Tire manufacturing method for improving the uniformity of a tire

a manufacturing method and tire technology, applied in the field of tire uniformity improvement, can solve the problems of reducing the uniformity of tires produced, requiring an extra manufacturing step, and affecting the ride and handling of vehicles, so as to reduce the after cure radial force variation (rfv) of tires produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

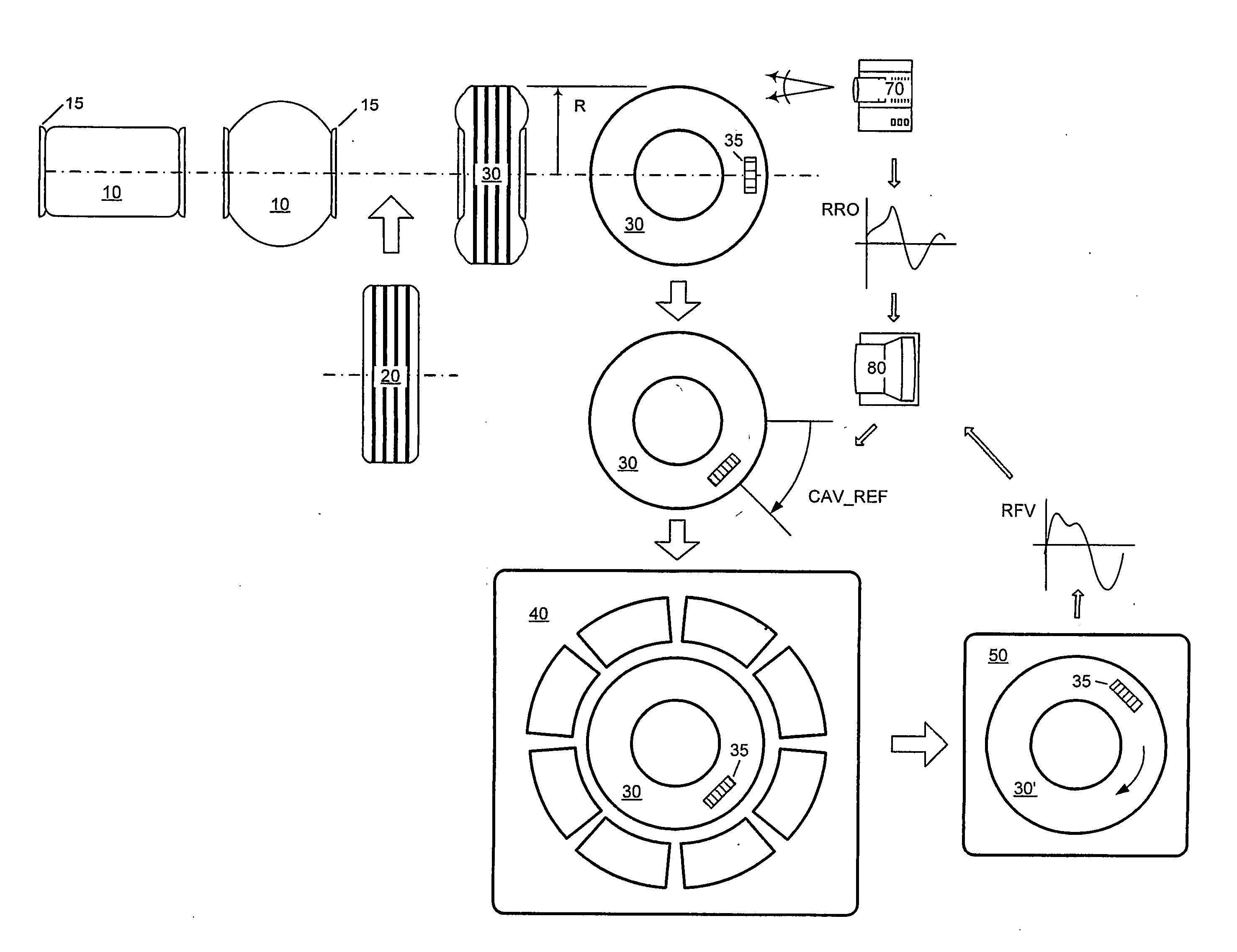

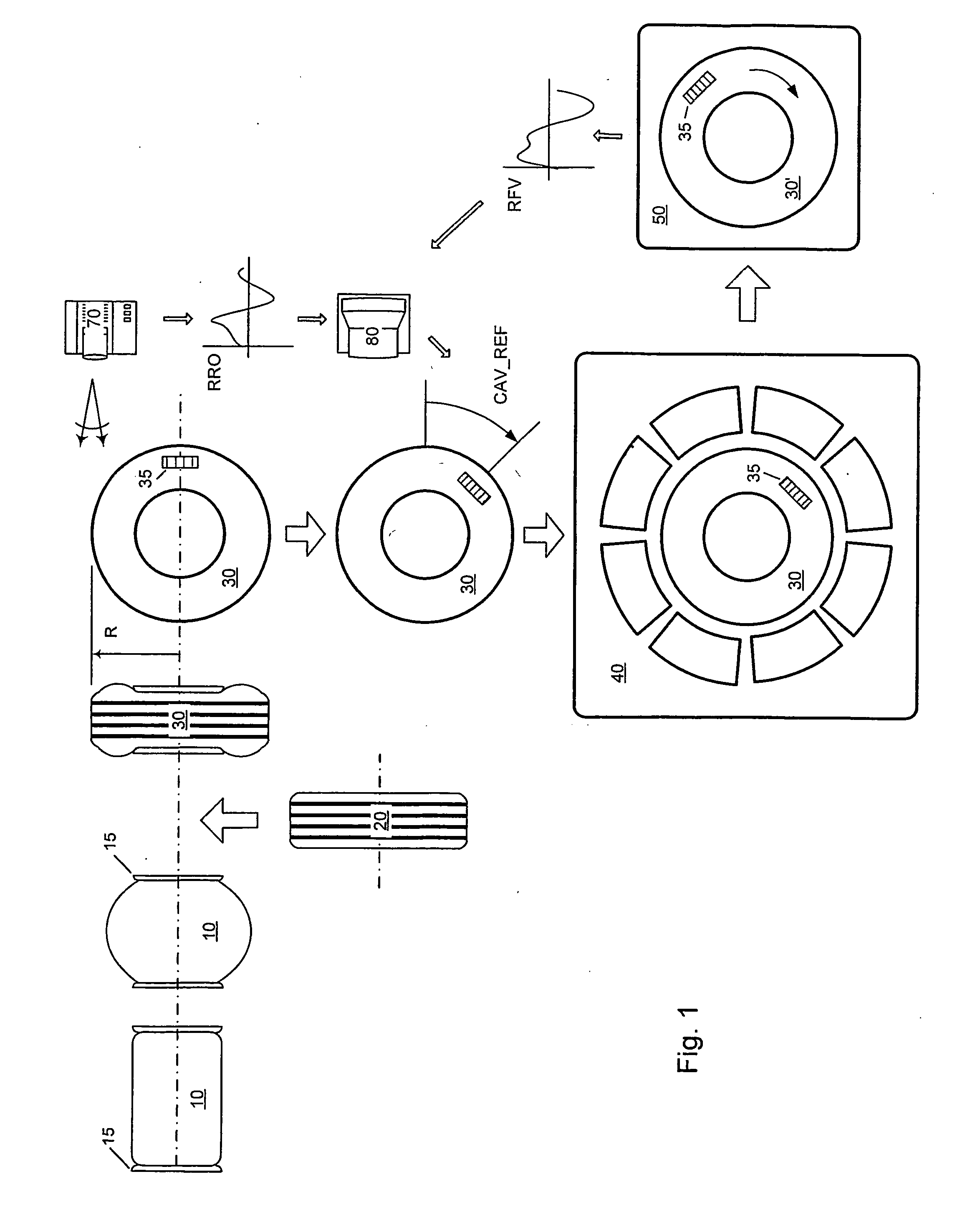

[0044] Reference will now be made in detail to exemplary versions of the invention, one or more versions of which are illustrated in the drawings. Each described example is provided as an explanation of the invention, and not meant as a limitation of the invention. Throughout the description, features illustrated or described as part of one version may be usable with another version. Features that are common to all or some versions are described using similar reference numerals as further depicted in the figures. The following Table 1 indicates the specific terminology employed herein. Note that the CBD_REF, FBD—REF, SBD_REF, TSR_REF, and CAV_REF are scalar quantities for the reference angles that are recorded during the tire manufacturing steps.

