Dye for milk silk-nonwoven fabric lace and dyeing technology thereof

A non-woven, milk silk technology, applied in the field of dyes, can solve problems such as inability to meet, and achieve the effects of improving stability, reducing hydrolysis, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

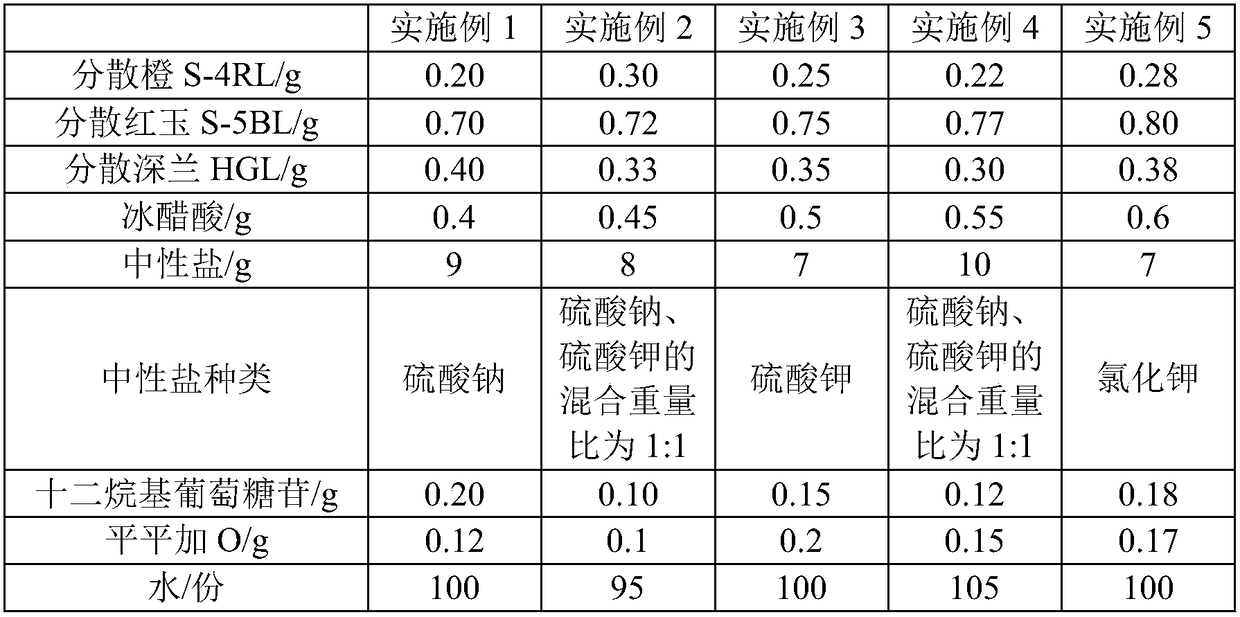

Embodiment 1-5

[0046] The preparation method of embodiment 1-5 milk silk non-woven fabric lace dyestuff is as follows:

[0047] A kind of preparation method of milk silk non-woven fabric lace dyestuff, comprises the steps:

[0048] Weigh Disperse Orange S-4RL, Disperse Ruby S-5BL, Disperse Dark Blue HGL, Glacial Acetic Acid, Neutral Salt, Lauryl Glucoside, Pingpinga O, water, and mix well.

