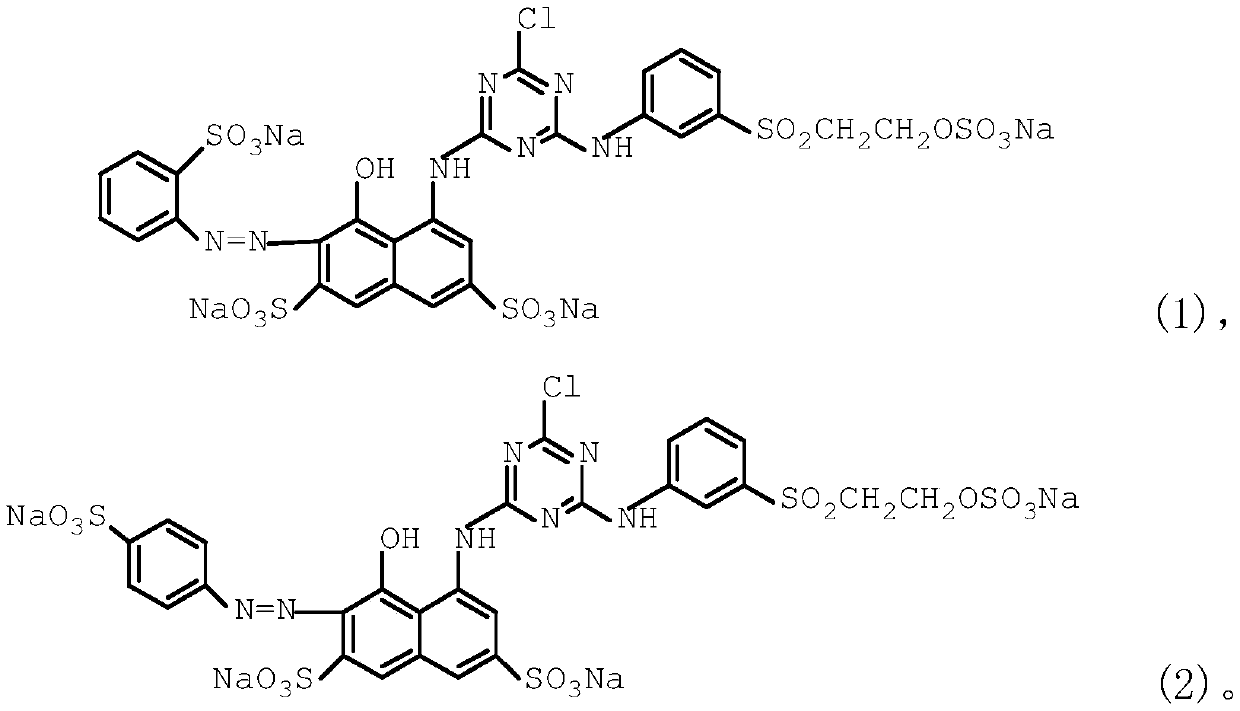

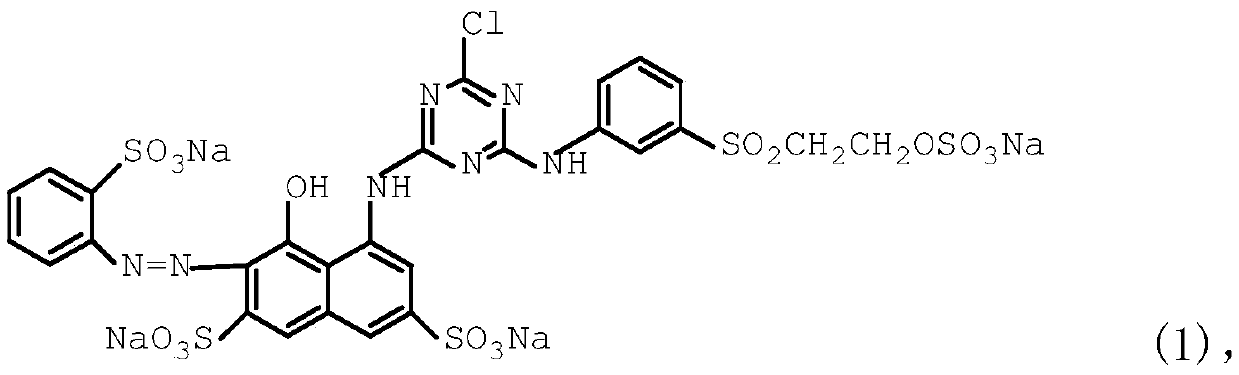

Composite bright red reactive dye and preparation method and application thereof

A reactive dye, composite technology, applied in reactive dyes, dyeing methods, azo dyes, etc., to reduce production costs, reduce production environmental pressure, and reduce cleaning water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

