Improved tire uniformity through compensation between radial run out and stiffness variation

一种径向跳动、轮胎的技术,应用在轮胎零部件、汽车轮胎测试、静态/动态平衡的测试等方向,能够解决尚未出现等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

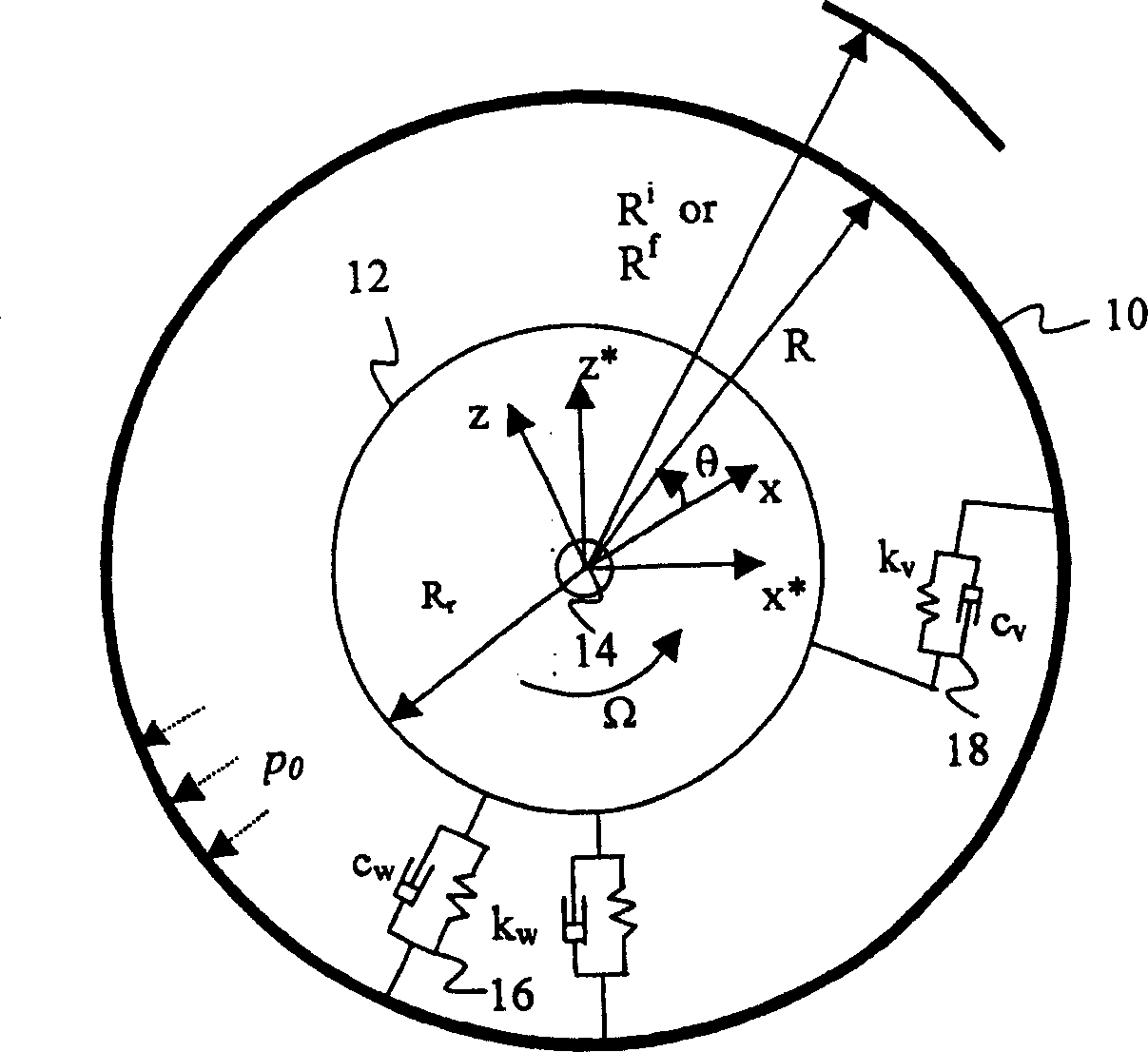

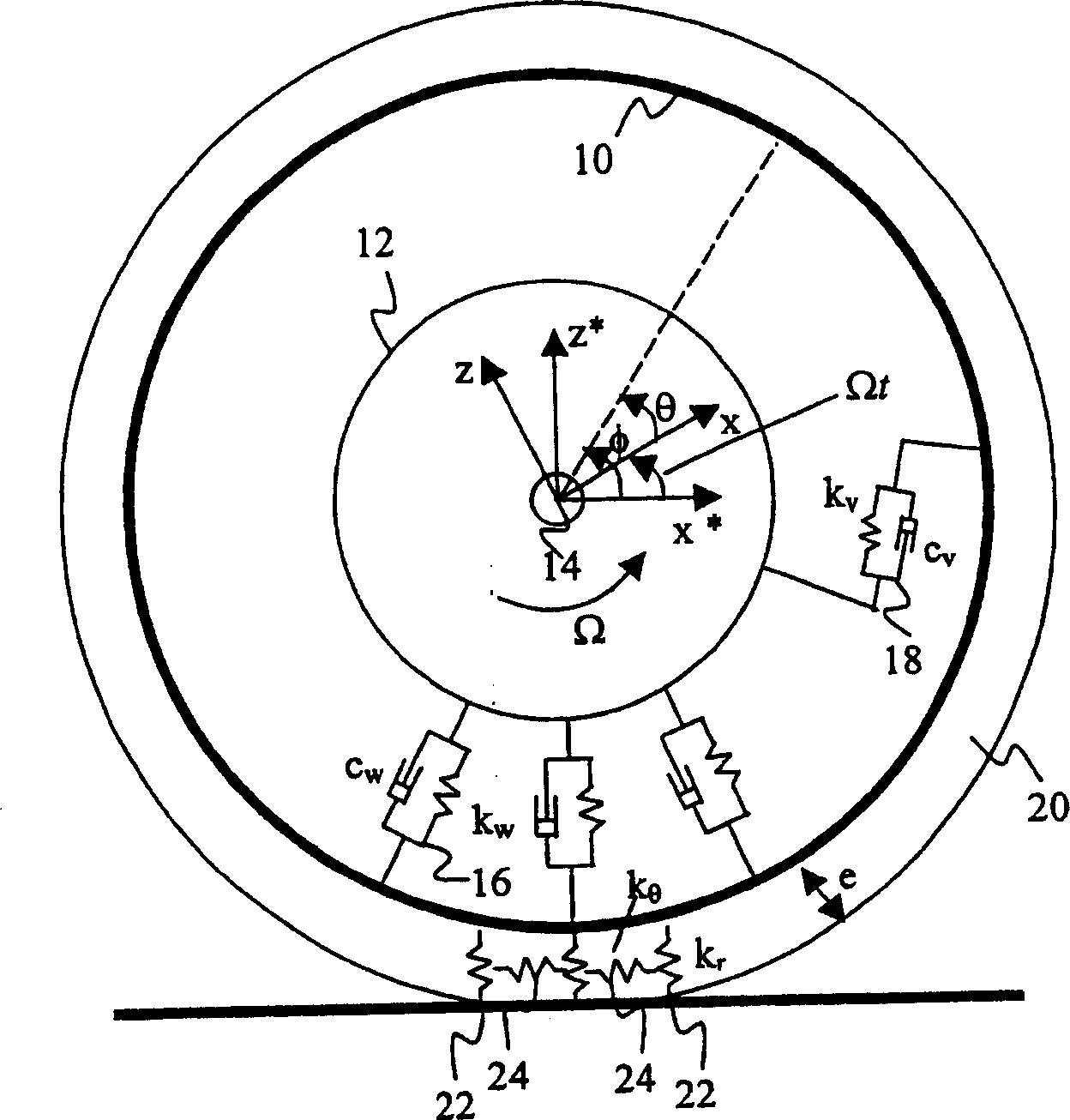

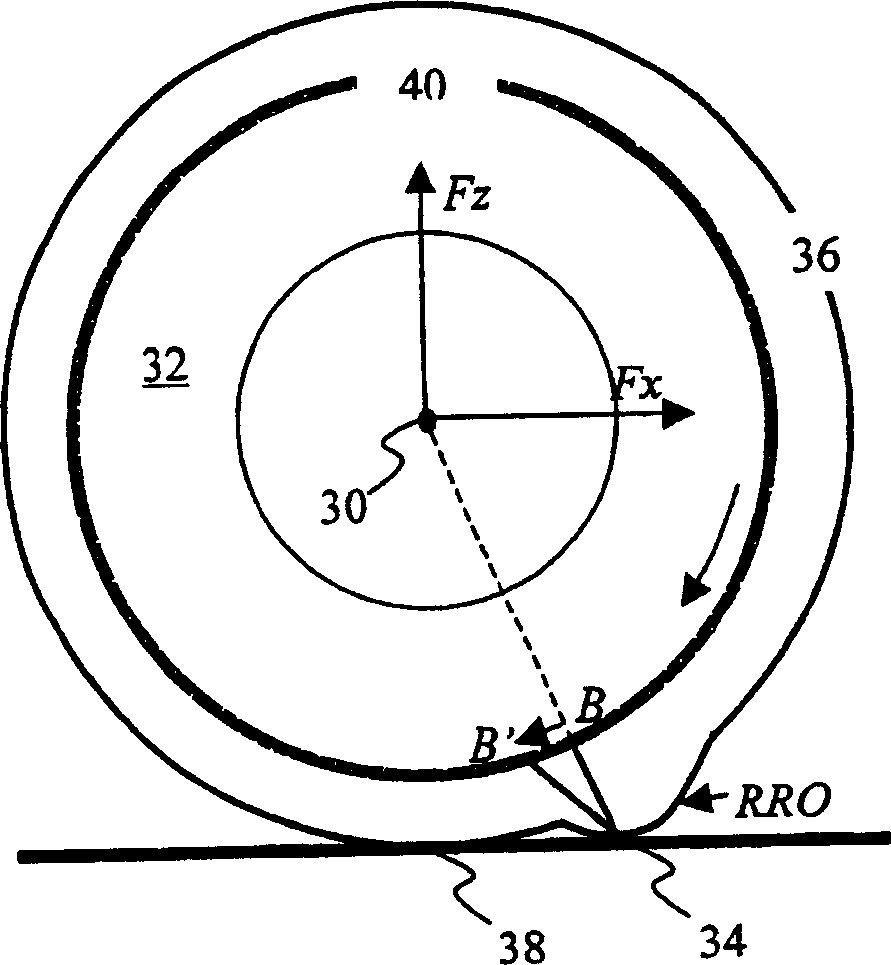

[0039] [0039] As stated in the Summary of the Invention, the present subject matter relates to the aspect of characterizing the low-speed and high-speed consistency aspects of a tire. The respective effects of radial runout and stiffness variations (eg, radial, tangential, bending, and extensional stiffness variations) on radial and tangential force variations were determined. Characterization of these parameters can be further applied to tire classification and / or rating processes and improvement of tire manufacturing eg in control and optimization of process reference angles.

[0040] [0040] The aspects of tire modeling and numerical analysis that provide an initial basis for the processing applications and methods of this subject are subsequently referred to separately Figure 1-8D to describe. In particular, about Figure 1-4 The discussion of corresponds to tire modeling and the presentation of the equations used to calculate radial runout and high-speed spindle forces,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com