U-shaped spring energy accumulation pressurizing sealing ring

A technology of spring energy storage and pressurized sealing, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of uneven elastic force, incomplete contact surface, affecting the performance of the motion system, etc., and achieve good sealing effect and deformation The effect of uniform amount and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

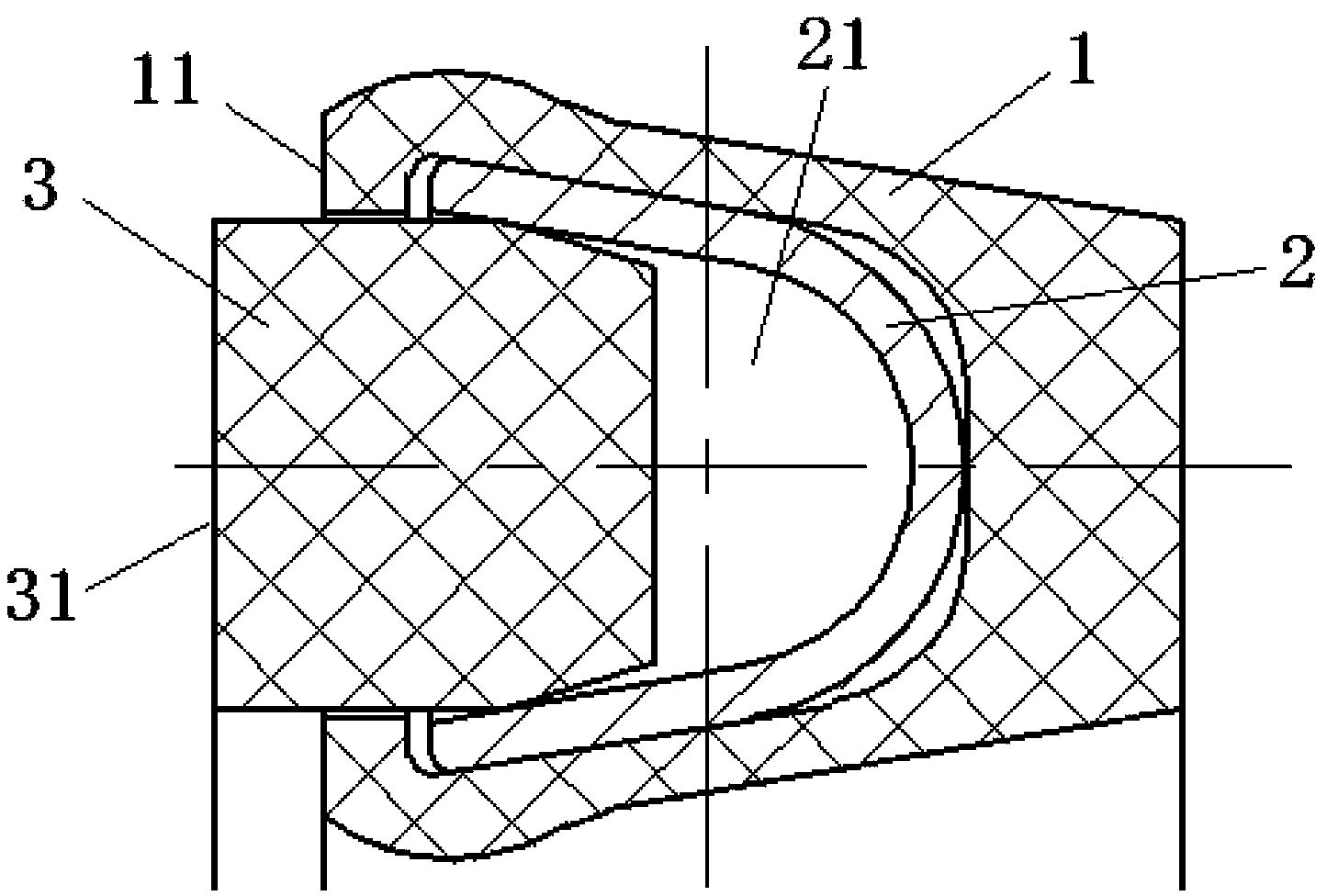

[0020] Embodiment: A U-shaped spring energy-storage pressurized sealing ring, which is composed of a non-metallic sheath 1, a metal U-shaped ring 2 and a back-up ring 3, wherein the cross-section of the metal U-shaped ring is U-shaped, and the The inner space of the metal U-shaped ring forms a U-shaped groove 21, the open end of the metal U-shaped ring faces the sealed medium side or the pressure side, and the non-metallic coating covers the metal U-shaped ring The outer surface of the non-metallic covering sleeve has a sealing end face 11 parallel to the opening end face of the metal U-shaped ring, the retaining ring is filled in the U-shaped groove of the metal U-shaped ring, and the The exposed surface 31 of the retaining ring parallel to the open end surface of the metal U-shaped ring is higher than the sealing end surface 11 of the non-metallic sheath.

[0021] The present invention uses a special stainless steel metal U-shaped ring as the skeleton, and is covered with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com