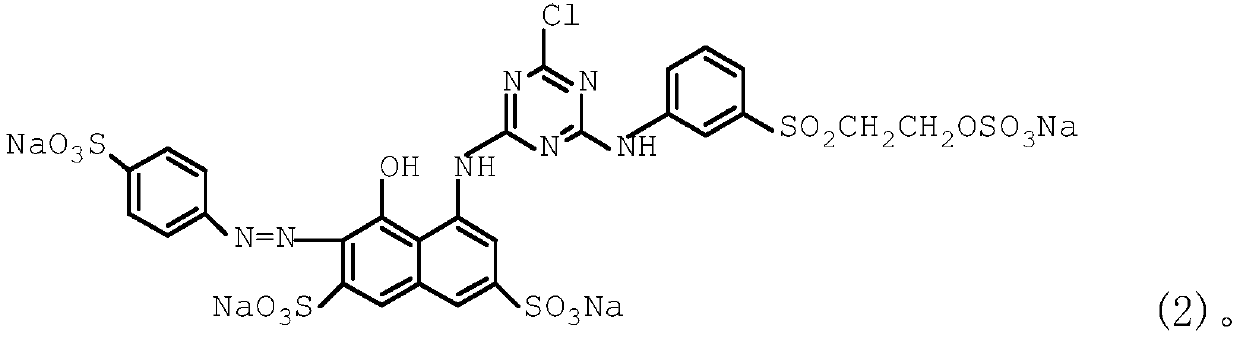

[0038] The preparation method of formula (2) compound is as follows:

[0039] ①Beat the H acid, adjust the pH to 7.0 with liquid caustic soda until dissolved, add it to the cyanuric chloride beating liquid for a condensation reaction, adjust the pH to 3.5-4.0, and react for 2 hours to obtain a condensation liquid for use.

[0040] ②Add the meta-ester to the above mixture solution, raise the temperature to T=40°C, maintain the pH=3.5-4.0, and react for 4 hours to obtain the secondary condensation liquid.

[0041] ③Add p-aminobenzenesulfonic acid and hydrochloric acid with water and ice for 30 minutes, add 30% sodium nitrite aqueous solution, maintain the temperature T=0~5°C, and use sulfamic acid to eliminate excess sodium nitrite after reacting for 1 hour; The potassium iodide test paper is colorless, and the Congo red test paper is blue. When the end point is reached, the diazo solution is obtained.

[0042] ④Add the above-mentioned diazo solution into the secondary shrinkag...

Embodiment 1

[0046] 75g of the compound of formula (1) and 25g of the compound of formula (2) were fully mechanically mixed to obtain a composite bright red reactive dye.

[0047] Take 4g of the composite bright red reactive dye prepared above and dissolve it fully with an appropriate amount of water, then set the volume in a 500ml volumetric flask, draw 10ml of the dye solution and mix it with 50ml of water, then add 4g of cotton cloth and 1.8g of sodium sulfate , raise the temperature to 60°C at a rate of 1°C / min, keep it for 30 minutes, add 1g of sodium carbonate, keep it at 60°C for 30 minutes, then take out the dyed cotton cloth and boil it with non-ionic detergent boiling soap for 15 minutes, After cross-washing in cold water and hot water, and drying at about 70°C, it can obtain a red color with high dyeing strength, good level dyeing property, good reproducibility, bright color and good resistance to oxygen bleaching.

Embodiment 2

[0049] 50g of the compound of formula (1) and 50g of the compound of formula (2) are fully mechanically mixed to obtain a composite bright red reactive dye.

[0050]Take 4g of the composite bright red reactive dye prepared above and dissolve it fully with an appropriate amount of water, then set the volume in a 500ml volumetric flask, draw 10ml of the dye solution and mix it with 50ml of water, then add 4g of cotton cloth and 1.8g of sodium sulfate , raise the temperature to 60°C at a rate of 1°C / min, keep it for 30 minutes, add 1g of sodium carbonate, keep it at 60°C for 30 minutes, then take out the dyed cotton cloth and boil it with non-ionic detergent boiling soap for 15 minutes, After cross-washing in cold water and hot water, and drying at about 70°C, it can obtain a red color with high dyeing strength, good level dyeing property, good reproducibility, bright color and good resistance to oxygen bleaching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com