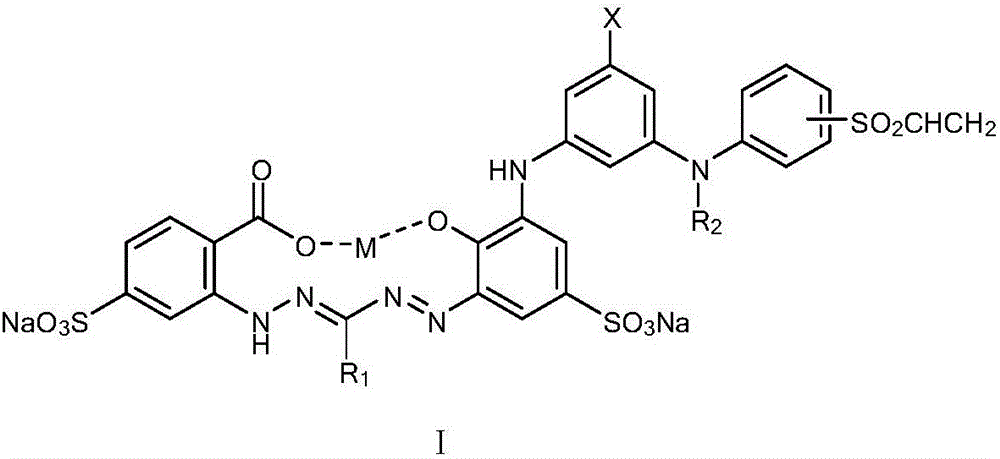

Reactive blue dye and preparation and application thereof

A reactive blue and dye technology, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of low color fixation rate, alkali resistance and light fastness, and achieve good color fixation rate, excellent performance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

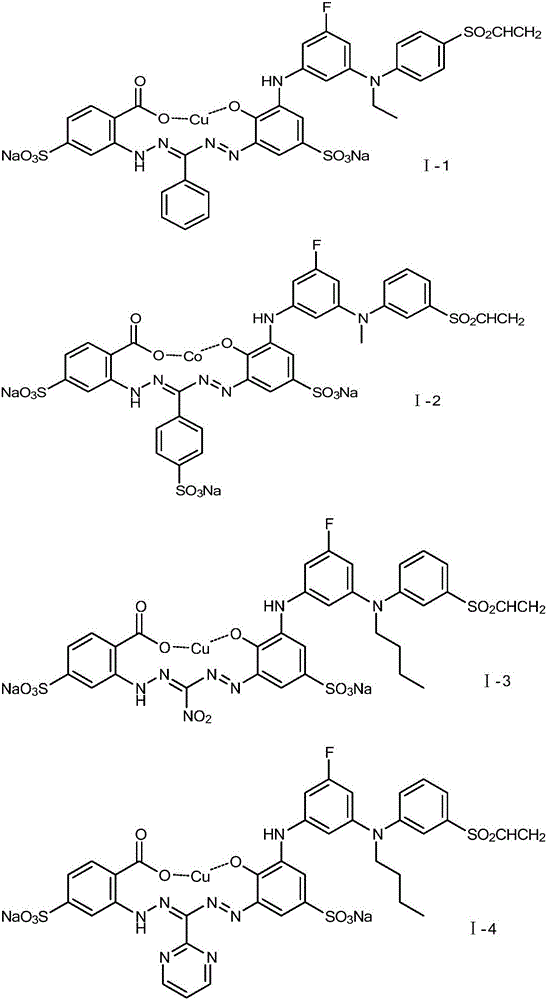

[0064] Embodiment 1: the preparation of formula (I-1) compound

[0065] (1) One diazo, coupling reaction

[0066] In a 250ml beaker, add 20 parts of ice (parts by mass), 24.3 parts of 30% hydrochloric acid, 21.7 parts of 2-amino-4-sulfonic acid benzoic acid, ice grinding and beating for 30min, slowly add 6.97 parts of sodium nitrite to generate diazonium salt, After the sodium nitrite is completely added, stir for 1 hour, and use sulfamic acid to eliminate the slight excess of sodium nitrite; slowly add the diazonium salt to 23.6 parts of diethyl phenylmalonate dropwise, and use baking soda while adding Adjust the pH to 3.5-5.0, continue the reaction for 2 hours after the addition, and the diazonium salt will disappear completely, while keeping the system temperature at 0-10°C.

[0067]

[0068] (2) Secondary diazonium, coupling reaction

[0069] In a 250ml beaker, add 20 parts of ice, 24.3 parts of 30% hydrochloric acid, 20.4 parts of 2-amino-4-sulfonic acid benzoic acid...

Embodiment 2-5

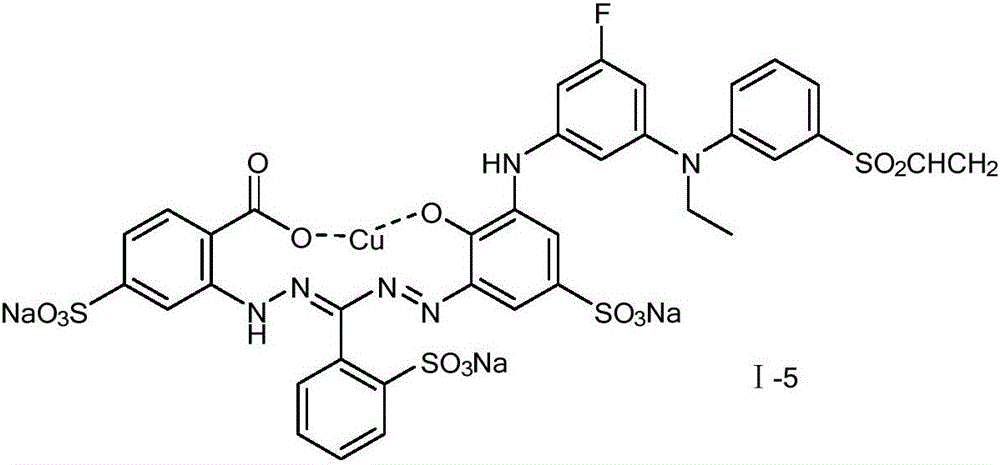

[0087] According to the method described in Example 1, the difference is that the components coupled with the malonic acid series, the amine and the chloroalkane for the alkylation reaction are reacted with the raw material compounds in equimolar amounts in the following Table 1, and the present invention can be obtained. The reactive blue dyes of the formula (I-2~I-5).

[0088] Table 1: Embodiment 2-5 makes reactive blue dye

[0089]

Embodiment 6

[0090] Embodiment 6: the preparation of reactive dark blue dye (II-6) compound

[0091] (1) Diazo, coupling reaction

[0092] In a 250ml beaker, add 20 parts (parts by mass) of ice, 24.3 parts of 30% hydrochloric acid, 28.1 parts of meta-ester, ice grinding and beating for 30 minutes, slowly add 6.97 parts of sodium nitrite to generate diazonium salt, wait until sodium nitrite is completely added Stir for 1 h, use sulfamic acid to eliminate the slight excess of sodium nitrite; add 31.9 parts of H acid to the diazonium salt, and continue the reaction until the diazonium salt disappears completely, while keeping the system temperature at 0-10°C.

[0093]

[0094] (2) Primary condensation of p-phenylenediamine and cyanuric fluoride

[0095] In a 1000ml flask, add 10.8 parts of p-phenylenediamine and 50 parts of ice water, add 13.5 parts (percentage) of cyanuric fluoride to p-phenylenediamine, adjust the pH to 3.5-5.0 with baking soda, and keep the temperature 0-10°C, react f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com