A paper luminescent structure and a preparation method based on a full printing process

A light-emitting structure and paper technology, applied in the fields of paper, printing and paper-based materials, can solve problems such as the inability to realize the preparation of large-scale functional layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

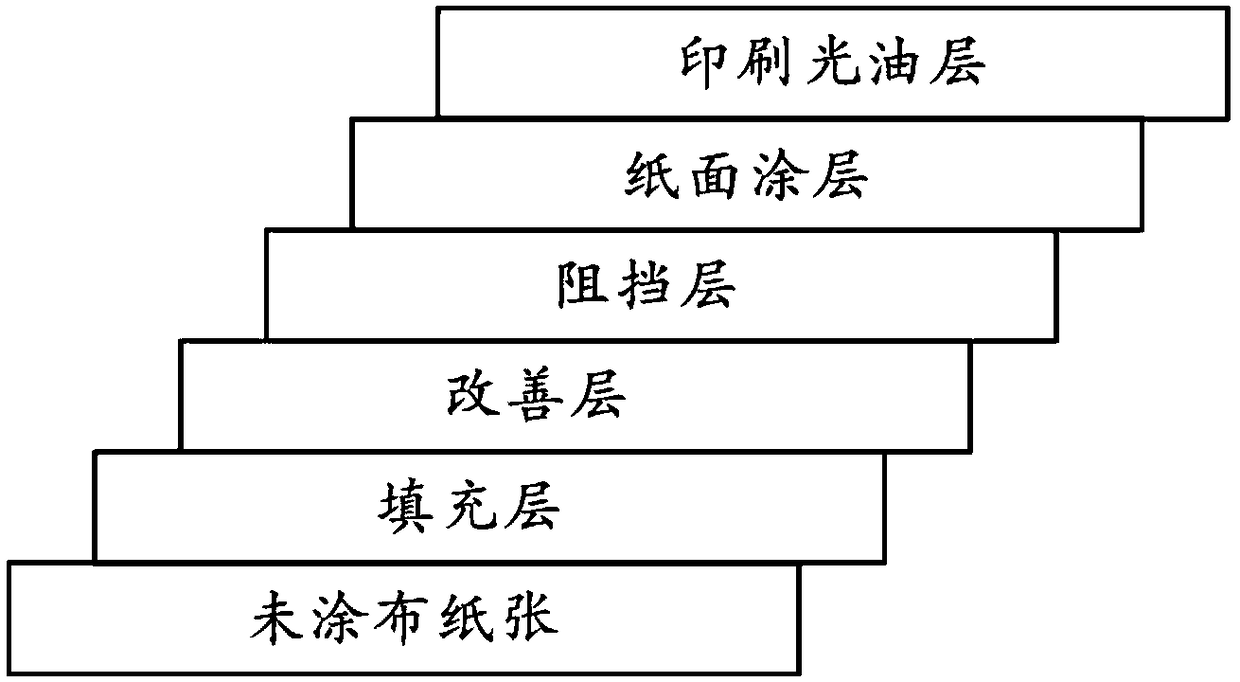

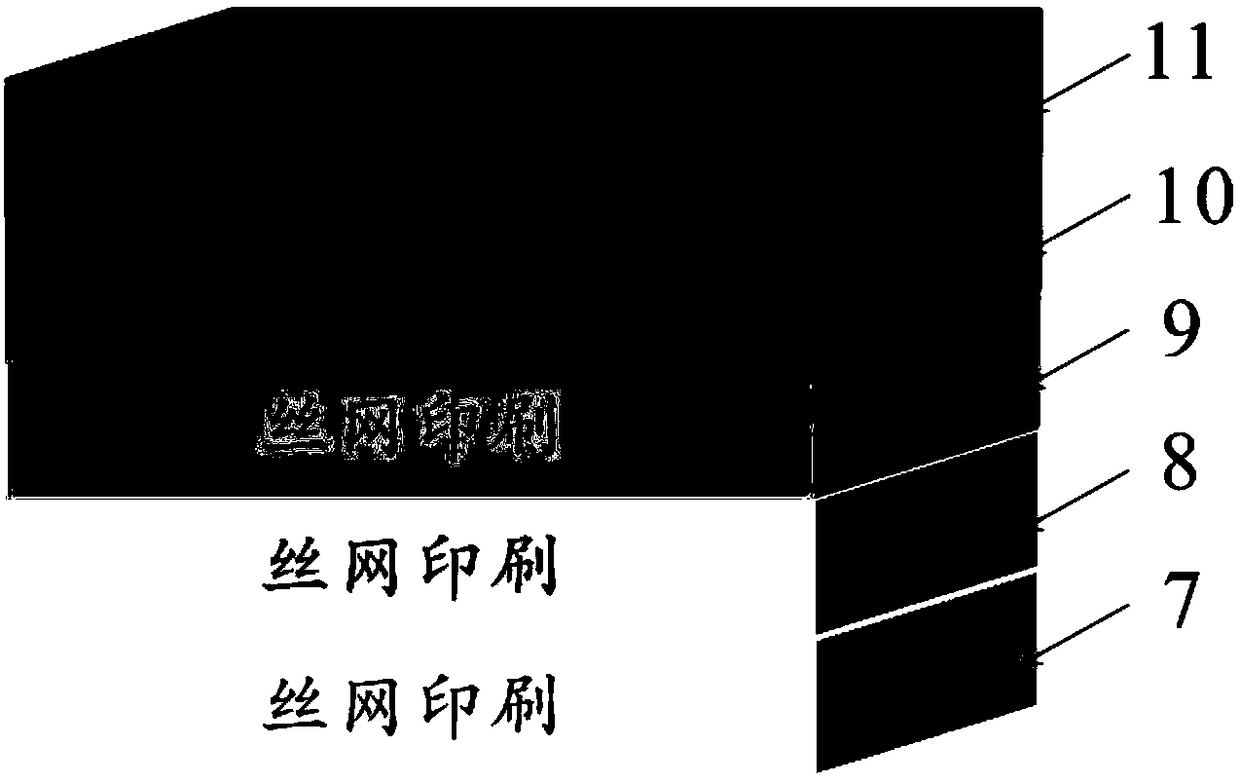

[0062] A method for preparing paper luminescence based on a full printing process, which is specifically implemented according to the following steps:

[0063] Finishing the paper:

[0064] (1) Generally, uncoated paper (uncoated on the surface) is selected as the base material of the device, and 80 g / m is selected in this embodiment. 2 copy paper. With low concentration (5%) fine ground ground calcium carbonate paint (90% of the ground calcium carbonate particle size is less than 2μm), the paper surface is filled by rod coating to form a filling layer on the surface, filling the paper surface. The pore structure was dried in an oven at 90 °C for 1 h, and the surface of the paper was smooth to form a filling layer on the surface.

[0065] (2) On the basis of the above, the kaolin coating of the sheet-like structure is coated by bar coating, and the coating amount is 9g / m 2 , After the coating is completed, it is dried in an oven at 90° C. for 1 h, and the surface roughness ...

Embodiment 2

[0077] A method for preparing paper luminescence based on an all-printing process, specifically implemented according to the following steps:

[0078] Surface modification of paper:

