Improvements in tire uniformity testing

A technology of tires and carriages, which is applied in the direction of automobile tire testing, vehicle testing, machine/structural component testing, etc. It can solve problems such as customer dissatisfaction, unfavorable tire measurement, and low tire revenue, so as to improve repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

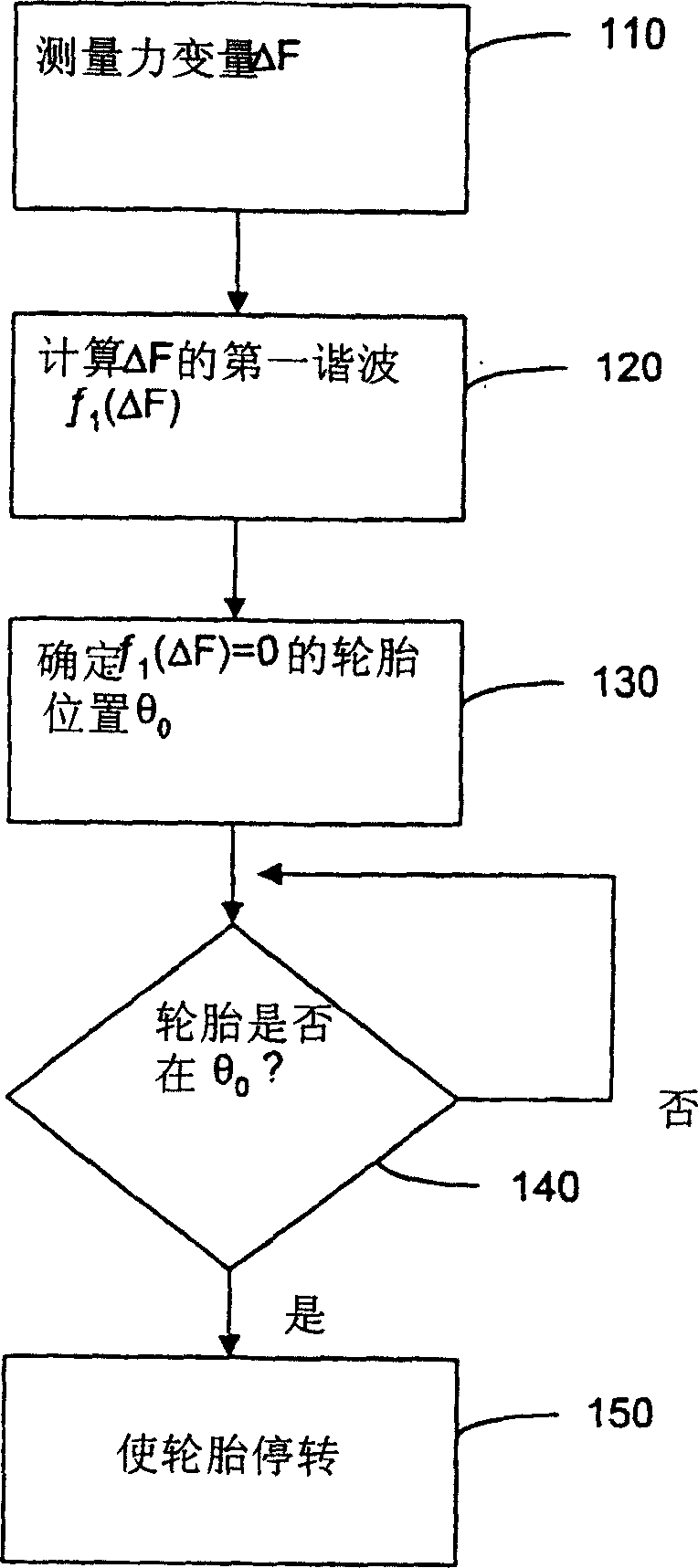

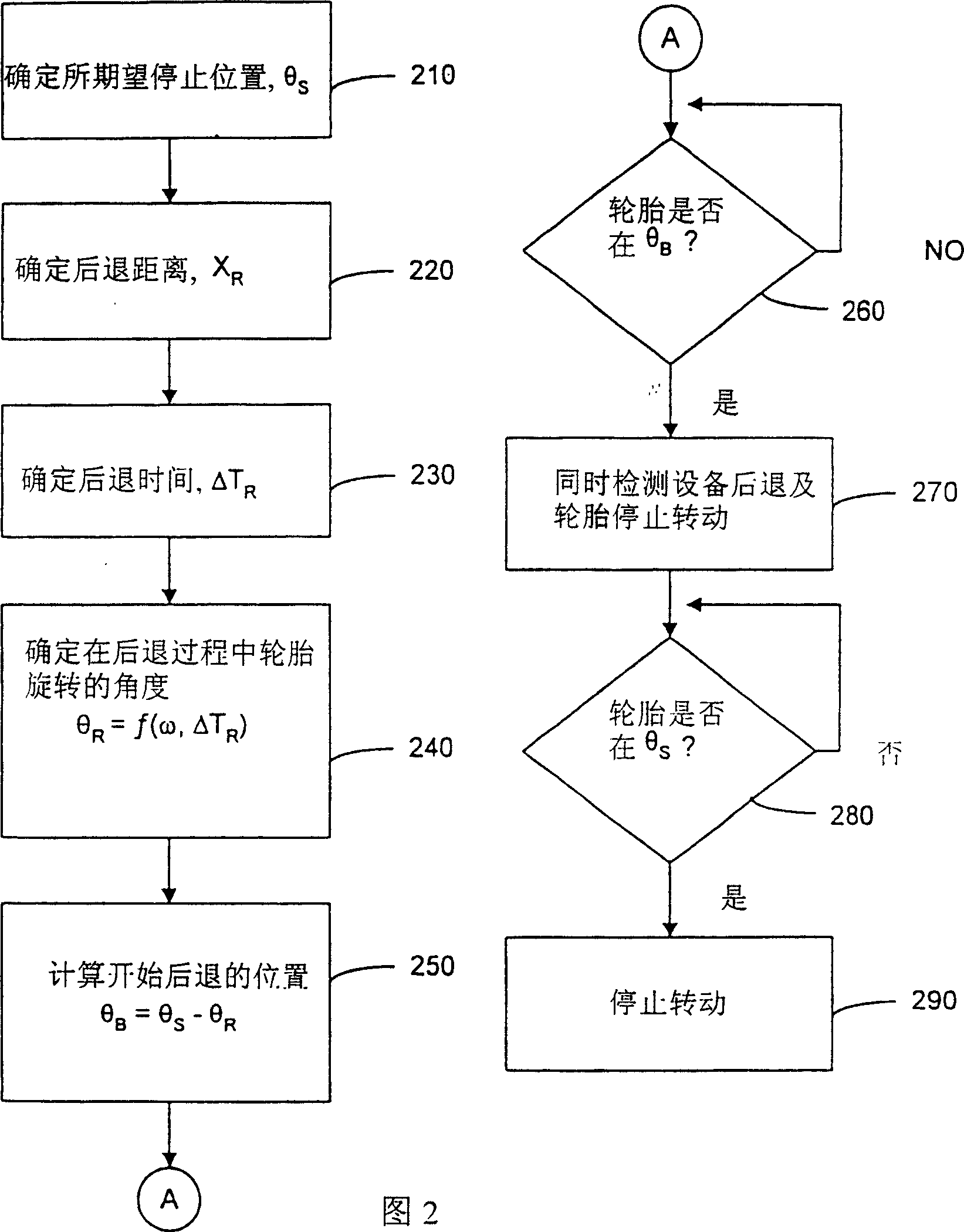

[0013] One reason for the decrease in the mechanical repeatability of the uniformity test is that when the tire is under load, when the tire rotation direction is reversed, the tire "adjusts" during the reversal process, and this "adjustment" will affect what is done in the second rotation direction Measurement, especially the measurement of radial force variables. It is believed that this effect can be predicted based on the angular position at which the tire reverses, from an increase in the radial force variable to a decrease in the radial force variable through almost no change. Since the radial forces in the two rotation directions show a high degree of similarity, the reversal can be controlled based on the measurement made in the first direction, so that a small radial force change is produced in the second direction. This enables the inspection machine to provide a true measurement of the radial force in the second direction on the basis of good repeatability.

[0014] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com