Device and method for assembling tire with wheel

An assembly method and assembly device technology, applied to tire installation, measurement devices, tire parts, etc., can solve the problem of damage to the appearance of tire and wheel assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

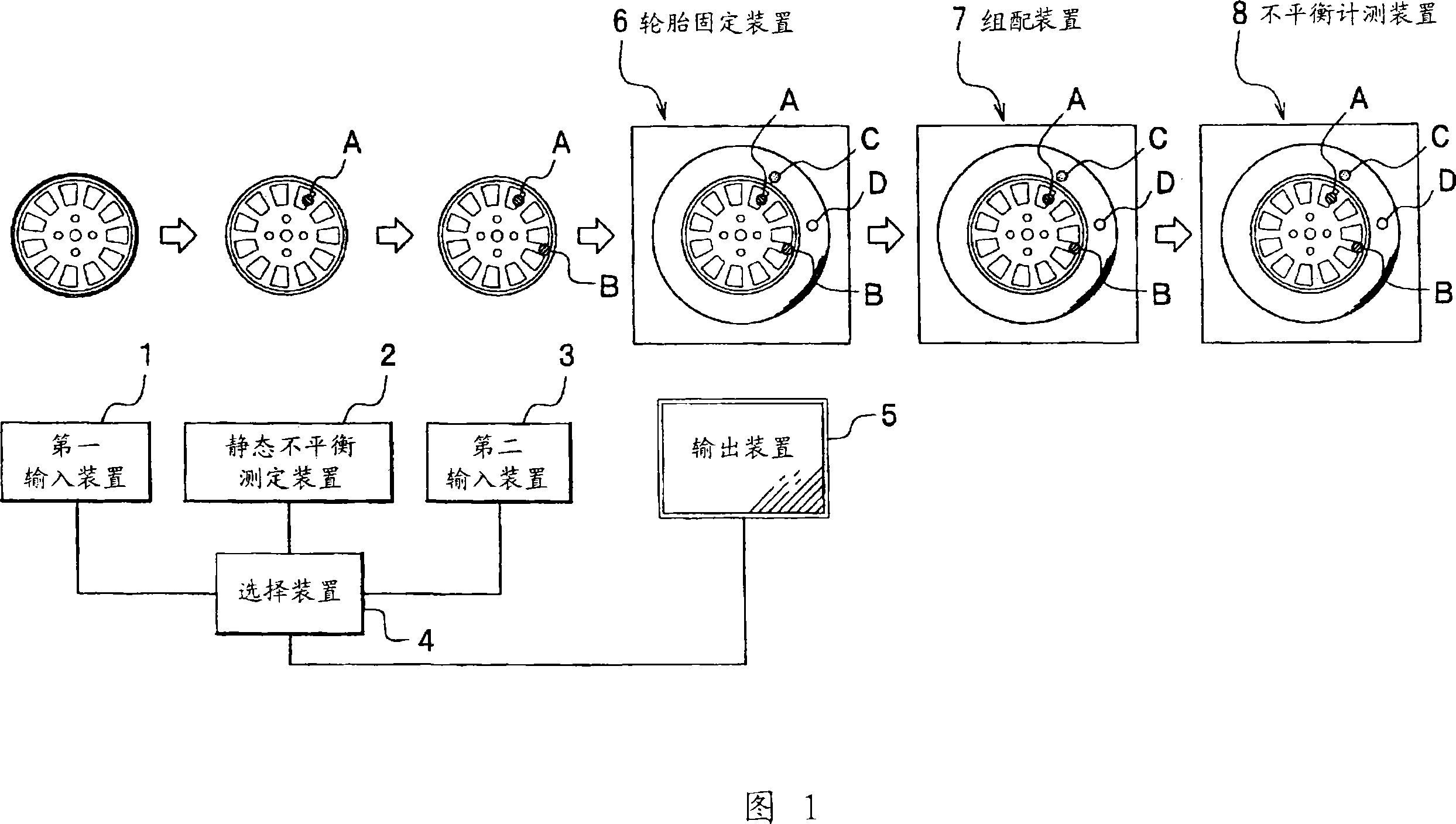

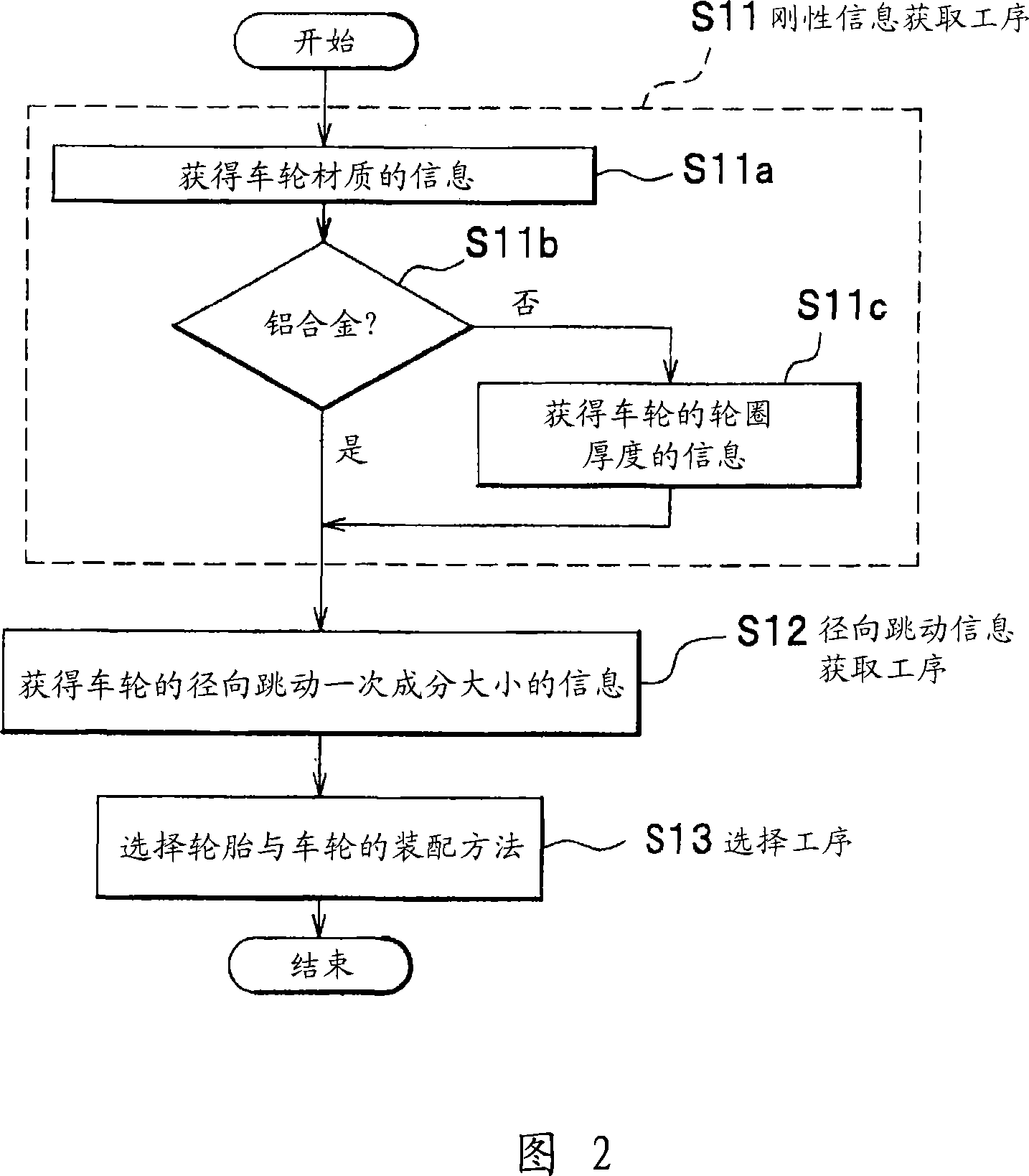

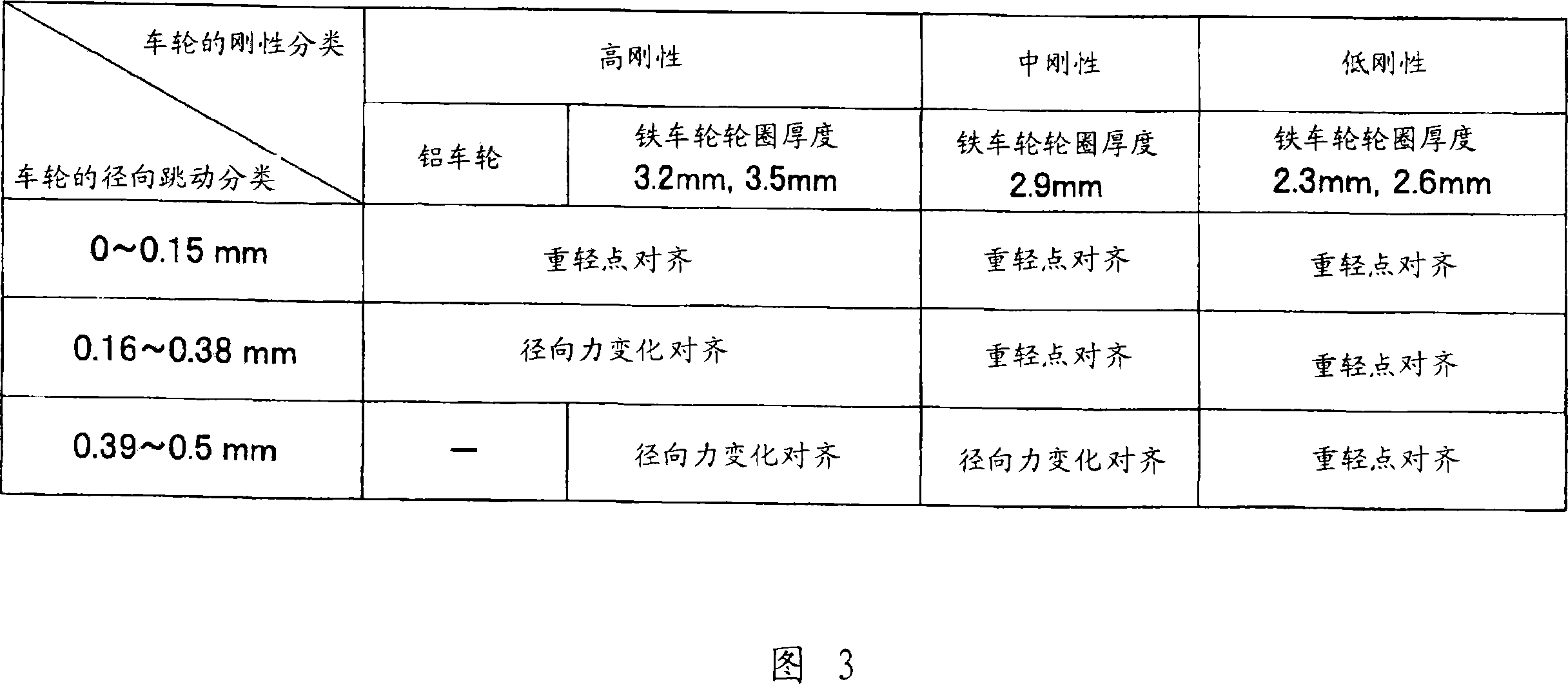

[0036] First, with reference to FIG. 5 and FIG. 6 , matters serving as the basis of creation of the present invention will be described. Fig. 5 shows the change in the length of the radius on the rim of the wheel when a load is applied to the radial direction of the wheel for wheels with different materials and rim thicknesses, that is, the extent to which the wheel is crushed under a certain load . The wheels used in this test are made of aluminum alloy (hereafter, the wheel made of aluminum alloy is called "aluminum wheel") and iron (hereafter, the wheel made of iron is called "iron wheel"). Among them, four types with rim thickness ranging from 2.3mm to 3.5mm are used. In addition, with regard to aluminum wheels, it can be known in another test that the crushing ratio of the wheel rim has nothing to do with the thickness of the rim, but increases with the proportional increase of the load, so the thickness of the rim is 3.5mm. In this way, the aluminum wheel is different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com