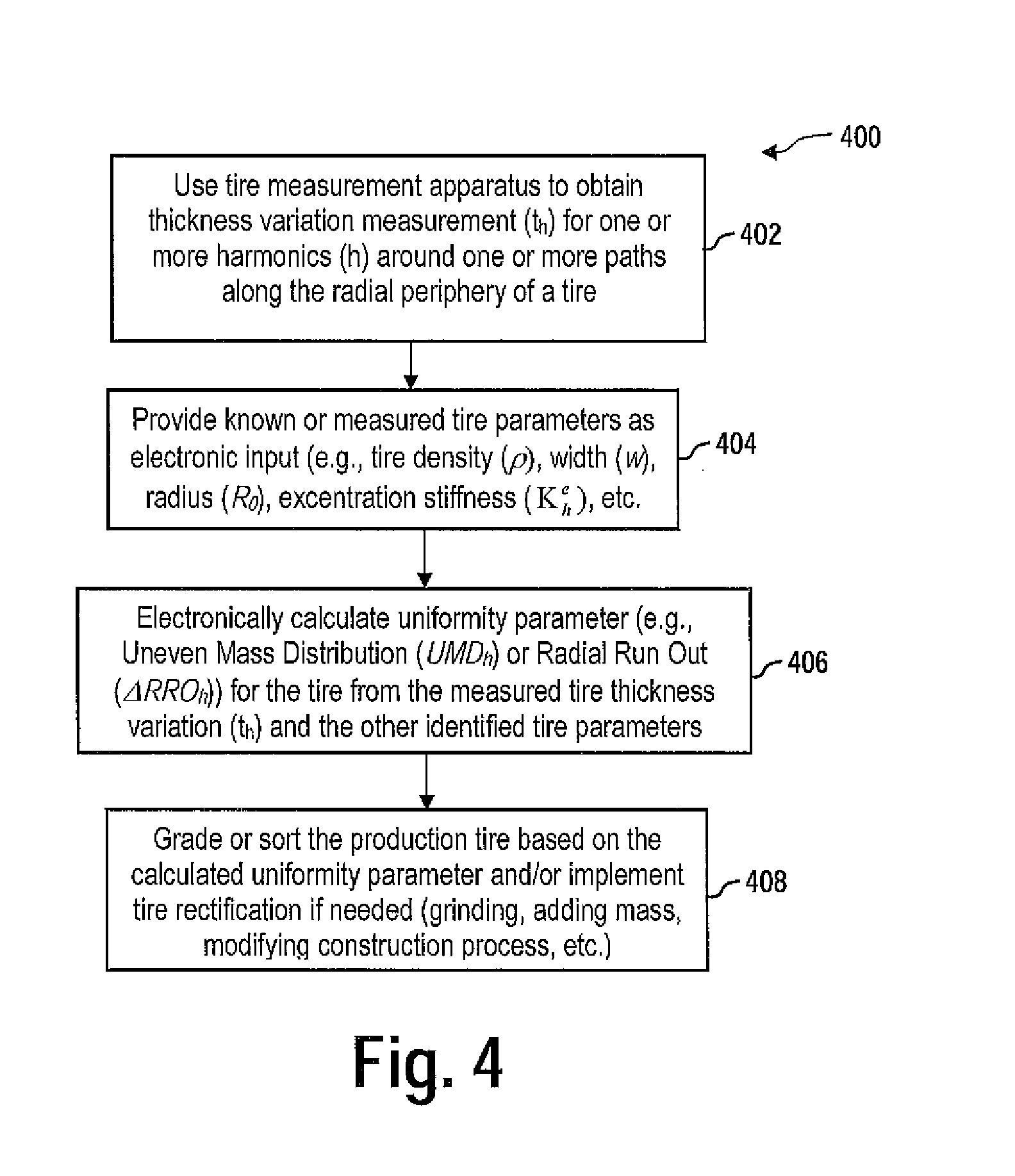

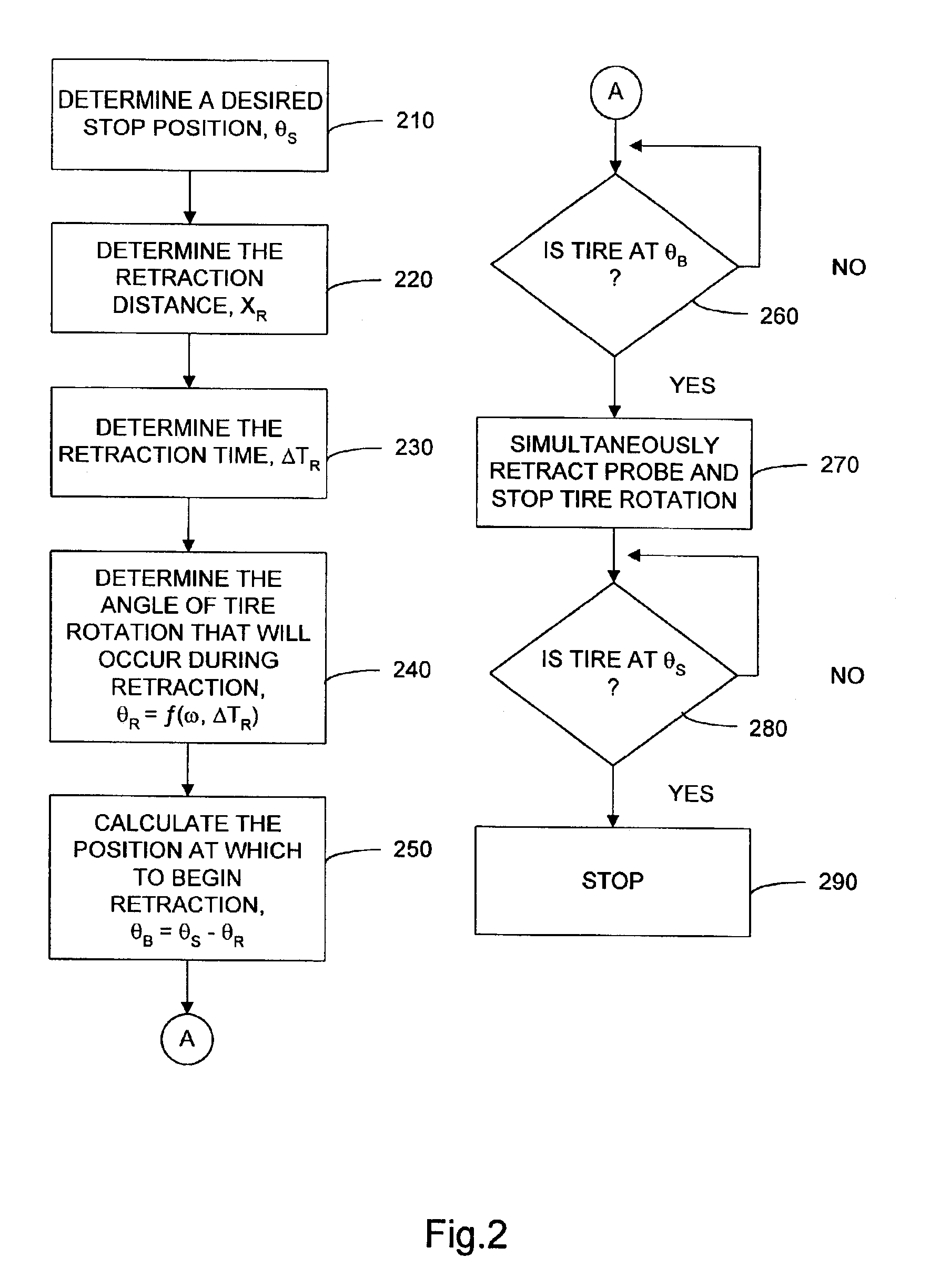

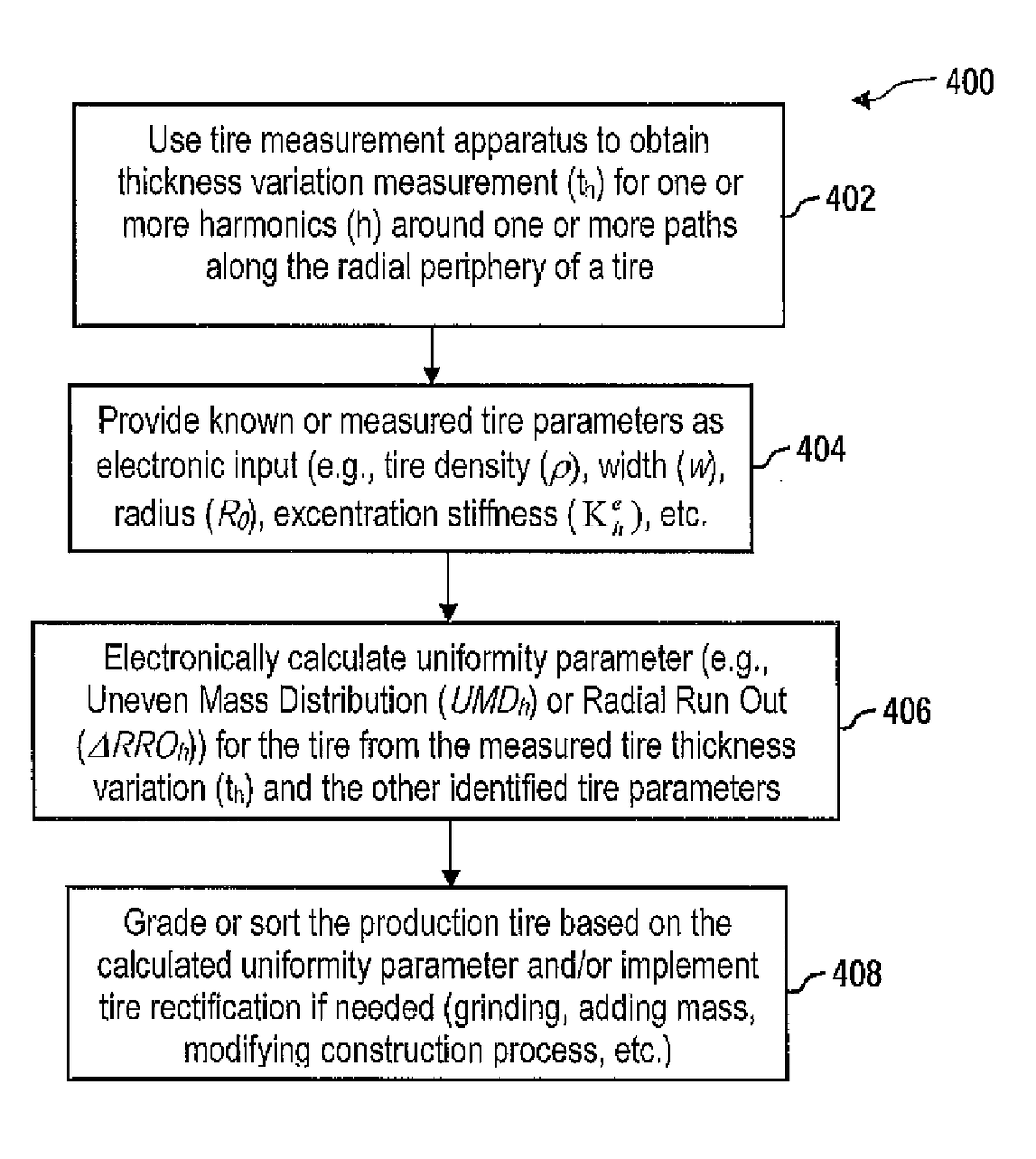

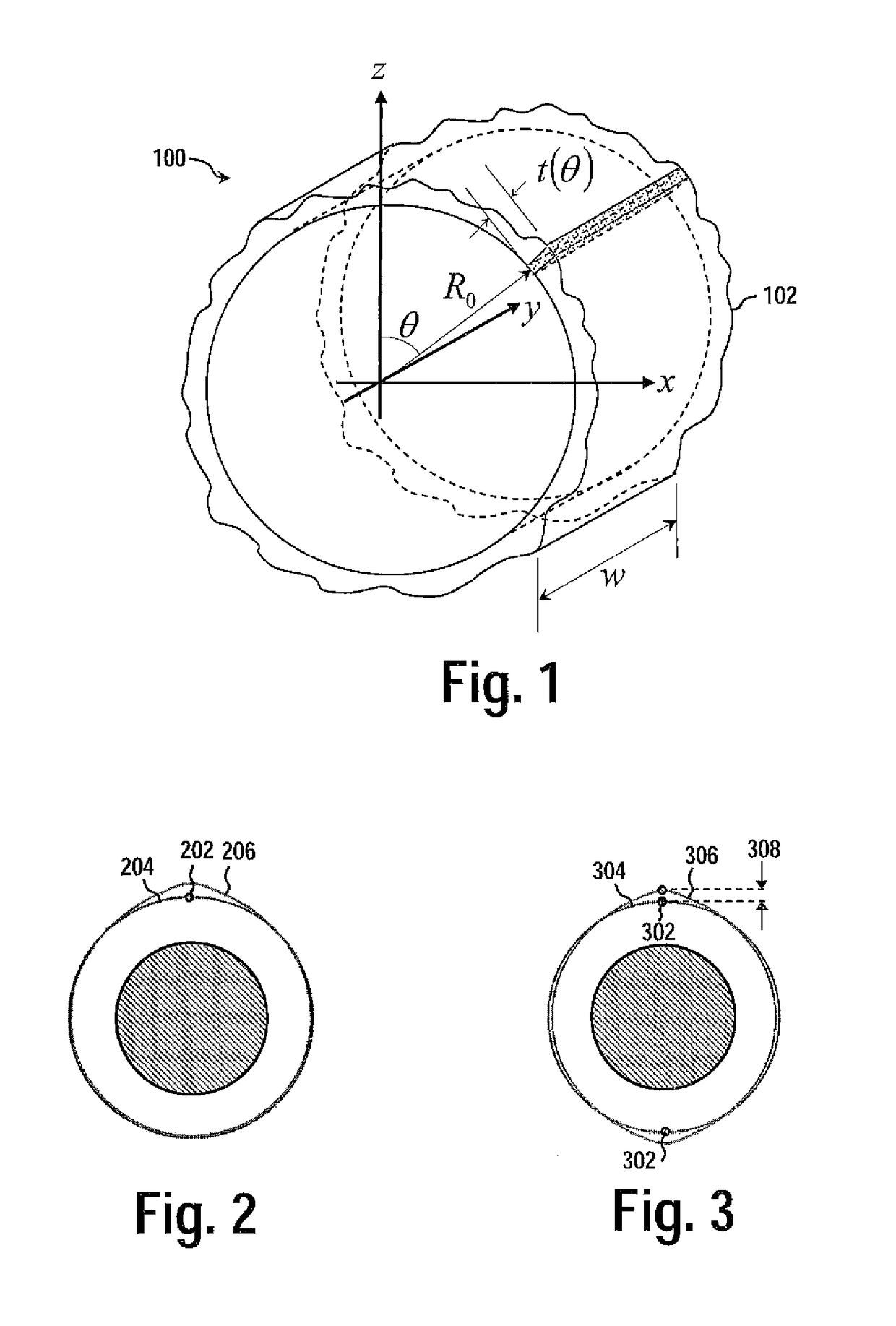

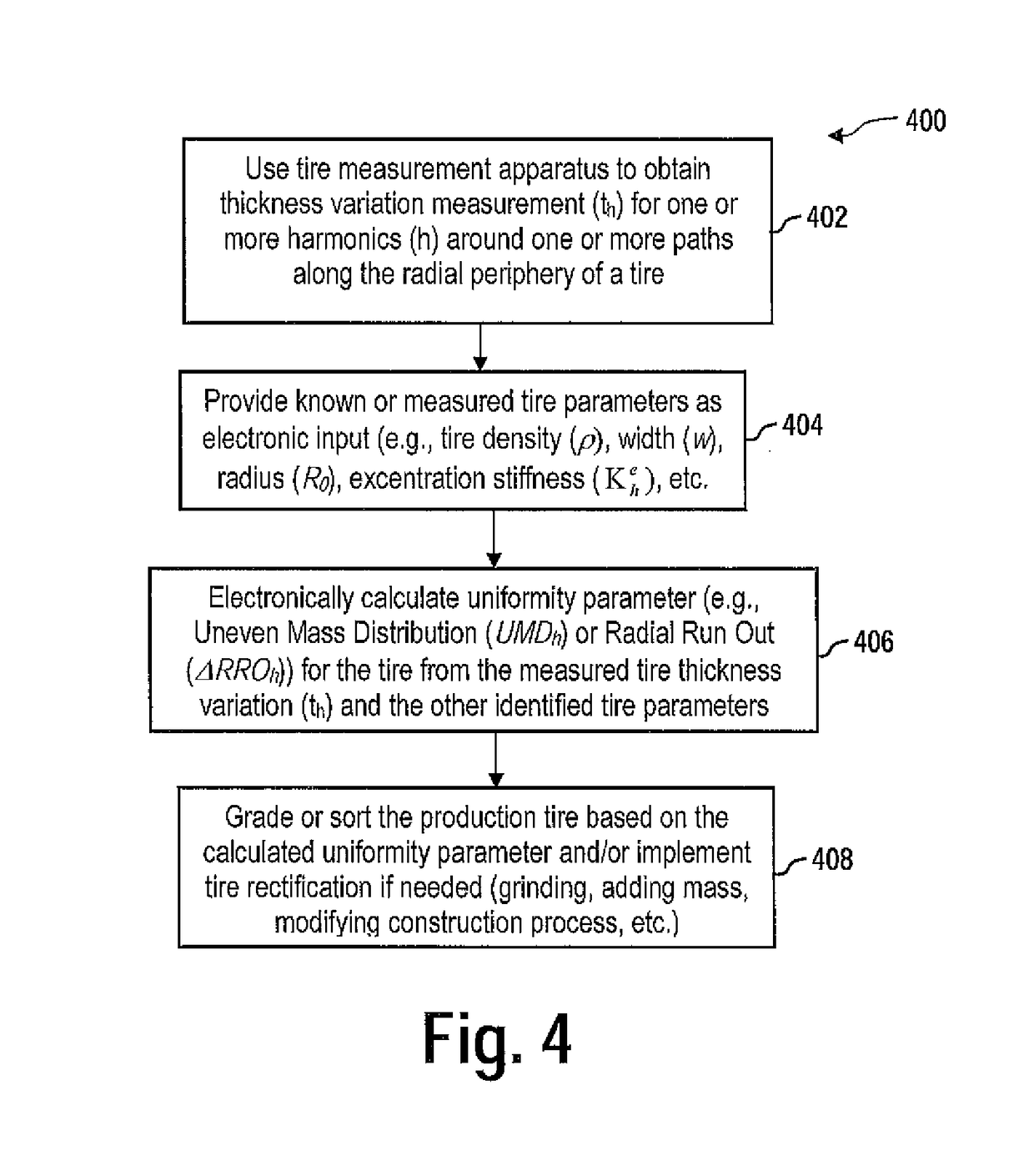

Method for prediction and control of tire uniformity parameters from crown thickness variation

Improved and more easily implemented methods for predicting uniformity parameters such as uneven mass distribution, radial run out and high speed radial force variation utilize other measurements such as the tire crown thickness variation. When high speed radial force variation is calculated, low speed radial force variation is also measured. Tire crown thickness variation can be measured in different fashions depending on the particular tire manufacturing process employed. By electronically determining resultant uniformity parameters, tires can be improved by rectification to address the uniformity levels. In addition, tire manufacturing can be improved by altering the resultant location of tire crown thickness variation relative to other aspects of the tire and / or tire manufacturing process.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tire manufacturing method for improving the uniformity of a tire

InactiveUS20060231191A1Effectively reduce the after cure radial force variation (RFV) of each tire producedTyresStatic/dynamic balance measurementTire uniformityVulcanization

A tire manufacturing method includes a method for optimizing the uniformity of a tire by reducing the after cure radial force variation. The after cure radial force variation vector is modeled as a vector sum of each of the vectors representing contributions arising from the tire building steps—the “tire room effect vector” and a vector representing contributions arising from the vulcanization and uniformity measurement steps—the “curing room effect vector.” In further detail, both the tire room and curing room effect vectors can be further decomposed into sub-vectors representing each radial force variation contribution for which a measurable indicator is available. For a series of tires, the method obtains such measurements as the before cure radial runout (RRO) at one or more stages of the building sequence, measurements of loading angles on the tire building equipment, and measurements made during vulcanization process.