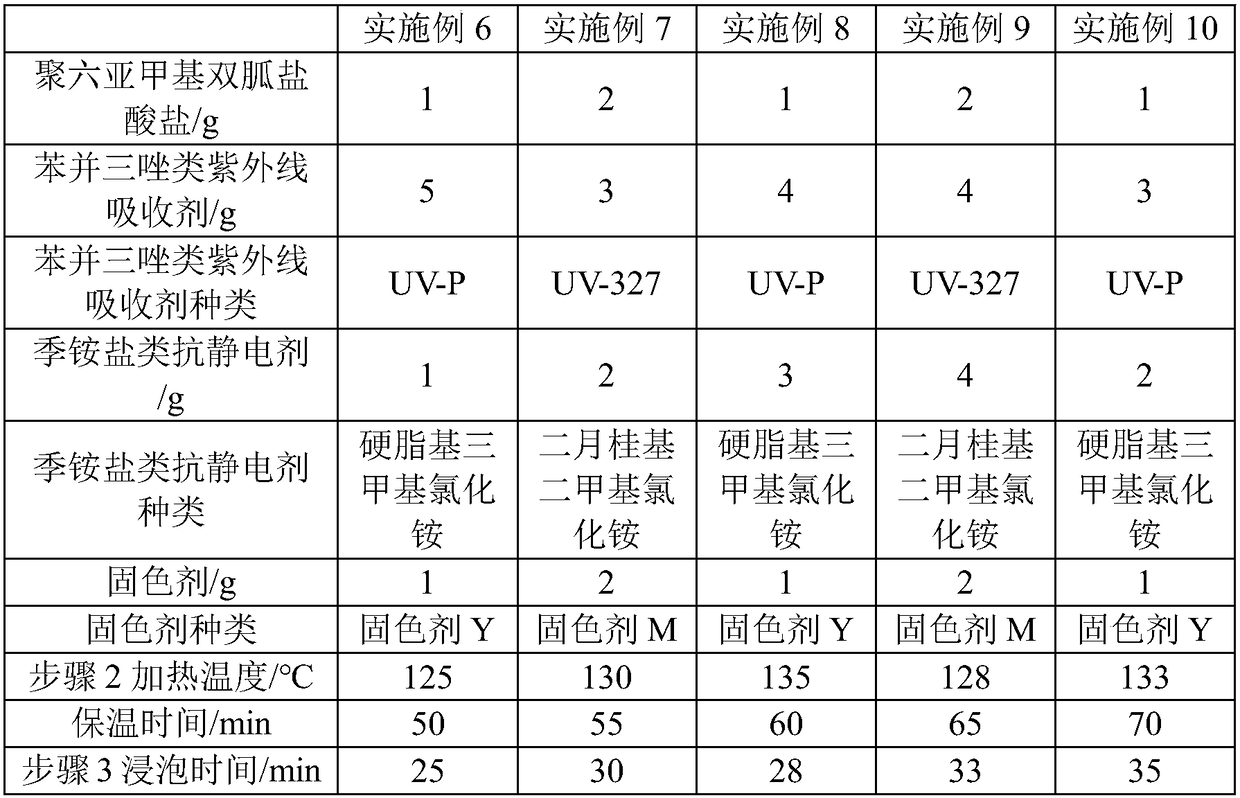

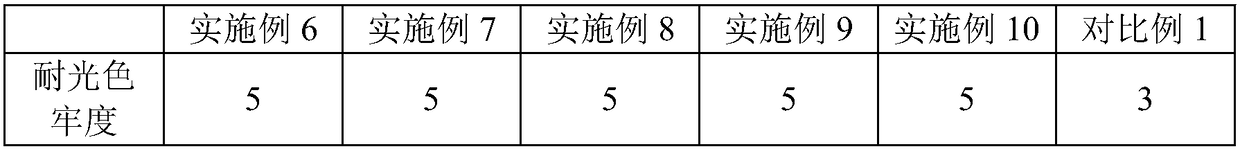

Embodiment 6

[0051] The dyes used in Examples 6-10 correspond to the dyes used for milk silk non-woven fabric lace prepared according to Examples 1-5. Wherein, embodiment 6 corresponds to embodiment 1, embodiment 7 corresponds to embodiment 2, embodiment 8 corresponds to embodiment 3, embodiment 9 corresponds to embodiment 4, and embodiment 10 corresponds to embodiment 5.

Embodiment 6-10

[0052] The dyeing process of embodiment 6-10 milk silk non-woven fabric lace is as follows:

[0053] A kind of dyeing process of milk silk non-woven fabric lace, comprises the steps:

[0054] Step 1: First, bathe the milk silk non-woven fabric lace in water at 100°C for 2 hours to dissolve the non-woven fabric, discharge and weigh;

[0055] Step 2: Add the milk silk non-woven fabric lace obtained in step 1 into the dye, the bath ratio is 1:20, heat it, keep it warm, dye it, and discharge it after dyeing;

[0056] Step 3: Add the milk silk non-woven fabric lace obtained in Step 2 into water, add functional finishing agent, soak and shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com