High-precision elastic tapered bore rolling device of cone sealing pipe joint

A sealed tube, high-precision technology, applied in the field of machining tools, can solve the problems of low processing efficiency, the surface of the taper hole is difficult to meet the surface roughness requirements of the drawing, etc., and achieves improved production efficiency, good versatility, and improved strength and hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

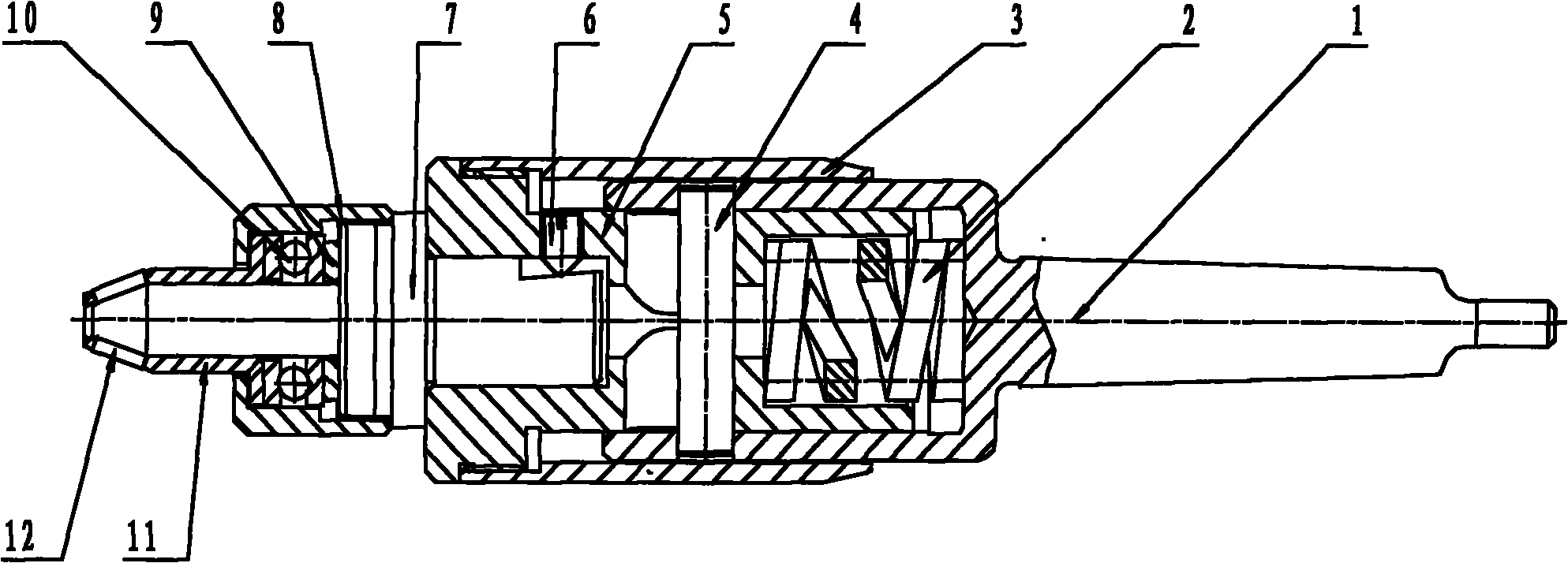

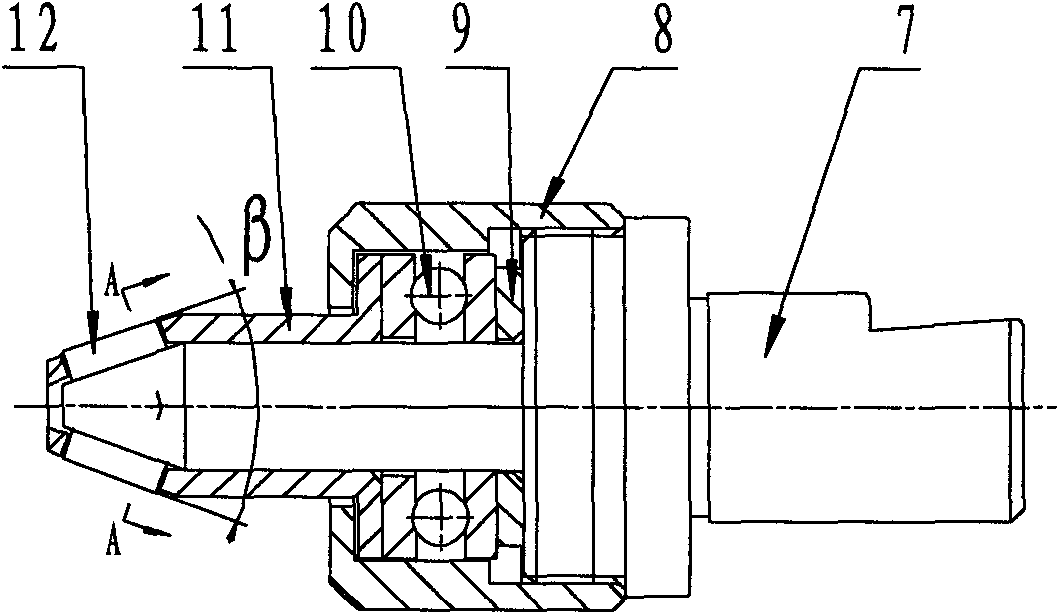

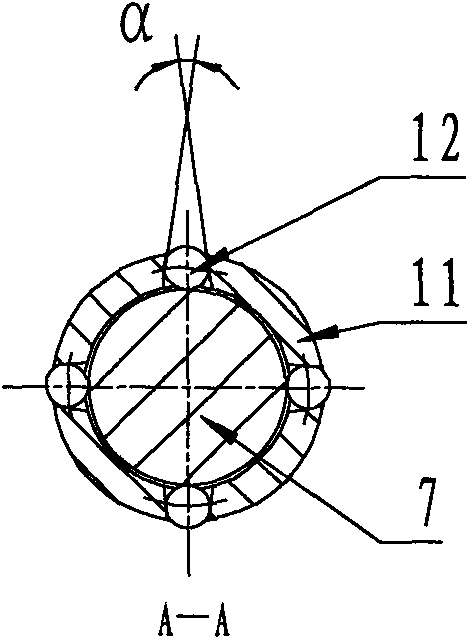

[0024] Such as figure 1 As shown, the device of the present invention consists of a tool handle body 1, a rectangular pressure spring 2, an outer sliding sleeve 3, a positioning pin shaft 4, a core sleeve 5, a set screw 6, a rolling mandrel 7, a bearing sleeve 8, and an adjustment pad 9. Thrust ball bearing 10, turnbuckle 11, roller 12 are formed. in:

[0025] (1) The right end of the tool handle body 1 is a Morse taper shank, which can be installed in the taper hole of the tailstock sleeve of the machine tool and accurately centered. The left end of knife handle body 1 is cylinder-shaped, and its inner hole is slidingly matched with the outer diameter of core sleeve 5, and the two are connected by a positioning pin 4 passing through a waist-shaped groove in the middle part of core sleeve 5. Place the rectangular pressure spring 2 in the hole at the right end of the core sleeve 5, the right end of the rectangular pressure spring 2 contacts with the bottom of the knife handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com