Disperse orange dye mixture

A technology of orange dye and mixture, which is applied in the field of environment-friendly disperse orange dye mixture, which can solve problems such as poor alkali resistance, color shift of textiles, and reddening of color light, and achieve the effects of strong market competitiveness, environmental protection, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

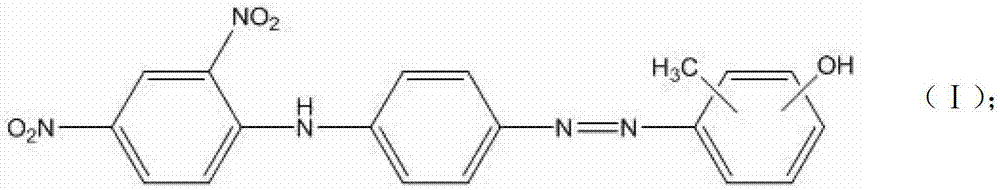

Image

Examples

Embodiment 1

[0047] Embodiment one: a kind of disperse orange dye mixture and its preparation

[0048] 1. Formula

[0049]

[0050] 2. Preparation of dye mixture

[0051] Convert the content of each dye to the weight of the original dye wet filter cake according to the formula and prepare materials (for example, 40% of the original dye wet filter cake is the dye content and 60% is water. According to this relationship, convert the content of each dye to the weight of the original dye wet filter cake ). Mix the wet filter cake of each original dye with dispersant sodium lignosulfonate B and sodium lignosulfonate 85A, diffusing agent MF and NNO, add water and sand mill, spray dry and use a small amount of dustproof agent JH2112 for dustproof treatment. to get the finished product.

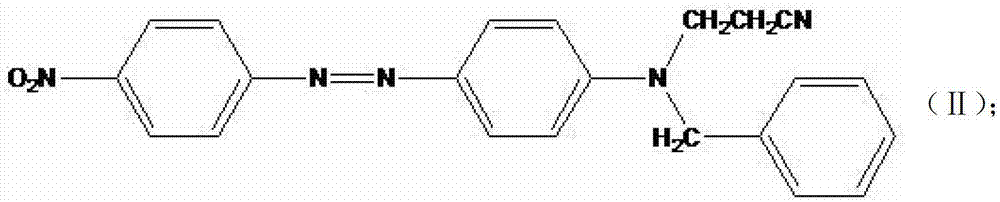

Embodiment 2

[0052] Embodiment two: a kind of disperse orange dye mixture and its preparation

[0053] 1. Formula

[0054]

[0055]

[0056] 2. The preparation of the dye mixture is the same as in Example 1.

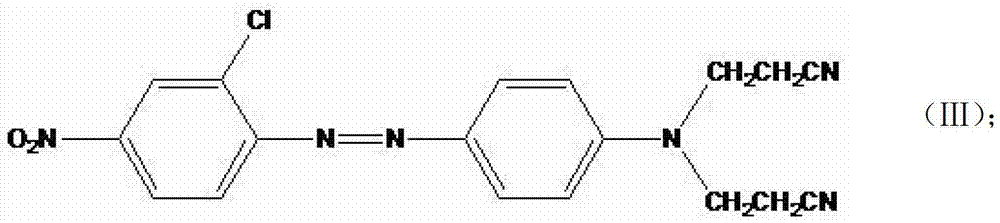

Embodiment 3

[0057] Embodiment three: a kind of disperse orange dye mixture and its preparation

[0058] 1. Formula

[0059]

[0060] 2. The preparation of the dye mixture is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com