Thermoplastic elastomer specially used for yoga belt and preparation process thereof

A thermoplastic elastomer and elastomer technology, applied in the field of plastic materials, can solve the problems of inability to withstand tensile force and strength, short service life of sporting goods, and bulky product quality, and achieve the effects of uniform strength, improved elasticity and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: A thermoplastic elastomer dedicated to yoga belts, the components included and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0056] Step 1, mix SEBS, polypropylene, POE elastomer, silicone masterbatch, filler, first auxiliary agent, calcium zinc stabilizer, second auxiliary agent, TPE elastomer, EVA-g-MAH, POE-g- GMA is thoroughly mixed to form a first mixture;

[0057] Step 2, white oil is added to the first mixture obtained in step 1, and fully mixed to form a second mixture;

[0058] In step three, the second mixture obtained in step two is subjected to extrusion granulation treatment, and the temperature of extrusion granulation treatment is 200-240°C.

[0059] Wherein, the filler is composed of heavy calcium carbonate and light calcium carbonate with a ratio of parts by weight of 1:1;

[0060] The first auxiliary agent is composed of erucamide and oleic acid amide with a ratio of parts by w...

Embodiment 2-5

[0063] Embodiment 2-5: A thermoplastic elastomer specially used for yoga belts. The difference from Embodiment 1 is that the included components and their corresponding parts by weight are shown in Table 1. Among them, the added TPE elastomer, EVA-g-MAH, and POE-g-GMA are all added in step 1 and mixed well.

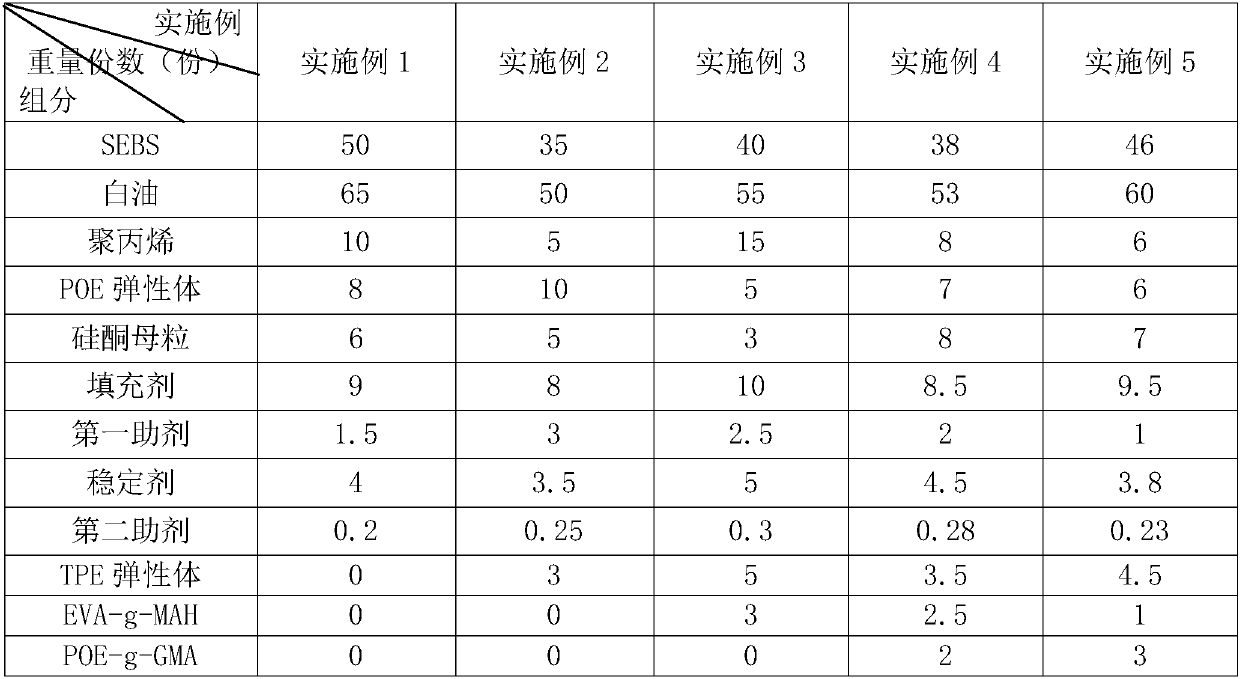

[0064] Components included in Table 1 Embodiment 1-5 and their corresponding parts by weight

[0065]

Embodiment 6

[0066] Embodiment 6: A special thermoplastic elastomer for yoga belts. The difference from Embodiment 1 is that the first auxiliary agent is composed of erucamide and oleamide in a ratio of parts by weight of 2.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com