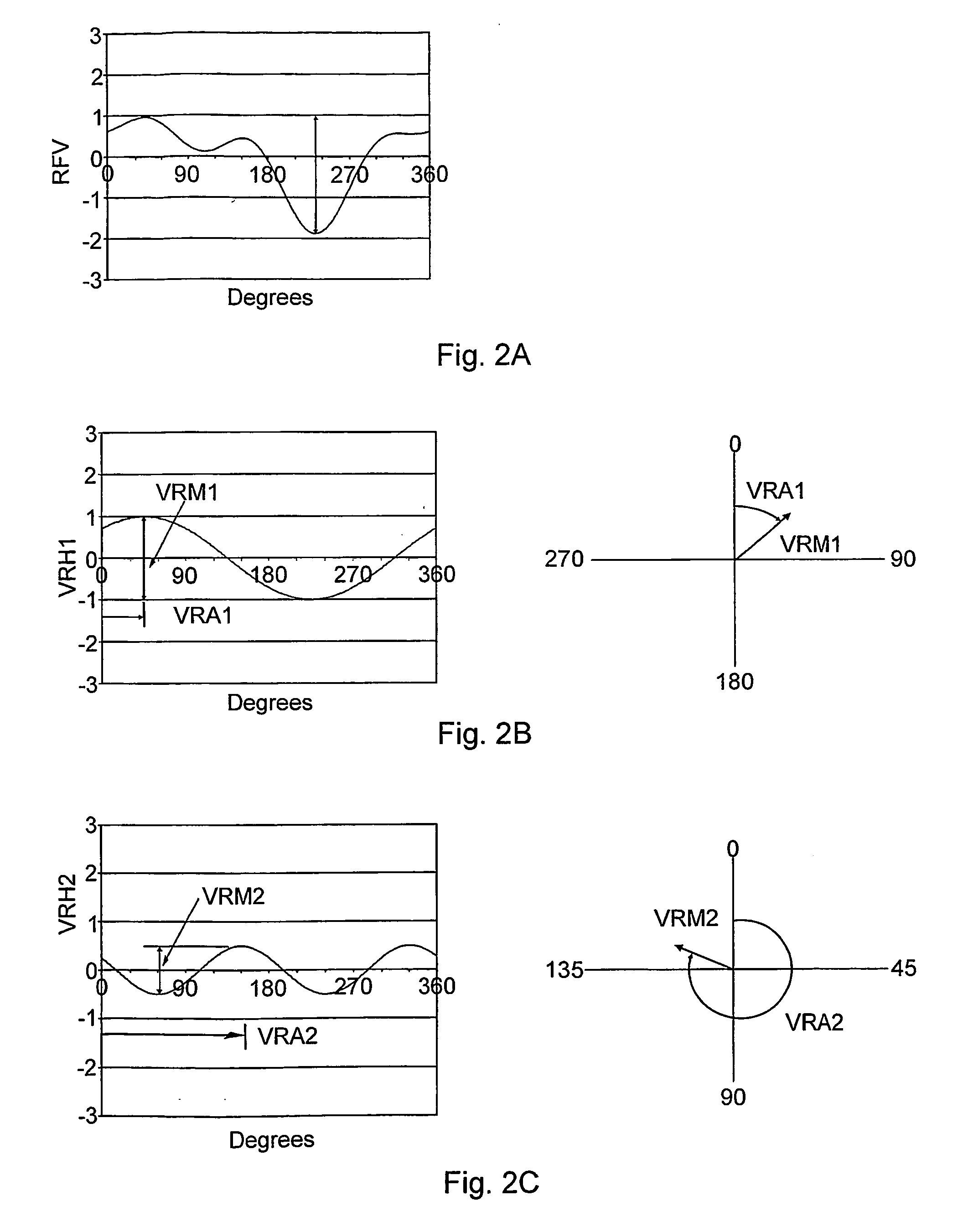

TABLE 1Vector NomenclatureVectorMagnitudeAzimuthRadial Force (VRH1)VRM1VRA1Carcass Green (RRO)FRM1CFRA1C(GR1C)Gain Carcass (GNC)GCθCTread Green RROFRM1TFRA1T(GR1T)Gain Tread (GNT)GTθTGreen Tire RROFRM1FRA1(GR1)Gain (GN)GNθFirst Stage Tooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com