Owner:MICHELIN RECH & TECH SA

Tire uniformity through compensation between radial run out and stiffness variation

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

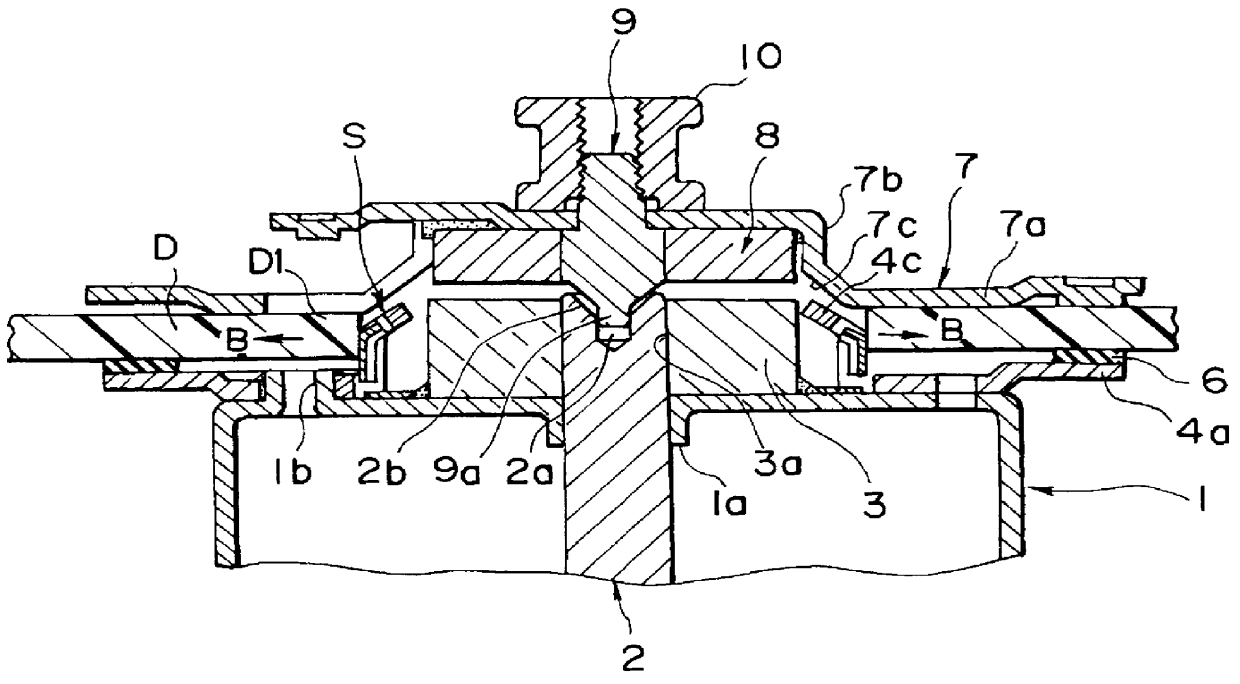

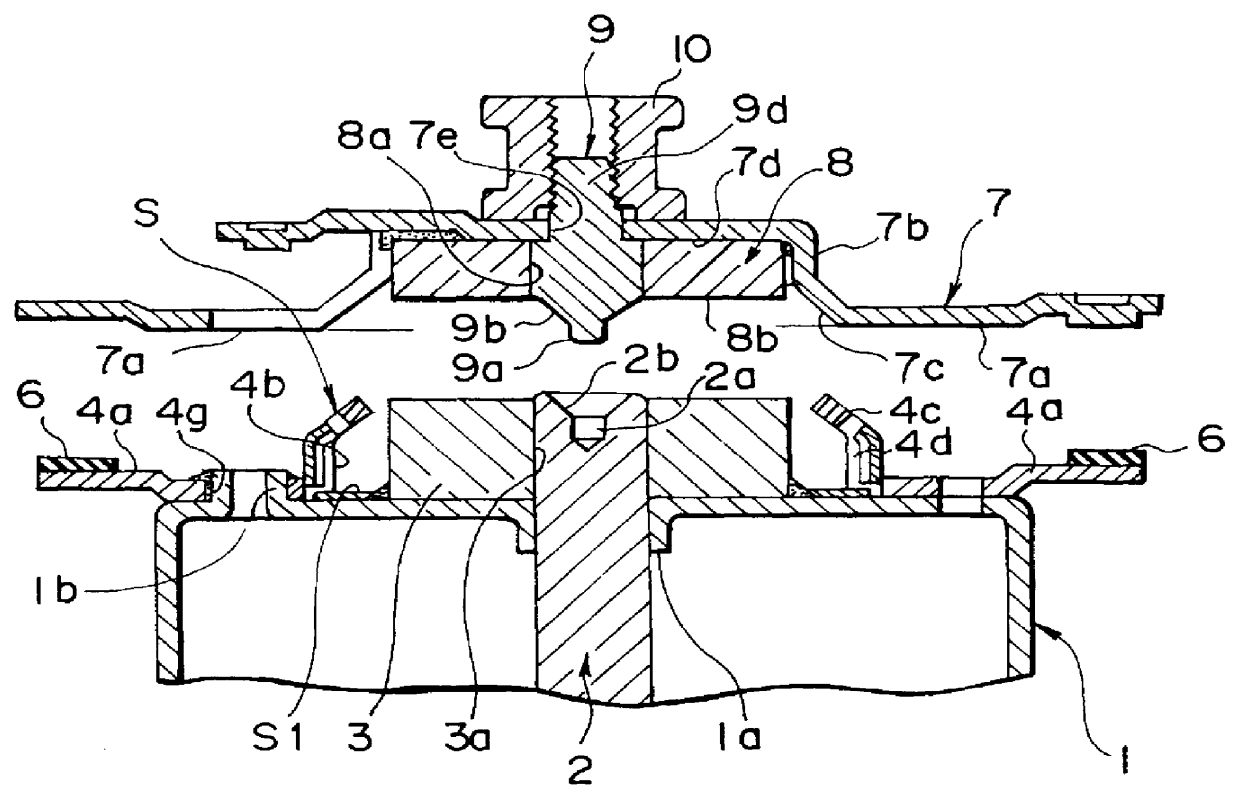

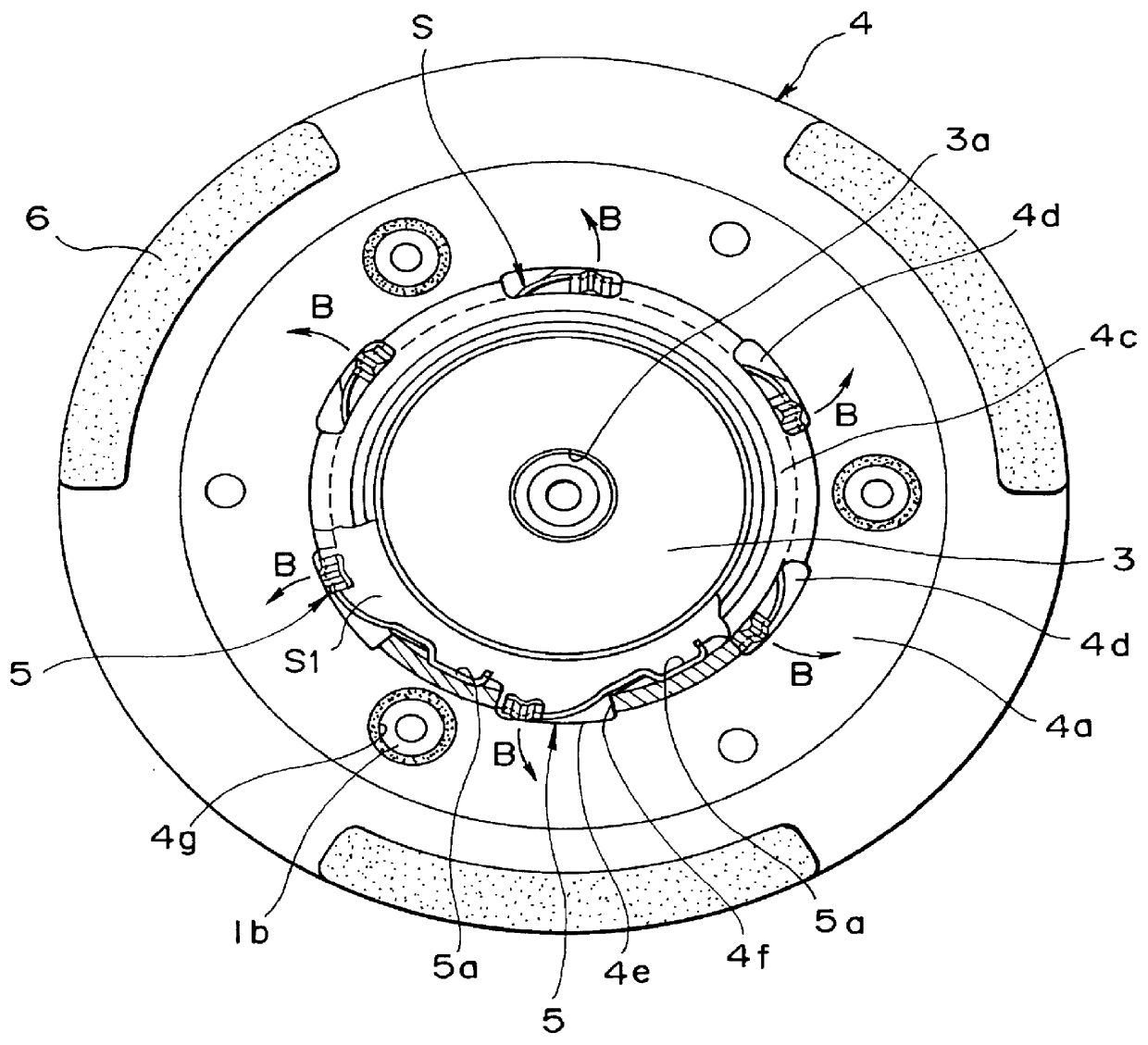

Disk driving device with small centering force variation

A disk driving device including a centering member mounted to an inner portion of a cylindrical portion of a turntable. The centering member includes a linking portion serving as fulcra and a centering portion separated from the linking portion. The centering portion is resiliently biased with an outward force that acts parallel to a flange providing a disk-mounting surface of the turntable in order to center a disk.

Owner:ALPS ALPINE CO LTD

Improved tire uniformity through compensation between radial run out and stiffness variation

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN & CO (CIE GEN DES ESTAB MICHELIN)

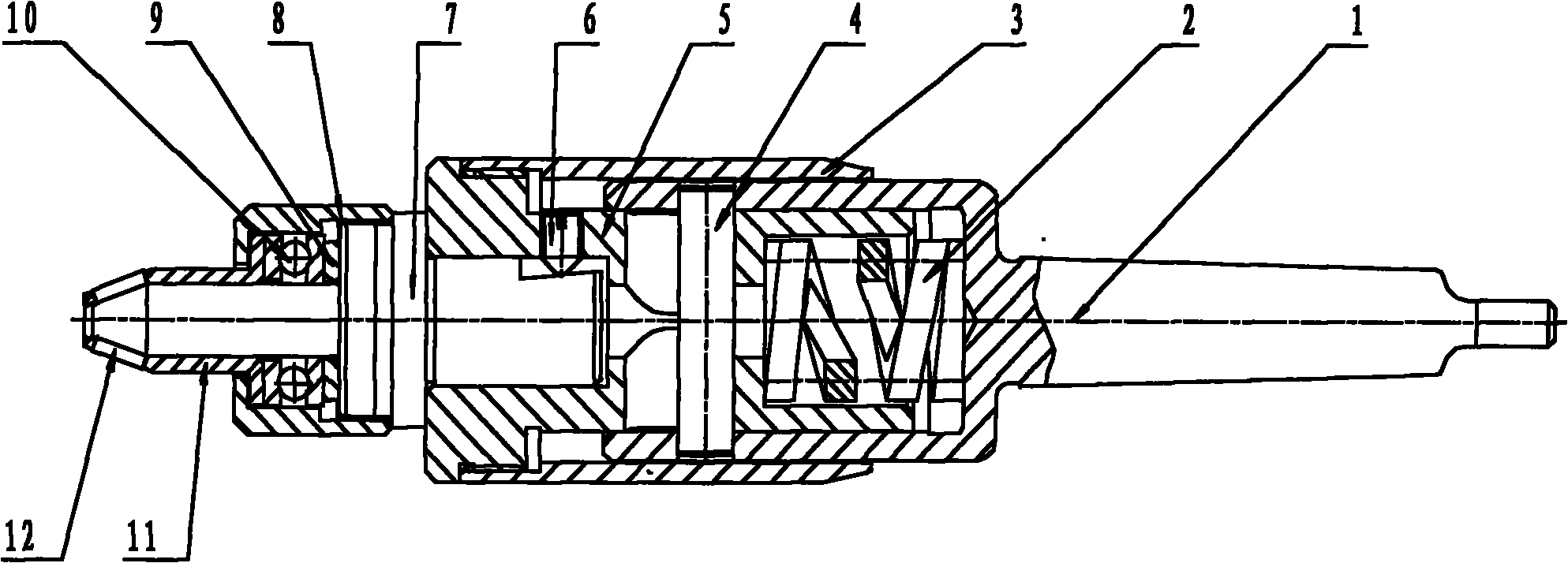

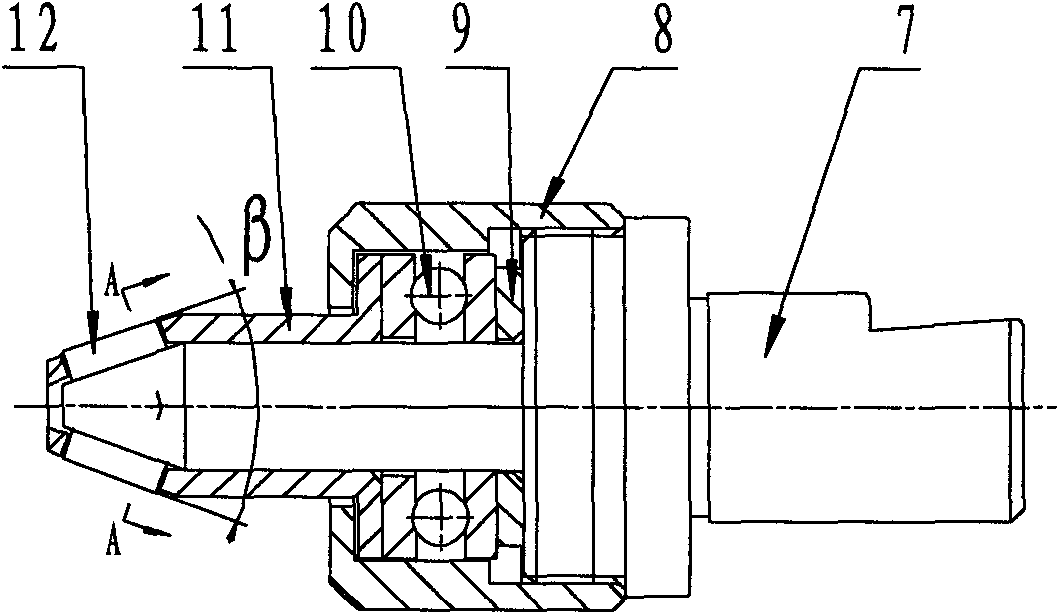

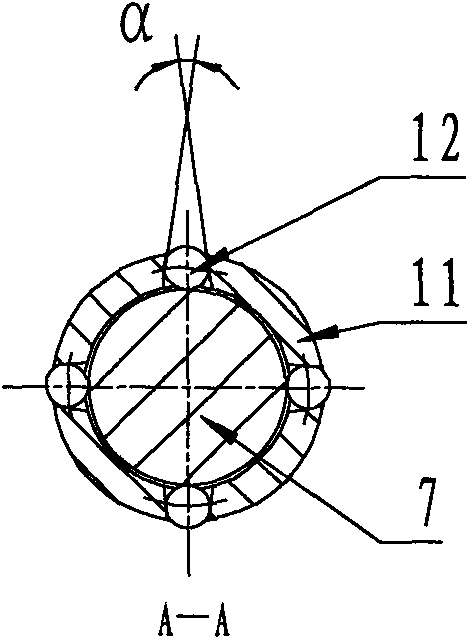

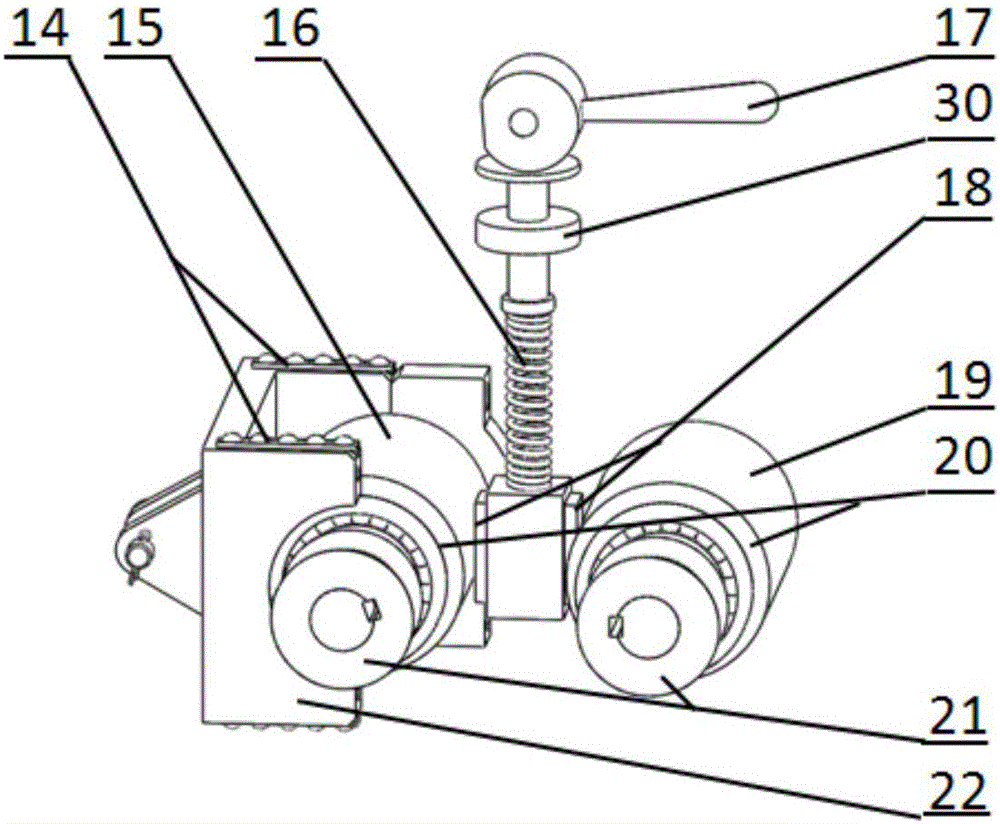

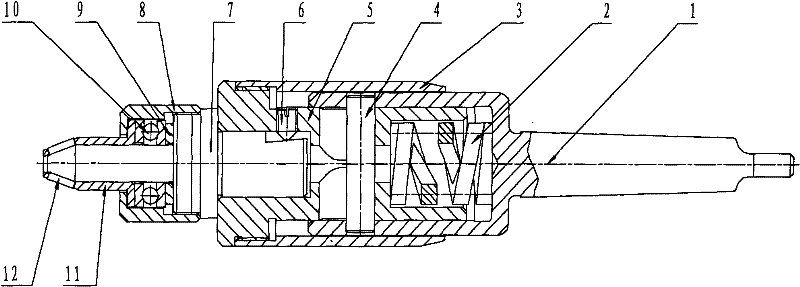

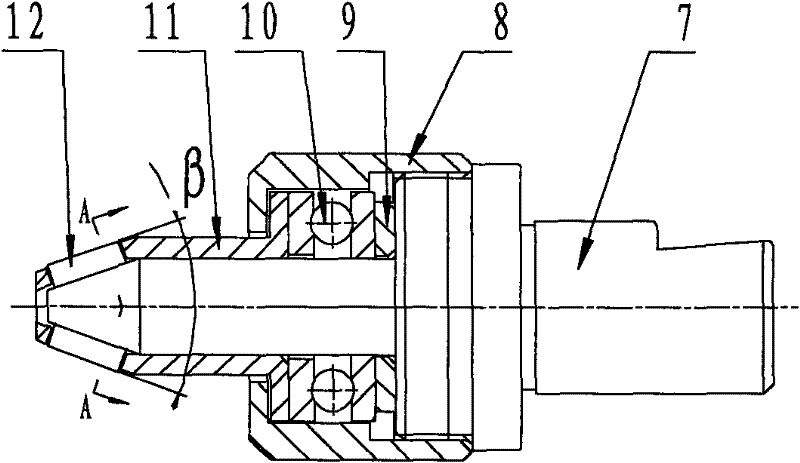

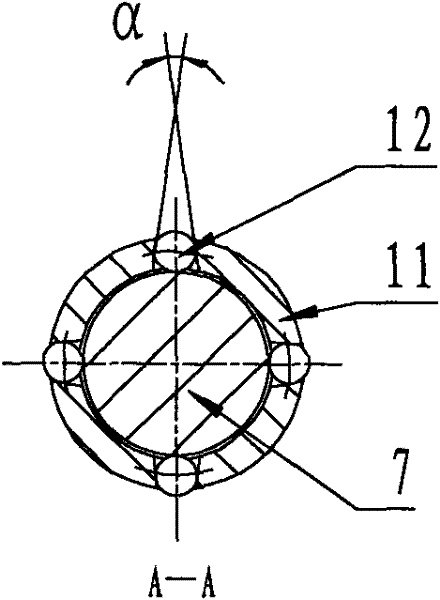

High-precision elastic tapered bore rolling device of cone sealing pipe joint

The invention relates to a high-precision elastic tapered bore rolling device of a cone sealing pipe joint, which belongs to a machine processing tool. The rolling device comprises a knife handle body, a rectangular pressure spring, an outer sliding sleeve, a locating pin roll, a core sleeve, a rolling mandril, a bearing sleeve, a thrust ball bearing, an adjusting pad, a flange sleeve and a roller. Compared with the traditional processing methods of drilling, internal boring and polishing, the production efficiency can be improved manyfold by adopting the rolling device to roll the conical surface inner bore of the cone sealing pipe joint; the surface roughness can be not more than Ra0.4 so that the requirements of a working drawing are stably reached, and the metal surface of the conical surface inner bore is strengthened, and thereby, the strength and the hardness of the surface layer are improved. The rolling device has good generality, and a rolling head fitting the size of the cone sealing pipe joint can be rapidly replaced. The elasticity of the spring can enable the changes of the axial force and the radial force which are borne by the rolling device in rolling the conical surface inner bore to be smaller; compared with a rigid rolling device, the abrasion of the rolling head of the rolling device is reduced, and thereby, the service life of the rolling device is prolonged by 3 to 5 times.

Owner:JIANGSU UNIV

Tire manufacturing method for improving the uniformity of a tire

ActiveUS20110114251A1Effectively reduce the after cure radial force variation (RFV) of each tire producedStatic/dynamic balance measurementTyresTire uniformityVulcanization

A tire manufacturing method includes a method for optimizing the uniformity of a tire by reducing the after cure radial force variation. The after cure radial force variation vector is modeled as a vector sum of each of the vectors representing contributions arising from the tire building steps—the “tire room effect vector” and a vector representing contributions arising from the vulcanization and uniformity measurement steps—the “curing room effect vector.” In further detail, both the tire room and curing room effect vectors can be further decomposed into sub-vectors representing each radial force variation contribution for which a measurable indicator is available. For a series of tires, the method obtains such measurements as the before cure radial runout (RRO) at one or more stages of the building sequence, measurements of loading angles on the tire building equipment, and measurements made during vulcanization process.

