UV nano metallic coating material

A nano-metal and coating technology, applied in the field of coatings, can solve the problems of poor adhesion and flexibility of UV metal coatings, and achieve the effects of enhancing adhesion and impact resistance, excellent adhesion, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation of UV nano metal coating of the present invention comprises the steps:

[0046] First, a certain weight percentage of composite modified polyurethane acrylate, modified epoxy acrylic resin, modified pure acrylic acid oligomer, 1.6-hexanediol diacrylate, monomer tripropylene glycol diacrylate and monomer tetramethyl Add propylenediamine into the container, stir well at room temperature, then add composite photoinitiator, UV adhesion promoter, defoamer, leveling agent, UV diluent according to weight percentage, and stir well at room temperature to obtain a UV nano Metallic paint.

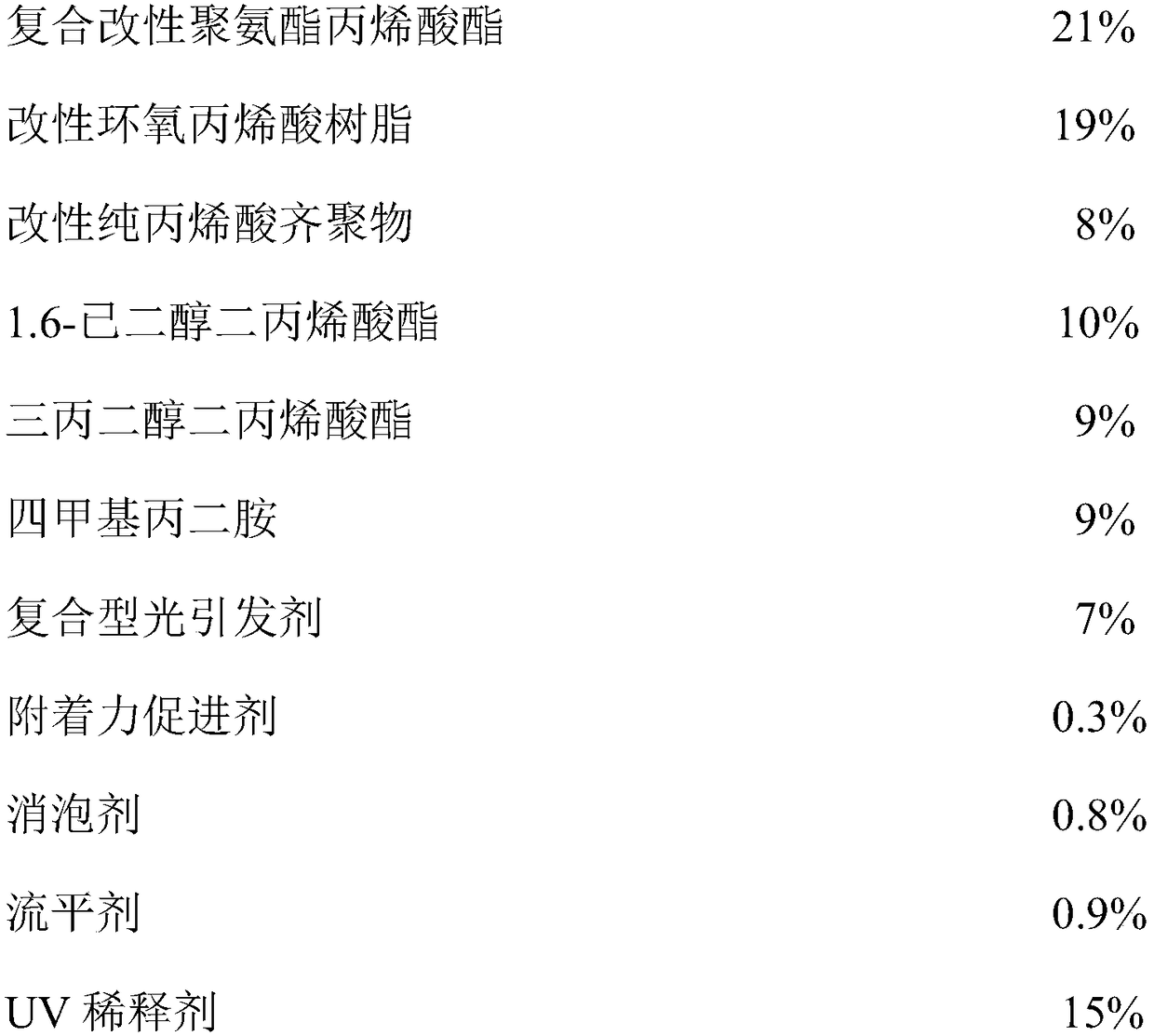

Embodiment 1

[0048] Its component of a kind of UV nano metal paint and percentage by weight thereof are:

[0049]

[0050] The preparation process is as follows: first compound the above weight percent modified polyurethane acrylate, modified epoxy acrylic resin, modified pure acrylic acid oligomer, 1.6-hexanediol diacrylate, monomer tripropylene glycol diacrylate, mono Add tetramethylpropylenediamine into the container, stir fully at room temperature, then add composite photoinitiator, adhesion promoter, defoamer, leveling agent, UV diluent in the above weight percentage, and fully stir at room temperature to get A UV nano metal coating.