[0079] (1) Generally, uncoated paper (surface uncoated) is selected as the base material of the device, and what this embodiment selects is 80g / m 2 copy paper. Use low concentration (5%) finely ground ground calcium carbonate paint (90% of the particle size of the ground calcium carbonate is less than 2 μm) to fill the surface of the paper by rod coating to form a filling layer on the surface and fill the surface of the paper. Pore structure, dry in an oven at 100°C for 1 hour, the surface of the paper surface will be flat, forming a filling layer on the surface.

[0080] (2) On the basis of the above, adopt the method of bar coating to coat the kaolin coating with flake structure, and the coating amount is 10g / m 2 , after the coating was completed, it was dried in an oven at 100° C. for 1 h...

Embodiment 3

[0091] A method for preparing paper luminescence based on an all-printing process, specifically implemented according to the following steps:

[0092] Surface modification of paper:

[0093] (1) Generally, uncoated paper (surface uncoated) is selected as the base material of the device, and what this embodiment selects is 80g / m 2 copy paper. Use low concentration (5%) finely ground ground calcium carbonate paint (90% of the particle size of the ground calcium carbonate is less than 2 μm) to fill the surface of the paper by rod coating to form a filling layer on the surface and fill the surface of the paper. Pore structure, dry in an oven at 80°C for 1 hour, the surface of the paper surface will be flat, forming a filling layer on the surface.

[0094] (2) On the basis of the above, adopt the method of bar coating to coat the kaolin coating with flake structure, and the coating amount is 8g / m 2 , After the coating is completed, dry in an oven at 80°C for 1 hour, the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com