Owner:MICHELIN RECH & TECH SA

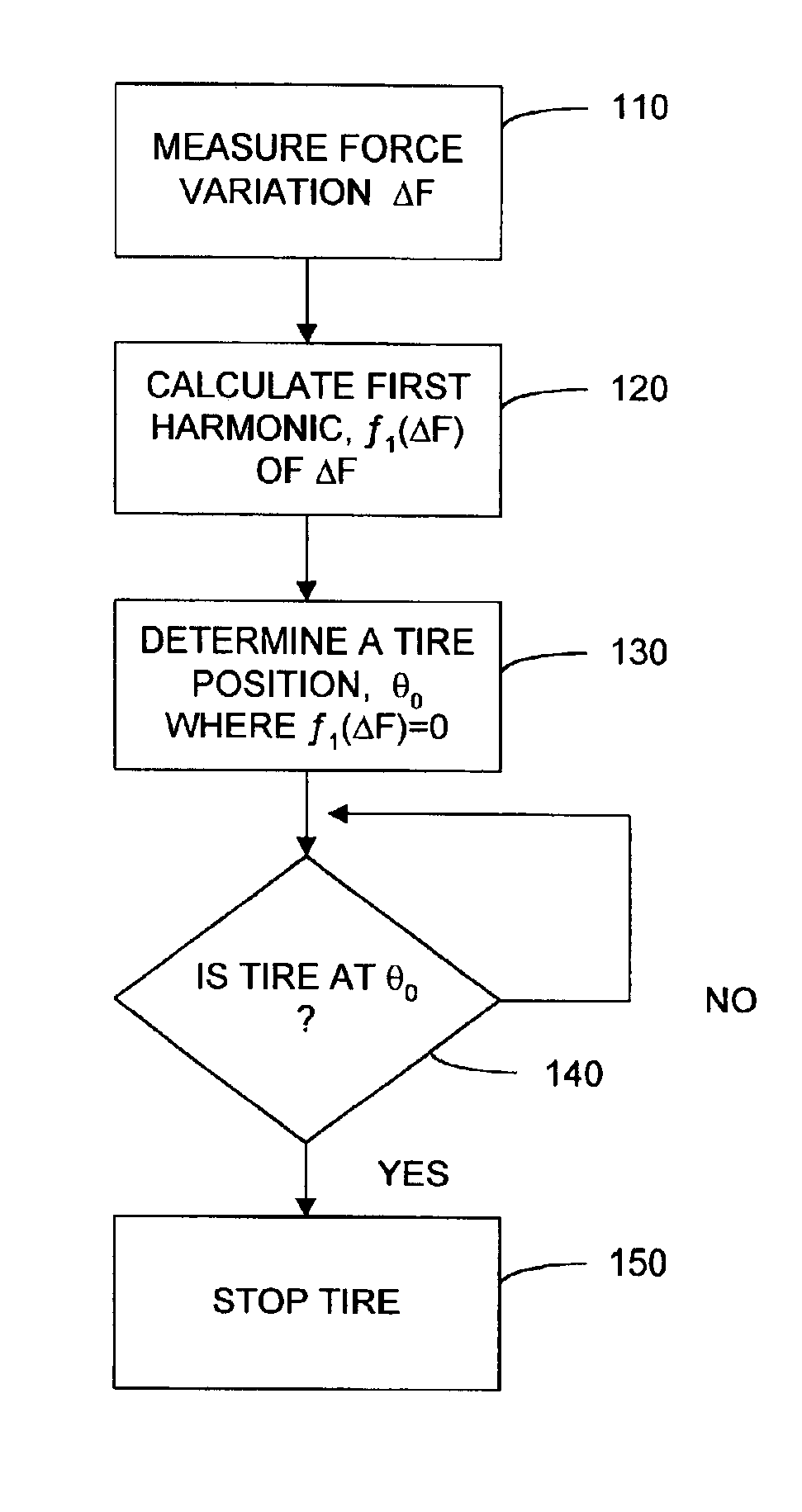

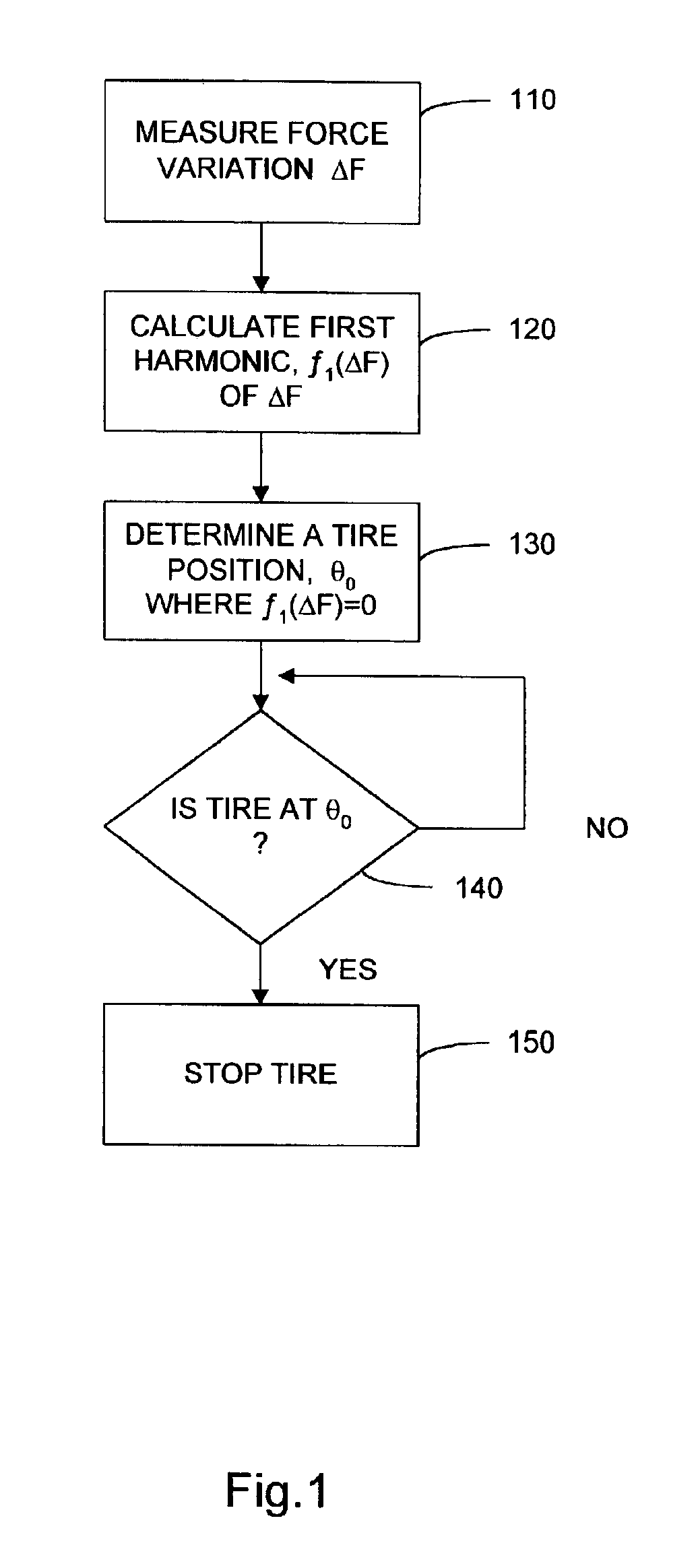

Improvements in tire uniformity testing

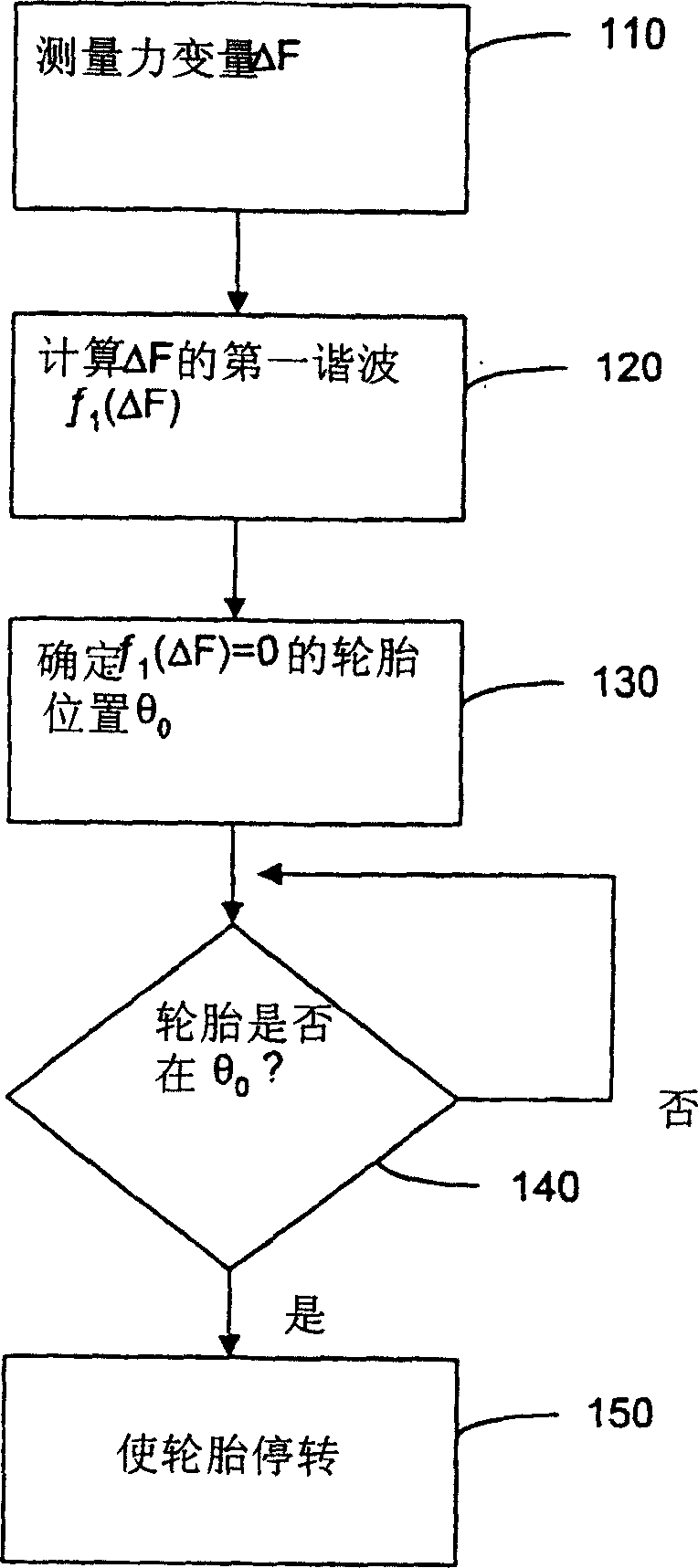

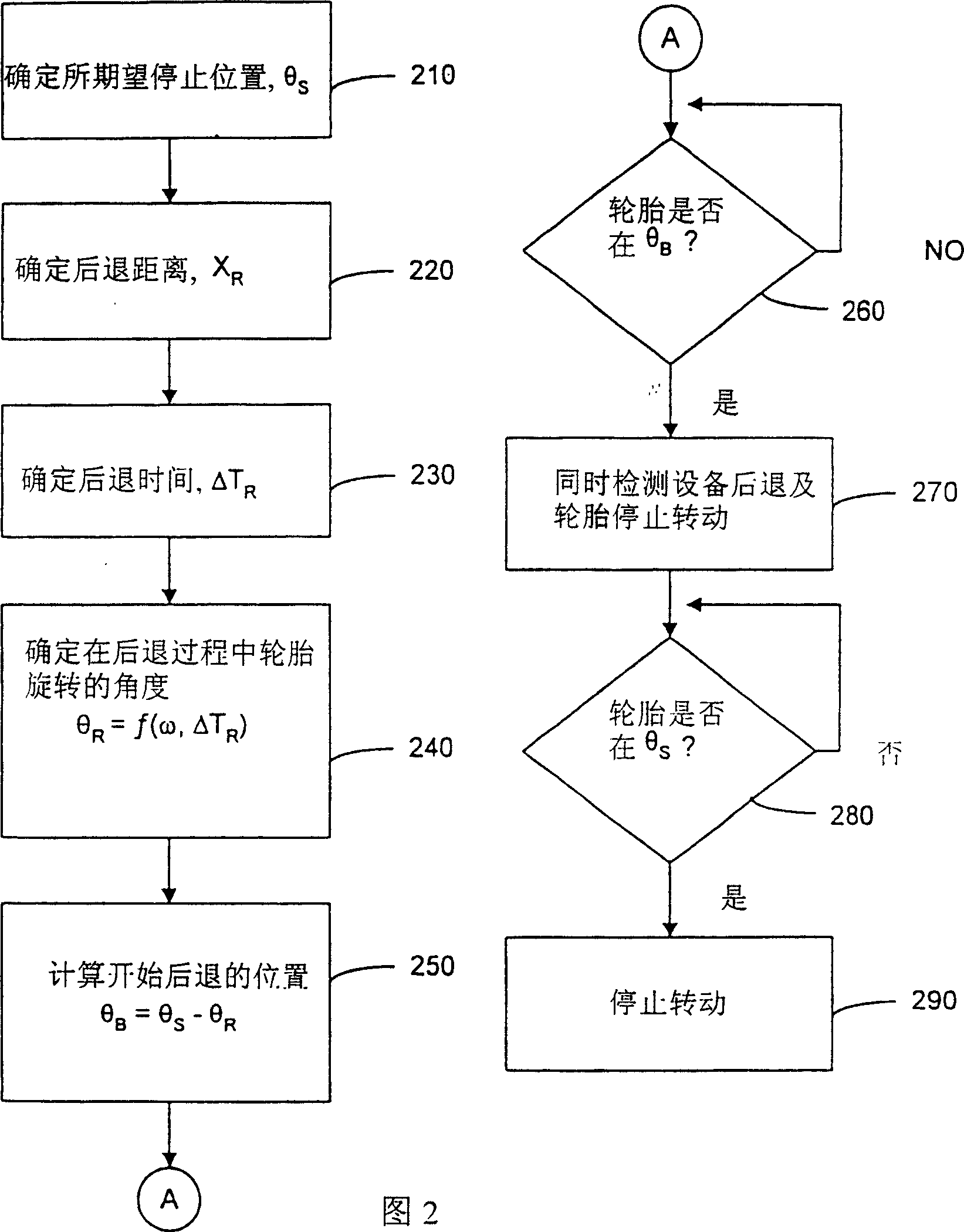

A method and apparatus for testing tires. In step (110), the radial force variation is measured in the current direction of rotation. The first harmonic of this force variation is calculated in step (120) and a tire position corresponding to either zero crossing of the first harmonic is determined in step (130). In step (140), the tire position is monitored until a zero crossing is reached. The rotation direction is reversed at the appropriate location in step (150) and the test is continued.

Owner:MICRO POISE MEASUREMENT SYST

Tire manufacturing method for improving the uniformity of a tire

InactiveUS8287675B2Effectively reduce the after cure radial force variation (RFV) of each tire producedLamination ancillary operationsTyresTire uniformityVulcanization

A tire manufacturing method includes a method for optimizing the uniformity of a tire by reducing the after cure radial force variation. The after cure radial force variation vector is modeled as a vector sum of each of the vectors representing contributions arising from the tire building steps—the “tire room effect vector” and a vector representing contributions arising from the vulcanization and uniformity measurement steps—the “curing room effect vector.” In further detail, both the tire room and curing room effect vectors can be further decomposed into sub-vectors representing each radial force variation contribution for which a measurable indicator is available. For a series of tires, the method obtains such measurements as the before cure radial runout (RRO) at one or more stages of the building sequence, measurements of loading angles on the tire building equipment, and measurements made during vulcanization process.

