Friction testing stand

A test bench, manual wheel technology, applied in measuring devices, instruments, mechanical devices, etc., to achieve the effects of simple operation, high degree of automation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

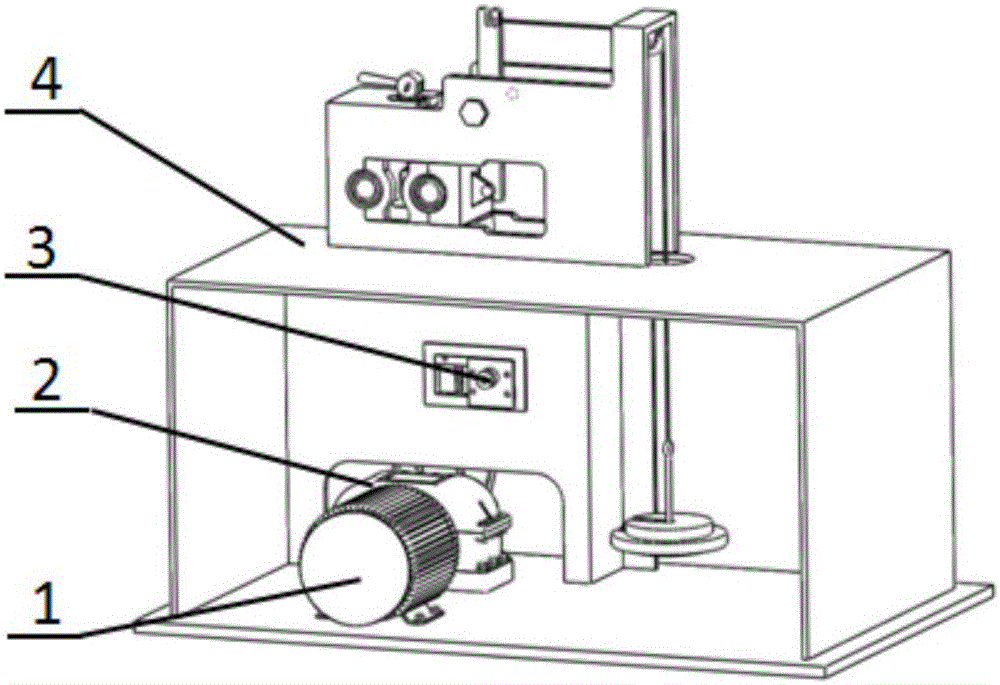

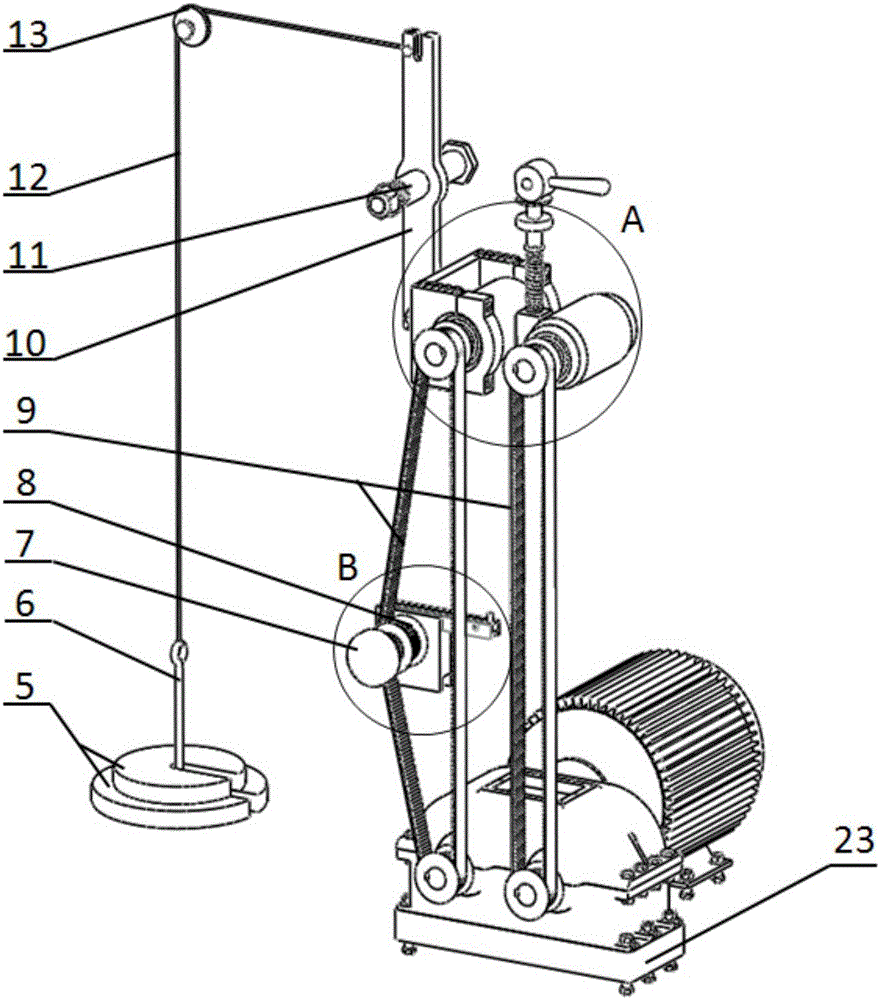

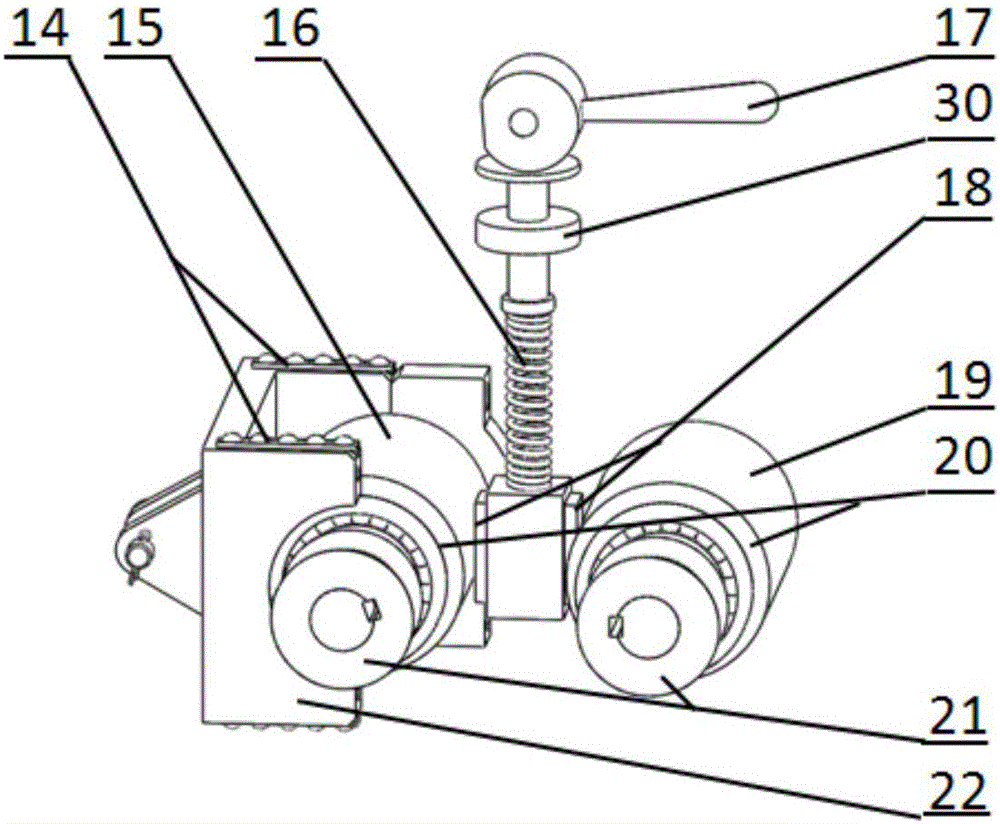

[0025] The present invention is made up of frame 4, vibration isolator 23, power system, loading system, test system, control and data processing system and auxiliary system. The auxiliary system is mainly composed of the timing belt tensioning mechanism 3, the sample shaft quick change mechanism, the spray system, the lubrication system, and the temperature detection system. Frame 4 supports all components of the friction test bench. The test system takes the sensor and the sample as a whole to directly measure the motion information of the sample; the control and data processing system solves the characteristics of the friction force according to the dynamic equation of the test system, and then solves the friction coefficient and friction vibration characteristics of the sample.

[0026] The present invention will be described in detail below with reference to the accompanying drawings.

[0027] refer to figure 1 , figure 2 with image 3 , the servo motor 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com