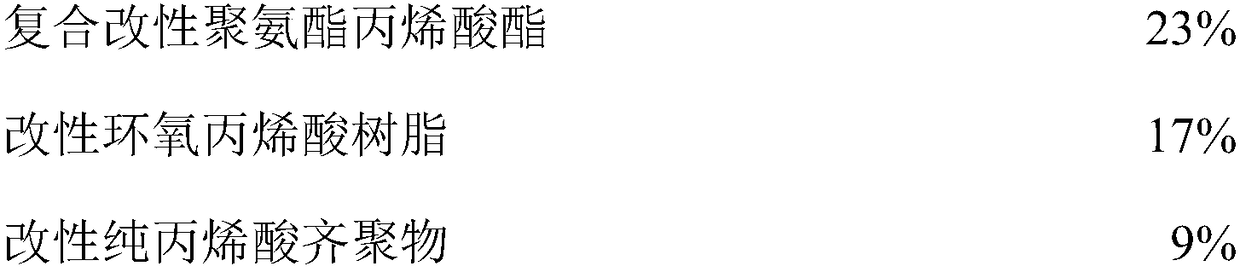

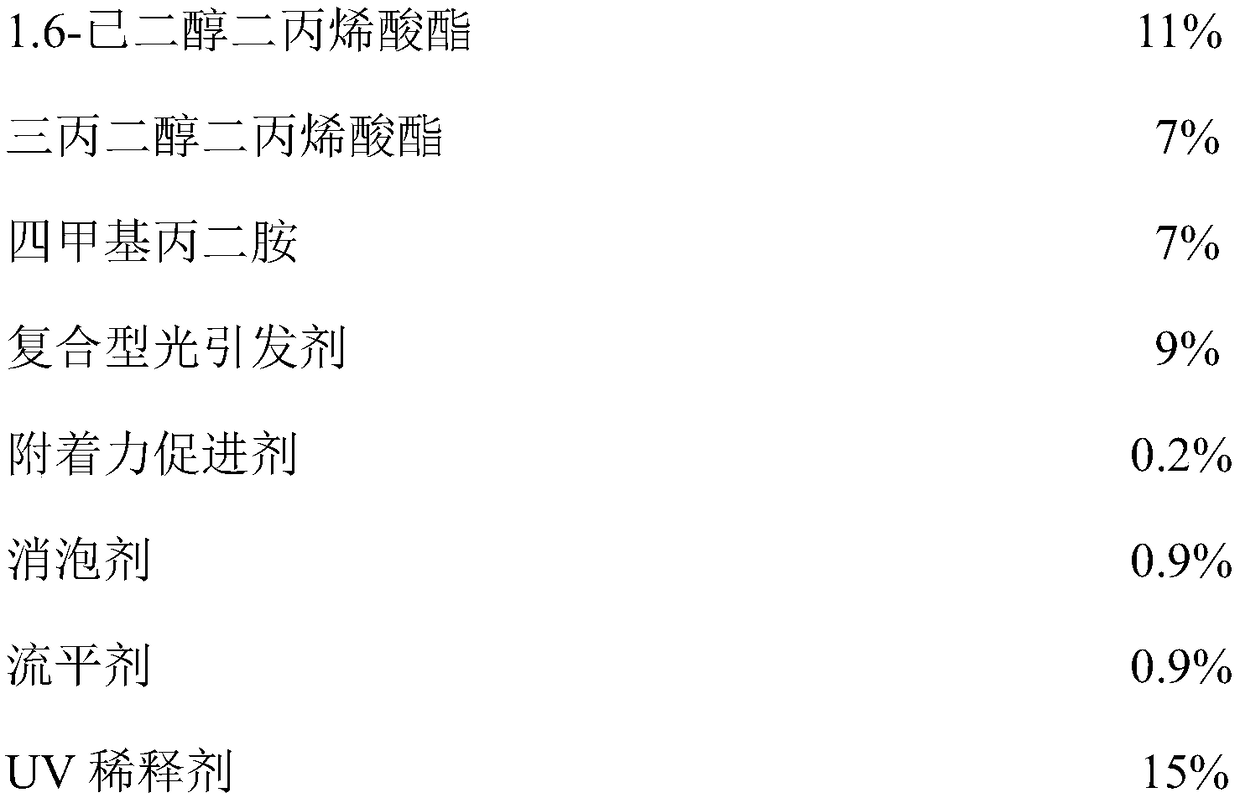

Embodiment 2

[0052] Its component of a kind of UV nano metal paint and percentage by weight thereof are:

[0053]

[0054]

[0055] The preparation process is as follows: first compound the above weight percent modified polyurethane acrylate, modified epoxy acrylic resin, modified pure acrylic acid oligomer, 1.6-hexanediol diacrylate, monomer tripropylene glycol diacrylate, mono Add tetramethylpropylenediamine into the container, stir fully at room temperature, then add composite photoinitiator, adhesion promoter, defoamer, leveling agent, UV diluent in the above weight percentage, and fully stir at room temperature to get A UV nano metal coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com