Owner:MICHELIN RECH & TECH SA

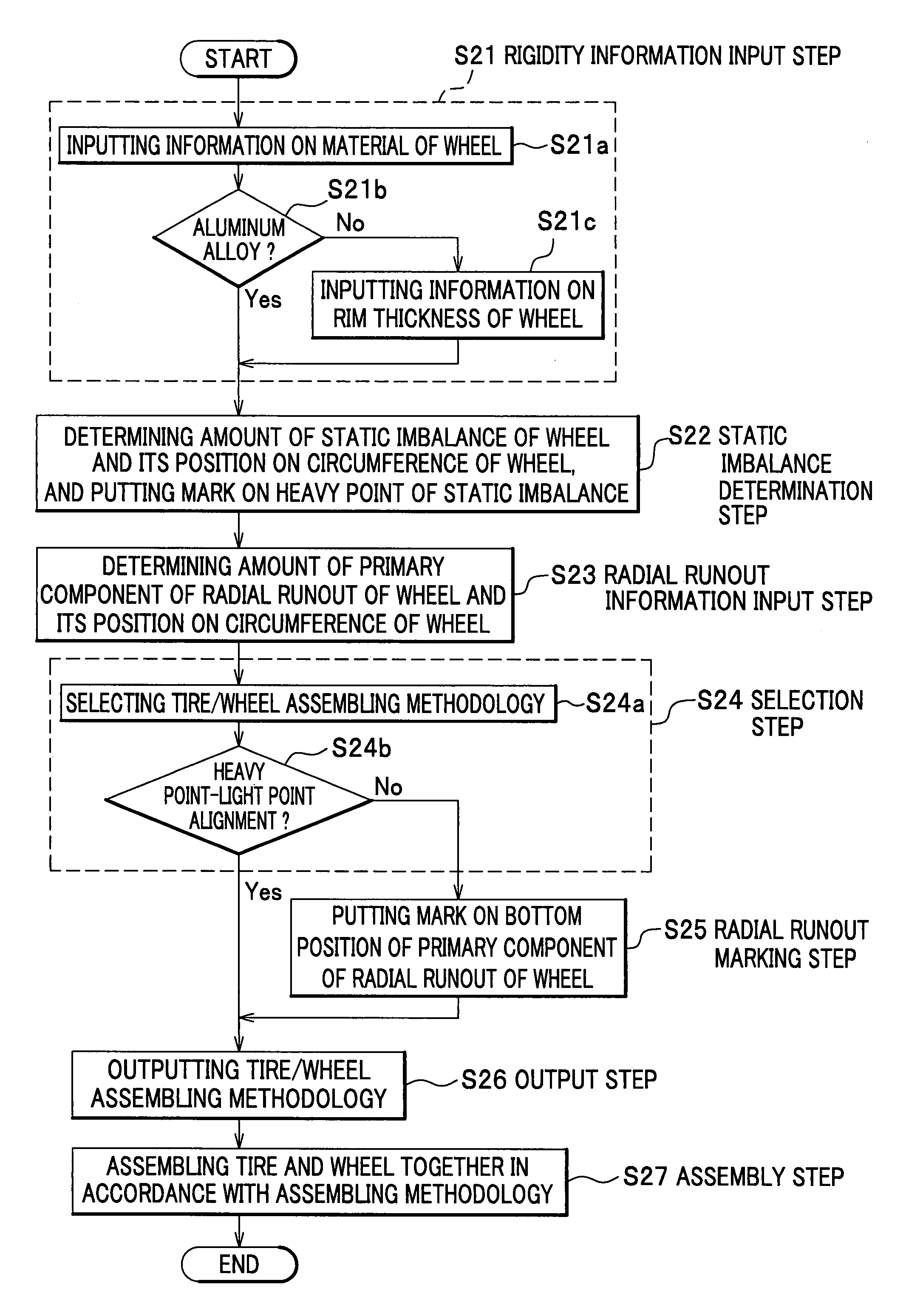

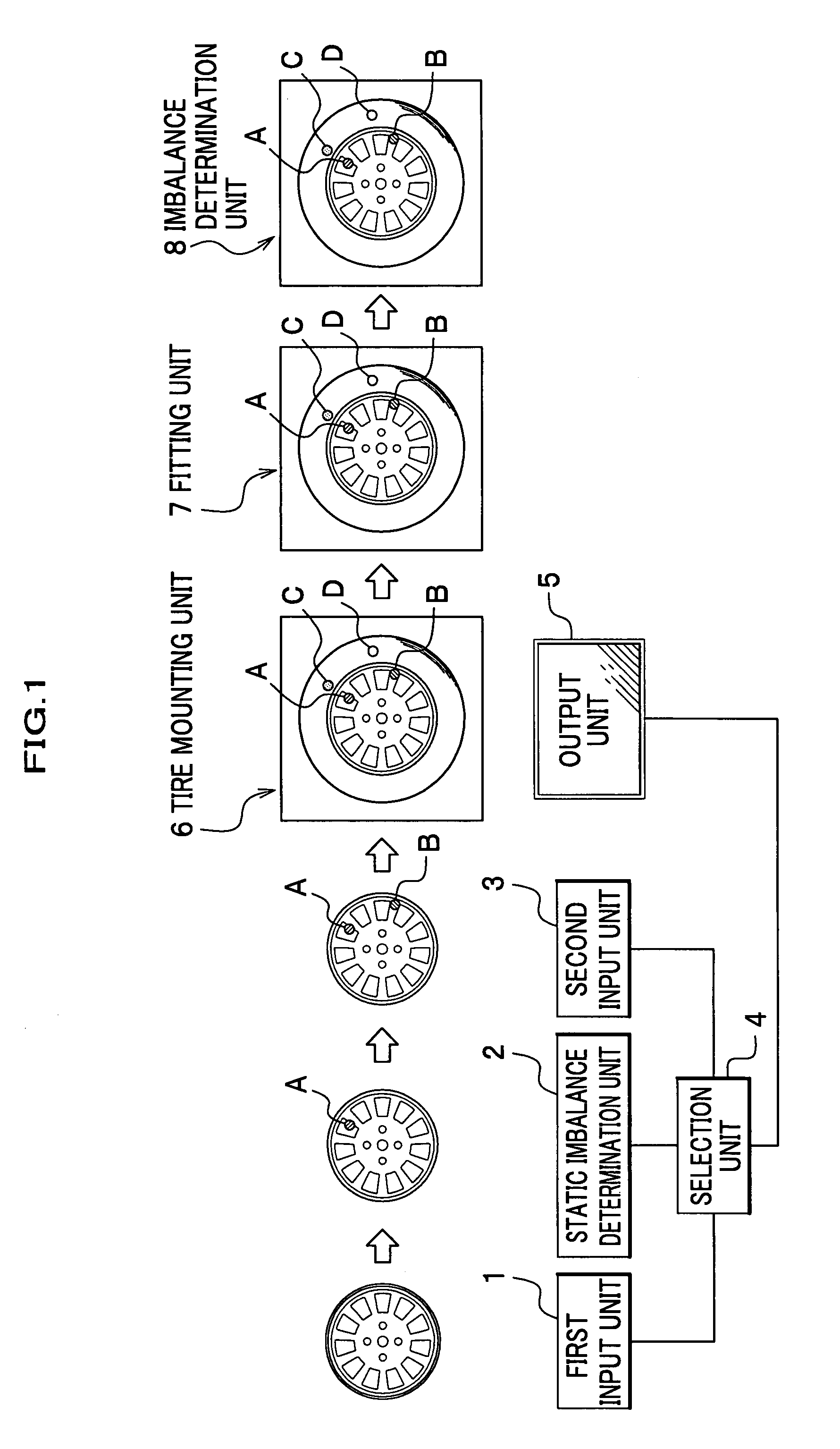

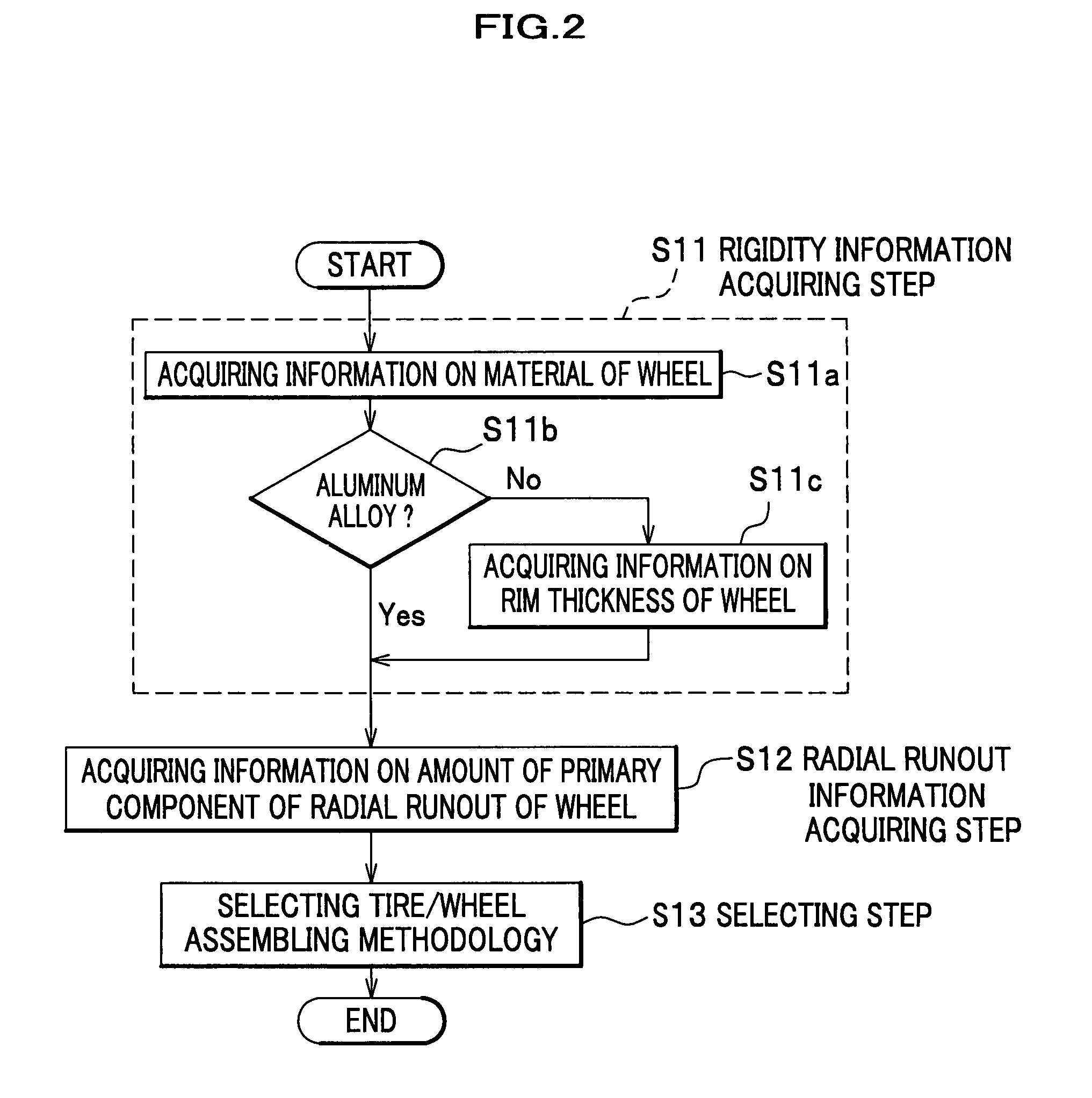

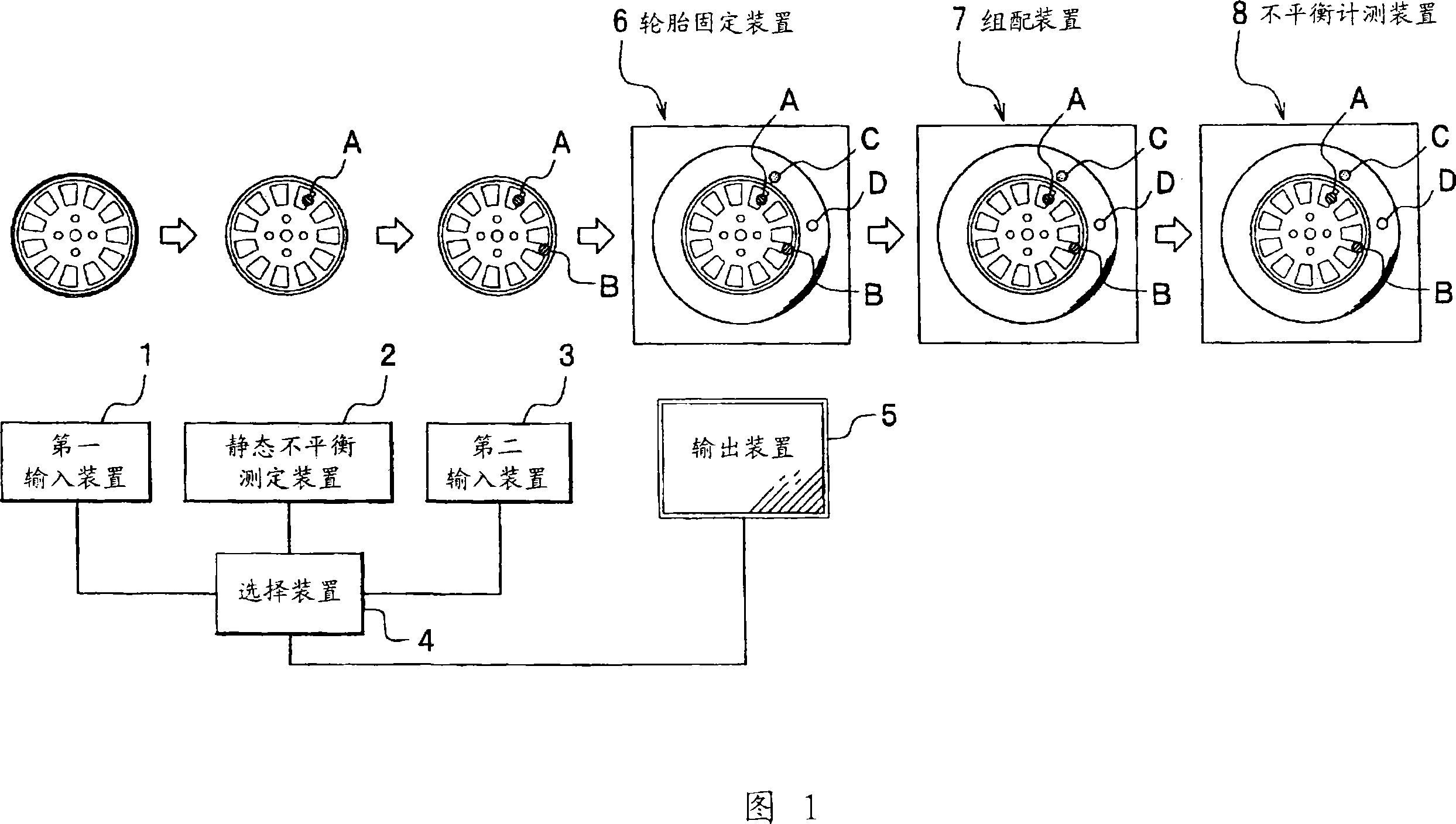

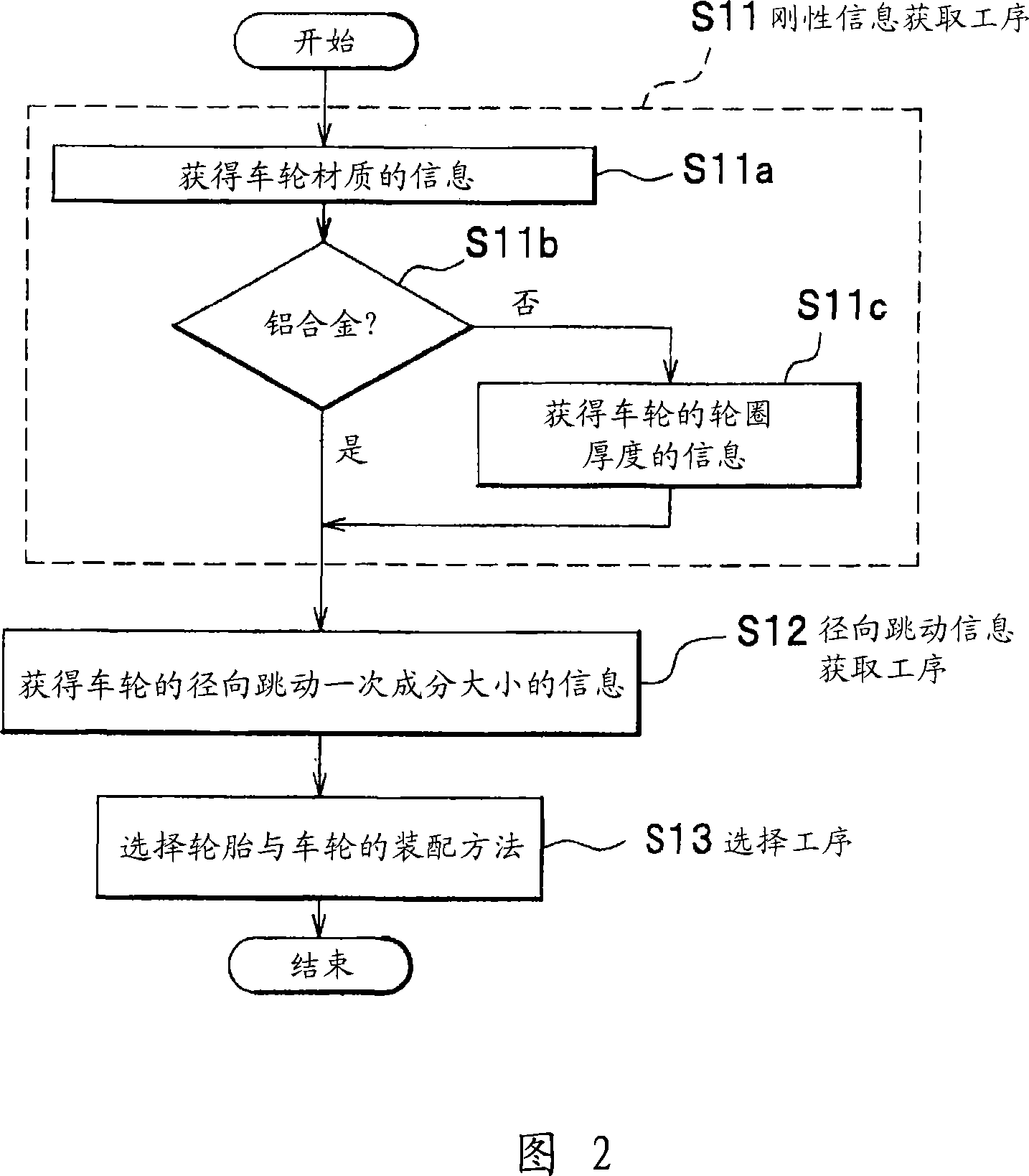

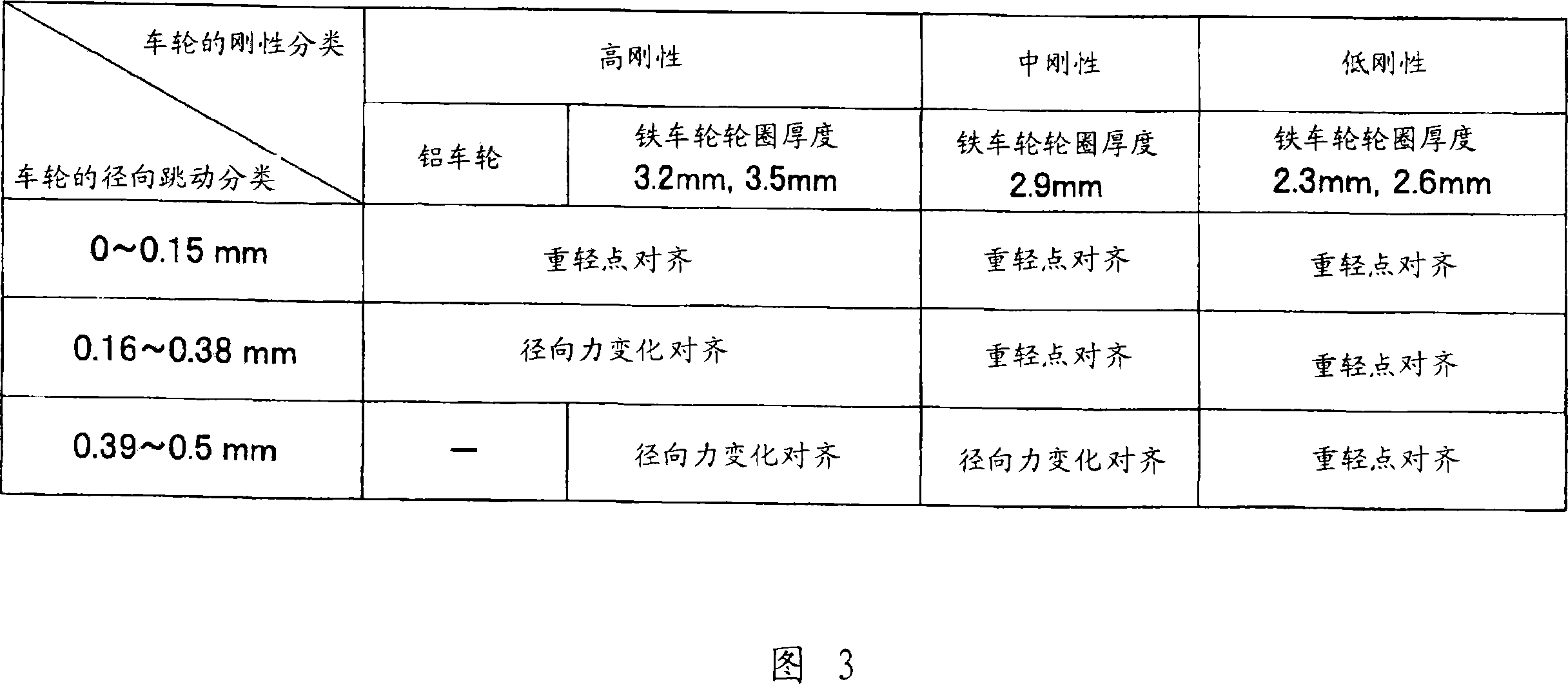

Apparatus and method for assembling tire and wheel based on rigidity and radial runout of wheel

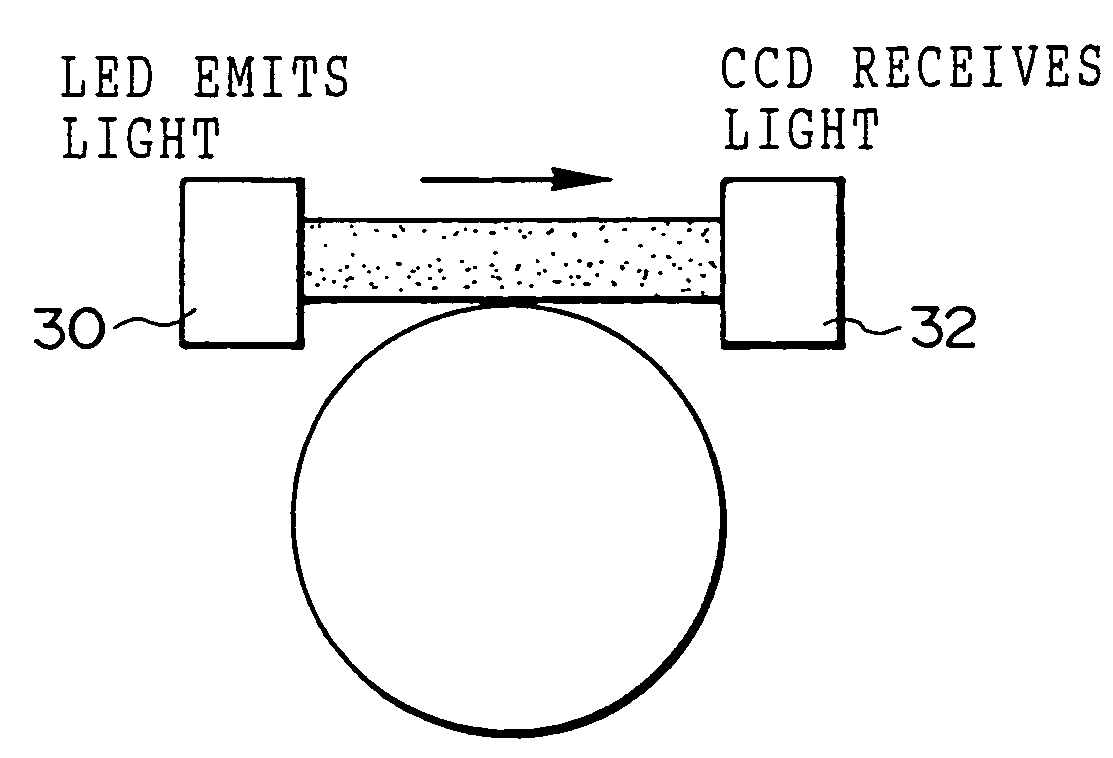

InactiveUS7664576B2Simplify device configurationReduce capital investmentSampled-variable control systemsRotating vibration suppressionPoint lightEngineering

Based upon rigidity classifications of wheels and radial runout classifications of the wheels, the lower the rigidity classification or the lower the radial runout classification, the more likely a methodology (heavy point-light point alignment) is selected in which a light point of static imbalance of the tire and a heavy point of static imbalance of the wheel are aligned with each other, than another methodology (radial force variation alignment) in which a peak position of a primary component of radial force variation of the tire and a bottom position of a primary component of radial runout of the wheel are aligned with each other, so as to assemble a tire and a wheel together.

