Environment-friendly wing spray booth

An environmentally friendly technology for spray booths, applied in the field of spray booths, can solve the problems of slow exhaust speed, inability to purify air, and poor treatment effects in spray booths, and achieve the effects of increased spraying efficiency, low processing costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

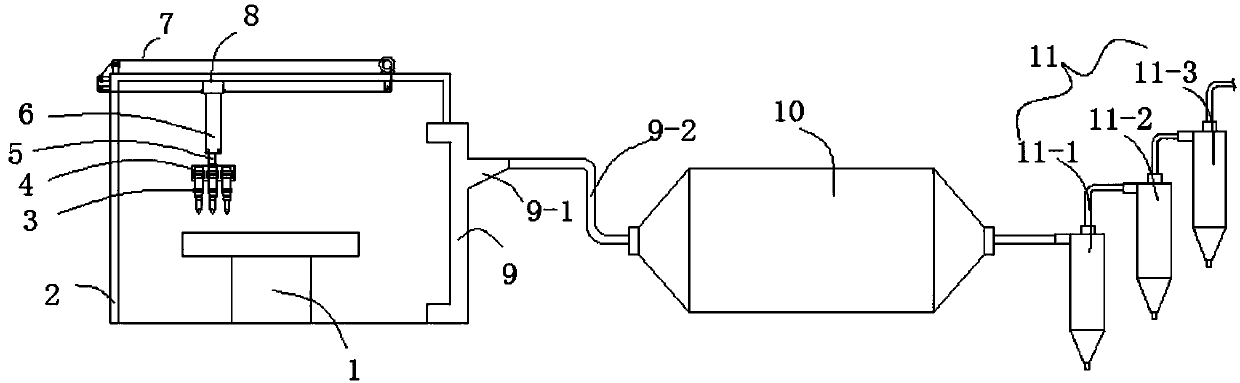

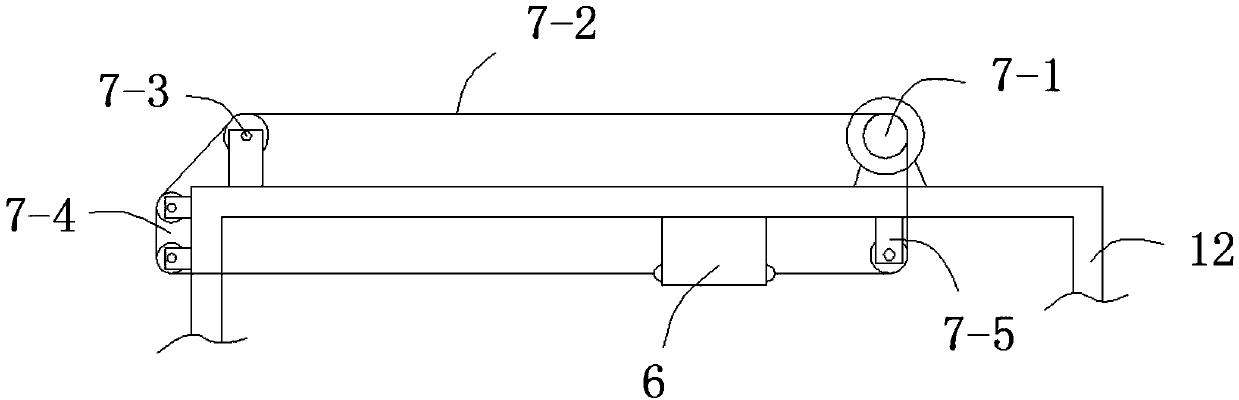

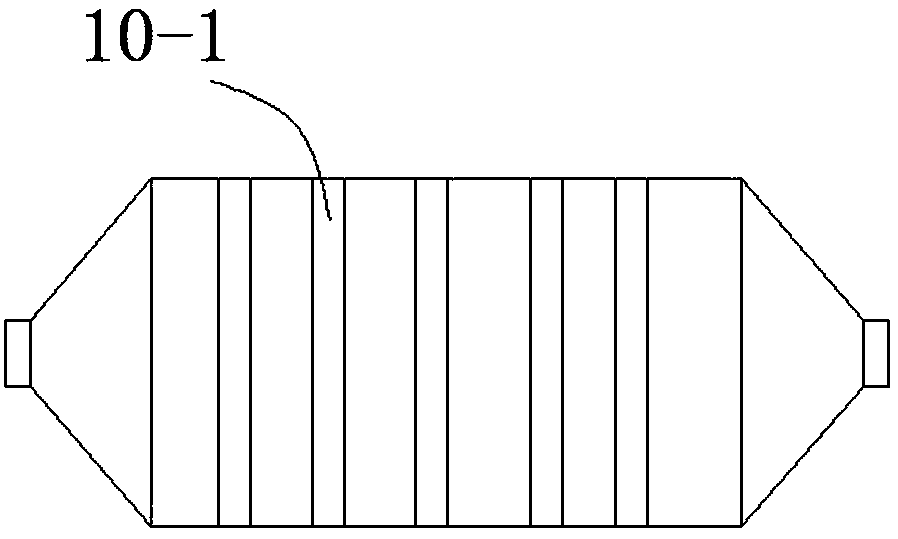

[0022] Such as Figures 1 to 4 As shown, the present embodiment provides an environment-friendly wing spray booth, including a spray booth 2, and a working surface 1 is arranged in the spray booth 2, and it is characterized in that a side dirt collection cover assembly is provided on one side of the spray booth 2 , one side of the spraying compartment 2 is provided with a water curtain cabinet 9, the air outlet 9-1 of the water curtain cabinet 9 is connected with a main absorption pipeline 9-2, and the end of the main absorption pipeline 9-2 is connected with an activated carbon adsorption tower 10 and a multi-stage Cyclone dust removal assembly 11, the top of the spray booth 2 is provided with a horizontal guide rail 2-1, and the horizontal guide rail 2-1 is clipped with a mounting seat 8 that reciprocates along the horizontal guide rail 2-1, and a lifting mechanism 6 is provided under the mounting seat 8 The bottom of the lifting mechanism 6 is connected with a spray gun fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com