Processing method for textile

A processing method and technology for textiles, applied in the directions of processing textile material carriers, processing textile material containers, processing textile material equipment configuration, etc. Mix, improve quality, touch full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

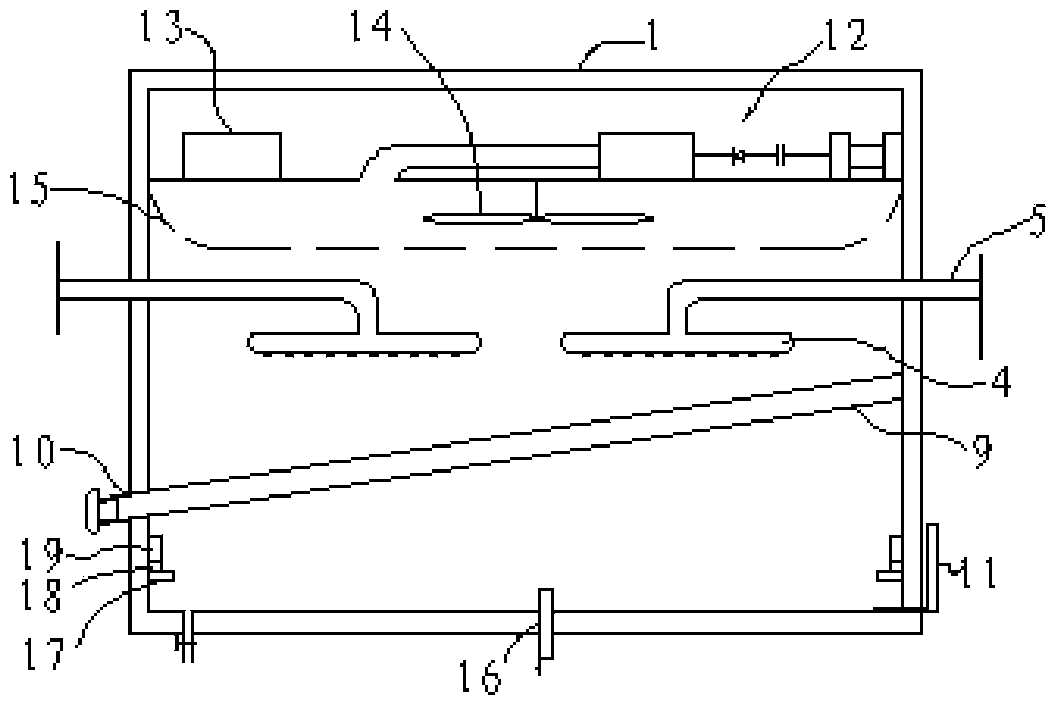

[0037] see Figure 1~4 , The processing device in this example mainly includes a box body 1, a transmission system, a liquid spray system, a microwave heating system 12, a temperature control system and a sampling system.

[0038] The box body 1 is made of stainless steel and is in the shape of a rectangular box. The box body 1 is composed of two layers inside and outside. A gap 3 with a width of 5 cm is reserved at the lower end of the door 2, through which textiles to be processed enter and exit the casing 1.

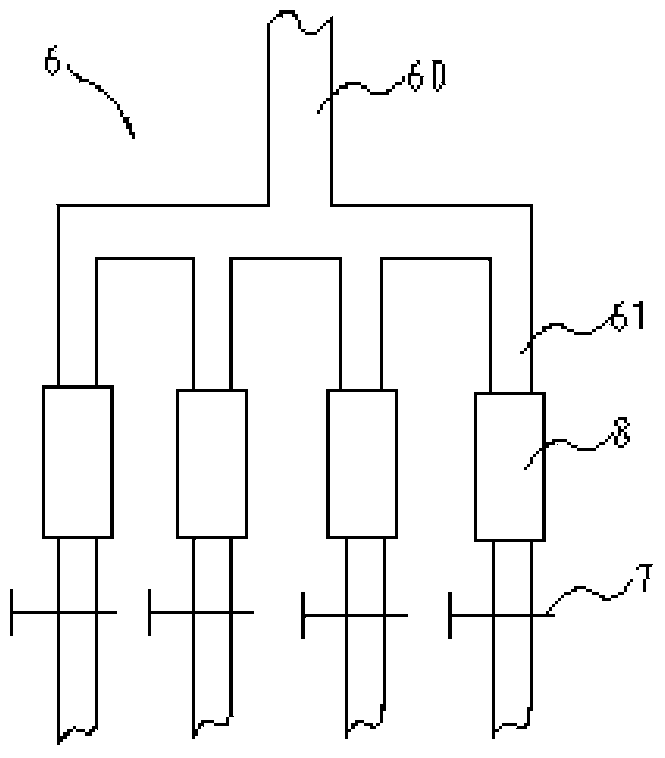

[0039] There is a row of a plurality of atomizing nozzles 4 on the left and right sides of the upper side of the box body 1, and an atomizing nozzle 4 is arranged every 1 meter in the forward direction of the textile, and the left and right are staggered. The infusion pipeline 5 is connected to the infusion pump, and the infusion pump is connected to the second infusion pipeline 6. The second infusion pipeline 6 includes a main pipe 60 and four sub-pipes 61, each sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com