Owner:HONDA MOTOR CO LTD

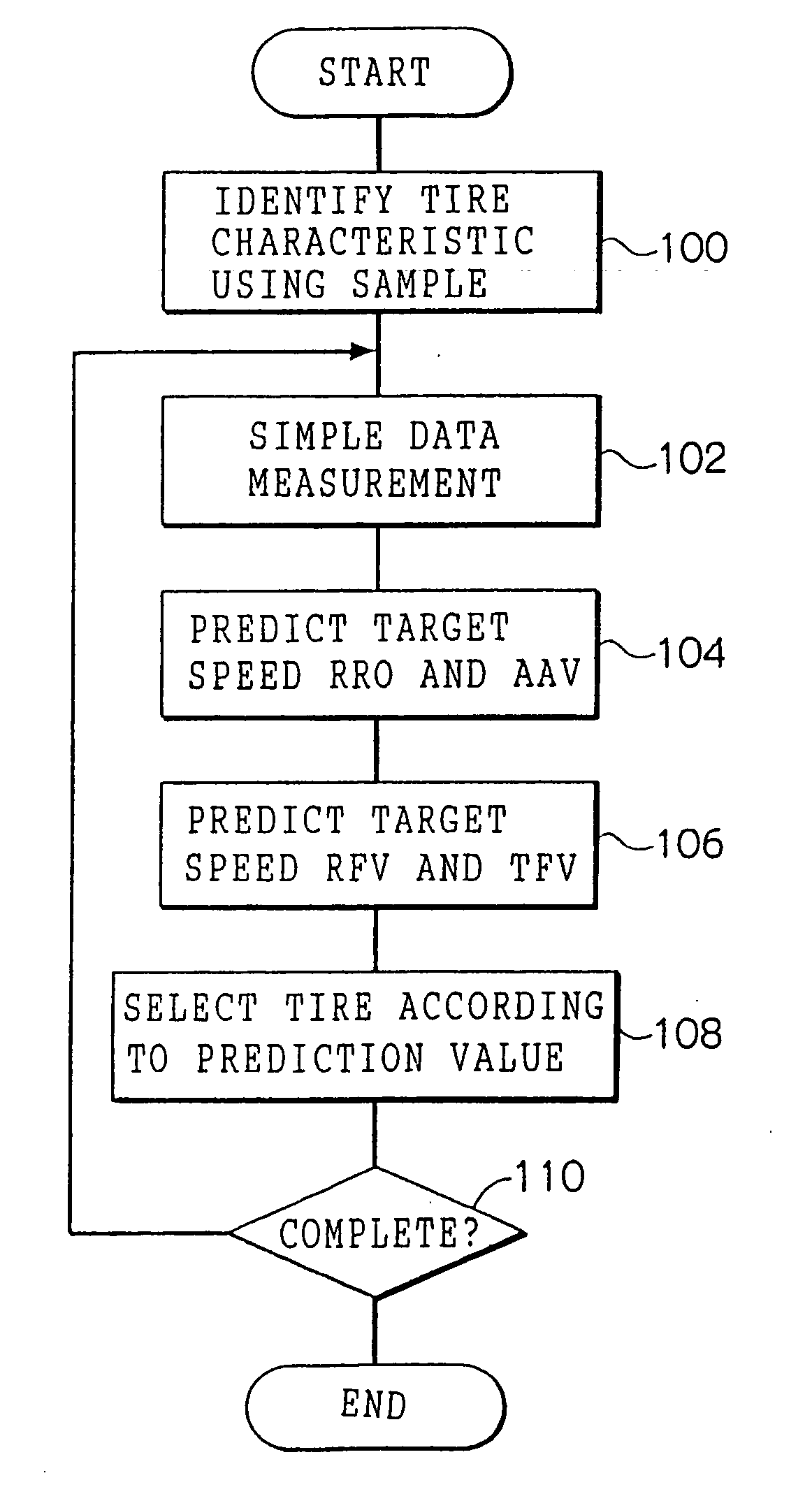

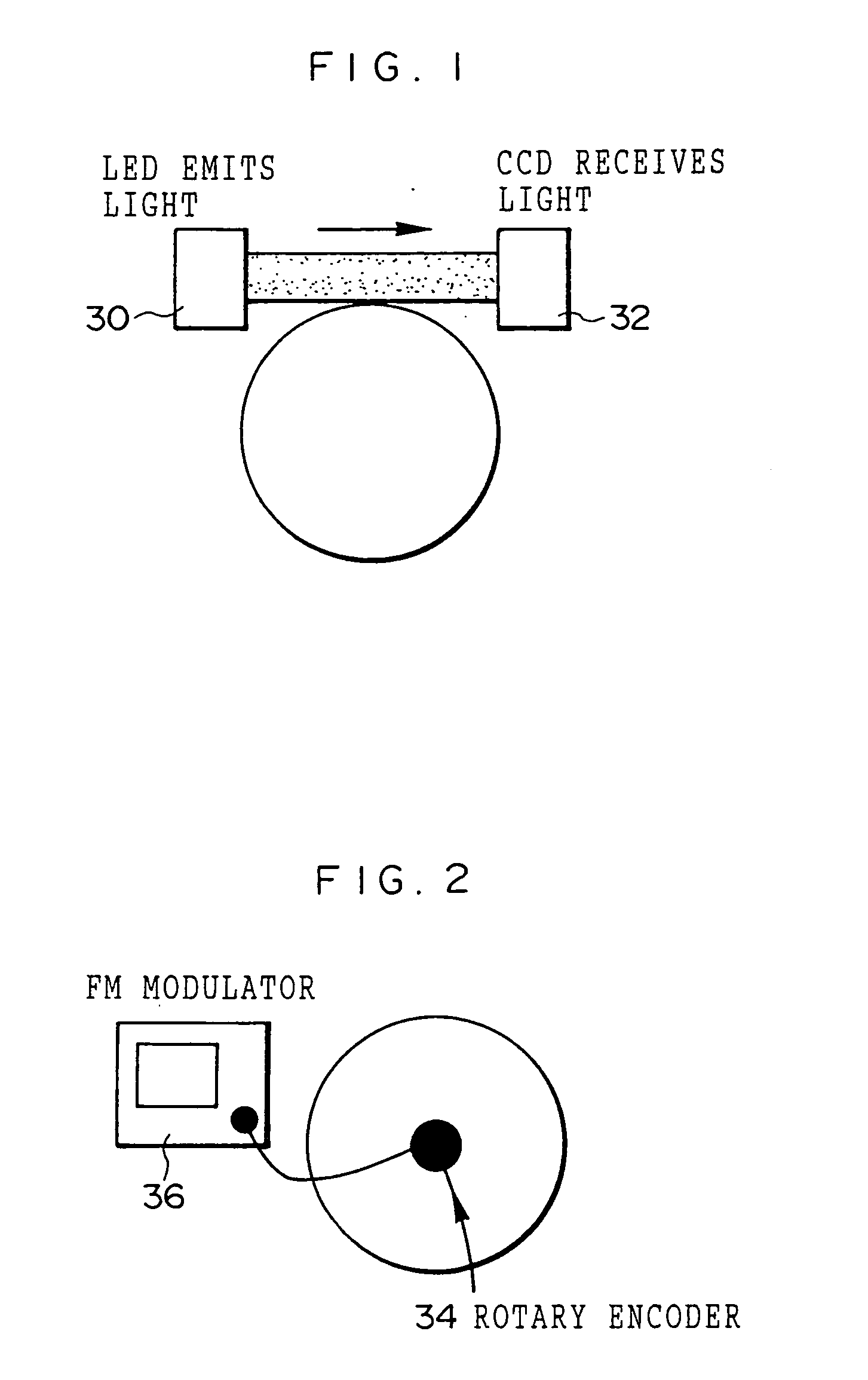

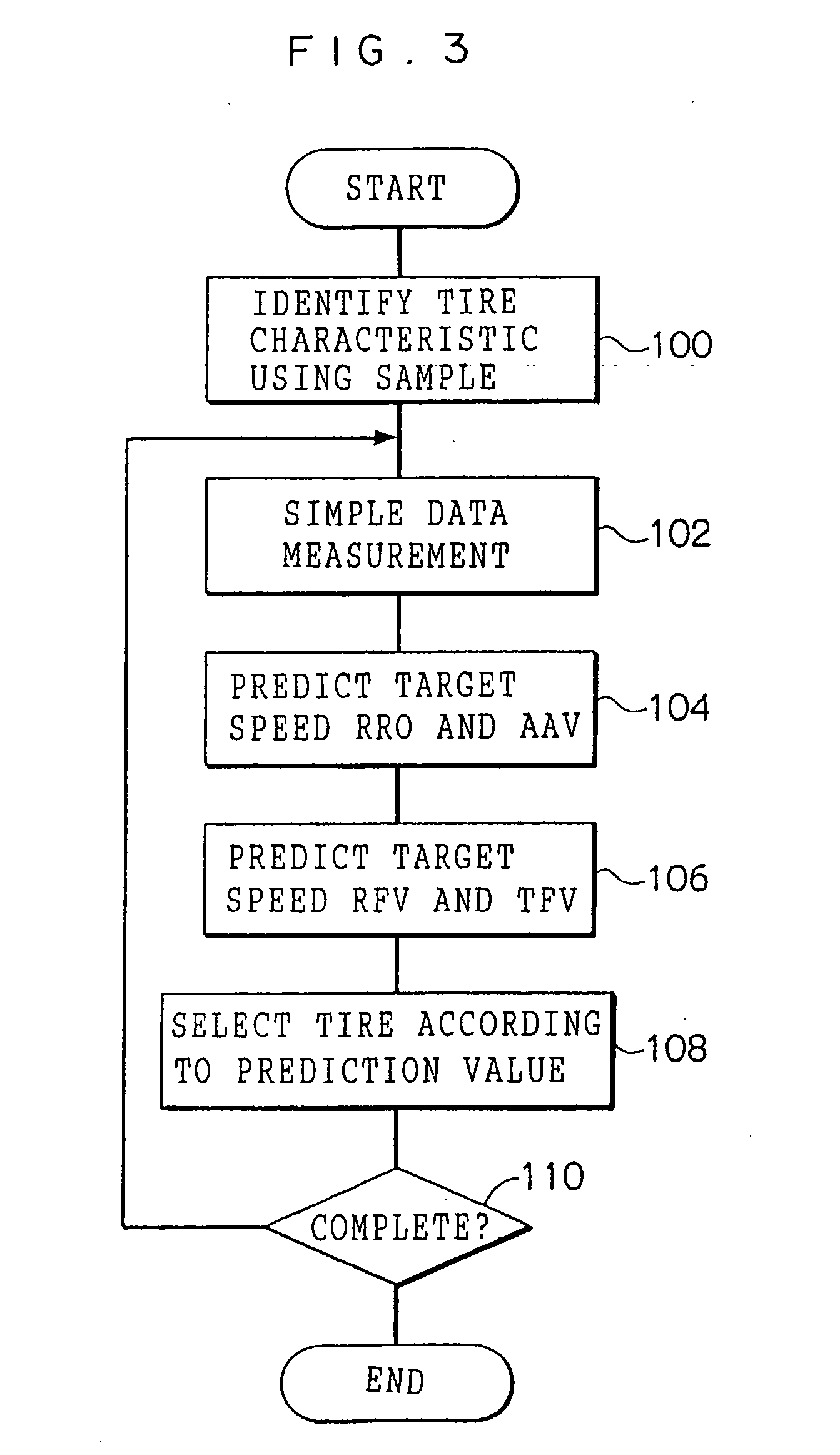

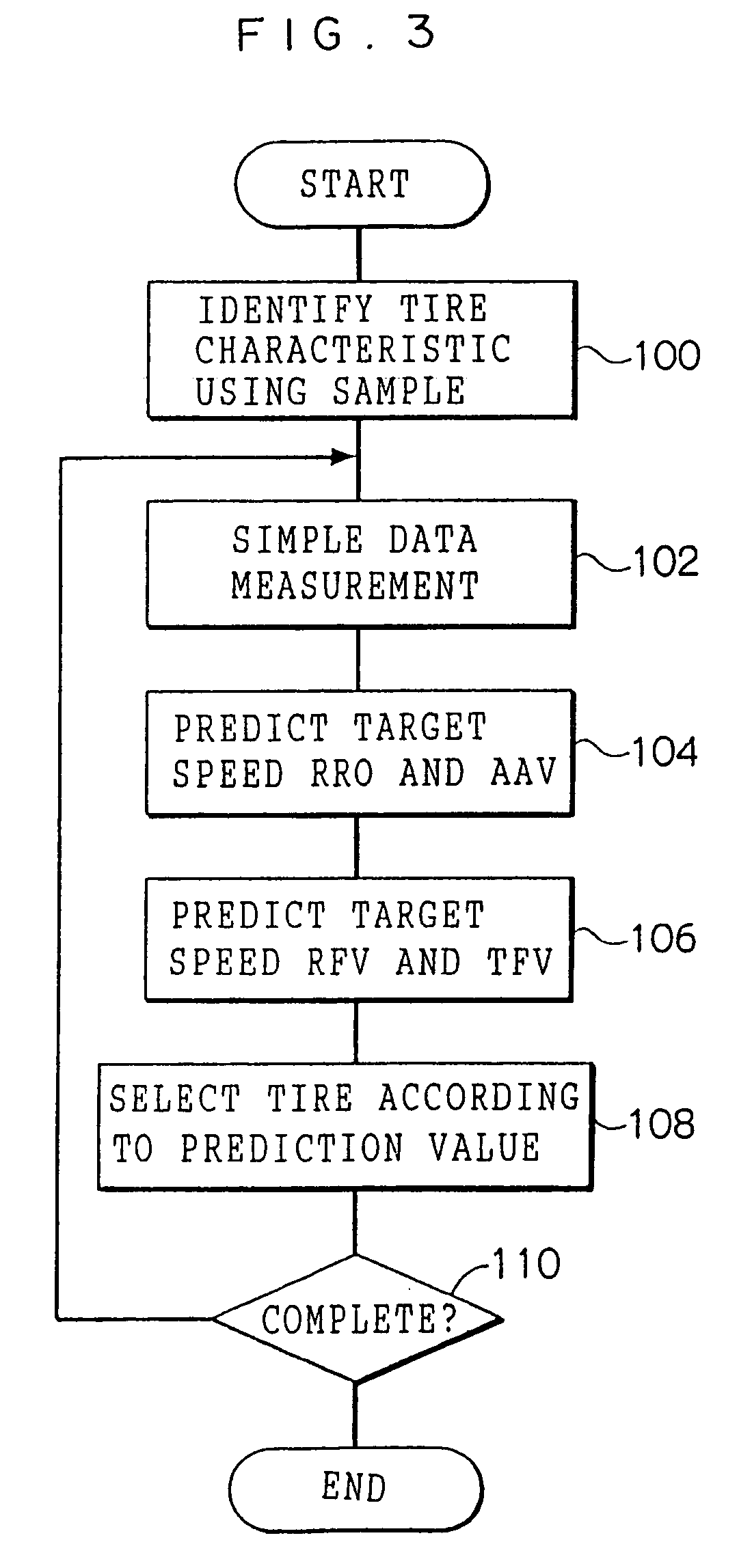

Radial force variation prediction method, tangential force variation prediction method, radial run out prediction method, tire angle acceleration fluctuation prediction method, radial run out measurement apparatus, radial run out estimation method, information acquisition method, an

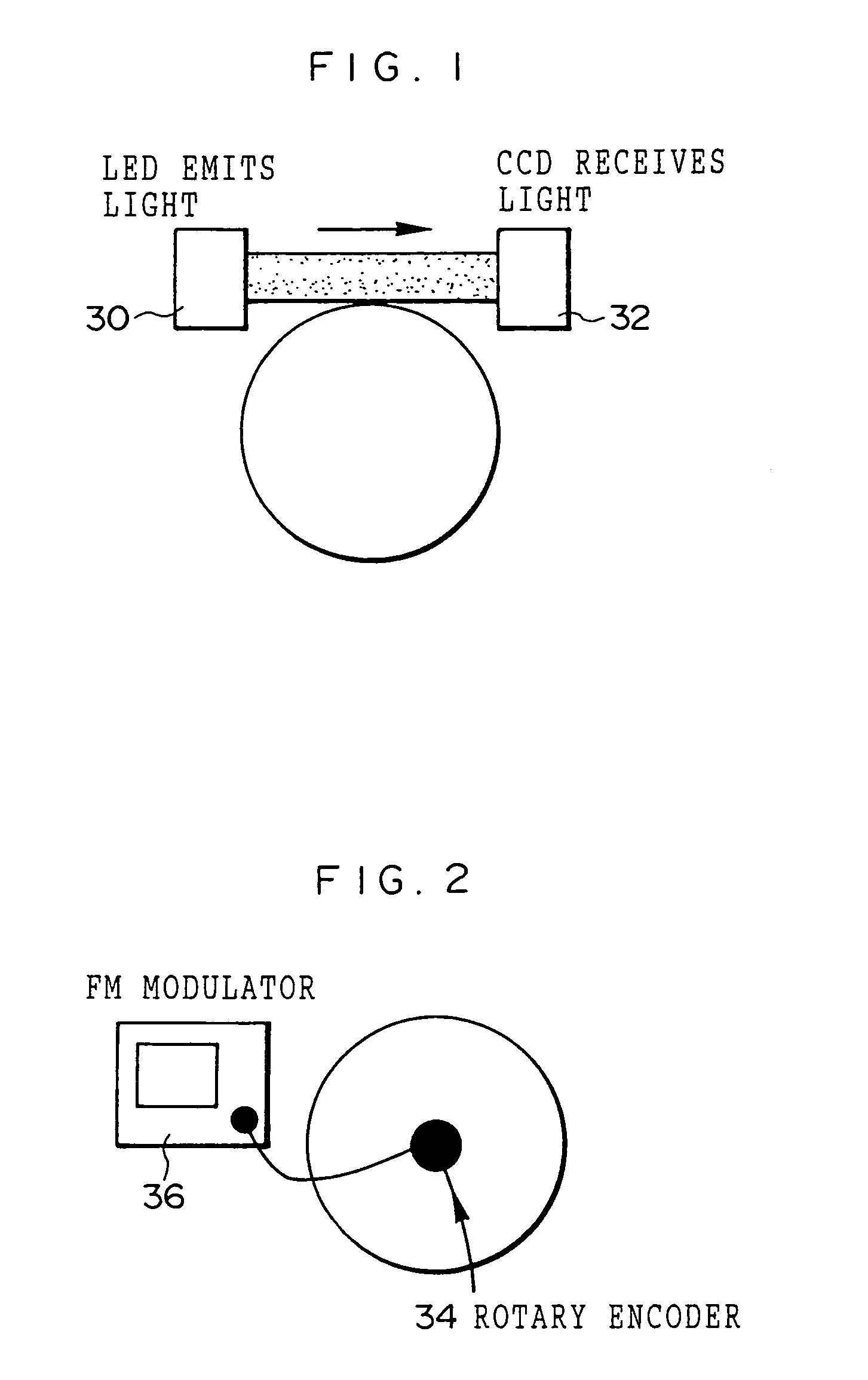

InactiveUS20050216224A1Reduce errorsIncrease speedTyre partsMechanical diameter measurementsLow speedMeasurement device

It is possible to significantly reduce a prediction error of the high-speed RFV and the high-speed TFV in a tire having a large PRO growth amount at high speed. Three or more sample tires are extracted from each lot. The PRO and RFV are measured and the least-square method is used to predict (100) the upper and lower and front and back natural angle frequency, attenuation ratio, upper and lower spring constant, and rolling radius coefficient. By using the PRO measurement apparatus, the PRO during idling is measured. By using an AAV measurement apparatus, an actual measurement value AAVL of the angle acceleration fluctuation at a low speed is measured (102). The PRO and AAV at a high speed are predicted (104) and the actual measurement value and prediction value are used to predict the high-speed RFV and TFV.

