Torsional vibration damper

A technology of torsional vibration damper and torsional elasticity, which is applied in the field of torsional vibration damper, can solve the problem of high scrap rate of leaf spring and achieve the effect of simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described with the following examples, which will help the advantages of the technical solution of the present invention, and the effect has a further understanding. Examples do not limit the protection scope of the present invention, and the protection scope of the present invention is determined by the rights Ask to decide.

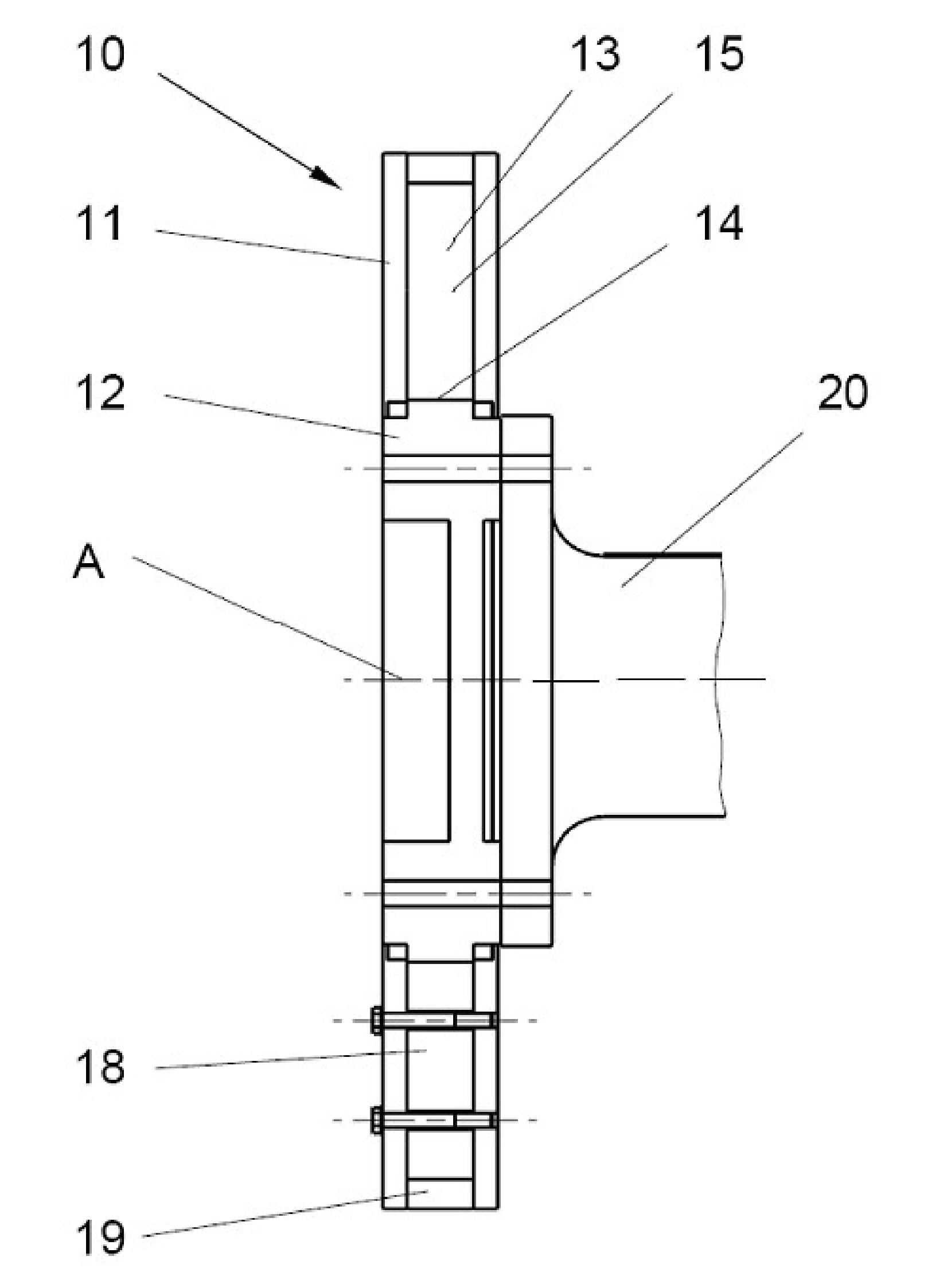

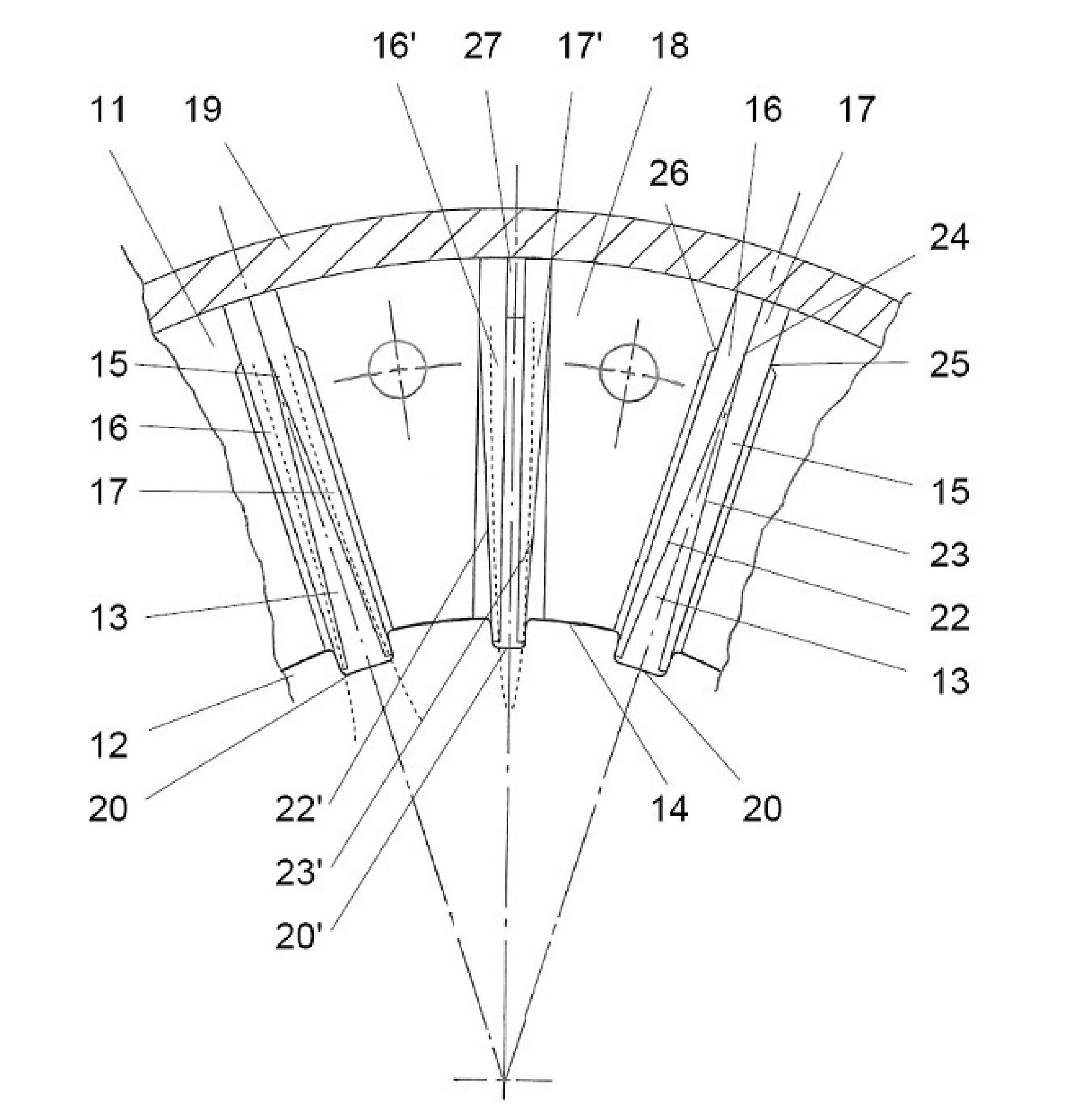

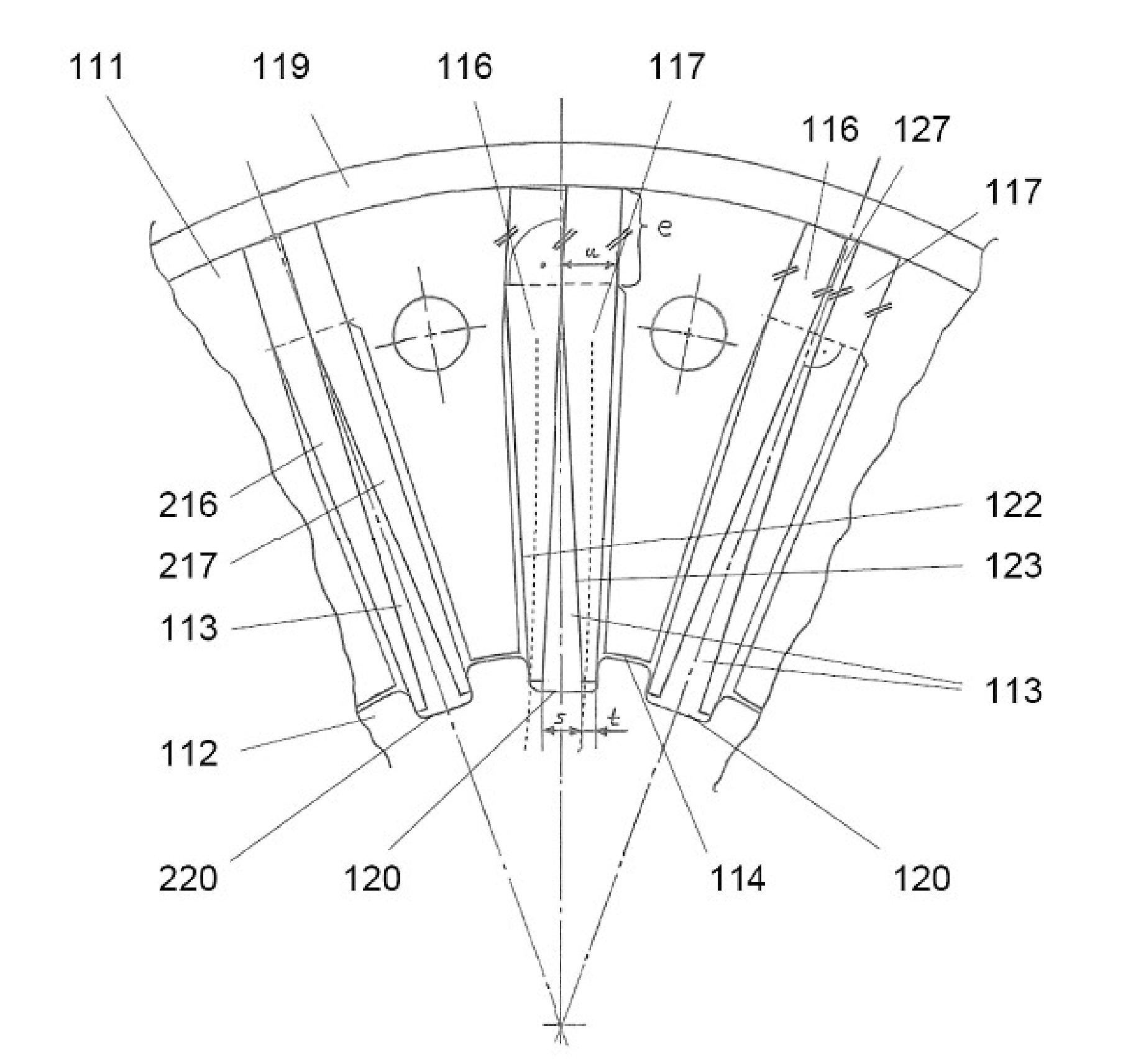

[0025] figure 1 and figure 2 Shown is a torsional vibration damper 10 coupled to a rotating component 20, such as a crankshaft. The torsional vibration damper 10 comprises a housing 11 extending along a longitudinal axis A and an inner part 12 coaxial with the housing 11 . A plurality of separate cavities 13 are formed between the outer shell 11 and the inner part 12, and the cavities 13 are filled with vibration damping medium, such as pressurized oil. The cavities 13 are distributed sequentially along the circumferential direction and are connected to each other through overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com