Method for detecting pressing force variation of winding of power transformer based on recursive quantitative analysis

A technology for transformer winding and quantitative analysis, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as inability to receive, and achieve the effects of less equipment, high detection sensitivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

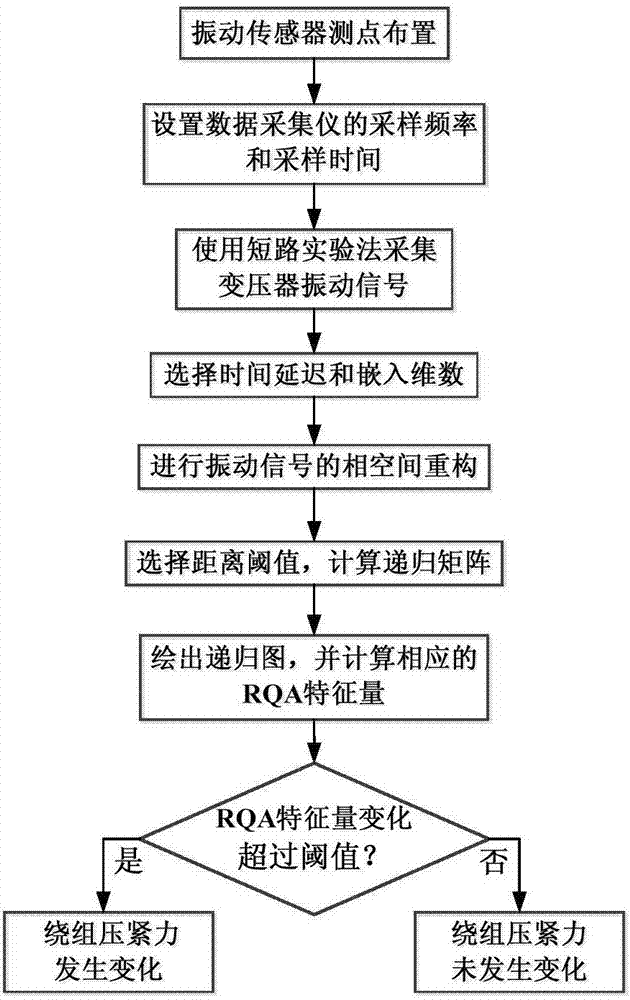

Method used

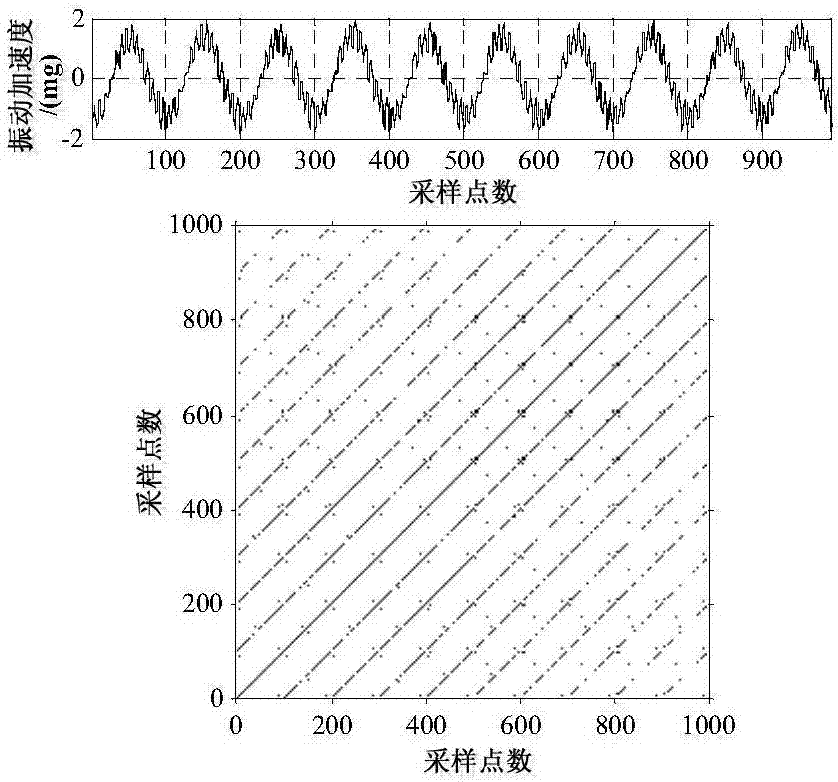

Image

Examples

Embodiment 1

[0068] In order to measure the overall compression degree of the transformer winding, this embodiment incorporates synchronously sampled multi-channel vibration signals into the analysis, and establishes an RQA measure for detecting the change trend of the overall compression force of the winding. At the same time, RQA analysis is directly performed on the vibration signal of a single sensor, and a local change trend measurement of the pressing force is established. The invention not only uses less equipment and is easy to operate, but also has accurate diagnosis and can accurately detect the looseness of the winding due to the change of the pressing force.

[0069] Step S7 also includes, according to the position of the monitoring point where the difference of the local RQA metric value exceeds the RQA metric difference threshold, judging the position where the winding of the transformer to be tested is loose. That is, if the local RQA metric values corresponding to a monit...

Embodiment 2

[0091] In this example, the winding compression force is set for a SFZ10-31500 / 110 oil-immersed power transformer of Nanjing Liye Transformer Co., Ltd., the transformer connection group is marked as YNd11, the rated voltage of the low-voltage side is 10.5kV, and the rated current is 1732A .

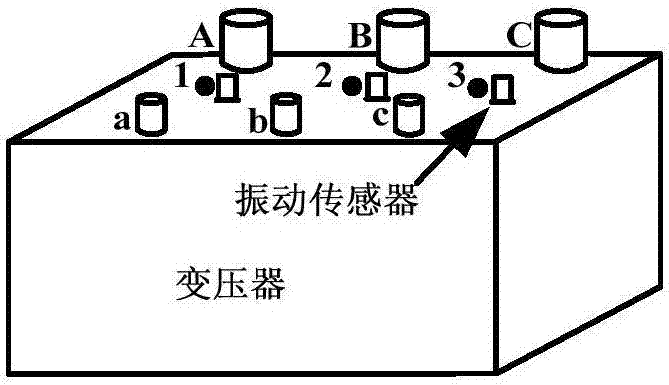

[0092] Vibration signal acquisition is carried out using a vibration acceleration sensor model JF2020 and a Nicolet data acquisition instrument. Place 3 measuring points on the surface of the transformer box, the positions are as follows figure 2 shown. Considering the frequency range of the transformer vibration signal, the sampling frequency is set to 10kHz during the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com