Owner:BRIDGESTONE CORP

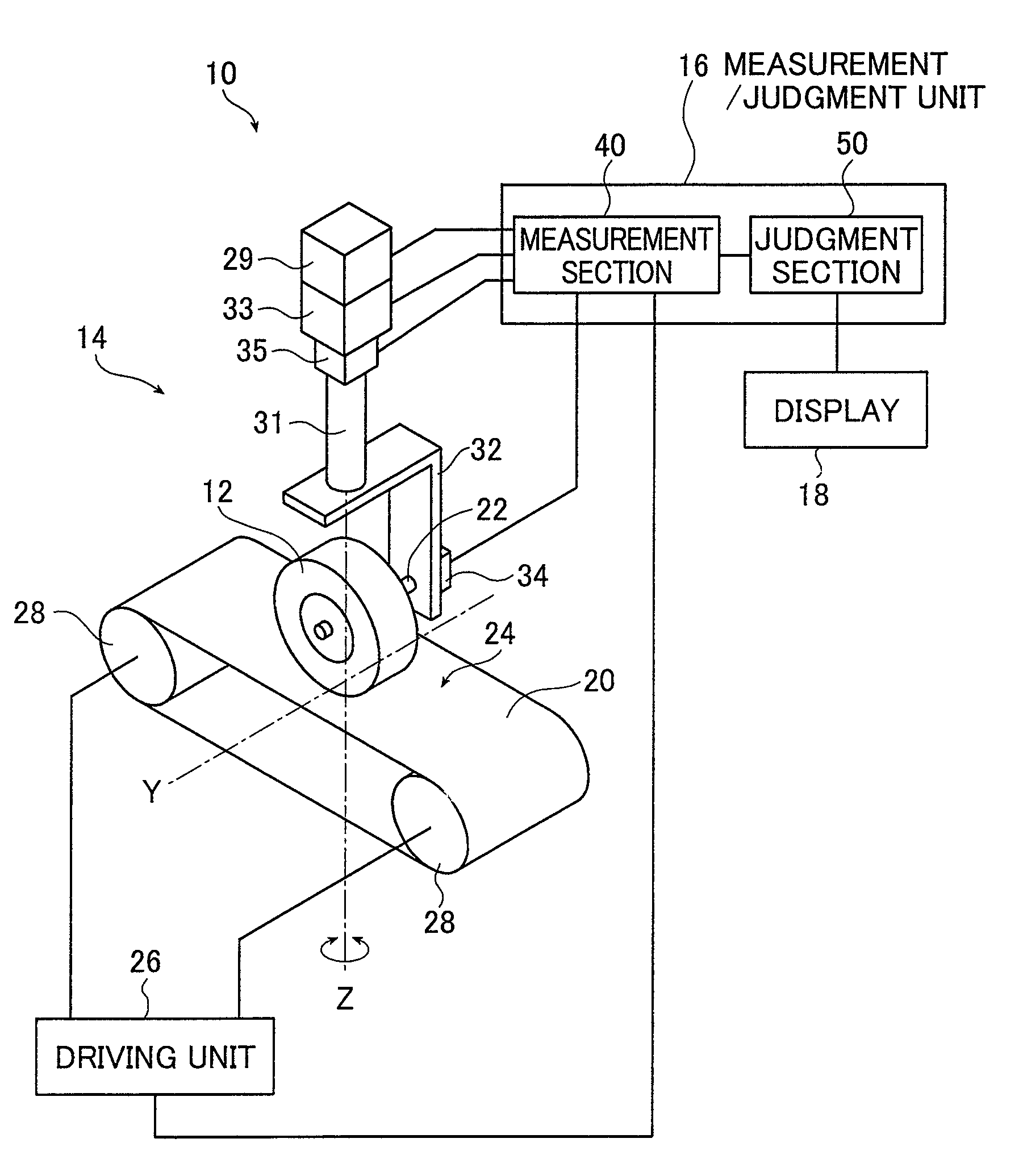

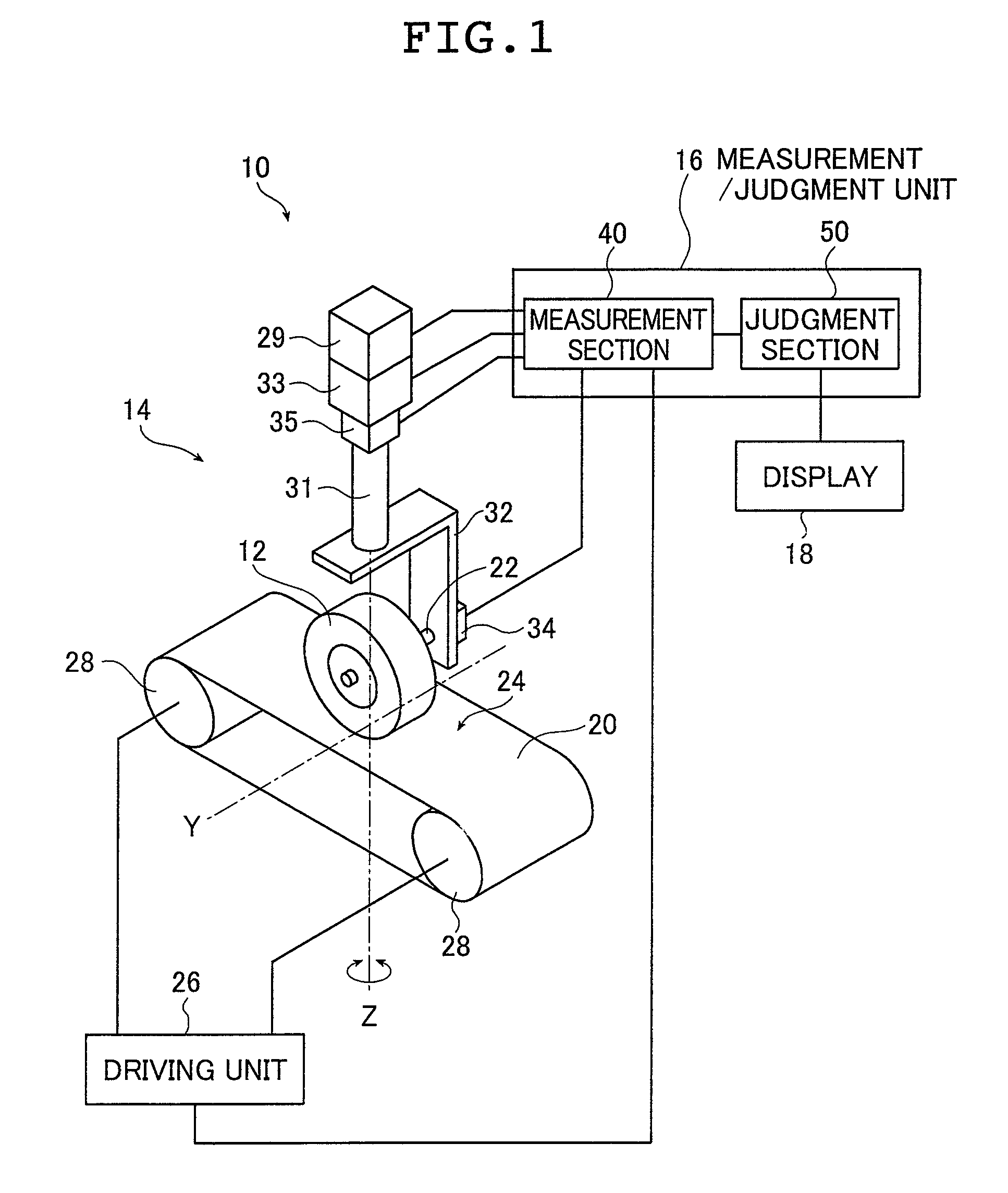

Tire characteristic judging method and tire characteristic judging device

A tire characteristic judging device judges a tire characteristic in the following way. At first, a load applied to a tire and a cornering force generated in the tire in time series while the tire is rolling are acquired. Then, an applied load variation amount is calculated from the acquired time-series applied load information and a cornering force variation amount calculated from the acquired time-series cornering force information. Next, an evaluation value is calculated based on the applied load variation amount and the cornering force variation amount. The calculated evaluation value and a preset reference value are compared with each other and whether or not the tire satisfies a desired characteristic is judged according to a result of comparison.

Owner:THE YOKOHAMA RUBBER CO LTD

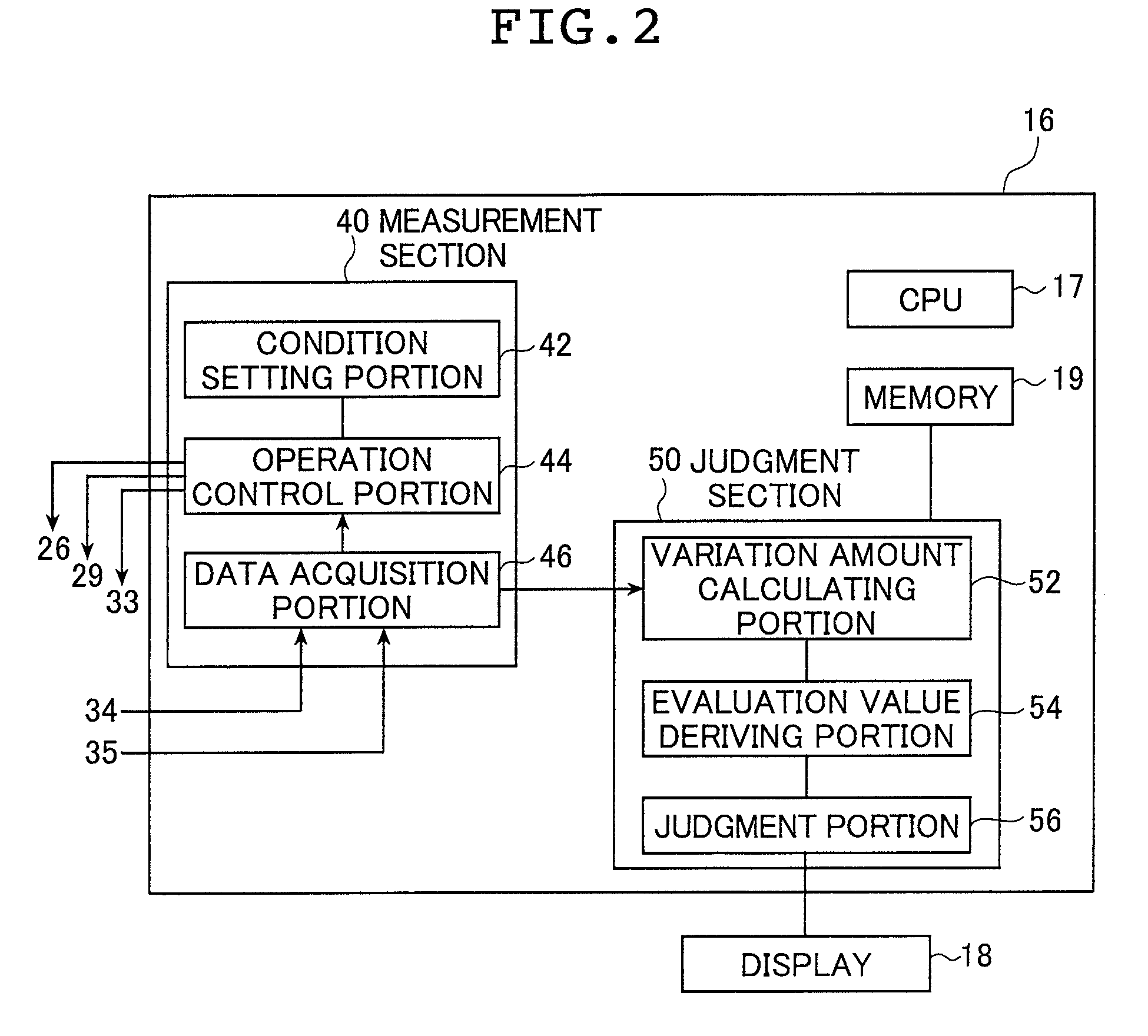

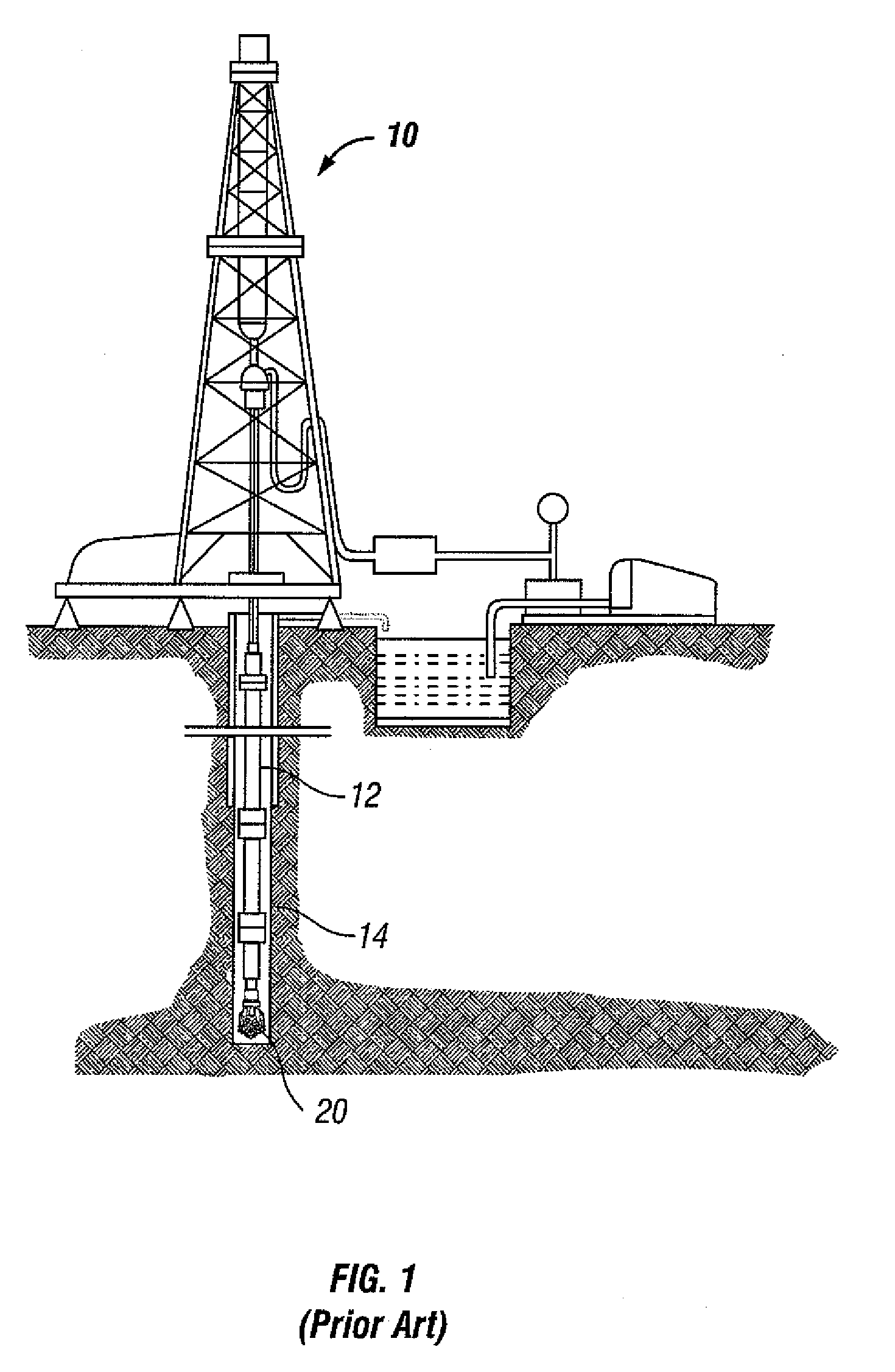

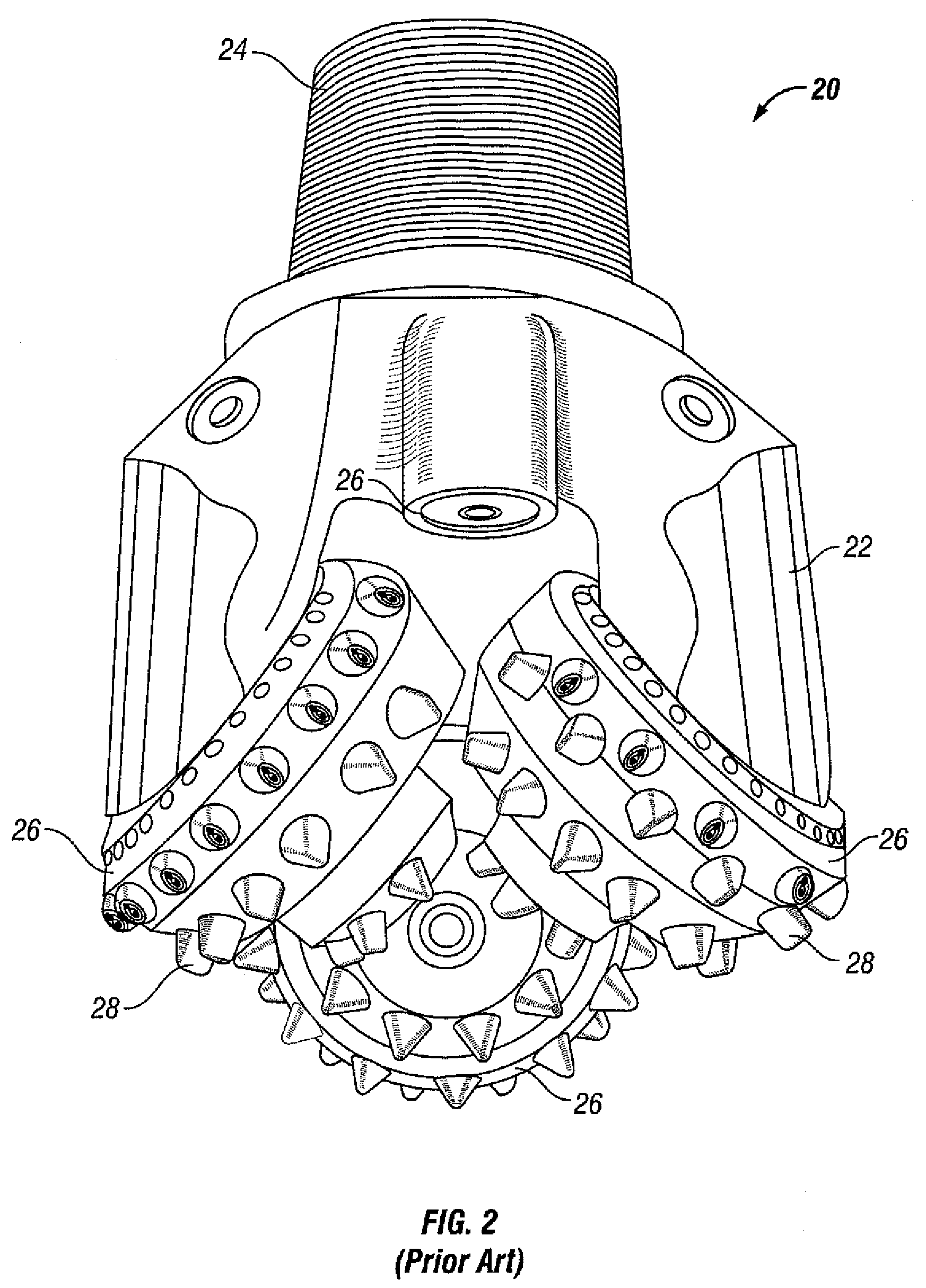

Radial force distributions in rock bits

A method for designing a drill bit in an earth formation, including defining parameters for a simulation of the drill bit drilling in earth formation, where the parameters comprise at least bit design parameters; executing the defined simulation; obtaining radial forces resulting from the executing of the defined simulation; applying a criterion to the obtained radial forces; and adjusting one of the at least bit design parameters in response to the applying of the criteria.

Owner:SMITH INT INC

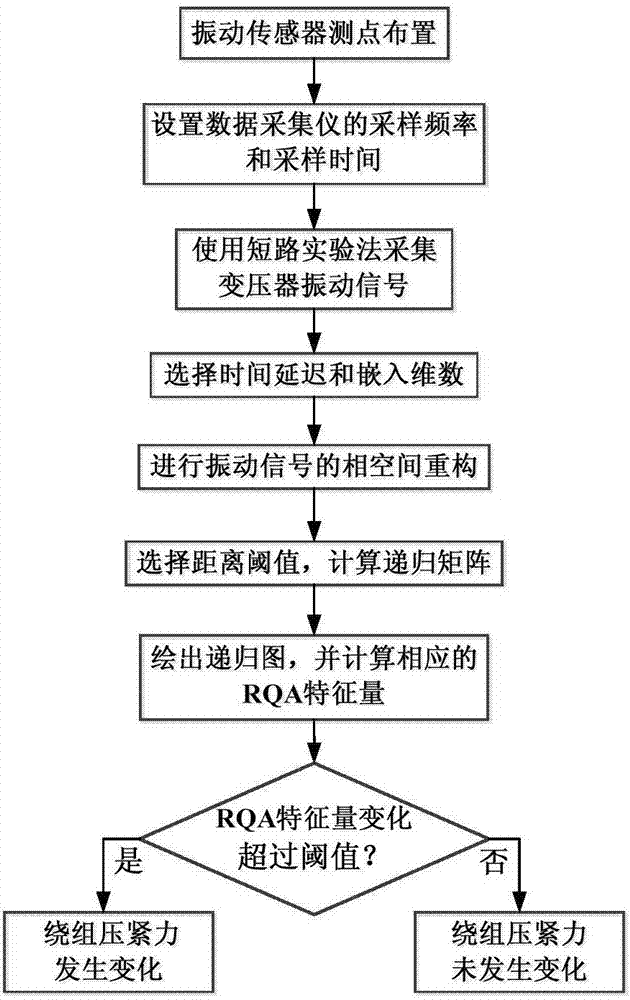

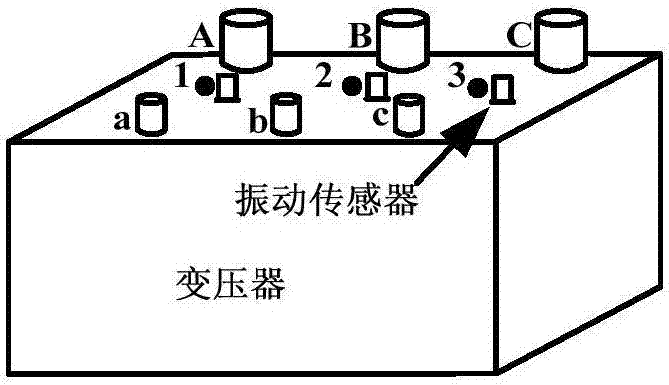

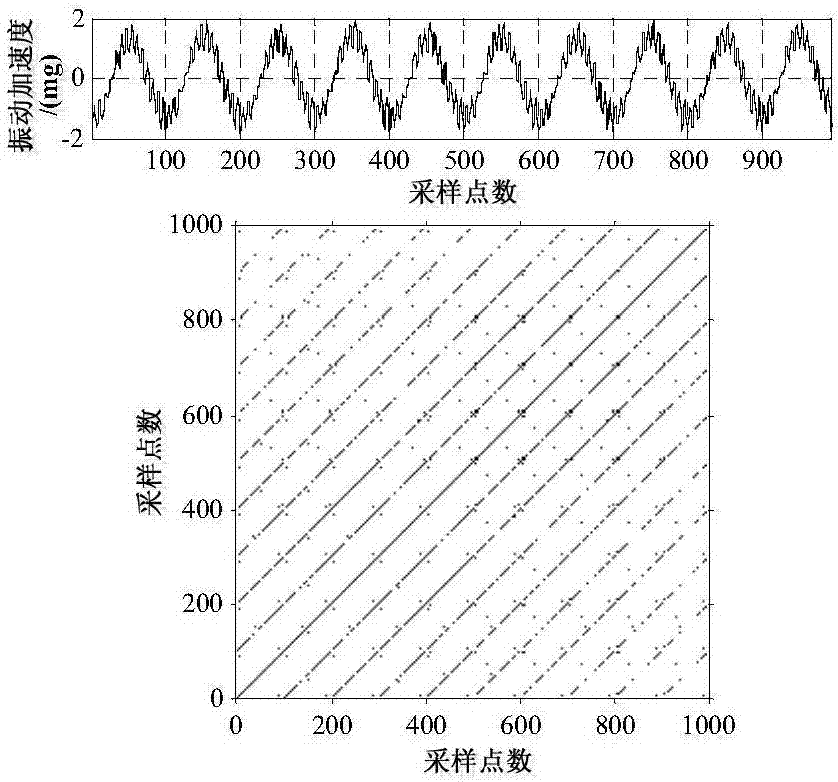

Method for detecting pressing force variation of winding of power transformer based on recursive quantitative analysis

InactiveCN107328467AEasy to operateHigh change detection sensitivitySubsonic/sonic/ultrasonic wave measurementExperimental methodsEngineering

The invention discloses a method for detecting the pressing force variation of the winding of a power transformer based on recursive quantitative analysis. The method comprises firstly using a short circuit experimental method to acquire a box surface vibration signal of a transformer with normal winding pressing force, and using a recursive quantitative analysis (RQA) method to obtain a reference RQA parameter; then acquiring a box surface vibration signal of a transformer with a winding to be detected by using the short circuit experimental method at the same sampling frequency and sampling time, and obtaining the RQA parameter of the transformer winding with unknown compactness by RQA; comparing the RQA parameter with the reference RQA parameter to determine if the transformer winding pressing force has changed. The method not only establishes the RQA measurement for detecting the variation trend of the overall pressing force of the winding, but also directly performs the RQA analysis on the vibration signal of a single sensor and establishes the local variation trend measurement of the pressing force. The method uses little equipment, simple in operation and accurate in diagnosis, can accurately detect the loosening of the winding due to pressing force changes.

Owner:HOHAI UNIV

Tire designing method, computer-readable recording medium, and tire manufacturing method

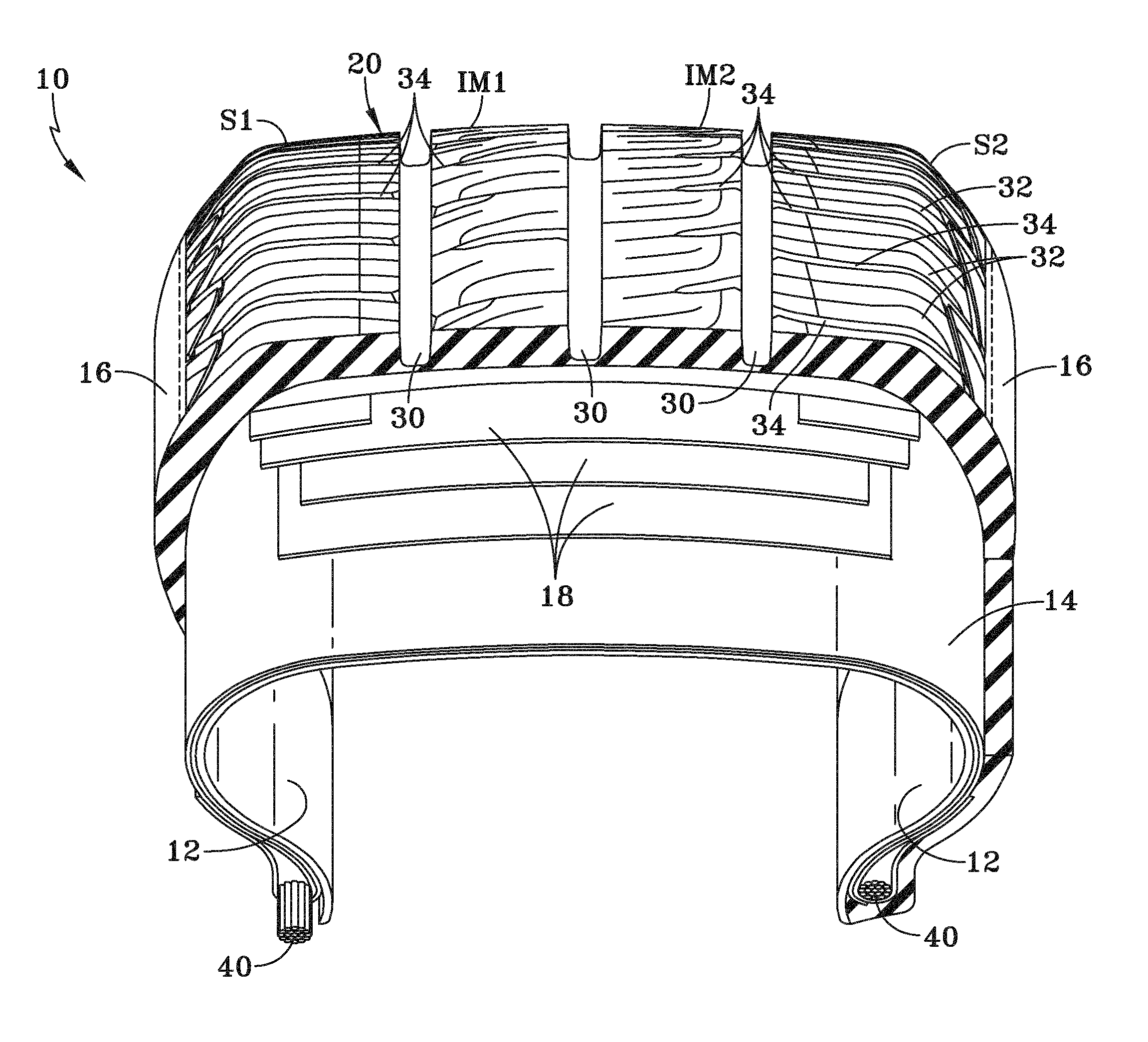

Evaluation tires, each having a plurality of structural elements including a target structural element, are prepared. Only the experimental structure of the target structural element is different among all the evaluation tires, while the structures of other structural elements are identical. Radial force variation of each of the evaluation tires is measured. Corrected radial-force variation of each of the evaluation tires is calculated by subtracting a 1st order component of the radial force variation from the radial force variation, and the structure of the target structural element is determined based on the corrected radial-force variations of the evaluation tires. This process is repeated for other structural elements.

Owner:NAKAMURA SACHIO +1

Tire uniformity testing

InactiveUS6915684B2Minimize impactGood repeatabilityStatic/dynamic balance measurementRoads maintainenceTire uniformityTire rotation

A method and apparatus for testing tires in a repeatable manner. Testing steps are performed in a manner that minimizes impact on the tire characteristics being measured. In one aspect, tire rotation reversal is performed at a zero crossing of a first harmonic of radial load variation exerted on a load carriage by the tire. In another aspect, load carriage retraction is performed so that the tire is unloaded when the tire stops rotating.

Owner:MICRO POISE MEASUREMENT SYST

Method for prediction and control of tire uniformity parameters from crown thickness variation

Improved and more easily implemented methods for predicting uniformity parameters such as uneven mass distribution, radial run out and high speed radial force variation utilize other measurements such as the tire crown thickness variation. When high speed radial force variation is calculated, low speed radial force variation is also measured. Tire crown thickness variation can be measured in different fashions depending on the particular tire manufacturing process employed. By electronically determining resultant uniformity parameters, tires can be improved by rectification to address the uniformity levels. In addition, tire manufacturing can be improved by altering the resultant location of tire crown thickness variation relative to other aspects of the tire and / or tire manufacturing process.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

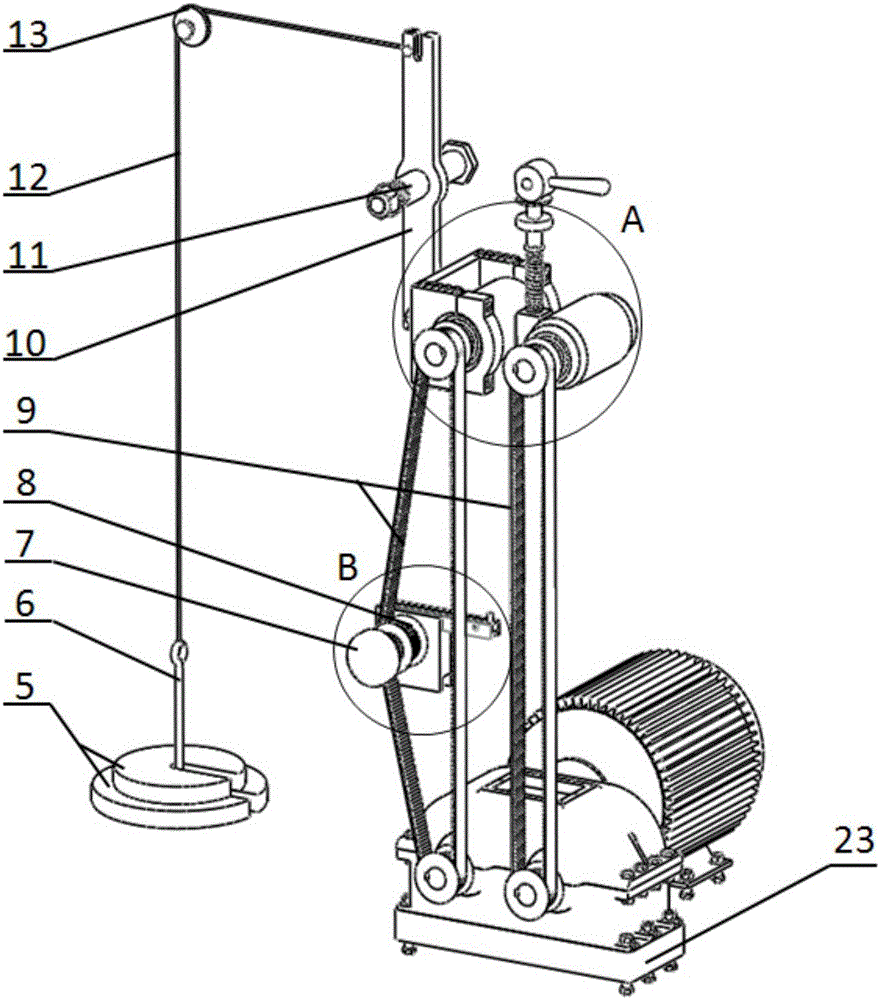

Friction testing stand

ActiveCN105004665AEliminate distractionsMeasured coefficient of frictionUsing mechanical meansMaterial analysisFrictional coefficientFriction force

Owner:NAVAL UNIV OF ENG PLA

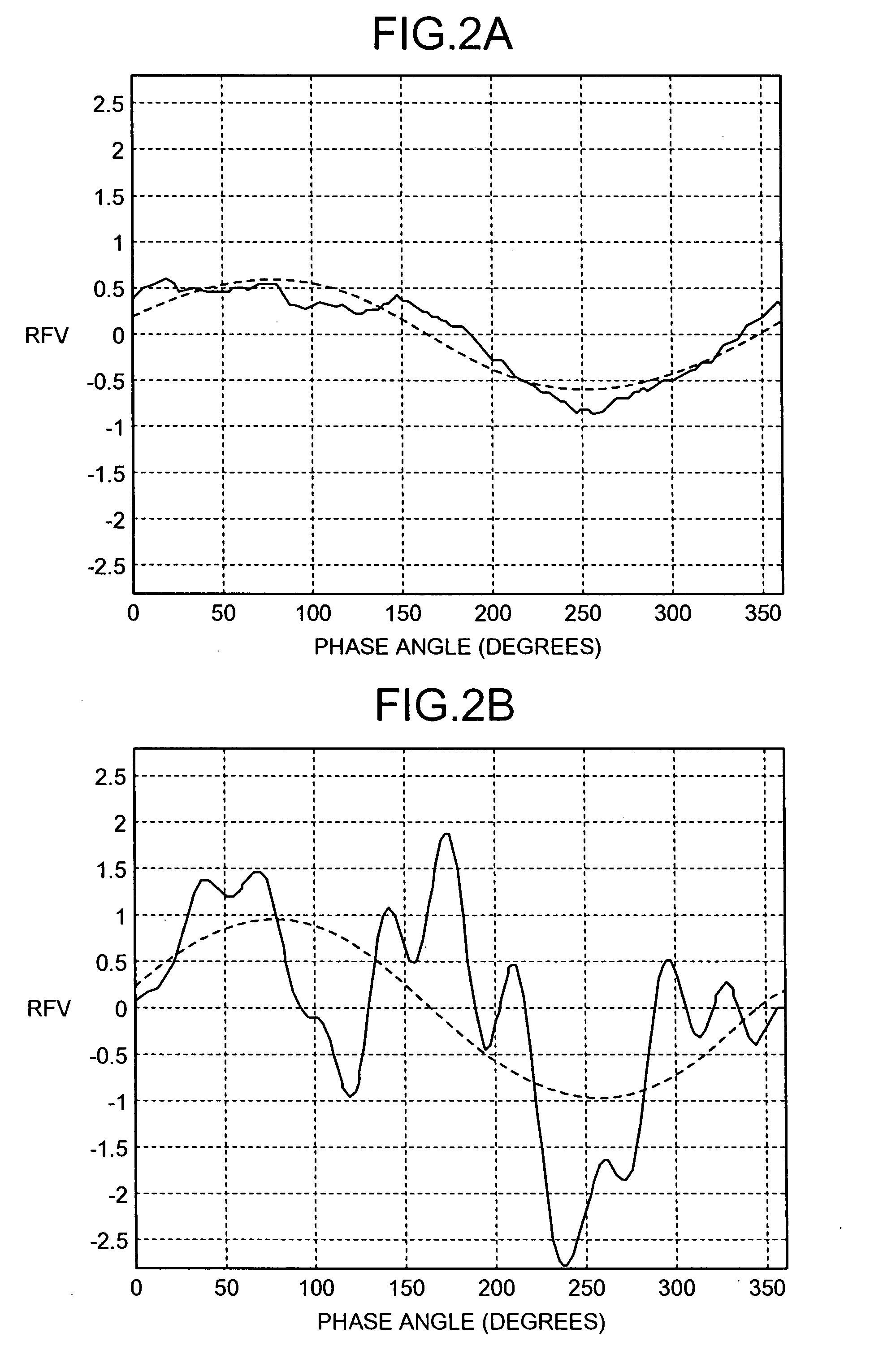

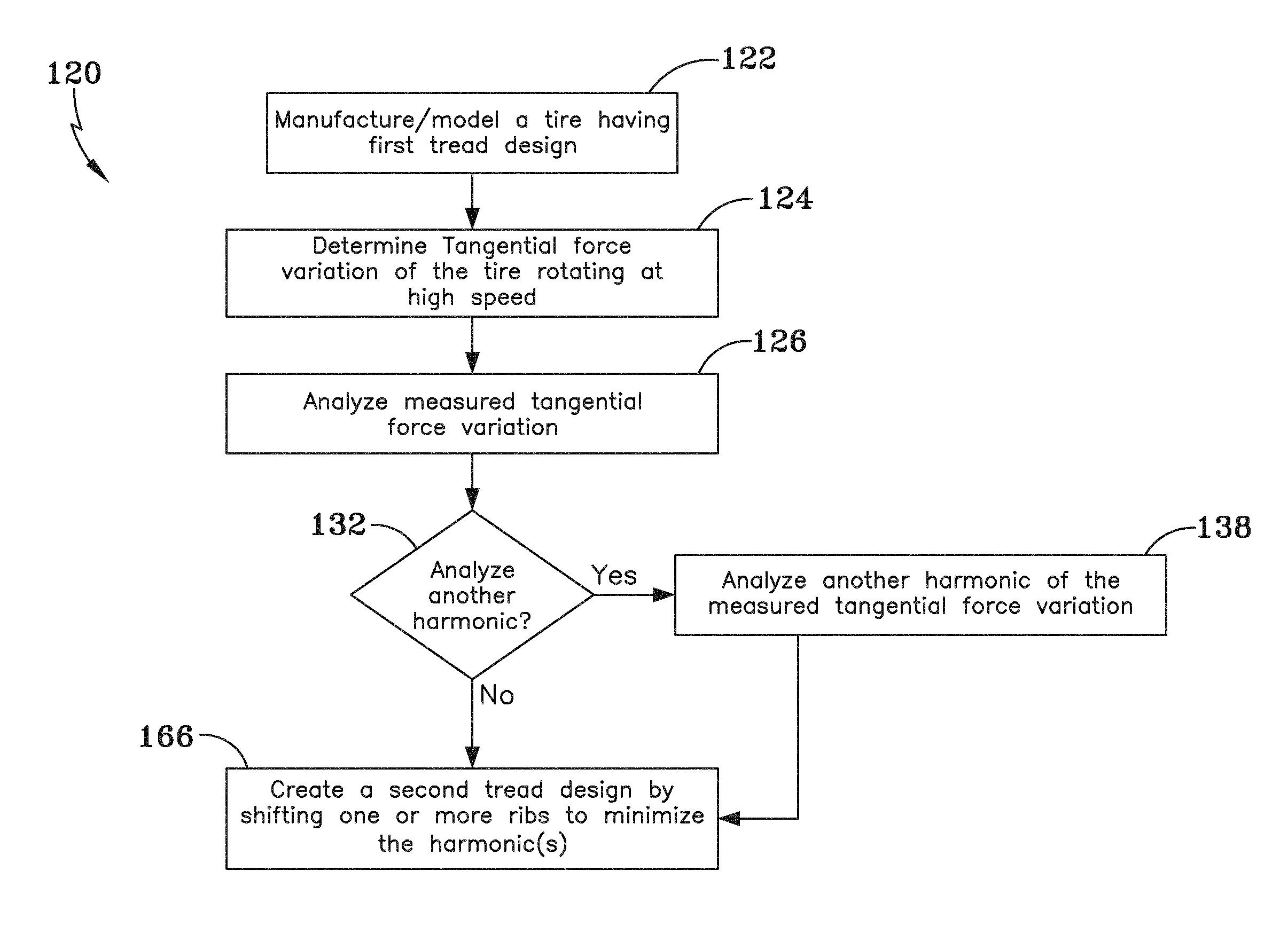

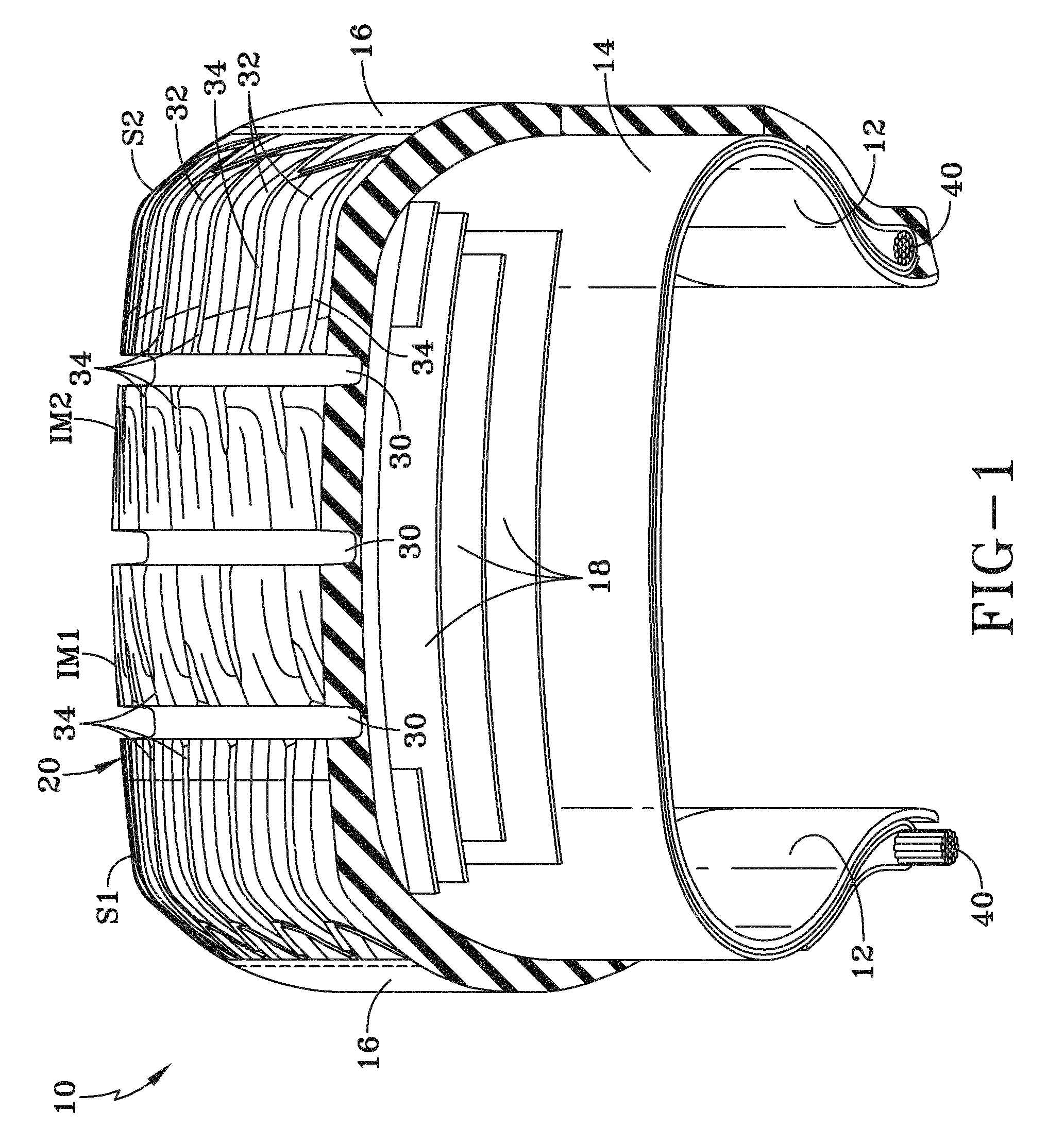

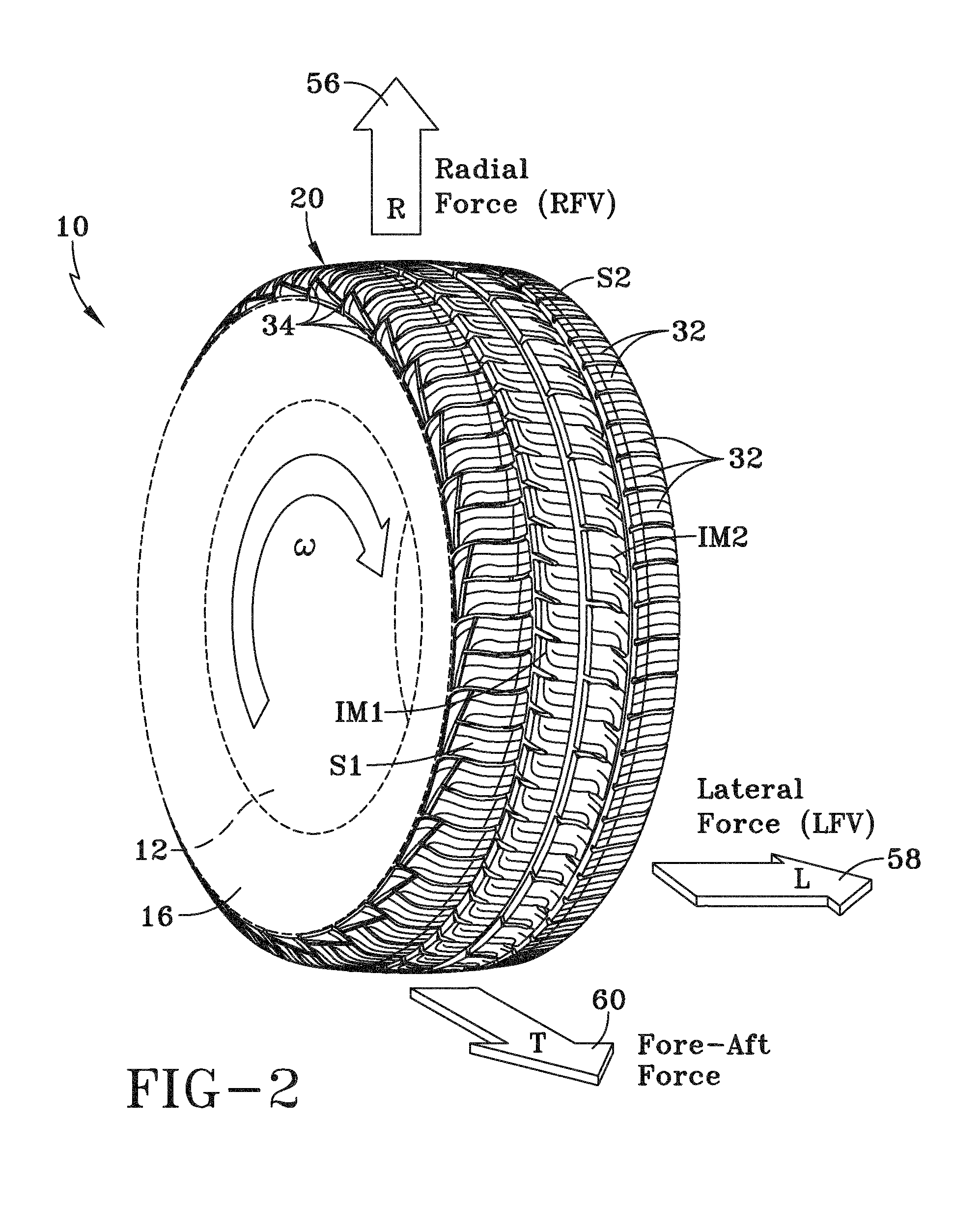

Tire second order harmonics with rib shift methodology

ActiveUS8718990B2Improving high-speed uniformityMinimize the second order harmonicGeometric CADDesign optimisation/simulationHarmonicEngineering

A method of improving the high-speed uniformity of tire performance that reduces low and / or high harmonics. The method includes determining a force variation that is created by rotation of a first tire, having a first tread design, at high speed. A second order harmonic of the force variation is analyzed. A second tire design is generated that circumferentially shifts one or more ribs of the first tread design to minimize the second order harmonic alone or in combination with other order harmonics.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire uniformity improvement using estimates based on convolution/deconvolution

InactiveUS20150377742A1Improving uniformity of tireDesign optimisation/simulationRoads maintainenceTire uniformityMeasurement point

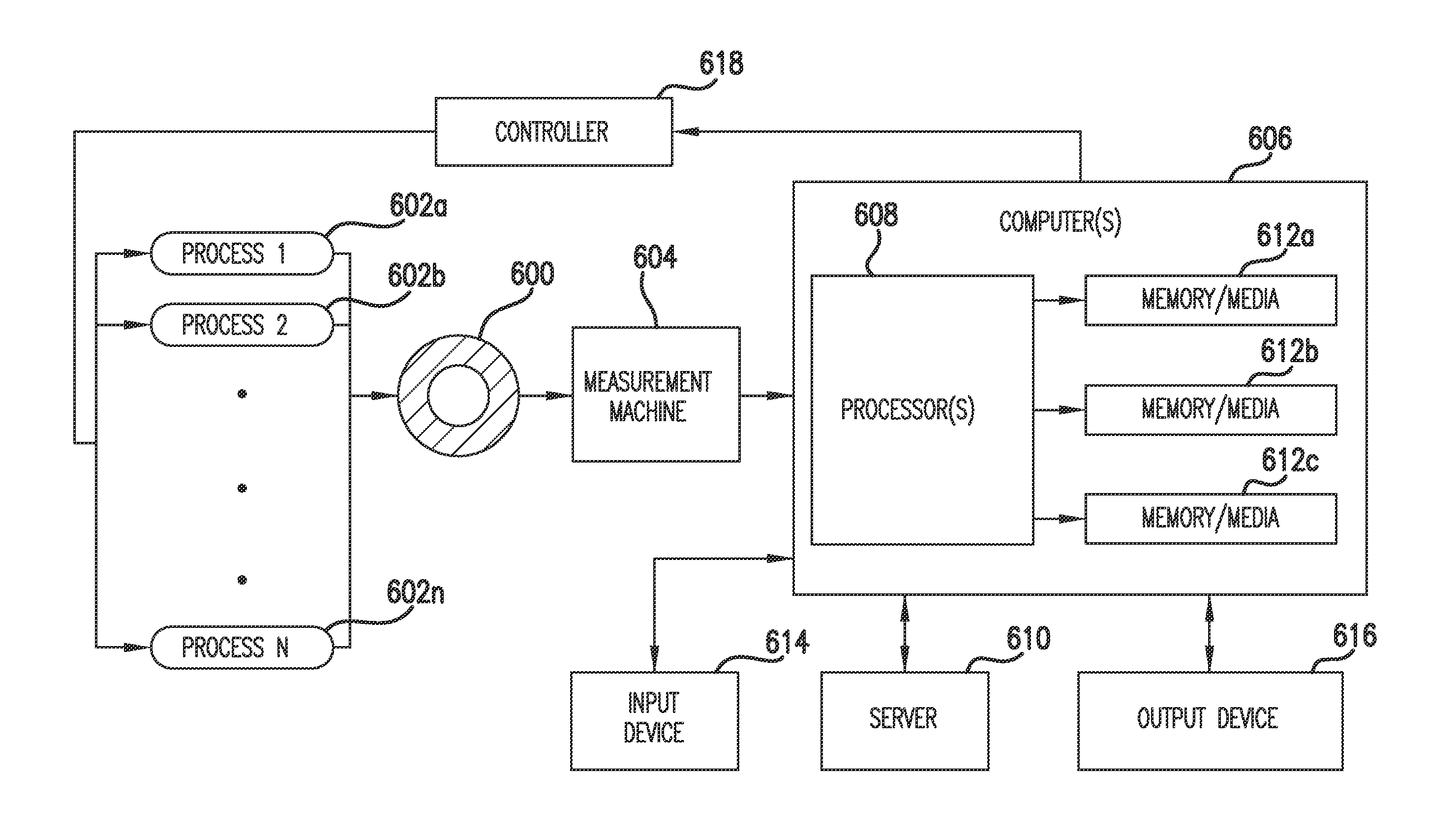

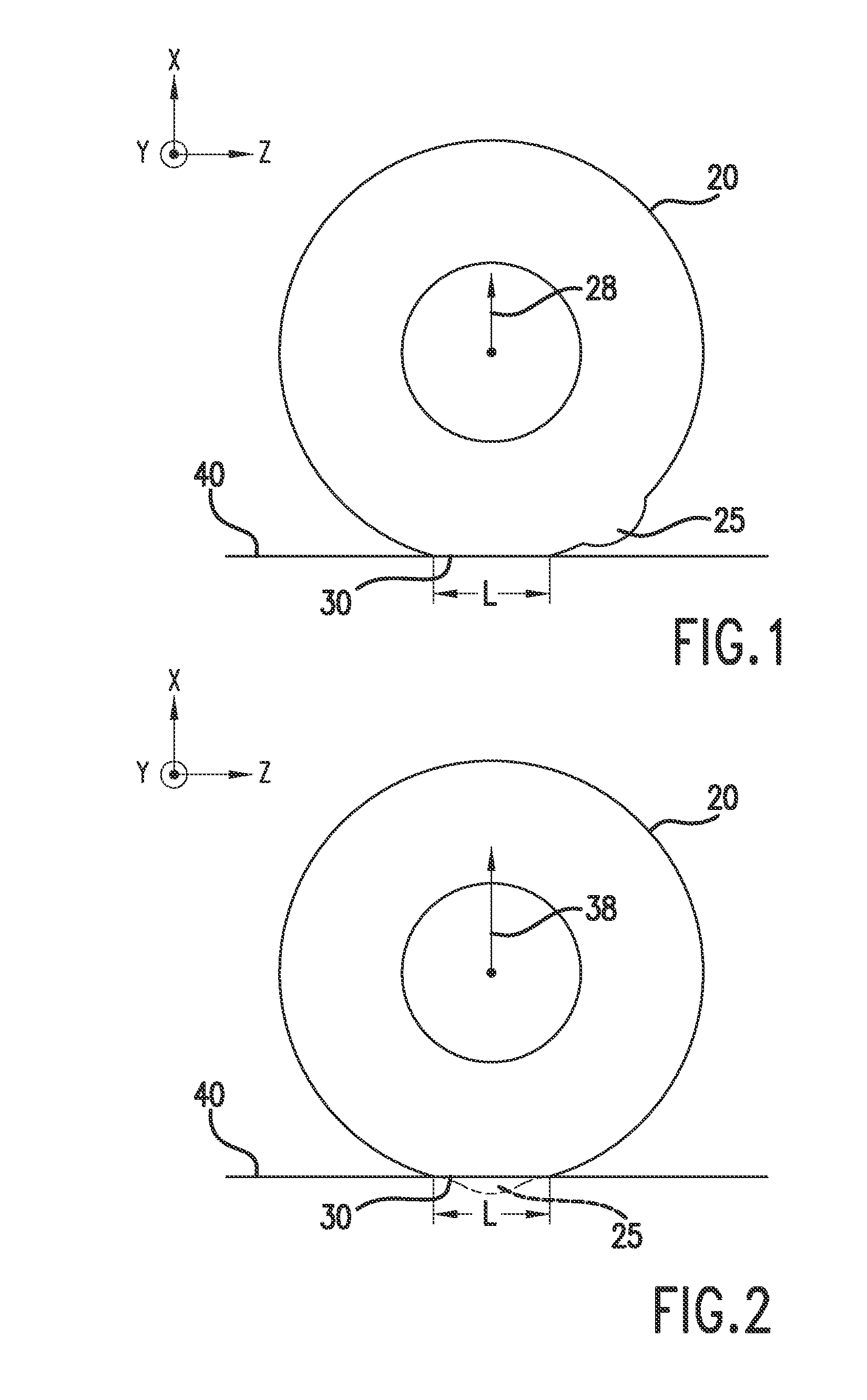

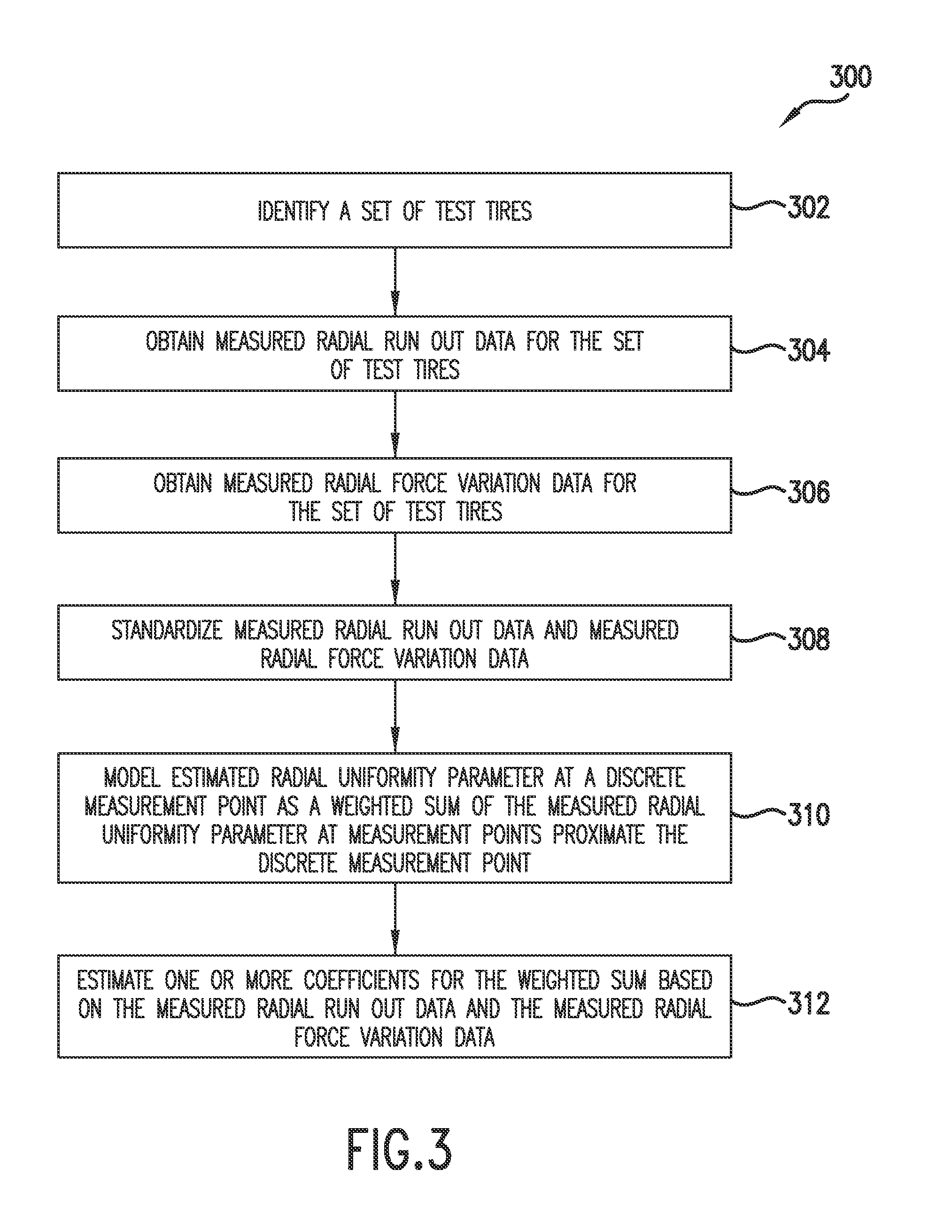

Systems and methods for improving the uniformity of a tire using convolution / deconvolution-based uniformity parameter estimates of a tire are provided. For instance, convolution can be used to estimate radial force variation from one or more uniformity parameter measurements, including radial run out parameter measurements. Deconvolution can be used to estimate radial run out from one or more uniformity parameter measurements, including radial force variation parameter measurements. The estimated uniformity parameter can be estimated from the uniformity parameter measurements using one or more models. The one or more models can represent an estimated radial uniformity parameter at a discrete measurement point as a weighted sum of the measured radial uniformity parameter at the discrete measurement point and one or more selected measurement points proximate the discrete measurement point. The measurement points can be selected based on the contact patch length of the tire.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Device and method for assembling tire with wheel

InactiveCN101014470ALess investmentRotating vibration suppressionStatic/dynamic balance measurementRadial Force VariationPrimary component

A device and a method for assembling a tire with a wheel. As the rigidity of the wheel is lower based on the classification of the rigidity of the wheel or the radial runout of the wheel is smaller based on the classification of the radial runout of the wheel, a method for aligning the light point of the static unbalance of the tire with the heavy point of the static unbalance of the wheel (alignment of heavy point with light point) is more selected than a method of aligning the peak position of the primary component of the radial force variation of the tire with the bottom position of the primary component of the radial runout of the wheel (alignment of radial force variation), and the tire is assembled with the wheel by using the method.

Owner:HONDA MOTOR CO LTD

Tire radial force variation prediction method

InactiveUS7174271B2Reduce errorsIncrease speedTyre partsMechanical diameter measurementsLow speedAttenuation ratio

It is possible to significantly reduce a prediction error of the high-speed RFV and the high-speed TFV in a tire having a large PRO growth amount at high speed. Three or more sample tires are extracted from each lot. The PRO and RFV are measured and the least-square method is used to predict (100) the upper and lower and front and back natural angle frequency, attenuation ratio, upper and lower spring constant, and rolling radius coefficient. By using the PRO measurement apparatus, the PRO during idling is measured. By using an AAV measurement apparatus, an actual measurement value AAVL of the angle acceleration fluctuation at a low speed is measured (102). The PRO and AAV at a high speed are predicted (104) and the actual measurement value and prediction value are used to predict the high-speed RFV and TFV.

Owner:BRIDGESTONE CORP

Method for prediction and control of harmonic components of tire uniformity parameters

ActiveUS9569563B2Static/dynamic balance measurementData acquisition and loggingTire uniformityHarmonic

Improved and more easily implemented methods for predicting high speed radial force variation and uneven mass distribution utilize other measurements such as radial nm out and other parameters. The prediction model for high speed radial force variation uses a speed-dependent calibration term for predicting higher harmonic components, while the same or other models can be used for the first harmonic. The uneven mass distribution prediction model accounts for deformation of the tire along multiple tracks, thus employing a more realistic model of crown deformation that accounts for changing tire stiffness levels across different harmonic components of the measured and predicted parameters.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

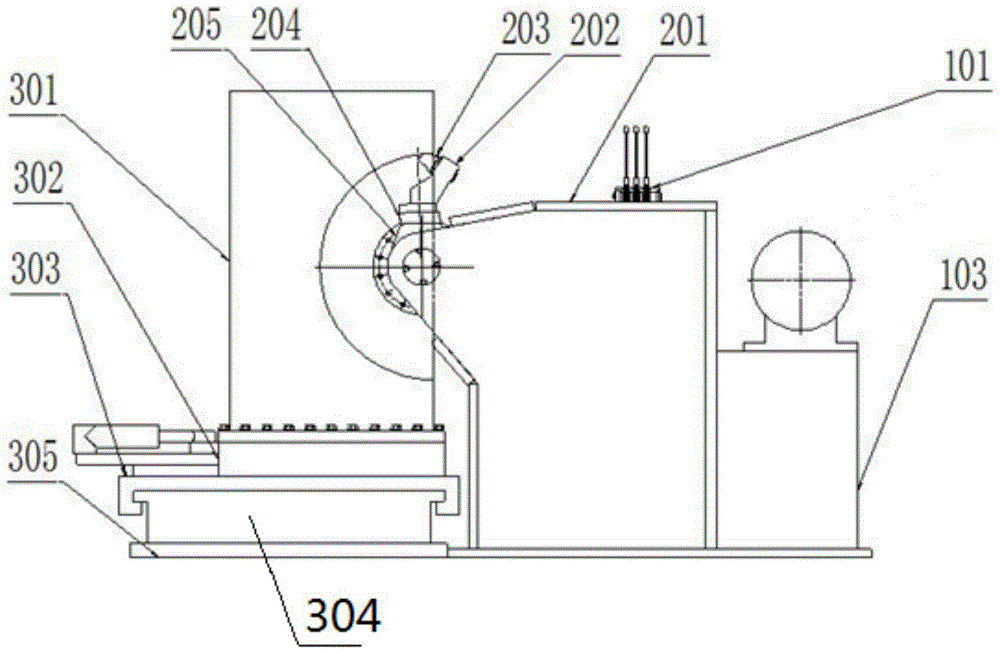

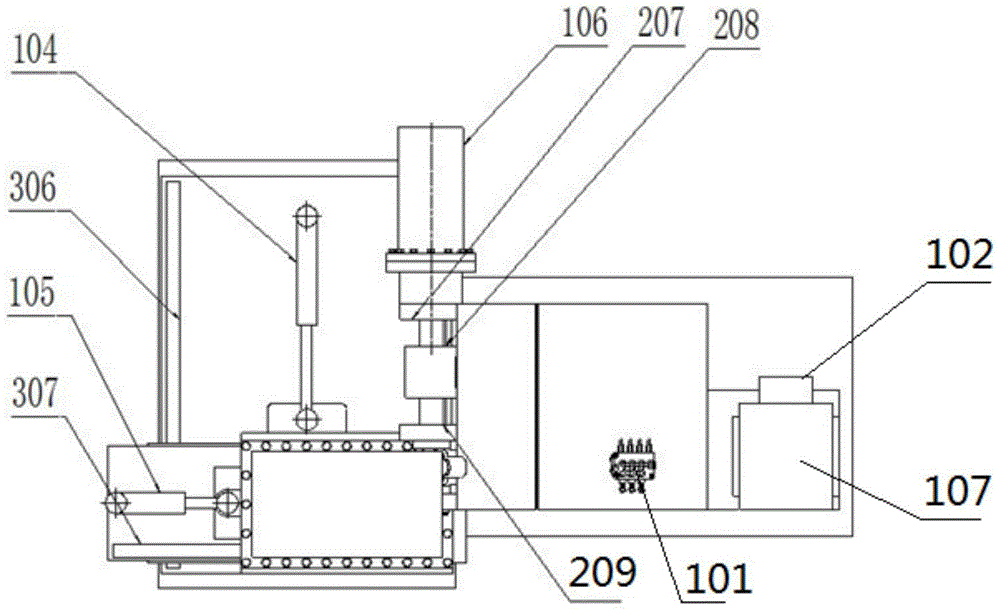

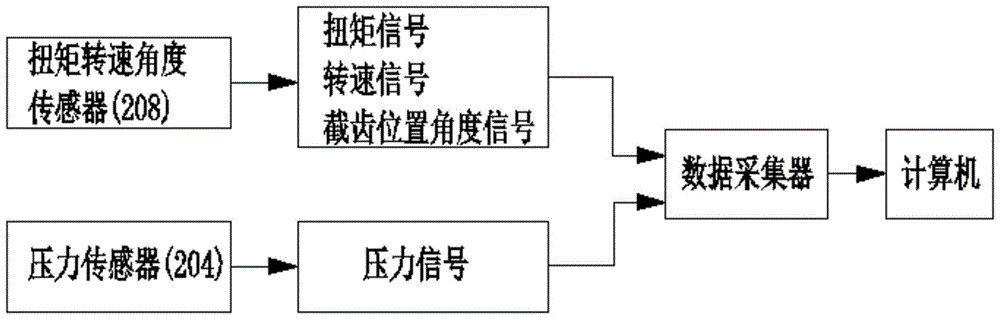

Mechanism test method for rock breaking by single-tooth rotary cutting

InactiveCN105424337BMachine part testingInvestigating machinabilitySize determinationData acquisition

Owner:CHONGQING UNIV

Tire second order harmonics with rib shift methodology

ActiveUS20120166167A1Minimize second order harmonicImproving high-speed uniformityGeometric CADDesign optimisation/simulationHarmonicEngineering

A method of improving the high-speed uniformity of tire performance that reduces low and / or high harmonics. The method includes determining a force variation that is created by rotation of a first tire, having a first tread design, at high speed. A second order harmonic of the force variation is analyzed. A second tire design is generated that circumferentially shifts one or more ribs of the first tread design to minimize the second order harmonic alone or in combination with other order harmonics.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com